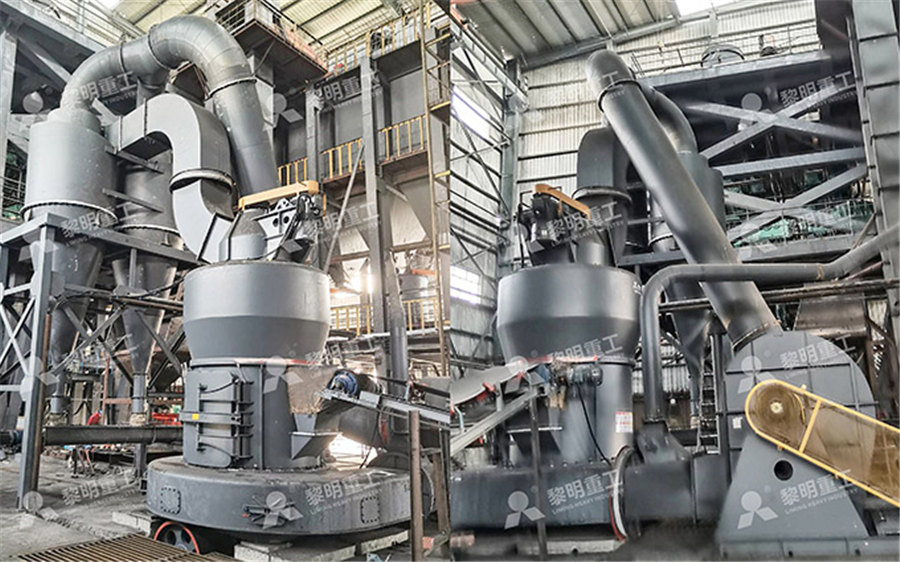

Carbon black deep processing equipment

Carbon Black Processing Equipment FEECO

Whether looking to produce carbon black from biomass, transform it into biochar or activated carbon, or recover it from waste tires, FEECO custom rotary kilns provide an ideal thermal processing environment2023年4月7日 Carbon black deep processing grinding equipment For further processing of the coarse carbon black from tire pyrolysis, we can use the HGM series ultrafine ring roller mill and CLUM series vertical roller mill Tire pyrolysis carbon black deep processing grinding Carbon black, a pure carbon form, is produced via regulated incomplete combustion, with a rising demand for higher quality and finer grades At RIECO, we provide customized systems for achieving the desired fineness, with Best Carbon Black Processing Plant Rieco Enquire NowAs the leading supplier of industrial carbon black milling equipment, we provide customers worldwide with the products they need to process nearly gritfree carbon black At Pulva Corporation, our range of PulvaSizer ™ carbon black Efficient Carbon Black Milling Equipment Pulva

.jpg)

Carbon Black Processing MachineHenan Lvkun

The carbon black deep processing equipment provided by lvkun environmental can increase the value of carbon black This product is suitable for natural rubber and various synthetic rubbers Reinforcement performance, elasticity and Unlock the full potential of carbon black with our advanced processing equipment designed for efficient reutilization Our innovative technology transforms the crude carbon black, obtained Carbon Black Processing Plant for Efficient ReutilizationCarbon black is a black powdery substance produced by incomplete combustion of hydrocarbons in the gas phase or by warm hydrolysis Due to the different production processes, various Carbon black production process and equipment selectionprocess flow 1 Cracking: Using continuous cracking equipment under high temperature and catalyst action, crude carbon black is cracked in negative pressure and some corresponding CAMC Horizontal Cracking Carbon Black Deep Processing Special

Carbon Black – Honiron Manufacturing

Black Honiron Manufacturing is a leading fabricator of process heat transfer equipment for the carbon black industry With more than 165 years in manufacturing of process equipment, our Find production technology for making Carbon black, and connect directly with leading machine manufacturers worldwide Products; Industries processing materials like carbon black or paracetamol require There is currently no Carbon Black Production Technology MakingRecovered Carbon Black (rCB):A sustainable alternative to traditional carbon black, rCB is produced by recycling carbon black from used rubber productsIt reduces waste and carbon emissions while offering performance comparable Best Carbon Black Processing Plant Rieco Enquire 2024年6月26日 24 Carbon black dispersions, compounds, plastic and rubber masterbatches 23 3 PROPERTIES OF CARBON BLACK 24 31 General physical and chemical properties 25 32 Definition of carbon black 27 33 Test methods, chemical and physical data 28 331 Determination of surface area 32 332 Determination of structure 33WHAT IS CARBON BLACK

.jpg)

Carbon Black Processing Equipment Supplies Environmental

PTFE Membrane fiberglass filter bag is one of the ideal filter bag in high temperature dust working conditions Fiberglass filter bag are widely used in industrial dust collection system in cement plant , carbon black processing, steel , Ferro alloy Factory , metallurgy , Industrial coal boiler , paper making , boiler filter bag This is important in matching a carbon black to the equipment by which it is to be dispersed The physical form (beads or powder) can affect the handling and mixing characteristics The ultimate degree of dispersion is also a function of the mixing procedures and equipment usedWhat is Carbon Black? Carbon Black 101 Birla Carbon2017年3月22日 Rubber Application The carbon black is classified by working condition and rubber type For example, tire tread should have better strong stretching intensity, abrasion resistance and antiaging The 1st Deep Processing Line for Pyrolysis Carbon BlackIn addition, carbon black is also adopted as the stain of inks, paints and plastic as well as the ultraviolet screening agent of plastic articles and so onThe carbon black can be used for construction bricks with clay, also can be used as fuelIf we feel like applying carbon black to various fields, we need to process carbon black into fine powder in accordance with standards Carbon Black Refinery Processing Equipment Beston waste

.jpg)

Carbon Black Processing Plant Process Carbon Black from Tyres

Beston carbon black processing plant is used for deep processing carbon black from waste tyre/plastic/rubber pyrolysis, biomass garbage, construction material grinding and so on The plant is also called carbon black grinding machine, which grinds the carbon black to a smaller, finer grainThese kinds of carbon black are more exquisite and have higher reinforcing performanceResults for black carbon equipment from Ecograce, HenanDoing, Doing and other leading brands Compare and contact a supplier near you Air Climate; Drinking from Carbon Black Deep Processing Plant Product line Kupp Model PE100 CarbonBlack Coated Water Pipe Carbonblack coated Black Carbon Equipment Environmental XPRTSmall particle size Carbon Blacks fulfi ll these requirements Coarser Carbon Blacks, which off er a more brownish undertone, are commonly used for tinting and are indispensable for obtaining a desired gray shade or color hue In the polymer industry, fi ne particle Carbon Black is used to obtain a deep jet black color A major attributeWhat is Carbon Black?Carbon Black Processing Machine Market Insights Carbon Black Processing Machine Market size was valued at USD 1448 Billion in 2023 and is expected to reach USD 2186 Billion by the end of 2030 with a CAGR of 56% During the Forecast Period 20242030 The Carbon Black Processing Machine Market is a niche segment within the larger machinery and manufacturing Carbon Black Processing Machine Market Size, Share Growth

.jpg)

A comprehensive analysis of the naming rules and brand

2024年9月29日 5 N600 Series Carbon Black The N600 series carbon black, including grades such as N660 and N683, is characterized by large particle sizes and low structure This type of carbon black is typically used in applications that require good processing performance, such as inner tubes and shock absorber rubber2020年4月20日 It presents the Carbon Black and Hydrogen Process (CBH Process) as an alternative option for hydrogen generation at large scale facility, suitable for supplying large amounts of highpurity Carbon black and hydrogen production process 2015年1月27日 The carbon black processing machine can grind the coarse carbon black into high quality carbon black Please get more details about this plant now Skip to content Menu Home; Just How The Biochar Equipment for Sale Could Save Dumping Fees And Generate Income Too; Categories Products Post navigation Plastic To Oil PlantCarbon Black Processing Machine Carbon Black Production Plant2023年8月18日 Pyrolysis was conducted at set temperatures of 380 °C, 400 °C, 450 °C, 500 °C, and 550 °C, respectively, with a feeding rate of 20 kg/min and a reaction time of 70 min After the reaction, the remaining solid material was cooled using a slagging system and transported to the carbon black deep processing lineInfluence of Pyrolytic Carbon Black Derived from Waste Tires at

.jpg)

Carbon black production process and equipment selection

Processing carbon black We generally use a mill, in industrial applications, carbon black usually needs to be processed to more than 425 mesh Between 4252500 mesh belongs to fine powder, micropowder category According to yourself choice of grinding equipment, 2024年3月18日 The Unseen Hero Austin Black 325 may not capture the headlines in the grand scheme of industrial materials, but its impact is undeniable From reinforcing the tires that carry us on our daily commutes to shielding materials from the sun’s harmful rays, carbon black plays a fundamental role in enhancing the performance and longevity of productsCarbon Black Particle Size CFI Carbon ProductsIf we feel like applying carbon black to various fields, we need to process carbon black into fine powder in accordance with standards of industries by carbon black processing plant Carbon black milling equipment can refine micro powder and submicron powder It is fit to dispose non inflammable and explosive brittleness materials within six Carbon Black Processing Machine Carbon Refinery Kingtiger It also acts as a pigment, providing deep black coloration and improving the aesthetic appeal of materials Additionally, carbon black offers excellent UV protection and thermal conductivity, making it an essential component in various industrial applications You can find this versatile chemical raw material at SBS Philippines CorporationSBS Philippines Corporation Carbon Black

What is Carbon Black and How is it Made? Prater

Processing Carbon Black The prime piece of equipment used for processing carbon black is the reactor in which it’s fired, with adjustments to conditions producing different grades Temperatures, flow rates, time in the reactor, and Carbon Black Our development efforts started with the properties of the carbon black used in the Blackhole formulation The carbon black performance is defined by several physical and chemical properties, including particle size, surface area, structure, surface chemistry and physical form Some of these properties areProcess Development and Process Control Methodology of a CarbonBlack 2024年10月21日 The performance and corresponding applications of polymer nanocomposites are highly dominated by the choice of base material, type of fillers, and the processing ways Carbon blackfilled rubber composites (CRC) exemplify this, playing a crucial role in various industries However, due to the complex interplay between these factors and the resulting DataDriven Exploration of Polymer Processing Effects on the mills Beaded carbon blacks are recommended for shot mills, ball mills and other high energy equipment Beading provides lower dusting, bulk handling capabilities, and higher bulk densities, while powdered carbon blacks offer improved dispersibility Carbon black aggregate – the true primary unit of carbon black Carbon black particleRaven and Carbon Blacks for

Everything You Need to Know About Carbon Black BioEnergy

2023年7月30日 Carbon Black is a commercial form of solid carbon that is manufactured in highly controlled processes to produce specifically engineered aggregates of carbon particles that vary in particle size, aggregate size, shape, porosity and surface chemistry Carbon Black typically contains more than 95 % pure carbon with minimal quantities of oxygen, hydrogen and nitrogenSo far, it is the most suitable mill for waste tyre pyrolysis carbon black micron powder making live chat more HGM series micro powde rmill HGM series micro powde rmill Product Fineness: 3253000Mesh Get Price; recycling carbon black Equipment Results for recycling carbon black equipment from DY, Mars Mineral, Doing and other leading carbon black processing machineryCarbon black deep processing equipment 1 Device composition The production line is mainly composed of: raw material conveying system, micronized powder system, air feeding system, granulation system, dust removal system, electric control system, etcFull Automatic Complete Set Of Carbon Black Deep Processing Equipment2020年9月25日 Radiation from the plasma torch, as well as heat convection from the plasma gas, provides enough energy for the pyrolysis of hydrocarbons Temperature is the important parameter in cracking reactions [38]After the conversion of hydrocarbons into carbon black and hydrogen, a waste heat recovery system takes advantage of the heat of the products to Carbon black and hydrogen production process analysis

Basic Properties of Pyrolysis carbon black of Waste Tyres and

2020年6月24日 The main chemical composition of pyrolysis carbon black of waste tires is C, O, Cu, Zn and so on The content of ash and fine powder in pyrolysis carbon black is high, and the 300% elongation produced carbon black is consumed by the tyre manufacturing industry and the remainder is used in rubber products and diverse applications such as plastics, paint and printing ink In the Netherlands the only carbon black manufacturer is Cabot BV, which has a production capacity of 80,000 tonnes carbon black/yearDecarbonisation options for the Dutch carbon black industrySpecialty carbon black delivering superior cleanliness and processability (higher masterbatch loadings) for demanding fiber applications BLACK PEARLS 3560 Specialty carbon black that offers a balance of cleanliness and color for standard fibers (eg high end carpets, coarse filaments) BLACK PEARLS New E570 New Product Existing Product BLACK SPECIALTY CARBON BLACKS FOR PLASTICS APPLICATION We are experts in custommanufacturing systems for efficient product changeouts and cleaninplace components, integrating dust collection technology for material isolation Trust us to keep your carbon black as pure as possible, from custom Carbon Black Processing Machines Horizon Systems

.jpg)

Carbon Black: Successful Handling and

2019年5月9日 Ensure a smooth flow of carbon black into the processing stream Use the appropriate screws when conveying the material storage equipment, transportation and more previous Classes of Butterfly Valves next Valve 2015年12月3日 The BMF series carbon black processing plant is used for deep processing tire/plastic/rubber pyrolysis carbon black, carbon from biomass garbage, construction material grinding and so on It makes the carbon black characterized as N220, N330,N660, which is more exquisite and has high reinforcing performanceCarbon Black Processing Plant – Waste Plastic/Tyre Recycling 2016年6月20日 Deep Processing of Carbon Black from Waste Tire Pyrolysis by adminwppnet Generally, through tyre pyrolysis process, we can get about 45% fuel oil, 35% carbon black, The carbon black milling equipment Deep Processing of Carbon Black from Waste Tire Pyrolysis2016年11月23日 5 The carbon black processing machine adopts the newtype narrow Vbelt drive, with the characteristics of large transmission power, smooth operation, high efficiency, etc Carbon Black Processing Plant Main applications and production technology of carbon black 1Introduction, Usage, and Characteristics of Carbon Black Grinding Equipment

.jpg)

Highquality, high purity conductive carbon blacks Imerys

Carbon black is an extremely versatile substance which is making an increasingly valuable contribution to the automotive industry Imerys is the leading supplier of highly conductive carbonbased solutions for conductive carbon black used in lithiumion batteries powering electric vehicles and consumer electronics It is also a valuable ingredient in polymer compounds used Small particle size Carbon Blacks fulfi ll these requirements Coarser Carbon Blacks, which off er a more brownish undertone, are commonly used for tinting and are indispensable for obtaining a desired gray shade or color hue In the polymer industry, fi ne particle Carbon Black is used to obtain a deep jet black color A major attributeWhat is Carbon Black?2021年9月20日 Then, a method of preparing and further carbonizing carbon materials by extracting carbon precursors from coal tar and forming resins by polymerization was suggested to not only convert coal tar waste into carbon materials with catalytic activity but also offer novel guidelines for the development of deep coal tar processing and the extension of the coal tar Carbon precursors in coal tar: Extraction and preparation of carbon The carbon black processing equipment manufactured by Beston Group is a dedicated advanced equipment There is no waste water or exhaust gas generating in the production process, which is a project approved by the environmental protection department Carbon Carbon Black Processing Plant/Machine for Sale Beston Group