Roller mill schematic diagram

6 High Reversible Cold Rolling Mill PPT SlideShare

2012年2月10日 The document provides information about a 6 high reversible cold rolling mill, including: 1 Schematic diagrams and descriptions of the mill components including work rolls, intermediate rolls, back up rolls, uncoilers, In this work, a four high cold rolling mill is modeled as a springmassdamper system considering horizontally and vertically applied timedependent forces due to the interaction between the(a) Schematic diagram of a four high rolling mill, (b) coordinate The compact mill rolls 20 metric ton continuously cast slabs of up to 135m width [7,8] (Fig 2) A feature of this second mill is the use of two variable pressure descaling headers and interSchematic diagram of the compact rolling mill (II )Roller mills are the most widely used mills for the production of wheat flour The process of obtaining flour on them is built through a multistage process consisting of successiveSchematic of the roller milling process for the production of

Roller Mill Springer

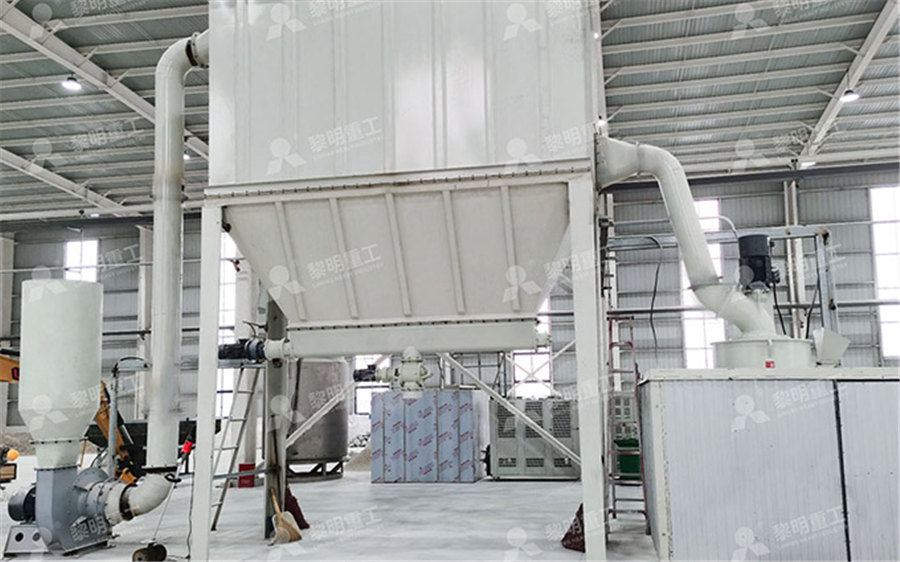

The basic structure of the roller mill includes the grinding roller, the grinding body, the force generation and transmission mechanism, airflow, and the device for easy replacement It can Summary: “Discusses the entire gamut of rolling process and the practices followed in rolling industry and operation and use of various rolling mill equipment and systems” Provided by Principles and Applications of Metal Rolling2022年5月31日 Schematic diagram of VRM: (a) A photo of the laboratoryscale VRM used in experiments; (b) Twodimensional diagram of VRM; (c) 3D model of VRM used in DEM Analysis of vertical roller mill performance with changes in material rolled products from one or similar group of input materials is called a rolling mill or rolling plant Rolling process can be classified based on various conditions/methods employedIntroduction to Rolling Process Cambridge University Press

.jpg)

Schematic structure of a hot rolling mill Download

In this article the AGC (Automated Gauge Control) system, of a hot rolling mill is analyzed and different methods are described to improve its performanceIn metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a Rolling (metalworking) Wikipedia2022年5月31日 Fig 1 represents the schematic diagram of VRM utilized in the experiment and DEM simulations The diameter of the millstone and grinding roller are 600 mm and 340 mm respectively, and the angle between the centerline of the grinding roller and the horizontal is 13°Analysis of vertical roller mill performance with changes in Schematic diagram showing the general configuration of a threeroll mill Mill roll texturing application of EDT was investigated by researchers such as Aspinwall et al (1992), McGeough and Rasmussen (1992), Simào et al (1994, 1996), Kim et al (1998), and Elkoca (2008)Roll Mill an overview ScienceDirect Topics

.jpg)

(a) Diagram of a rice mill machine (b) The cross

The detailed size parameters of the rotating roller in our rice mill machine are shown in Table 1 During a milling process, the rice bran can be removed from a single rice grain by contact with Photos: Compact rice mill, schematic diagram (left) with rubber roller on top and steel polisher on the bottom, compact rice mill in Indonesia (right) Photo: Two separate machines for two stage, two pass milling with rubber roller husker on the left and a steel polisher on the rightMilling systems IRRI Rice Knowledge BankDownload scientific diagram Schematic of the Pfeiffer's 2800 C vertical roller mill from publication: Matrix Model Simulation of a Vertical Roller Mill with HighEfficiency Slat Classifier On Schematic of the Pfeiffer's 2800 C vertical roller millADVERTISEMENTS: After reading this article we will learn about: 1 Meaning of Rolling 2 Process of Rolling 3 Principles 4 Load and Power Requirement 5 Lubrication 6 Defects Meaning of Rolling: The process of shaping metals into semifinished or finished forms by passing between rollers is called rolling Rolling is the most widely used metal []Rolling of Metals: Process and Principles (With Diagram)

.jpg)

The schematic of cold rolling mill process [8] ResearchGate

Download scientific diagram The schematic of cold rolling mill process [8] from publication: NonOriented Electrical Steel Sheet: The Magnetic Properties Losses on Thickness Lamination Using 41 Mill Stand Components and Mechanisms 168 411 Rolling mill rolls 169 412 Roll neck bearings 186 413 Roll chocks 197 414 Mill housings 201 415 Mechanisms for roll adjustment and roll balance 205 416 Roll change device 217 417 Sendzimir cluster mills 220 418 Guides and repeaters 223 419 Guide tables and loopers 228Principles and Applications of Metal RollingDownload scientific diagram Sugar mill roller shaft with final groove ready for shipment from publication: Internal Cracks and NonMetallic Inclusions as Root Causes of Casting Failure in Sugar Sugar mill roller shaft with final groove ready for shipmentTemper Mill (both Stands) 510 mm ~ 560 mm Pinion Stand 15 : 1 (2inputs, 2outputs) Double Red Mill (Stand #1) 360 mm ~ 400 mm Mill Speed 0 / 557 / 1500 mpm (Stand #2) 510 mm ~ 560 mm Exit SBridle Rolls (2 rolls) Backup Roll Diameter: Roll Diameter 510 mm For both Temper DR mill 1,140 mm ~ 1250 mm Drive Motor #1 450 kW @ 936 rpmCold Rolling Mill Tenova

.jpg)

Operation of Rolling Mills

addition it suggests what mill size is most suitable for given ranges of products so as to ensure reasonable efficiency in working the mill Perhaps one of the most important single factors where roll life is concerned is the wear properties of the roll material and this is commented on for the various materials available Roll MaterialsThe schematic diagram of rice milling process is shown in the Fig 1The rubber which is used in the shelling process should be prepared in consideration with the following requirements: Young's Schematic of rice milling process Download Scientific Download scientific diagram Schematic diagram of rolling mill roll system and transmission machinery from publication: Adaptive dynamic surface constraint control of rolling mill torsional Schematic diagram of rolling mill roll system and The Diorit roller mill grinds wheat, durum, rye, barley, corn and spelt It comes in a wide range of sizes and options, including four and eight rollers It has a sturdy cast iron frame for 24/7 operationRoller Mills Milling Bühler Group

.jpg)

Schematic of roll bite with lubrication Download Scientific Diagram

Download scientific diagram Schematic of roll bite with lubrication from publication: Rolling mill chatter mechanism based on the unsteady lubrication performance The unsteady lubrication is Download scientific diagram Schematic diagram of ring rolling mill from publication: The combined ring rolling process and the stiffness condition Different from the conventional ring rolling Schematic diagram of ring rolling mill ResearchGateThe vertical roller mill used in the cement industry is a large piece of equipment that works without interruption and is essential in productionVertical mill and its schematic diagram: (a) vertical mill and (b 2019年6月3日 Common parts of a Roller Body 1 Break roll feed box 2 Feed inlet 3 Middle wall 4 Impulse transmitter 5 Feed gate segment 6 Feeding device 7 Break feed rollRevolution of Grinding Mill (Roller Body), Design, Operation

.jpg)

Twodimensional schematic diagram of a CVC6 mill WR

Download scientific diagram Twodimensional schematic diagram of a CVC6 mill WR denotes the work roll; IMR denotes the intermediate roll; BR denotes the backup roll from publication: Influence Download scientific diagram Schematic of the four roll mill ͑ top view ͒ with the experimental flow field in the drop trajectory coordinate system ͑ see Fig 2 ͒ from publication Schematic of the four roll mill ͑ top view ͒ with the experimental Download scientific diagram Sketch map of rod and wire rolling mill from publication: Finite element simulation of rod and wire continuous rolling This paper discusses the application of Sketch map of rod and wire rolling mill Download Roller Press with Ball Mill Cement Grinding Systems Selection Principle As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully Ball Mill Roller Press for Cement Grinding Process

.jpg)

Schematic diagram of stress form on the backup roll surface

Download scientific diagram Schematic diagram of stress form on the backup roll surface from publication: Analysis of Spalling in Roughing Mill Backup Rolls of Wide and Thin Strip Hot Rolling Download scientific diagram The tworoll rubber mill from publication: Application of the Quality Function Deployment Method in the Mechanical Structure Design of the Tworoll Rubber Mill Frame The tworoll rubber mill Download Scientific DiagramSchematic diagram of the mill structure Furthermore, the range of the external excitation amplitude (F0) at which the rolling mill roll system vibrates violently, that is, 568e5 NSchematic diagram of the mill structure ResearchGateschematic diagram – Vertical mill schematic diagram – Vertical mill Showing every Component of Vertical Raw Mill Previous Post fls smidth , Lafarge , Most importnant manuals , most important excel sheets VERTICAL ROLLER MILL GRINDING SYSTEM PLEASE HELP HOW TO INCREASE THE PRODUCTION OF THE VERTICAL RAW MILL ?! click here to schematic diagram Vertical mill INFINITY FOR CEMENT EQUIPMENT

Schema of the wire rod rolling mill Download Scientific Diagram

Download scientific diagram Schema of the wire rod rolling mill from publication: A Wire Rod Rolling Mill Digital Twin for the Simulation of the Rolls Replacement Process Smart Manufacturing Download scientific diagram Typical flour milling flowsheet with four break rolls Reprinted with permission from [38] from publication: 12010 GCampbell book chapter ResearchGate, the Typical flour milling flowsheet with four break rolls Reprinted with Download scientific diagram Schematic diagram of a hot mill stand from publication: Fuzzy and Fuzzy GreyBox Modelling for Entry Temperature Prediction in a Hot Strip Mill In hot strip mills Schematic diagram of a hot mill stand ResearchGateDownload scientific diagram Mechanical structure of roller crusher from publication: A novel control method for roll gap of roller crusher based on FuzzyPID with decision factor self Mechanical structure of roller crusher Download Scientific Diagram

Schematic diagram of UCM cold rolling mill bending

Download scientific diagram Schematic diagram of UCM cold rolling mill bending from publication: Modeling and validation of bending force for 6high tandem cold rolling mill based on machine 2 Principles and Applications of Metal Rolling (ii) Shape of the rolled product flat, sections or hollow sections rolling (iii) Direction of rolling lengthwise, transverse, and skew rolling (iv) Mode of rolling mill operation continuous (unidirectional), and reverse rolling, where direction of rotation of rolls are reversed When two rolls of equal diameter and with axis lying in same Introduction to Rolling Process Cambridge University Press2007年1月1日 From its invention in 1873, the roller mill triumphed rapidly over millstones, such that by the turn of the century the revolution was essentially complete The factors of wheat hardness, international grain trade and bread quality that gave rise to its birth are still those that dominate the practice of flour milling todayChapter 7 Roller Milling of Wheat ScienceDirectThe Functionality of a Ball Mill Diagram A ball mill is a crucial equipment used for grinding materials into fine powders in various industries It operates on the principles of impact and attrition, where the grinding media are balls to be fed into the mill The ball mill diagram visually represents the use and efficiency of the millThe Ultimate Guide to Understanding Ball Mill Diagrams

A schematic diagram of a tubular ball mill The balls compose

Download scientific diagram A schematic diagram of a tubular ball mill The balls compose the milling elements and drive rollers help to rotate the milling chamber Adapted from Loh et al [12] %PDF15 %µµµµ 1 0 obj >>> endobj 2 0 obj > endobj 3 0 obj >/ExtGState >/Font >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 612 792] /Contents 4 0 R Pellet mill die and roll design Feed StrategyThe rolling mill is adequate if the required power for the operation is less than or equal to the available power Power required per roll, 60000 FLN P roll p ¢ = kW Roll separating force, ( ) ÷ ÷ ø ö ç ç è æ ÷÷ + ø ö çç è æ = avg avg f h L F Lw Y 2 1 3 2 µ L= RDh= (0375)(0075006)=0075 m 00675 2 0075 006 = + h avg = m Rolling IIT BombayFIGURE 133 Schematic illustration of various roll arrangements: (a) Twohigh mill; if a twohigh mill is used for thick but short workpieces, it will commonly roll a billet back and forth in multiple passes, known as a reversing mill (b) Threehigh mill Manufacturing Engineering and Technology, Eighth Edition

Analysis of vertical roller mill performance with changes in

2022年5月31日 Fig 1 represents the schematic diagram of VRM utilized in the experiment and DEM simulations Vertical roller mill (VRM) that involves the complicated motion of particles and mechanical components is a highefficiency grinding equipment and has been commonly used to grind particle materials in industryDownload scientific diagram Schematic operation principle of a VRM [1] from publication: Application of perfect mixing model for simulation of vertical roller mills Vertical roller mills Schematic operation principle of a VRM [1] ResearchGate