Which welding rod is suitable for welding ore grinding machine properties Can be good

Welding Rods Compared: 6010, 6011, 6013, 7018 7024

There is a wide variety of rods available to a welder, but in general, a stick electrode has a coated metal core However, they differ in the type of core 展开2024年3月2日 Selecting the perfect welding rod is a gamechanger The right rod ensures: Always match the rod to your specific welding task Consult your project’s requirements before choosing a rod Check your metal types and the How to Choose a Welding Rod: Expert Selection Guide2009年6月26日 There are several factors to consider in welding rod selection: Base metal properties; Tensile strength; Welding current; Base metal thickness, shape and joint fitup; Factors for Selecting the Right Stick Electrode MillerWelds2022年7月31日 Welding rods are commonly used in shielded metal arc welding (SMAW) It can also be called a welding electrode It mainly provides filler metal to the workpiece and conducts electric current to the arc Choosing the right Different Types of Welding Rods Their Uses

Welding Rod Sizes, Amperage Metal Thickness Chart

2022年2月22日 See our chart and guide on how to select the right welding rod size diameter and amperage depending on metal thickness and other variables2023年11月7日 To achieve strong, durable, and visually appealing welds, it’s essential to choose the right welding rod for the job Welding rods, also known as welding electrodes, come in various types, each designed for specific How to Choose the Right Welding Rod? Welding of Different types of welding rods are suitable for different industries and application scenarios, as follows: (1) Carbon steel welding rod: suitable for a wide range of manufacturing, construction, Choice Of Different Types Of Welding RodsTo make the correct choice you should know about the different types of electrodes out there and what the differences are Don’t forget to think about how many electrodes you will actually need and how to correctly store the excess Welding Rods: Types, Sizes Uses (the ULTIMATE Guide)

Different Types of Welding Rods: Tips, Types, and

Certain rod types are better suited for specific positions, such as horizontal, vertical, or overhead welding The choice of the rod depends on the welding current (AC or DC) and polarity used, affecting arc stability and penetration 2023年7月25日 Compared with traditional fusion welding, laser welding and highfrequency welding have the characteristics of fast welding speed, high energy density and small heat input Therefore, the heat affected zone is The Most Complete Guide to Stainless Steel Welding 2023年7月20日 (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration, grinding cycle load, etc (3) And grinding material properties, including ore grindability, feeding particle size, etc Huge energy and steel consumption in ore grinding process greatly affect the subsequent separation Ore Grinding SpringerLink2022年11月1日 ENiFeMnCI Stick Welding Rod: ENiFeMnCI is a stick welding rod for cast iron It’s an allposition welding rod, which means it can be used on all surfaces of the weld, on both sides of the joint, and in any position This makes ENiFeMnCI a great choice for the professional who needs to get work done quickly and efficientlyWhat Kind of Welding Rod to Use on Cast Iron? Ultimate Guide!

Welder’s Guide to welding Stainless Steel to Mild Steel

In a nutshell, stick welding of stainless steel to mild steel (carbon steel) will be performed with an E309L welding rod This welding rod is also used for welding stainless to itself This welding electrode can be used in all positions and produces a weld that will match the corrosion resistance of the base metal, making it ideal for welding 2023年9月18日 Singlephase AC welding machines do not have these features and are only suitable for spot welding of insignificant workpieces, with welding machine power generally not exceeding 400KVA The electrode for spot welding aluminum alloy should use a Class 1 electrode alloy with a spherical end face to facilitate compression and solidification of the molten core, Spot Welding: Tips and Techniques for Precision Bonding2019年11月1日 A third type of grinding machine is a surface grinding machine Surface grinding machines are unique because they feature an adjustable head The head on a surface grinding machine can be lowered down to the workpiece Once lowered, the head can then rotate back and forth under the machine’s grinding wheelExploring the Different Types of Grinding Machines2023年4月3日 E7018: Another suitable welding rod for GI pipes is the E7018 lowhydrogen electrode This rod is designed to minimize hydrogeninduced cracking and provides excellent mechanical properties The E7018 welding rod is suitable for DC current and is ideal for critical applications, such as highpressure pipelines and structural supportsBest welding rod for GI Pipe

Welding of Cast Iron: Explained MachineMFG

2023年9月1日 Welding cast iron, a common material in machinery and construction, presents unique challenges due to its high carbon content and brittleness This article dives into various methods like shielded metal arc welding, gas welding, and brazing, providing techniques to overcome issues such as cracking and white iron formation You'll learn practical tips for 2024年8月10日 The handheld laser welding machine has a fast welding speed, which is 2 to 10 times faster than traditional welding methods, and can save at least two welders per year The welding seam after laser welding is smooth and attractive, reducing the need for postweld grinding, saving time and costHandheld Laser Welding Machine: The Basic Guide2023年9月2日 211 Diameter of the welding rod The diameter of the welding rod has a significant impact on the welding quality and is closely related to improving productivity Using a welding rod that is too thick will cause incomplete penetration and poor weld formation; using a welding rod that is too thin will reduce mon Welding Processes for Thin Plate: Expert Guide2023年2月14日 An E6011 rod is the worst rod you can pick to weld cast iron The cracking risk is too high because a 6011 generates an aggressive arc and a thin slag covering The results are a casting that expands very fast, a weld What Welding Rod to Use on Cast Iron? With Helpful

Free PDF Chart for Welding Electrode and Filler wire

2021年6月3日 Looking for a Welding Electrode and Filler Wire Selection Chart? Access our comprehensive PDF guide to simplify your electrode and filler wire selection process Discover the key factors to consider, such as base metal 2022年6月16日 It means that some machines may offer different welding processes If you don’t want to be limited in welding options, look for a welding machine that can handle more than one process There are some MIG 15 Different Types of Welding Machines Their Uses 2024年9月12日 Power Source – Ensure that your welding machine can handle the current requirements of the rod size you choose Skill Level – Larger diameter rods require good technique and are generally recommended for more experienced welders due to the higher heat and deeper penetration When To Use 7018 Welding Rod?7018 Welding Rod Specifications: Properties, Amperage (Sizes) 2023年1月6日 S355J2 is a Carbonmanganese steel with lowtemperature properties The welding wire selection hence requires a weld metal with high weld deposit toughness Stick welding (SMAW) of S355J2 can be carried out using E7018 or E70181 welding rods TIG and MIG (MAG) welding of S355J2 can be carried out using ER70S2 or ER70S6 welding wireWelding S355 Steel

Welding Cast Iron for Beginners: Types, Processes, Steps

2023年2月13日 Hydrogen can crack the metal after welding, and oxygen can cause porosity and inclusions in the metal If you weld clean cast iron and porosity appears, it’s because of impurities inside the casting In a situation like this, you remove the bead by grinding and passing it again until you get a bead without porosity 3What is the best allaround welding rod? The best allaround welding rod is 6011 but beginners may find it difficult to use (6013 would be better for novices) Nonetheless, the 6011 welding rod is the best because it can be used to weld in any position with any polarity It is also a fastfreeze rod but is still used to weld dirty steelsWhat is The Best Welding Rod For Rusty Metal Welding Mania2023年1月26日 Stick welding cast steel requires the right welding rod and welder to make a good quality weld Most common cast steel welding rods are E6013, E7015 and E7018 For low alloy cast steel, welding rod depends on the type of cast steel ie, CrMo, or Nickel base or stainless steel cast steelHow to weld cast steel Material Welding2021年8月24日 One of the best welding rods for cast iron is Hobart 7018 Stick Hobart provides affordable and durable options It is a low hydrogen electrode and can be used in all positions In addition, it is suitable for low to medium and high carbonated steels5 Best Welding Rods For Cast Iron Professional Suggestions

TIG Welding (GTAW)

2022年4月6日 Machines MIG welding machines can make quick work of those around the house projects With a basic configuration, you can setup your MIG welding machine with “gasless” filler material commonly known as “Flux Core“ It welds ok But, if you want “clean” results you need a bottle of Argon/Co2 75/25% mix and “bare” filler wire2023年3月6日 In general, minor cracks or damage that do not affect the structural integrity of the engine block can be repaired using various methods such as welding, brazing, or epoxy (Eg, JB Weld) If the damage is extensive How to Weld Repair Engine Block Material Welding2023年1月8日 Copper Base Electrodes and Rods; Hardfacing welding rod types The American Welding Society (AWS) has set forth two specifications: AWS A513 and AWS A521, which cover the different types of hardfacing Welding Rods for Hardfacing: Everything you need to The root requires a controllable welding process and filler capable of delivering the necessary corrosion resistance The welding process for the filling runs can be selected to provide maximum productivity, and the consumable selected to deliver the required mechanical properties (strength and toughness) The range of suitable welding processesWELDING GUIDELINES FOR DUPLEX SUPERDUPLEX STAINLESS

Laser Welding SpringerLink

2024年7月15日 Both welding methods are also suitable for welding materials with a high melting point or with high thermal conductivity due to a very low thermal effect during welding When welding with a laser, the shape and quality of the weld seam can be varied and thus optionally adapted to the taskOre grinding machines can be divided into many types according to different classification methods, each with significant characteristics The following is a general introduction to the types of oregrinding machines and their characteristics According to the different media of the mill, the grinding machines are divided into: If the medium is steel balls, it is called a ball mill;Ore Grinding Machines: Ball Mill, Rod Mil Grinding MediaPrefix R: Indicates a welding rod Prefix E: Indicates a welding electrode Prefix RB: Indicates use as either a welding rod or for brazing filler metal Prefix ER: Indicates whether an electrode or welding rod The system for identifying bare carbon steel electrodes and rods for gas shielded arc welding is as follows: ER indicates an electrode Welding Electrodes: Coatings and Classifications2023年8月6日 The 6013 welding rod is easier to use, making it ideal for beginners or those who need a versatile welding rod Conclusion Selecting the right welding rod for GI pipe welding can be challenging, but with the right information, it doesn’t have to be When choosing a welding rod, consider the GI pipe’s properties, the welding type, and the Best Welding Rod for GI Pipe ThePipingMart Blog

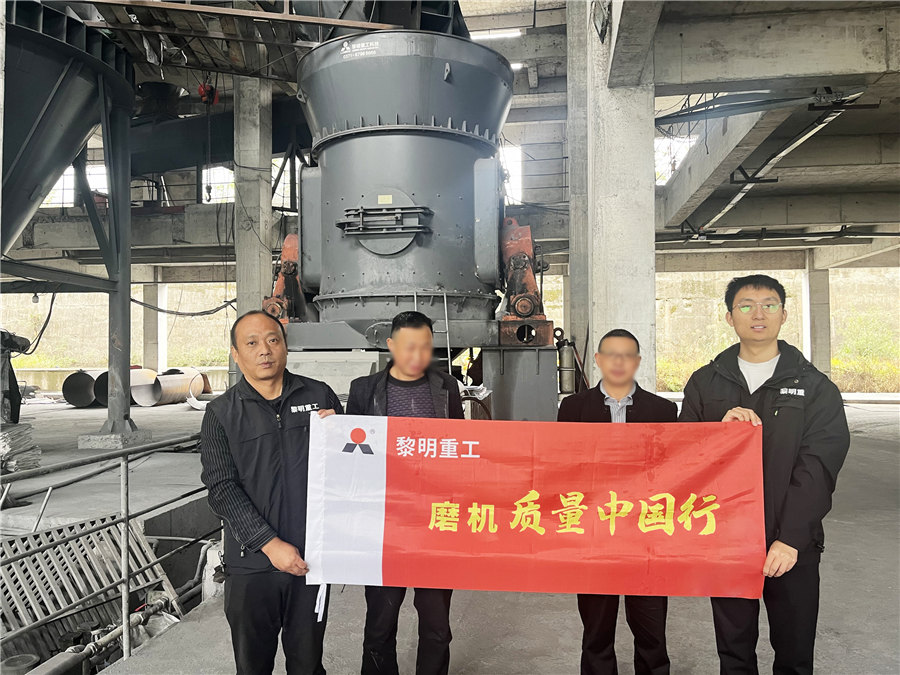

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Welding Electrode: Chart and Selection Weld Guru

2024年1月12日 Coatings The coatings of welding electrodes for welding mild and low alloy steels may have from 6 to 12 ingredients, which includes: Cellulose – to provide a gaseous shield with a reducing agent in which the disintegration of cellulose produces the gas shield surrounding the arc; Metal carbonates – to adjust the basicity of the slag and to provide a reducing 2024年11月18日 For instance, the E6013 welding rod, known for its tensile strength of approximately 60,000 pounds per square inch, is essential for applications like generalpurpose fabrication, shipbuilding, and metal structures Incorrect welding rod selection can lead to poor weld quality, reduced strength, and an increased likelihood of cracking or failureWelding Rod Consumption: Calculation Guide MachineMFG2021年6月16日 Abrasives can be used to enhance several steps in the welding and fabrication process: Cutting aluminum Deburring cut edges Preparing aluminum surfaces for welding Back cutting and back grinding welds Cleaning and blending aluminum welds Polishing to a brushed or satin finish Buffing to a polished or mirror finish Cutting Aluminum Aluminum sheets and plates Ultimate Guide – Aluminum Fabrication, Grinding Empire 2023年2月20日 The best welding rod for galvanized steel is the E6011 because it has a cellulosic flux covering The cellulosic flux is ideal against the zinc coating because it creates an aggressive arc, has the lowest silicon content, and What Is the Best Welding Rod for Galvanized Steel?

What is a Grinding Machine: Definition, Types,

2024年1月27日 H3: Grinding Machine History and Developments from Ancient Times to Modern Days The evolution of grinding machines is marked by several key developments: Ancient Times: The origins of grinding can be traced back 2013年6月16日 Coated welding electrodes comprise of a core wire or rod which is coated with a layer of flux and other ingredients which provides the specific operating characteristics and properties The function of the core rod is to Electrode Quality Steel for Welding Electrodes2023年12月3日 There are many welding machines available here in the Philippines Some are more durable and have better materials than others One of these brands is the Mitsubishi welding machine which gives you excellent and wise use, which is best for aluminum Key Features The Mitsubishi welding machine offers you quality features10 Best Welding Machines in Philippines 2024: Top Brands2022年7月31日 For example, using a 6010 welding rod can determine the tensile strength by the first two numbers This number is represented by the pound per square inch (psi) Multiplying 60 by 1000, you will get 60,000 (psi), which means this is the pressure that the weld can withstand The third number of the welding rod defines the optimum position for Different Types of Welding Rods Their Uses [Explained] PDF

Welding of Carbon Steel: Explained MachineMFG

2024年8月9日 3 Key Points of Welding Process (1) Prewelding preparation Prewelding preparation includes the following aspects: 1) Preparation of groove The preparation of the groove should be done using cold working methods, but hot working methods can also be used2019年1月13日 The most common welding rod recommended for welding stainless steel is an AWS E308L or E316L rod These rods are made of a similar alloy as the base metal being welded and are designed to produce a strong, durable weld with good resistance to corrosion Other options include E309L andWhat welding rod for stainless steel? Industries Days2022年2月16日 When stick welding, you’ll need to know what the different types of stick welding electrode numbers mean and what applications they’re suitable forSome of the key considerations are welding materials, welding position, polarity and penetration Below is a chart of the different types of stick welding rod and explanations of what the different numbers meanWelding Rod Number Meaning Welding Rod ChartThe type of welding rods you are going to be using will depend upon the type of metal you are going to be working onOn top of this, the thickness and the specific type of weld you are looking for will also determine the choice of electrodes To begin with, electrodes can be broadly categorized into consumable and nonconsumable The reason for this nomenclature is fairly Welding Rods: Types, Sizes Uses (the ULTIMATE Guide)