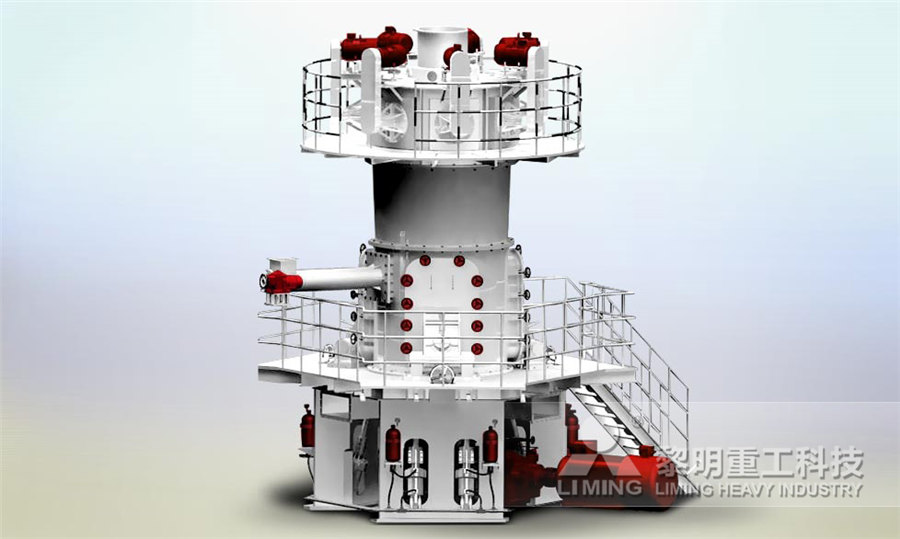

Vertical coal crusher

.jpg)

Cemco® Vertical Shaft Impactor (VSI) Superior

Superior's Cemco VSI boasts global usage, persistently processing a wide range of materials in diverse industries The Cemco Vertical Shaft Impactor creates cubical aggregates, manufactured sands, and eliminates unsound materialVSlam™ VSI Models from Stedman are vertical shaft impactors for all your coarsetofine crushing needs VSI crushers offer significant savings over higherpriced competitive crushers The VSlam, with its low horsepower per ton of Vertical Shaft Impactors VSI Crushers Stedman Vertical Coal Mill is specially used for ultrafine grinding of raw coal and bituminous coal materials in cement, power plants, iron and steel plants and other fields The GRMC coal vertical mill coal grinding machine CHAENGA vertical shaft compound crusher is a special type of crushing equipment that combines the characteristics of vertical crushers and impact crushers It usually consists of the rotor and impact plate of a vertical crusher, which can perform Vertical Shaft Compound Crusher JXSC Mineral

Research on vertical crusher equipment for coal mining and

Coal crusher is a specialized equipment to crush large coal lumps into the desired size This crushing process helps increase the contact area of coal with air, thereby improving A vertical shaft compound crusher is a screenless, adjustable fine crushing equipment optimized and placed by our company to absorb advanced fine crushing technology at home and abroad It is suitable for fine crushing of Vertical Shaft Compound Crusher JXSC MachineBoth proprietary ranges allow coal to be milled more effectively than ever before thanks to some patentpending designs A FiveinOne Vertical Coal Mill Solution Expand One and Expand+ Vertical Coal Mill MagotteauxHigh crushing ratio, energy saving Fine crush and grind Moisture content of raw material up to about 8% Suitable for crushing hard material Excellent shape of final product Small VSI SERIES VERTICAL SHAFT IMPACT CRUSHER

.jpg)

Vertical Shaft Impact Crusher

Designed for low service requirements and easy of operation, the Kinglink KLSeries Vertical Shaft Impact Crusher will readily fit into any existing or proposed crushing plant the cascade Our coal vertical mill utilizes advanced dynamic and static separators for efficient particle separation during coal grinding The advanced control system and grinding structure precisely control key parameters, ensuring the desired HighEfficiency Vertical Coal Mill Enhancing Coal The Kinglink KLSeries Vertical Shaft Impact Crusher can crushed metallurgical slag, which achieve slag recycling 3 6 Model MaxFeeding Rotation Speed (r/min) Power Capacity Weight inch mm hp kW lt/h t/h lt t KL5 118 30 22582600 4060 3045 2959 3060 470 478Vertical Shaft Impact CrusherExpand One and its sister product range Expand+ set new standards in vertical coal mill technology Both proprietary ranges allow coal to be milled more effectively than ever before thanks to some patentpending designs A FiveinOne Vertical Coal Mill Solution Expand One and Expand+ work in five distinct waysVertical Coal Mill Magotteaux

.jpg)

How Vertical Grinding Mills Work (Coal Pulverizer

Want to continue learning about engineering with videos like this one? Then visit:https://coursessavree/ Want to teach/instruct with the 3D models shown2024年1月11日 With a vertical roller mill (VRM) VRMs consist of a rotating table or bowl and rollers 1 To grind the coal, feed raw or initially crushed coal into the mill which is then ground between the rotating components; 2 Finally, hot air removes moisture, carries the pulverized coal out, and a classifier segregates the particles; Here is all you need to know about the VRM:How to Process Coal into Pulverized Coal in 5 Steps?Find your coal crusher easily amongst the 106 products from the leading brands (Fritsch GmbH, Fabo, Liming, ) on DirectIndustry, the industry specialist for your professional purchasesCoal crusher, Coal crushing plant All industrial manufacturersReduced Wear Costs from Durable Hammer Crusher Wear Parts; Hammer Mill Parts for the Aggregates Sector; The Market Leader in Impact Crusher Parts; Vertical Cement Mills Without Compromise; Vertical Coal Mill Technology for Power Stations; 100 Years of Experience in Vertical Mill Mining; Magotteaux’s Tables for Vertical Roller MillsVertical Coal Mill Magotteaux

.jpg)

Vertical Coal Mill Crusher Mills, Cone Crusher, Jaw Crushers

Caiman Vertical roller coal mill for coal grinding plant Vertical roller coal mill main characteristics 1, High efficiency grinding of coal, oil, Mobile CrusherJaw Vertical coal mill is a type of vertical mill used for grinding coal and applied widely Coal mill include ball mill , raymond mill , vertical mill In coal crushing process, several types of coal crusher are used,such as jaw crusher , impact crusher What type of crusher is use to crush coal for steam boilers Types Of Coal Crushers Crusher Mills, Cone Crusher, Jaw CrushersVertical Coal (Charcoal) Crusher The vertical coal crusher is widely used for crushing various materials like stone, granite, trap rock, coke, coal, manganese ore, iron ore, emery, fused aluminum, oxide, fused calcium carbide, lime stone, quartzite, alloys, etc Usually applied in coal, charcoal briquette plantYou must match crusher if the input size of your raw material is larger Vertical Coal/Charcoal Crusher bestbriquettepressWe are manufacturer of jaw crusher, cone crusher machine, vertical shaft impact crusher, aggregate, coal crushing machine in Wada Mumbai India Home; About Us; Techinova Engineering Design; Design Verification; Analytical Services; Training; Innotech Aggregate And Coal Crushing Plant; Bucket Elevator;Jaw, Cone Crusher, Vertical Shaft Impact Crusher Manufacturer in

Coal Crushers, Ringmills ACC Series Reduction

ACC Series Rolling Ring Crusher American Pulverizer's ACC Series Rolling Ring Crushers come in many sizes to fit your specific needs They are designed to be more operator friendly and easy to operateWe are manufacturer of jaw crusher, cone crusher machine, vertical shaft impact crusher, aggregate, coal crushing machine in Wada Mumbai India Home; About Us; Techinova Engineering Design; Design Verification; Analytical Services; Jaw, Cone Crusher, Vertical Shaft Impact Crusher Vertical compound crusher Discharge size:340mm Production capacity:5100(t/h) Power: 30160Kw Application: Mining Aggregate Slag, Sand Making coal, and other ores in building material industry, mining, metallurgy, and chemical engineering This crusher is an ideal machine for crushing highmoisture and viscous materials, Vertical compound crusher Ore Crusher Forui Mining Machinery2016年1月15日 This paper presents an optimal control model to improve the operation energy efficiency of a vertical shaft impact (VSI) crushing process The optimal control model takes the energy cost as the performance index to be minimized by accounting for the timeofuse tariff and process constraints such as storage capacity of the VSI crusher hopper, capacity of the main Optimal energy control of a crushing process based on vertical shaft

.jpg)

A Comparison of Three Types of Coal Pulverizers Babcock Power

As shown in Figure 2, coal and preheated primary air first enter the crusher section Here the coal is im pacted on a grid section by swing hammers, reducing the coal to a nominal 1/4" size Drying of the coal also occurs in this section After the coal passes through the grid section, it enters the twostage pulverizing sec tion2016年1月15日 The coal crusher present in the aforesaid coal conveying system is not included in the optimal energy control problem since it is the coal crusher in [8] is assumed to be a VSI crushing machine and therefore, the same system is Conclusion Vertical shaft impact (VSI) crusher is one of the most used crushing machine in the Optimal energy control of a crushing process based on vertical shaft Vertical fine grinding mills; Laboratory equipment Back Laboratory equipment Automated This significantly reduces machine vibrations and loads on surrounding structures and makes the crusher ideal for use in both mobile and semimobile Bauxite, ore, coal, overburden Product size 0 to 300 mm 0 to 400 mm Capacity 2,500 to 4,000 Roll crushers – ERC and double roll crusher – FLSAll You Need to Know About: Vertical Shaft Impactor (VSI) Primers By Eric Marcotte, Inside Sales Manager, Stedman Machine Company Vertical Shaft Impactor What Is VSI? All roads, you might say, lead to the Vertical Shaft Impactor (VSI) because these crushers make it possible to create roadways and just about everything else Francis E Agnew of California patented one of the All You Need to Know About: Vertical Shaft Impactor (VSI) Primers

Compound Coal Crusher Vertical Coal Pulverizer

The compound coal crusher is also known as the vertical coal pulverizer The coal crusher is a new type of industrial equipment launched in response to the current situation of the coal plant Its high efficiency and low consumption are its outstanding characteristicsCoal Crusher System and VibrationIsolation Platform Three coal crushers in the Linyou, Shangluo, and Ezhou power plants in China were tested to investigate their vibration performances However, the maximum vertical vibration displacement of the coal crusher in the Linyou power plant was 21939 Vibration Test and Shock Absorption of Coal Crusher Chambers in VSI5x Series Crusher is the Binq's newest generation of vertical shaft impact crusher coal mill; coal crusher; small crusher; Semen Tonasa menerangkan bahwa : Nama : PT SEMEN PADANG – beritaVertical Coal Mill Pada Semen Tonasa Crusher MillsEngineered to produce highquality, wellshaped particles and fine aggregates, our range of Trio® vertical shaft impactors (or "vertical impact crushers") use innovative technology to deliver outstanding performance in secondary, Our Range of Trio® Vertical Shaft Impactor Crushers

.jpg)

Types of Crushers Explained: Everything You Need to

2024年4月19日 A shorthead cone crusher has a short crushing chamber and it is designed for the production of finer output sizes, generally between 6 mm and 25 mm A fine cone crusher, also known as a tertiary cone crusher, is used for 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and energetic Design features of our coal pulverizer emphasize improved system reliability, constant product size control, and reduced energy requirements Vertical Roller Mill Coal Pulverizer Williams Vertical Roller Mill Pulverizers are perfect for coal and pet coke applications requiring fine to ultrafine particle sizes for direct firing into boilers Coal Pulverizer Manufacturer Pulverizing System Williams Crusher2024年11月19日 Coal Crusher Manufacturer Coal Crusher Manufacturer in Gujarat As a Coal Crusher Manufacturer in Gujarat, we understand the unique needs of our customers in this regionGujarat is known for its rich coal reserves, and our crushers are designed to handle the tough coal found in this region, providing a reliable and efficient solution for coal crushingCoal Crusher Manufacturer in Gujarat Royal Engineering

COAL VERTICAL MILL Xinxiang Great Wall Machinery Co, Ltd

Process introduction GRMC coal vertical mill produced by CHAENG adopts a special structure design and production technology, and the quality is up to the leading level in China It is the first choice equipment for grinding raw coal and bituminous coal 1 The raw coal is screened from the raw coal storage yard and then dropped onto the belt conveyor through the grid screenPropel's Vertical Shaft Impactor, designed with insights from aggregate producers, elevates aggregate shape and enhances surface structure Discover now! Crusher impact combined with speed gives the unique shape resulting in production of highquality manufactured sand confirming to C 144 standards WATCH VIDEOVertical Shaft Impactor Crusher Manufacturer Propel2020年9月15日 PDF The coal crusher generates large vibrations when crushing coal blocks, which can affect the equipment itself, Vertical stiffness of the vibration isolator (kN/m) 1150(PDF) Vibration Test and Shock Absorption of Coal Crusher Chambers The mediumspeed coal mill can handle different types and quality of coal, which can adapt to different coal supply and production needs Energy Efficient and Low Cost Our ZGM MPS coal vertical mill uses highefficiency pulverizing technology to MPS ZGM Coal MillGrinding Equipment YingYong Machinery

.jpg)

Coal Crushers, Shredders, Mills for Mining Power Industries

We make many types of coal crushing equipment, like our ACC Series Rolling Ring Crusher with capacities ranging from 630–2,350 TPH We also offer hammermills, impactors, double and singleroll crushers, frozen crackers, and more for handling any Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a Vertical Grinding Mill (Coal Pulverizer) ExplainedLT Feeder Breaker is ideally suited for primary coal crushing applications at mines LT Kemco Cone Crusher and cavity design Vertical Shaft Impactor LT VSI are ideally suited for tertiary application for shaping of aggregates Its Crushers – LT Construction Mining Machinery2023年10月8日 Jaw crusher + impact crusher + vibrating screen: Suitable for factories that have high requirements for output size and capacity Jaw crusher + double roller crusher + vibrating screen: Suitable for coal with high water content, which is not easy to block and produces finer discharge particle size6 Types of Coal Crusher: Which Is Best for Crushing My Coal?

Asia's Largest Crushing Screening Manufacturer Puzzolana

Puzzolana Asia's Largest Crushing and Screening Manufacturer, offers highquality equipment made in India and focused on innovation and excellence in the industryA coal mill is also called a coal pulverizer or coal grinder It is a mechanical device used to grind raw coal into pulverized coal powders The most used coal mills in cement plants are airswept ball mills and vertical roller mills At present, most cement plants use coal as the main fuel in the clinker production processCoal Mill in Cement Plant Vertical Roller Mill AirSwept Ball PFL series Vertical Compound Crusher (compound crusher) is one of the common equipment in crushing plant and sand making plant menu Home; About Us About Us; sandstone, blast furnace slag, coal gangue, lump coal, metallurgy solvent, etc Get Price Leave Message Tel: +86379 EMail: lydhcrusher@huazn lydhcrusher@huazn PFL Vertical Compound Crusher Luoyang DahuaWhether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceVertical roller mills FLSmidth Cement

Optimal Energy Control Modelling of a Vertical Shaft Impact

2014年1月1日 This paper presents an optimal control model to improve the operation efficiency of a vertical shaft impact 2011 (6) subject to constraints (2)(5) 4 Case study and simulation results The coal crusher present in the conveying system, given in [3] was not included in the optimal energy control problem since it was stated that The Colorado School of Mines offers courses in chemistry, geology, and physics, with a focus on mining geology and astroparticle physicsPREDICTING THE PRODUCT PARTICLE SIZE DISTRIBUTION FROM A VERTICAL