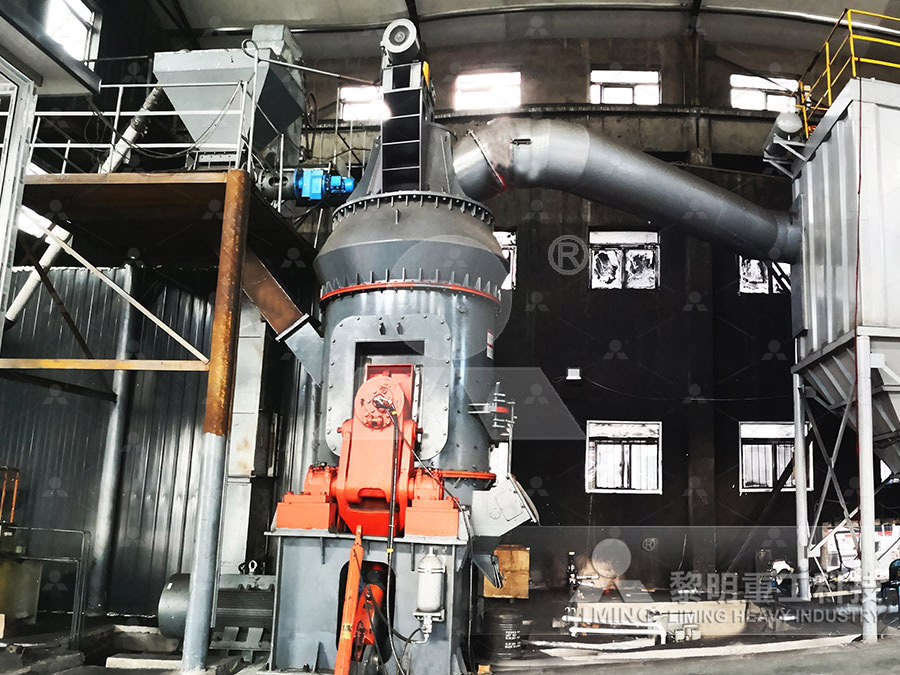

Construction plan for vanadium grinding slag treatment project

.jpg)

ReviewVanadium extraction from steel slag: Generation, recycling

2024年2月15日 Herein, vanadium production, consumption, and steel slag properties are discussed A detailed review of methods for extracting vanadium from vanadiumbearing steel 2021年5月1日 The metallurgical treatment of vanadium bearing slag has been conducted through the roastedassisted leaching process on industrial scale, but the main problems that A review on the metallurgical recycling of vanadium from slags: 2022年4月16日 In brief, the approach mainly consists of the hydrogen reduction of vanadium slag, the recovery of metallic iron from the reduced vanadium slag with ferric chloride solution, A New Approach for the Comprehensive Utilization of Vanadium VRP will produce battery grade vanadium pentoxide VRP will produce vanadium chemicals for use in vanadium redox flow batteries and LiV cells The vanadium comes from steel slag and Introduction Vanadium Recovery Project (VRP) Critical Metals Ltd

Vanadium extraction from steel slag: Generation ResearchGate

2023年12月1日 By proper treatment and utilization, steel slag can not only contribute to resource conservation but also reduce environmental pollution Steel slag utilization in Japan, 2016年1月31日 Traditional processes for treating vanadium slag generate a huge volume of solid residue and a large amount of harmful gas, which cause serious environmental A novel process for comprehensive utilization of vanadium slag2020年11月16日 Vanadium could be recovered from the slag by direct leaching, roasting leaching, submolten salt technology, and intensified with surface wettability leaching Sub An innovative method for recycling vanadium and valuable 2024年2月15日 Herein, vanadium production, consumption, and steel slag properties are discussed A detailed review of methods for extracting vanadium from vanadiumbearing steel Vanadium extraction from steel slag: Generation, recycling and

Review of the VILD project – Vanadium in Steel Slags ResearchGate

2013年1月1日 Within a project called VILD (Vanadium in Steel Slags), with the aim to recovery vanadium in Swedish and Finnish steel slag, a slag reduction concept and a twostep 2024年8月1日 Compared to traditional methods, which faced challenges such as enormous toxic waste and low efficiency, selfpressure acid leaching (SPAL) presented a promising solution Innovative strategy for comprehensive utilization of vanadium slag 2019年2月16日 In this process, the metallic iron was firstly removed from the converter slag by a series of grinding, sieving and magnetic separation After beneficiation , the content of iron in the vanadium slag significantly decreased from 422 to 310%, while the content of vanadium increased from 696 to 857%A Multistep Process for the Cleaner Utilization of Vanadium2016年5月16日 The average rate of generation of LD slag is approximately 150–180 kg per ton of crude steel in India []Researchers also found that this rate of production of LD slag somtimes reaches a high of 200 kg per ton of crude Sustainable Approaches for LD Slag Waste

.jpg)

Current Development of Slag Valorisation in China

2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, 2021年3月19日 The thermal treatment of steel slag up to 900 °C indicated that this solid is almost stable and few contained phases change their structures Xray diffraction (XRD) pattern of EAF slags(PDF) New EAF Slag Characterization Methodology for2010年1月1日 It is expected that for use in the cement industry and road construction, the vanadium content in the slag should be lower than 01% by mass and 03% by mass, respectively, according to Swedish Recovery of vanadium from vbearing bofslag using an eaf2019年11月20日 New technology is developed for preparing pure vanadium pentoxide from vanadiumcontaining metallurgical slag As a result of the selective extraction of vanadium from calcined slag, solid residues containing from 7 to 10% of manganese are formed, which are suitable for extraction A study of the mineralogical composition of solid residues shows that Technology for Extracting Manganese from Vanadium Converter Slag

.jpg)

(PDF) Study on roasting parameters for extraction of vanadium

2013年1月1日 TGDSC curves for vanadium slag during roasting process 32 Parameters of sodium salt roasting process Effects of addition amount of sodium carbonate, roasting temperature and roasting time during 2020年1月21日 Vanadium is a strategic metal existing naturally in about 65 different minerals Vanadium compounds have been widely used in many industries [1, 2], due to their unique physical and chemical properties []Vanadium slag , a steel byproduct slag produced during metallurgical treatment of vanadium titanomagnetite ore, is the direct raw material for Study on the Mechanisms for Vanadium Phases’ Transformation 2021年10月1日 Steel slag is a solid waste derived from the steelmaking process, which accounts for approximately 15% of the total crude steel output (Furlani et al, 2010; Pang et al, 2016)By 2016, approximately 832 million tons of steel were produced in China with an annual output of more than 100 million tons (Hasanbeigi et al, 2016), which exceeded half of the total Review Use of steel slag as sustainable construction materials: A 2024年8月21日 Fig 2 shows the distribution of vanadium ore in the world The world's vanadium ore reserves are about 24165 × 10 7 t, which represents the portion that meets requirements of current extraction and production The reserves of vanadium in China, Russia, South Africa and Australia account for 99 % of the world's reserves, and China's vanadium ore reserves are the Research progress of vanadium extraction processes from vanadium slag

A Method to Extract Vanadium from HIsmelt Reduction Slag: In

2023年4月28日 The HIsmelt smelting reduction process is an efficient direct reduction process for smelting vanadium titanomagnetite ores About 80% vanadium is enriched in the reduction slag, however, due to the low vanadium and high calcium content in reduction slag, it is difficult to extract the vanadium economically In this study, a process featuring in situ sodium salt 2018年8月1日 Steel slag is a byproduct generated by the steel manufacturing industry It poses environmental contamination and health hazards without effective treatment Upcycling steel slag as a construction material has attracted attention because of its desirable physicochemical properties (strength, durability, and resistance to corrosion)Steel slag in China: Treatment, recycling, and management2019年5月9日 Constructed wetlands for steel slag leachate management: Partitioning of arsenic, chromium, and vanadium in waters, sediments, and plants(PDF) Constructed wetlands for steel slag leachate 2024年7月1日 Previous studies have identified many approaches, such as fine grinding [15], [19] and chemical and thermal activation [20], [21], have been applied to improve the properties of steel slagFor example, Shi et al [22] and Qiang et al [23] found that finely ground carbon steel slags, with particle sizes under 20 μm, exhibit a distinct hydraulic activity, positioned between Cogrinding treatment for developing integratedproperties

Overview of the VILDproject ResearchGate

slag additives The carbon/slag rate is about 130 kg per ton slag and the energy consumption is about 15 MWh/ton cold BOFslag About 220 kg of metal with up to 10 % vanadium could beat 800 °C, while the V maximum leaching rate of 625% of vanadium is obtained after three hours of slag cogrinding with NaOH and Na 2 CO 3 and roasted at 600 °C The Mo leaching rate, meanwhile, reaches 958% using KOH for one hour of cogrinding the slag followed by roasting at 600 °C Graphic AbstractProcess for Enhancing the Valuable Metal Recovery from 'Electric Sweco Finland assigned to plan Europe´s first production plant producing vanadium from recycled material The Vanadium Recovery Project, a joint venture between Australian companies Critical Metals Ltd and Neometals Ltd, paves the way for a significant increase in high purity vanadium (V) production and selfsufficiency in EuropeSweco Finland assigned to plan Europe´s first production plant 2021年9月1日 A hydrometallurgical process for recovering vanadium from slag, a byproduct of steelmaking, has been significantly scaled up Previously deployed at minipilot and bench scales, the process, developed by Neometals Ltd, has now been expanded by a factor of 25, to process 14 tons of slag (corresponding to a throughput of around 25 kg/h) from three different steel Vanadium recovery from steel slag scales up Chemical Engineering

.jpg)

Slag grinding operation approved for construction near Port of

2019年8月20日 Walan Specialty Construction Products received permit approval from DNREC Monday to build a slag drying and grinding facility in south Wilmington The The approval includes a dust control plan, DNREC concluded that the proposed construction project complies with federal and state air pollution laws and regulationsVanadium is primarily used in the manufacture of highgrade steel and stainless steel, and additionally in the manufacture of vanadium chemicals used in titanium alloys and energy storage (batteries) The aim of the Vanadium Recovery Project (VRP) is to produce highpurity vanadium pentoxide for the needs of the European industryVanadium Recovery Project Oy Critical Metals Ltd2024年2月15日 Leaching is a direct extraction method of vanadium from steel slag, including direct leaching,roastingleaching and other related leaching methods (Chen et al, 2017; Xiang et al, 2018b) At present, roastingleaching is the only steel slag treatment method that has been put into largescale industrial production (Lee et al, 2021)Vanadium extraction from steel slag: Generation, recycling and 2020年8月3日 Titaniumbearing magnetite ore is generically defined as magnetite with > 1% titanium dioxide (TiO2) and is usually vanadiumbearing The iron and titanium occur as a mixture of magnetite (Fe3O4 (PDF) Evaluation of TitaniaRich Slag Produced from

Recent applications of steel slag in construction industry

13 Utilization of steel slag Utilization of steel slag in various industries as raw material can provide environmental sustainability and therefore ensure the reduction in exploitation of natural resources (Yüksel, 2017)Toward the sustainable environment, the use of industrial waste can minimize the disposal of wastes to the environment which helps the environmental regulations 2021年2月5日 The results show that the Cr leaching rate reaches 975% for one hour of the slag cogrinding with a NaOH and Na 2 CO 3 mixture followed by roasting at 800 °C, while the V maximum leaching rate of 625% of vanadium is obtained after three hours of slag cogrinding with NaOH and Na 2 CO 3 and roasted at 600 °CProcess for Enhancing the Valuable Metal Recovery from2023年12月1日 For vanadiumcontaining steel slag, the treatment effectiveness is constrained by solely extracting vanadium and disregarding the utilisation of the remaining slag In this study, Vanadiumcontaining steel slag served as the primary material, the Si/Al ratio was the adjustment parameter, and rice husk ash, SiO 2 , and Al 2 O 3 were used as the adjustment materialsReduction and reconstruction of vanadiumcontaining steel slag 2009年8月1日 Request PDF Mineralogical characterisation of vanadium slag under different treatment conditions Synthetic vanadium slags were melted at 1673 K and then cooled to a predetermined temperature Mineralogical characterisation of vanadium slag under different

Comprehensive Analysis of Steel Slag as Aggregate for Road Construction

There are many studies on the use of BOF slag for road construction, but they use treated slag or remain at a laboratory level, as reflected in the reviews conducted by Kambole et al [23] and 2022年1月15日 Many technologies devoted to effective recovery of vanadium and chromium (Rout et al, 2018, He et al, 2018, Bao et al, 2018, Kim et al, 2018, Fang et al, 2017)Sodium roastingwater leaching/acid leaching is typically used in the treatment of vanadium slag (Wang et al, 2018)And then ammonium precipitation method is utilized to obtain ammonium Deep understanding of sustainable vanadium recovery from 2021年6月30日 Titaniumbearing blast furnace slag (BFS) has valuable compositions and potential environmental hazardousness Thus, developing efficient and green approaches to utilize BFS is highly desired for resource economization and environmental protection In the past decades, many attempts have been adopted to reuse BFS efficiently, and significant advances Recent progress of efficient utilization of titaniumbearing blast 2024年6月5日 To shorten the wetextraction process of vanadium slag and reduce the loss of a large number of valuable elements—such as iron, manganese, and chromium—this study directly used molten vanadium slag to smelt alloys Vanadium slag with 16 wt% carbon, 20 wt% CaO (R = 097), and 5 wt% Al2O3 was reduced at 1550°C for 2 h, and a FeV(CrMn) alloy with FeV Recovery of Valuable Elements from Molten Vanadium Slag

Extraction of vanadium from converter slag by twostep

2017年9月1日 Request PDF Extraction of vanadium from converter slag by twostep sulfuric acid leaching process Because of its potential to achieve a high recovery rate of vanadium, the mechanical 2018年4月10日 Ground granulated blastfurnace slag (GGBFS) is mainly consisting of CaO, SiO 2 and Al 2 O 3In recent decades, the use of GGBFS as an alternative binding material (alkaliactivated slag, AAS) and partial replacement of cement has increased [13], [14]Nevertheless, the low strength development of cement based materials with GGBFS restricts its utilization in Selfhydration characteristics of ground granulated blastfurnace slag 2024年11月11日 The vanadium slag for this study was sourced from Desheng Iron and Steel Group Co, Ltd, Sichuan, China Vanadium tailings were produced using oxygen pressure leaching method [18] The detailed chemical composition of both the vanadium slag and vanadium tailings are provided in Table 1, and the Xray diffraction patterns are presented in A facile process for the efficient extraction of vanadium from vanadium Today there is ~2 million tonnes LDof slag available for vanadium recovery The slag contains a relatively high concentration of vanadium, when compared to vanadium mines and alternative vanadium recovery projects globally t various A times, the slag has been used in industrial applications such as the manufacture ofVANADIUM RECOVERY PROJECT

The Complete Guide to Tunnel Slag Treatment sbmchina

2023年4月26日 According to the planning schedule of the project, the slag is produced in the tunnel construction process, which means that the difference of the rocks may be relatively large, and the quality of machinemade sand is unstable If the slag is produced by multiple tunnels, this situation will be more obvious2017年7月14日 The high roasting temperature and low leaching efficiency of vanadium from vanadiumbearing converter slag are regarded as the main factors significantly influencing the application of calcification roasting–acid leaching processes in the cleaner production of vanadium In this study, a mechanical activation treatment was performed to enhance the Effect of Mechanical Activation Treatment on the Recovery of Vanadium Request PDF On Jul 1, 2024, Oluwasegun Samuel ODEBIYI and others published Effect of Mechanochemical Activation Parameters on Vanadium Recovery from VanadiumBearing Steel Slag: Critical Speed Effect of Mechanochemical Activation Parameters on Vanadium 2023年1月29日 Ferrous slag is mainly composed of calcium and silicon, whereas nonferrous slag can be broken down into copper, lead, and zinc slag Ferrous slag can have environmental impacts such as the accumulation of trace elements in groundwater and surface water, while nonferrous slag can have more severe environmental impacts due to the presence of heavy metalsWhat Is Slag In Construction? – HPD TEAM

A clean and efficient method for recovery of vanadium from vanadium

2017年2月16日 A cleaner method has been developed for the extraction of vanadium from vanadium slag Compared to the traditional alkaline salts roasting followed by the water leaching process, in the nonsalt 2023年2月1日 Vanadium is a kind of heavy metal pollutant listed as priority control by various countries, but it is also a strategic valuable metal The current treatment of vanadiumcontaining wastewater suffers from the waste of vanadium resources and produces large volumes of hazardous wastes An innovative approach was proposed to address these problemsClean process for vanadium extraction from vanadiumbearing converter slag