Lepidolite processing

A novel process for extracting lithium from lepidolite

2012年6月1日 A lime–milk autoclave process was used to extract lithium from lepidolite The leaching efficiency of lithium reached 989% under the optimal condition The purity of the 2021年5月1日 The findings showed that NaOH concentration, temperature, and stirring rate are the most significant process parameters The addition of Ca(OH) 2 facilitates the leaching of Leaching of lepidolite and recovery of lithium hydroxide from 2023年1月15日 This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination methods, and analyzes the resource intensity, Lithium extraction from hard rock lithium ores 4 天之前 Lepidolite ore was subjected to roasting with a mixture of sodium sulfate (Na2SO4) and calcium sulfate (CaSO4) as roasting agents A comprehensive investigation was conducted to Study on the Extraction of Lithium from Lepidolite Ore by

.jpg)

Procedure for Lepidolite Concentrate Processing

We have developed a procedure for lepidolite concentrate processing, ensuring decreased power consumption and shorter time for the concentrate breakdown with simultaneous increase in 2015年11月16日 Mixed grinding with Na 2 S followed by water leaching was performed to extract Li from lepidolite The leachability of Li increases dramatically in the ground mixture, regardless of the mixing ratio over the Extraction of Lithium from Lepidolite Using Mixed 2018年6月21日 Results of the research set up preconditions for largescale involvement of lepidolite in the hydrometallurgy of lithium, given the large number of proven deposits of Complex Loosening of Lepidolite Concentrate by Sulfuric AcidIt is critical for the clean and effective utilisation lepidolite to accomplish the deep removal of fluorine during the lithium extraction process Firstly, the typical methods to extract lithium from lepidolite were discussed such as sulfuric acid A Review of Lithium Extraction from Lepidolite and

Research Portal Murdoch University

The energy intensive extraction of lithium from αspodumene (LiAlSi2O6) involves decrepitation at 1100 oC followed by sulphuric acid roasting (200 oC) and water leaching The extraction of lithium from lepidolite (K(Li,Al)3(Al,Si)4O10(F,OH)2) also involves high temperature (750 – 1000 oC) roasting with additives or direct leaching The leaching in acid or alkaline media is less 2023年5月15日 “Hydrofluoric acid is produced during the procession of lepidolite and is highly poisonous,” a Chinese lithium trader said A South Koreabased consumer source added: “It is important to deal with the pollutants properly Chinese lepidolite integral to global lithium supply2020年11月4日 The recovery and leaching kinetics of lithium from lepidolite by sulfuric acid method were investigated in this study, and a new method of nanofiltration to separate Al/Li from lepidolite leaching solution was coupled Recovery of Lithium from Lepidolite by Sulfuric Acid Lepidolite processing is less developed than in brines, although downstream pull factors to diversify raw material resources have accelerated the research and development process High levels of impurities have previously hindered lepidolite processing, causing high energy consumption and increased production and environmental costsScrutinising the lithium technology boom – Part 3 CRU Group

.jpg)

Key technologies and development trends for efficient flotation

2024年9月1日 It analyzes the physicochemical properties of lepidolite and its associated gangue minerals, addressing the challenges of separation and exploring potential solutions Furthermore, it addresses practical issues in industrial lepidolite processing in a unique way, including combined flotation techniques and regional case studiesLepidolite is an important lithium resource in China The development of efficient lithium extraction process is of great significance to ensuring the sustainable development of lithium industry Due to the strong electronegativity of fluorine(F), about 5%~10% of F attacks the lepdolite lattice by taking interfacial hydroxyl groups It is critical for the clean and effective utilisation A Review of Lithium Extraction from Lepidolite and Current 2021年5月1日 Table 2 summarises various lepidoliteprocessing techniques proposed in the literature At present, most of the techniques proposed for extracting lithium from lepidolite may involve energy intensive high temperature (850–1000 °C) roasting with additives followed by atmospheric leaching with water or digestion with concentrated acids (Chagnes and Leaching of lepidolite and recovery of lithium hydroxide from 2018年1月1日 Recently, an alternative process for extracting lithium from a lepidolite ore, constituted by mechanical activation and sulphuric acid digestion, avoiding the calcination step, was proposed and studied in detail (Vieceli et al, 2017b)The effects of several factors on the structural transformations of the mineral phases were evaluated in this studyRecovery of lithium carbonate by acid digestion and

Separation of lepidolite from hardrock pegmatite ore via dry

2022年9月1日 Under the scope of the Flexible and Mobile Economic Processing Technologies (FAME) H2020 project, which focused on improving mineral processing technologies for the recovery of valuable materials from lowgrade ores, a Portuguese lepidolite ore from the Gonçalo deposit was investigated in this study2020年9月3日 Scientific Reports Comparison of three different bioleaching systems for Li recovery from lepidolite Skip to main content higher efficiency and green processing parison of three different bioleaching systems for Li Nature2022年9月1日 Under the scope of the Flexible and Mobile Economic Processing Technologies (FAME) H2020 project, which focused on improving mineral processing technologies for the recovery of valuable materials from lowgrade ores, a Portuguese lepidolite ore from the Gonçalo deposit was investigated in this studySeparation of lepidolite from hardrock pegmatite ore via dry 2015年11月16日 Mixed grinding with Na2S followed by water leaching was performed to extract Li from lepidolite The leachability of Li increases dramatically in the ground mixture, regardless of the mixing ratio over the Extraction of Lithium from Lepidolite Using Mixed

.jpg)

Complex Loosening of Lepidolite Concentrate by Sulfuric Acid

2018年6月21日 Experimental study of complex extraction of lithium and other valuable components from lithia mica – lepidolite was carried out A method of complex processing of lepidolite is suggested in the present work, that provides extraction of such valuable components as lithium, potassium, cesium, rubidium, aluminum, and beryllium from this mineral Moreover, 2018年1月1日 After mining, processing of lithium ores involves their comminution, followed by beneficiation using techniques such as flotation, optical sorting, magnetic separation or heavy media separation, Lepidolite is a valuable mineral resources of lithium, rubidium and cesiumRecovery of lithium carbonate by acid digestion and 2023年11月14日 The starting point was a lepidolite sample, which was cut into squares of 05 × 05 cm 2 approximately The powders were ground in a vessel of nylamid in a highefficiency Spex 8000M mixer/mill by 30, and 60 min []After this, the powders were recovered and leached with hydrochloric acid, at 60 °C and 100 °C, to extract alkali metalsLepidolite characterization using a selection of techniquesThe primary separation of lepidolite from complex silicate minerals is froth flotation In this paper, M Processing a spodumeneore to obtain lithium concentrates for addition to glass and ceramic bodies Minerals Engineering, 1999, 12(4), 433436 DOI: 101016/s08926875(99)000230 Google ScholarThe Flotation Process of Lepidolite in Jiangxi Province in China

.jpg)

Global Lepidolite Market Size, Share Trends FMI

The Global Lepidolite market size is projected to grow from USD 1099 Billion in 2022 to USD 15144 Billion by 2032, at a CAGR of 304% in forecast period, 2022 to 2032 Login MENU Industry Automotive Consumer Product Food Beverage Chemicals and Materials Healthcare Travel Tourism Process Automation 2017年2月9日 Lithium recovery from lepidolite was studied experimentally, and a sulfuric acid procedure for lithium recovery was suggested It ensures the maximal degree of lithium recovery from this mineral at minimal power consumption The suggested procedure creates prerequisites for largescale involvement of lepidolite into lithium metallurgy, taking into account large Procedure for lepidolite concentrate processing Russian lepidolite without thermal treatment of sulfation and defluorination This study may provide information for the use of low grade lepidolite as a source in Li production 2 Experimental Section 21 Materials The lithiumcontained lepidolite was provided by the Boam mine (Uljin, Korea), and it was upgraded through crushing and optical sorting Extraction of Lithium from Lepidolite Using Mixed Grinding with 2023年8月2日 The separation and enrichment of lepidolite, an important mineral for extraction of lithium, through froth flotation, have been widely investigated This paper summarizes the latest research progress on lepidolite flotation emphasizing aspects such as cationic collectors and their combination with anionic collectors, as well as the flotation mechanism and application of Research Progress in Flotation Collectors for Lepidolite Mineral:

.jpg)

Efficient Extraction of Lithium and Rubidium from Lepidolite by

2024年11月11日 The traditional process of lithium extraction from lepidolite has the disadvantages of a low extraction rate, poor selectivity and a long process In this study, the efficient extraction of lithium and rubidium from lepidolite was achieved by mediumtemperature chlorination roastingwater leaching process Experimental results indicated that the optimal 2022年12月21日 Lithium is considered to be the most important energy metal of the 21st century Because of the development trend of global electrification, the consumption of lithium has increased significantly over the last decade, and it is foreseeable that its demand will continue to increase for a long time Limited by the total amount of lithium on the market, lithium extraction A review of lithium extraction from natural resources2023年7月12日 Lithiumrich minerals such as lepidolite and spodumene hav Xinhai provides ore processing plant and full set equipment: Ball mill, Hydrocyclone, Flotation, Washing plant, CIP, CILExtraction And Application Of Lithium Ore From 2021年3月25日 The annual processing capacity of the two major mining areas can reach 55 million mt of raw lepidolite ore in 2021 Therefore, it is estimated that domestic annual output of lithium carbonate produced from lepidolite can reach 65,000 mt, with the capacity utilization rate of SMM survey of China’s Lithium Industry—Jiangxi SMM

.jpg)

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日 Lastly, lepidolite was selectively floated at pH 2 from the second concentrate because lepidolite was expected to show higher electrostatic interaction with STAC than quartz and albite at this pH Lepidolite recovery of 763% was reported by this procedure with a concentrate grade of 38 times higher Li 2 O% than that of the feedLEPIDOLITE PROCESSING USING SULPHATION BAKING: A COMPARISON AGAINST CONVENTIONAL PROCESSING FLOWSHEETS By Adam J Roper and Christopher S Griffith ANSTO Minerals, Australia Presenter and Corresponding Author Adam J Roper ABSTRACT Processing of hardrock Libearing minerals other than spodumene and petalite are LEPIDOLITE PROCESSING USING SULPHATION BAKING: A 2022年9月1日 Request PDF Separation of lepidolite from hardrock pegmatite ore via dry processing and flotation A mineralogical study of Gonçalo lithiumbearing micarich pegmatite ore (Portugal Separation of lepidolite from hardrock pegmatite ore via dry 2024年4月17日 Lepidolite Properties Physical Characteristics Lepidolite crystal, with its gentle nature and composition, boasts a unique character On the Mohs hardness scale, it clocks in at a modest 253, placing it firmer than amber yet softer than shungite or malachiteAdditionally, this mineral showcases a remarkable attribute – a flawless basal cleavage, meaning it can be Lepidolite Crystal: Meaning, Healing Properties Benefits

.jpg)

A review of lithium extraction from natural resources PMC

Existing methods are summarized by the main resources, such as spodumene, lepidolite, and brine The advantages and disadvantages of each method are compared Finally, Processing of lithium ores: Industrial technologies and case studies — A review, Hydrometallurgy, 201(2021), art No 2021年5月1日 Table 2 summarises various lepidoliteprocessing techniques proposed in the literature At present, most of the techniques proposed for extracting lithium from lepidolite may involve energy intensive high temperature (850–1000 °C) roasting with additives followed by atmospheric leaching with water or digestion with concentrated acids (Chagnes and Leaching of lepidolite and recovery of lithium hydroxide from After the processing facility's successful launch, phase two will kick in 12 to 24 months later Here, we'll directly convert lithium concentrates into coveted lithium carbonate and hydroxide forms No more exporting to China – we're Lithium Ore Suppliers In Nigeria: Lepidolite, 2023年1月15日 The processing cost of lithium extraction from lepidolite by sulfate roasting method is higher than that from spodumene by sulfuric acid due to the consumption of highvalue sulfate However, the production costs of Lithium extraction from hard rock lithium ores

.jpg)

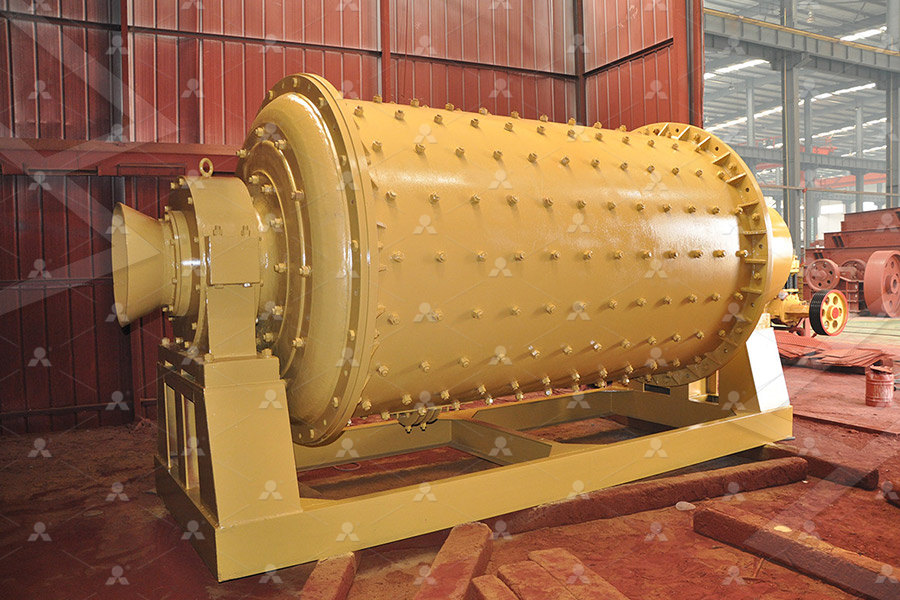

10TPH Lepidolite Processing Plant JXSC Machine

2023年5月16日 This setup is for processing lepidolite stone ore to recover lithium It is a flotation separation plant with a high recovery ratio for Li2O For lepidolite ore, the lithium concentrate (Li2O) grade can reach about 45% after 2022年11月7日 Lepidolite Processing Layout This 500tpd lepidolite flotation process plant is configured with a hopper+vibration feeder, jaw crusher, fine jaw crusher, vibration screen, storage bin+electromagnetic feeder, ball mill, slurry pump, spiral classifier, flotation machines, thickener, disc vacuum filter machineLepidolite Flotation Process Plant JXSC Machine2024年11月7日 As an alternative method for the steambased defluorination process, in situ capture of F by a roasting process has been considered, but this makes lepidolite processing more complicated On the other hand, Vieceli et al [ 44 ] observed a defluorination effect when lepidolite is mechanically activatedMechanochemical Treatment for the Extraction of Lithium from2023年6月15日 Separating lithium from lepidolite can cost as much as 100,000 yuan per metric ton, compared to 40,00050,000 yuan for brine and 50,00060,000 yuan for spodumene, analysts saidIn China's lithium hub, mining boom comes at a cost Reuters

Here Are 4 Methods for Recovering Lithium from Lepidolite

2023年4月8日 03 Lepidolite lithium ore alkaline extraction process Lepidolite ore alkaline processing is limestone roasting method Its basic principle is to use alkaline to dissolute the SiO 2 in the solution In alkali or gypsum, heating transforms the silicate into soluble lithium aluminate2022年11月22日 Meanwhile, lepidolite, which is another alternative feedstock for lithium chemicals production with an average grade of 35%, used to be undervalued before the demand for lithium chemicals picked up However, the narrative has since changed significantly, with grades lower than 15% being used and even lithium slag becoming attractive, said a Chinese China's lithium chemicals prices lack momentum for further increase2017年10月1日 Request PDF Recovery of lithium carbonate by acid digestion and hydrometallurgical processing from mechanically activated lepidolite Lithium extraction from hardrock ores has regained Recovery of lithium carbonate by acid digestion and 2023年4月4日 “Whilst the results of the lepidolite testwork are not a surprise to Matsa, we were less certain as to how polylithionite, also a lithium mica, would behave in Yongxing’s lepidolite processing plant,” Poli said “The testwork has in fact demonstrated that polylithionite is also processable through the existing lepidolite processing Matsa’s Thailand lepidolite testwork shows battery grade lithium