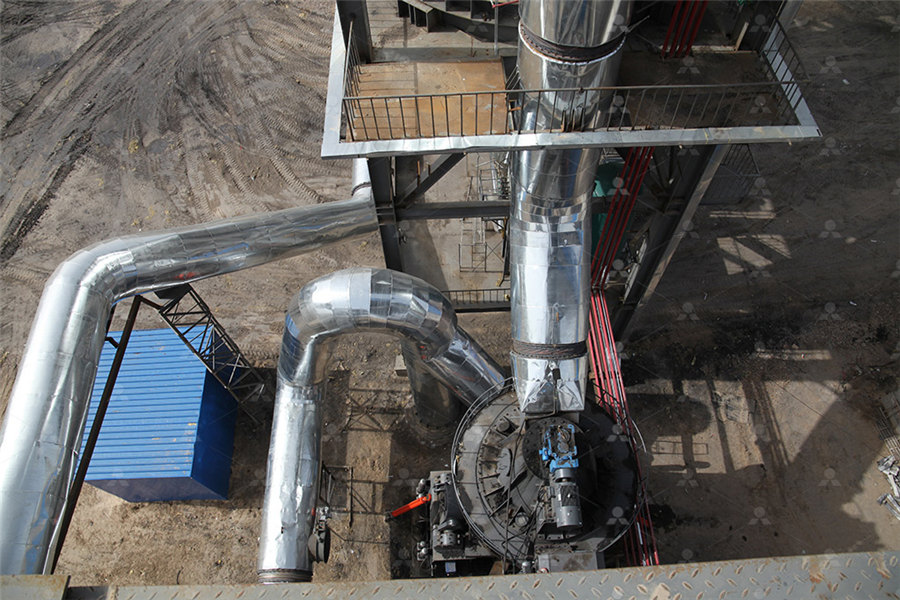

Y limestone g type highefficiency hydraulic ore mill assembly process

EnergyModel and Life CycleModel for Grinding Processes of

2022年5月22日 Therefore, the first aim of this research work was the examination of main grinding parameters of the limestone particles to determine an empiric energymodel Dry and HPGRs (high pressure grinding rolls) have been developed within the last decades for energy efficient processing of a wide variety of ores Special interest has been raised by projects Quantification of HPGR energy efficiency effects on downstream 2023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding Optimization of Ball Mill Grinding of a LimestoneType Brecciated 2021年12月1日 Lime also positively impacts gold absorption onto carbon in CIP/CIL circuits compared to other pH modifiers The quantity of lime consumed depends upon several factors, Lime use in gold processing – A review ScienceDirect

Modeling of Bauxite Ore Wet Milling for the Improvement of

2021年9月5日 This study aimed to model bauxite grinding and assess the optimum material filling volume in a laboratory ball mill in order to improve mill and overall process efficiency 2014年7月27日 In this study, I carried out my works with two specific objectives: quarry technology (drilling technology and blasting design) and quarry management (transportation (PDF) Quarry technology and management of ore limestone in 2017年7月1日 With the intent of increasing the specific surface area of limestone and consequently the gypsum production, the raw limestone was treated in a highenergy mill The Enhancing the recovery of gypsum in limestonebased wet flue 2024年7月17日 Features: Vertical mill is a largescale grinding equipment, suitable for dry grinding of nonmetallic ores such as limestone Its advantages are simple equipment Which Grinding Mill Is Suitable For Processing Limestone?

Recycling of steel plant mill scale via iron ore pelletisation process

2009年8月1日 Mill scale is an iron oxide waste generated during steelmaking, casting and rolling Total generation of mill scale at JSWSL is around 150 t/day and contains 60–70%FeO and 30–35%Fe2O32023年4月13日 The effect of ball size and interstitial filling on the performance of dry ball mill grinding was investigated for a limestonetype brecciated uranium ore The optimum grinding was obtained with the combination of different balls (127–375 mm) and interstitial filling of 50% (20% ball filling ratio at fixed material filling ratio = 4%) The net power consumption in a ball mill is Optimization of Ball Mill Grinding of a LimestoneType 2024年7月29日 Baichy Machinery is a factory supplier of mining machinery, mainly focusing on stone crushers, powder grinding mills, and mineral beneficiation plantsWe can offer you a free design and completed solutions according to your project Baichy Heavy Industry has grown into a hightech mining equipment comprehensive enterprise, integrating RD, manufacturing, sales, YGM 75 type Raymond mill Ore Grinding Unit Ships to Morocco2012年6月1日 As the cylinder starts to rotate, the grinding balls inside the cylinder crush and grind the feed material, generating mechanical energy that aids in breaking bonds, activating the catalyst, and Grinding in Ball Mills: Modeling and Process Control

Mill tailings based composites as paste backfill in mines of U

backfill (%) (%)2020年3月3日 Figure 22 shows schematic sketch of a blast furnace indicating different sections, and Fig 23 shows the general constructional features of a blast furnace It is circular in cross section and around 30–40 m in height The outer shell of BF is made of steel plates, and refractory lining is at the inside of shellBlast Furnace Process SpringerLink2024年7月17日 Features: A highpressure suspension roller mill is a new type of grinding equipment, suitable for dry fine powder processing of limestone and other materials Its working principle is to use a highpressure device to generate a certain pressure between the grinding roller and the grinding ring on the roller shaft, squeeze and grind raw materials such as Which Grinding Mill Is Suitable For Processing Limestone?Final products size: 0315mm Capacity: 500tph Equipment: Vibrating Feeder TSW1548 → European Type Jaw Crusher PEW1100 → HST Single Cylinder Hydraulic Cone Crusher HST315 → HPT Series HighEfficiency Hydraulic Cone Crusher HPT300 → Vertical Shaft Impact Crusher 5X1145(2 sets) → Vibrating Screen 2YZS2460(2 sets) → Vibrating Screen 4YZS2460(2 sets)500T/H Highspec Crushing and Screening Plant

.jpg)

HPT Hydraulic Cone Crusher,high efficiency Hydraulic Cone

HPT series high efficiency Hydraulic Cone Crusher is a worldlevel cone crusher developed from the uptominute technology of Germany Unique interparticle crushing action, Advanced hydraulic system, Integration of the hydraulic station and lubrication system,Advanced liner retention technology,Much more reliableThe cone crusher ’s motor drives the horizo2018年10月1日 Request PDF Treatment and water reuse of leadzinc sulphide ore mill wastewaters by high rate dissolved air flotation Simulated wastewaters (concentrate and tailings thickener overflows), from Treatment and water reuse of leadzinc sulphide ore mill2023年7月4日 It was successfully designed in 1984, the first high pressure roller mill was applied in the cement industry in 1985, and by 2015 it had been widely used in various metal and nonmetallic minerals such as iron ore, manganese ore, cement raw Roller Mill SpringerLink2023年5月15日 Make sure we have a grinding mill that is the appropriate size and type for processing limestone Mill type (such as a ball mill, vertical roller mill, or Raymond mill), capacity, power consumption, and overall efficiency are all What is Limestone Grinding Mill SBM Mill Crusher

.jpg)

THE BENEFITS OF HIGH CLASSIFICATION

2013年1月1日 The return of 100400% of the ore mass to the mill typically reduces the retention time of the material inside the mill increasing the grinding capacity, improving the energy efficiency, resulting 2018年3月1日 Mill tailings based composites as paste backfill in mines of Ubearing dolomitic limestone ore March 2018 Journal of Rock Mechanics and Geotechnical Engineering 10(2)(PDF) Mill tailings based composites as paste backfill in mines 2023年12月15日 White mud (WM) is a solid waste that is generated when an Na 2 CO 3 solution reacts with CaO to regenerate NaOH during the caustic reaction in the alkali recovery process of paper (ie, pulp) mills Approximately 2 tons of dry WM is obtained for each ton of NaOH regenerated by the pulp mill (Cheng et al, 2009a)The main component of waste WM is A new disposal method for white mud: Replacing limestone in iron ore 2016年6月20日 Qu = A x B x C x D x E x F x G x H x J x K x L x Af, where: Qu = Screening capacity [t/h] (passing through) A = Nominal capacity [(m³/h)/m²] (passing through) B = Oversize factor C = Halfsize factor D = Deck location factor E = Wet screening factor F = Material weight [t/m³] (bulk density) G = Efficiency factor H = Shape factor for mesh holesOre, Rock Aggregate Screening (Complete Guide)

.jpg)

Understanding the SAG Mill in Copper Ore Mining Process

Rod Mill The rod mill is another type of grinding mill used in the copper ore mining process This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills The rods grind the ore by tumbling within the mill, similar to the action of a rotating drum2020年8月12日 VRM has been widely researched in processing of cement (Ito et al 1997;Jorgensen 2005;Wang et al 2009, Ghalandari et al 2021), coal (Tontu 2020), iron ore (Reichert et al 2015), zinc ore (van An investigation of performance characteristics and energetic 2024年1月29日 Next, choose the appropriate type of grinding machine, such as a ball mill or roller mill, based on these requirements Consider the machine's production capacity to ensure it meets your production needs Additionally, focus on energy efficiency to reduce production costsHow to choose limestone grinding mill? SANDMINE2016年2月29日 The most common type of rod mill is the overflow mill There are two typed of ball mills used Overflow discharge and grate discharge Separation efficiency is not very high and the concentration process must be repeated several times in the same unit Typically the process can process ores whose gold content is 0811 g/tGold Extraction Recovery Processes 911Metallurgist

HPT Hydraulic Cone Crusher,high efficiency

HPT series high efficiency Hydraulic Cone Crusher is a worldlevel cone crusher developed from the uptominute technology of Germany The cone crusher not only improves the production capacity and crushing efficiency, but also widen Due to the depletion of highgrade ores and th e increasing needs of the industry for critical elements,includingrareearthelements(REEs),whi charerequiredformanyhightechapplications, mining of lowgrade ores and treatment of second ary Modeling of Bauxite Ore Wet Milling for the Improvement of Process 2019年11月4日 The compressive strength of limestone is generally around 150 MPa, which belongs to soft rock The limestone crusher machine has jaw crusher, impact crusher, cone crusher, etc JXSC custom makes limestone crushing Limestone Rock Crushing Flow Price JXSC MachineChrome ore beneficiation Most of the chrome ores around the world are beneficiated by gravity concentration techniques A conventional chromite ore beneficiation process plant (Figure 3) consist of two sections: > Communition (for preparing the material for the subsequent unit operations) > Concentration (classification and beneficiation)Process optimization of a chrome ore gravity concentration

.jpg)

(PDF) Recycling of mill scale in sintering process Science of

2011年1月1日 Infect only a few investigators worked on the kinetics of mill scale reduction [24][25][26][27][28][29][30]In previous studies on the use of the catalyst for iron ore or mill scale reduction 2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove impurities The eighth chapter of this book deals with mining and beneficiation of phosphate ore The principle and operating conditions of important Mining and Beneficiation of Phosphate Ore IntechOpen2020年12月21日 Tumbling mills have been widely implemented in many industrial sectors for the grinding of bulk materials They have been used for decades in the production of fines and in the final stages of ore Increasing Energy Efficiency and Productivity of the PDF On Dec 9, 2015, Momen Marwan Mohsen published Cement Manufacturing Find, read and cite all the research you need on ResearchGate(PDF) Cement Manufacturing ResearchGate

Introduction to Mineral Processing or Beneficiation

The general focus of this document will be on metaliferrous ores represented by runofmine material described in category 3 above An exception to the above discussion of mineral processing arises when the valuable component of the 2022年11月10日 Increasing the efficiency of crushing circuits is associated with a decrease in the particle size of finely crushed ore and the use of dry magnetic separation of crushed oreIron ore beneficiation technologies in Russia and ways to improve 2014年1月20日 In this process, a highpressure grinding roller (HPGR) and a stirred mill were employed as primary comminution techniques and a nanobubble flotation column as a key separation process(PDF) Effects of High Pressure ORE Grinding on the and interstitial lling on the performance of dry ball mill grinding was also investigated for a limestonetype brecciated uranium ore The ball mill grinding was modeled by the combined use of the matrix and the PBM The breakage function was determined by the BII method Monosize fraction for the determination of was avoided, and SOptimization of Ball Mill Grinding of a Limestone‐Type

The Kinetics of Calcination of High Calcium

2012年2月1日 A pesar de esto, se reportan pocas investigaciones en la literatura especializada sobre la evaluación y/o optimización del consumo de energía en este proceso [3,14,16,17,18]Vertical mill is a highefficiency and energysaving grinding equipment, If you need to process ultrafine limestone powder (such as D97≤10μm), PE500x750 and PE600x900 Jaw Crusher Gold Ore Crusher Machine For Primary Crushing In Ethiopia 2 plays change batchLimestone Processing MachineLimestone Grinding Mill MachineThe MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and energyefficient is the optimum solution when it comes to performing several process steps in one unitCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2015年10月23日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a EnergyEfficient Technologies in Cement Grinding IntechOpen

.jpg)

THE EFFICIENCY OF LIMESTONE IN NEUTRALIZING ACID MINE

2017年1月11日 The neutralization of acid mine drainage (AMD) by limestone proved to be effective in various laboratory tests and realscale applications worldwide2017年12月21日 (a) Acidic iron ore pellet without mill scale (b) Acidic iron ore pellet with 15% mill scale Figure 6 Effect of mill scale on apparent porosity in acidic pellet(PDF) Mill scale as a potential additive to improve the quality PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGateIron Ore Pelletizing Process: An Overview ResearchGateLimestone Raymond mill 80600 mesh Discharge fineness: 80600 mesh Feed size: 35 mm Output: 0435 t/h Materials: various nonflammable and explosive materials with Mohs hardness less than 93 and humidity less than 6%Limestone Raymond mill 80600 mesh SBM Ultrafine Powder