Environmentally friendly and energysaving gypsum powder making process and production line

.jpg)

CNA Production process of environmentfriendly

The invention discloses a production process of environmentfriendly and energysaving gypsum powder by effectively utilizing waste heat, which comprises the following steps: (1)2024年4月12日 It also analysed and evaluated the environmental properties and leaching and release patterns of heavy metals in modified phosphorus building gypsum, so as to provide Highly efficient modified phosphogypsum building gypsum 2016年12月31日 weight gypsumbased composites permit a savings on energy in the production of modules and in the performance of the products Research has been done in which gypsum Sustainability of gypsum products as a construction materialThe technology of FD chamber boiling furnace technology can effectively prevent the mixing of raw materials with gypsum powder in the process of calcining Traditional calcining technologies such as vertical boiling furnace , Gypsum Powder Making Machine Gypsum Powder

Gypsum Board Making Machine, Gypsum Board Production Line, Gypsum

We are Gypsum Board Making Machine, Gypsum Board Production Line and Gypsum Powder Equipment ManufacturersSuppliers,welcome to contact us Highquality, highperformance, highefficiency, energysaving, environmentallyfriendly, and highquality production lines are available to customers Industrial Gypsum Powder Equipment Read More2024年1月23日 In addition, due to its green, environmentally friendly, energysaving, and other characteristics, many people invest in gypsum powder production lines Gypsum Powder Grinding Equipment Gypsum powder is Gypsum Powder Grinding And Processing Plant Natural dihydrate gypsum (CaSO42H2O) is a versatile, nonrenewable and recyclable green natural resourceBuilding gypsum (βCaSO405H2O) produced with natural dihydrate gypsum can produce a series of new gypsum building materials: paper gypsum board, plastering gypsum, plastering gypsum, gypsum drymix mortar, gypsum strip, gypsum block, Selfleveling gypsum Natural dihydrate gypsum (CaSO42H2O) powder production lineDesulfurization gypsum powder production line is to process raw gypsum ore into gypsum powder It is not only more energysaving and environmentally friendly, but also easily realizes largecapacity productionChina Desulfurization Gypsum Powder Production Line

Synthesis and properties of CO2based plastics: Environmentally

2018年5月1日 Synthesis and properties of CO 2based plastics: Environmentallyfriendly, energysaving and biomedical polymeric materials Author links open overlay panel Yonghang Xu a b c 1 , Limiao Lin a 1 , Min Xiao a , Shuanjin Wang a , Andrew T Smith c , Luyi Sun c , Yuezhong Meng a2024年4月12日 Highly efficient modified phosphogypsum building gypsum powder and environmentally friendly utilisation in selflevelling mortar April 2024 DOI: 101007/s43452024009336Highly efficient modified phosphogypsum building gypsum powder 2024年2月1日 An environmentally friendly tile that can be used as an alternative to traditional flooring because it is made using less energy When compared to regular tile, the price is far lower They are simple to install and come in a wide variety of Sustainability through materials: A review of green options in 2013年6月1日 In this phase, the government planning and regulation will be considered The implementation of ESGD will take financial compensation measures to balance interests of corresponding stakeholders In the Phase II, the cost based optimal dispatching will be conducted, making ESGD not only energysaving, environmentally friendly but also leastcostPromoting energysaving and environmentally friendly

Green production and green technology for sustainability: The

2023年12月1日 GP and GT use environmentally friendly technologies and production processes to reduce waste and EC and ensure sustainability [10, 11]Such activities and technologies minimize environmental impact, conserve natural resources, reduce carbon footprints during production [12], and minimize EC, which leads to the conservation of natural resources and In the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle Gypsum Powder Ultrafine Grinding Mill2023年1月6日 The growing concern about environmental damage and the inability to meet the demand for more versatile, environmentally friendly materials has sparked increasing interest in polymer composites derived from renewable and biodegradable plantbased materials, mainly from forests These composites are mostly referred to as “green” and they can be widely A review of environmental friendly green composites: production Finally, qualified gypsum powder is collected through a dust collector to complete the entire production process The gypsum powder production line can not only process gypsum but also process ultrafine powder of nonflammable and explosive brittle materials with medium and low hardness, Mohs hardness ≤ 6, such as calcite, dolomite, carbon Gypsum powder production line Baichy Heavy Industry

.jpg)

Energysaving and environmentallybenign integrated ammonia production

2021年11月15日 In this work, an integrated conversion system of coal to ammonia (NH 3) is developed with the objectives of total energy efficiency maximization and process simplificationThe system integrates drying, chemical looping hydrogen production, cryogenic nitrogen separation, NH 3 synthesis, and power generation Due to this integration, the total The process of making gypsum boards involves several key steps Initially, a foaming agent stock solution is diluted twice to stabilize foam amounts, enhancing the production process's efficiency and reliability [1]Subsequently, a mixture of phosphogypsum, graphite, zinc oxide aluminum powder, and titanium dioxide is prepared, dried, and ground to create finished gypsum What is the process of making gypsum boards?The company has a complete production system,a firstclass technical staff team,with more than1 00 sets of complete processing equipment,and has invested a lot of money to introduce largescale CNC gantry milling machines,CNC boring machines,CNC machining centers,CNC machine tools and other highend equipment,so that our company can provide highend Gypsum Board Production Line Manufacturer, Gypsum Powder Production 2009年10月16日 Relatively little energy is spent for the production of gypsum binders, about 20 % compared to the other building binders (cement, lime) The reason for this is quite lower temperatures in the MATERIAL AND ENERGY BALANCE OF PRODUCTION OF GYPSUM FLUIDIZATION PROCESS

Decarbonising cement and concrete production: Strategies,

2024年6月1日 Efficient dust collection systems can also contribute to energy savings by minimising material loss and optimising process efficiency [[157], [158], [159]] Energy management systems and regular energy audits are effective tools for identifying energysaving opportunities and optimising energy use in cement plants2023年5月1日 promoting sustainable concrete construction are examined, stressing the need for interdisciplinary collaboration(PDF) Smart materials and technologies for sustainable concrete 2019年12月1日 One of the biggest challenges of the 21st century is to maintain sustainability in all levels of energy resources and environmental context (Palmer, 2002)There is a steadily increasing concern in the energy and environmental sectors (Wazna et al, 2018)In the energy sector, concern is mainly due to the imbalance between the consumption and limited Environmentallyfriendly thermal and acoustic insulation 2024年1月1日 Request PDF Environmentally responsible production of lime from recycled gypsum and weakly alkaline wastewater Benefits associated the treatment of wastewater from a returnable glass bottle Environmentally responsible production of lime from recycled gypsum

.jpg)

Sustainability of gypsum products as a construction material

2016年12月31日 The upper punch covers the gypsum powder 11 078 07 10 0 and should provide an energysaving building process and result At the for production (EnvironmentallyFriendly Gypsum 2017年2月1日 Gypsum in the form of calcium sulfate hemihydrate (CaSO 4 ⋅05H 2 O) is commonly utilized in lightweight applications such as gypsum plasterboard [14], gypsum brick [15,16], gypsum block [17, 18 (PDF) Lightweight Gypsum Based Materials: A multistage production process is necessary to transform the SO 2 in flue gas, into panelgrade FGD gypsum that will meet the precise specifications of gypsum panel manufacturers As flue gas is generated, it is passed through an electrostatic precipitator that separates fine particles, including fly ash, from the gasFGD Gypsum Production ProcessThe invention discloses an energysaving gypsum calcination system and an energysaving gypsum calcination process The energysaving gypsum calcinations system comprises a paddle dryer, a vibrating screen, a cement bulk truck, a pelletizer and a cement delayed coagulation device, a fluidized bed calcinator, a building gypsum processing device, and an oscillation flow Energysaving gypsum calcination system and process

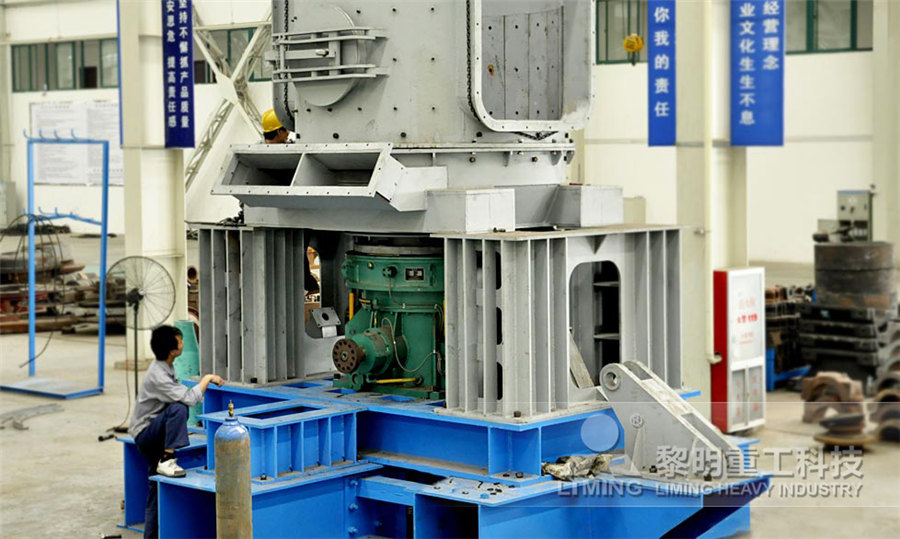

Gypsum Powder Production Line

1Introduction of gypsum powder production line Natural gypsum powder can be used as: paperfaced gypsum board, plastering gypsum mortar, gypsum strips, gypsum blocks, selfleveling gypsum mortar, laminated board, various decorative boards, etc Low energy consumption for gypsum production: about onefourth of that of cement productionGypsum Powder Making Machine is also called Gypsum Powder Production Line Equipment ,Natural gypsum powder is dihydrate gypsum (CaSO42H2O) after crushing, grinding, calcination, cooling homogenization, aging, packaging and made; gypsum powder production is the core technology of calcination (dehydration) system, the two gypsum crystal Structure, various Gypsum Powder Making Machine,Gypsum Powder Production Line 2021年1月23日 Request PDF Slag uses in making an ecofriendly and sustainable concrete: A review A single ton of ordinary Portland cement (OPC) demands around 40 G Joule energy and creates about a ton of Slag uses in making an ecofriendly and sustainableThe technology of FD chamber boiling furnace technology can effectively prevent the mixing of raw materials with gypsum powder in the process of calcining Traditional calcining technologies such as vertical boiling furnace , rotary kiln ,general boiling furnace, etcDue to the effect of mixing function of the machinery and air flow, dihydrate gypsum ,semihydratedgypsum and anhydrite Vertical Boiling Furnace Technology Calcined Gypsum Powder Production Line

A comprehensive study of building materials and bricks for

2024年4月26日 In the realm of residential building construction [1], the use of traditional bricks has been an old practice, deeply rooted in conventional construction methodsHowever, the growing awareness of environmental concerns and the need for sustainable building practices have led to a paradigm shift in the choice of construction materials [2]2014年5月1日 Request PDF Environmentally friendly Manufacturing Processes in the Context of Transition to Sustainable Production This article highlights the importance of the sustainable manufacturing Environmentally friendly Manufacturing Processes in the 2022年9月6日 It is an environmentally friendly mineral powder, which is made by grinding mill Used as a cosolvent and scavenger in the glass production process c: Used as filler in industrial production of plastics, rubber, Gypsum Powder Making Machine In Gypsum Powder Making Machine Zenith Crusher2022年1月1日 On the road to sustainable development, the concepts of energy saving and environmental protection are deeply rooted in people’s hearts, and their technology has penetrated into all aspects of life(PDF) Application of Environmental Protection and Energy Saving

.jpg)

Production of cement and its environmental impact ScienceDirect

2023年1月1日 The addition of SCMs in cement makes it economically cheaper and also environmentally friendly SCMs reduce energy consumption in cement production, hence reduce CO 2 emissions associated with the production of concrete with the added benefit that the industrial waste streams are recycled and turned into valueadded streams2024年8月15日 Scholars have increasingly focused on dealing with large quantities of PG It is well known that there is a high demand for gypsum materials in engineering and construction, so recycling PG as a building material has been recognized as a powerful measure to solve the problem [[12], [13], [14]]Although there is considerable potential for resourcing PG building Phosphogypsumbased building materials: Resource utilization Gypsum powder production line can not only process gypsum, but also process ultrafine powder of medium and low hardness, nonflammable and explosive brittle materials with Mohs hardness ≤6 Such as calcite, chalk, limestone, dolomite, carbon black, Read More; Production Line Xiangyi Machanical Factory Gypsum Powder Making MachineGypsum Powder Production Line Hebei Xiangyi Mechanical 2018年5月1日 CO 2based plastics may soon become commercially accessible as a new class of environmentallyfriendly, energysaving and biomedical polymeric materials Introduction Carbon dioxide (CO 2 ) is one of the most fundamental carbon sources abundant, inexpensive, and nontoxic, making it an ideal raw material for chemical synthesis [1]Synthesis and properties of CO2based plastics: Environmentally

Preparation of environmentally friendly and energysaving

2019年12月30日 Preparation of environmentally friendly and energysaving autoclaved aerated concrete using gold tailings December 2019 Journal of New Materials for Electrochemical Systems 22(3):159164Gypsum blocks are environmentally friendly and energysaving materials due to their good properties, small dimensional change and easy application, and are very popular in buildings[30,31] Natural gypsum has long been used as raw materials for gypsum blocks The development of copper smelting processes resulted in a growing number of titanium Gypsum blocks produced from TiO2 production byproducts2024年1月12日 Lightweight aggregate has been developed in China for nearly half a century The rapid expansion of China 's lightweight aggregate product market has promoted the continuous development of lightweight aggregate [1], [2]The use of lightweight aggregate in buildings can not only greatly reduce the weight of the building itself, but also save Preparation of lowcarbon and environmentally friendly non