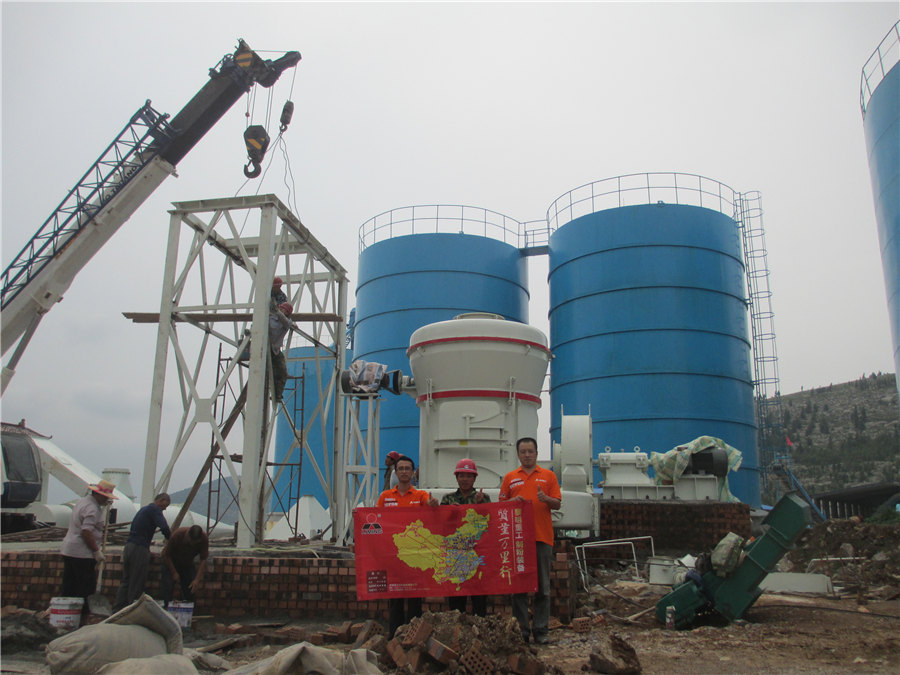

Screening sand ore vertical mill for less money

Metso Vertimills

VERTIMILL® is Metso’s gravityinduced, vertical stirred mill Its vertical configuration allows for large throughputs while maintaining a small footprint in your circuit The VERTIMILL® can Vertimill® is a unique product offered exclusively by Metso Grinding efficiency, reduced media consumption, lower installation cost, minimal maintenance, and minimal liner wear make Vertimill® MetsoHorizontal ball mill and vertical Raymond mill can be used for milling of 200+ ores, with a fineness of 1002500 mesh The mobile crushing station has crawler type and tire type chassis, which Ore Crushing, Sand Making, Grinding Machinery Bellian Mining RHEWUM is capable of designing semistationary sand processing plants with firstclass industrial sand screening equipment such as the linear vibrating screen RHEflex ® and the Screening machines for industrial sand screening RHEWUM

Mobile Crushing Screening,Grinding,Sand Making Equipment

Our crushing and screening, grinding equipment is renowned worldwide for robust construction, reliability and high performance Liming Heavy Industry is designing, manufacturing and 5 天之前 In this article, we’ll detail the advantages and disadvantages of 8 kinds of screening machines, and tell you how to choose the right screening machine for your processing operationScreening Machines Comparison JXSC MachineryExplore our mining equipment to find the ideal wholesale vertical sand mill machine model and mills for any mining challengeVertical sand mill machineEach fuelefficient model features the largest possible screening area and integrated conveyors that optimize stockpiling Sandvik mobile scalpers maximize your productivity while minimizing Mobile scalpers Sandvik’s efficient screening SRP

.jpg)

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE

2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plantand screening sizes, Meka screens provide screening efficiency that is high quality and dependable Our screens come in various sizes starting from 2 m² up to 16 m² and are equipped with up to four decks that can be supplied with different types of meshes, such as grizzly, perforated sheet, polyurethane and steel meshes, withCRUSHING SCREENINGScreening Metso’s high efficiency screening solutions provides dependable screening performance for large material volumes with hard and abrasive ores Grinding Metso’s comprehensive line of grinding mills and systems provide the most effective and energy efficient technology across wet or dry, horizontal or vertical stirred milling operationsMetso Vertimills

.jpg)

(PDF) Crushing and Screening Handbook Academia

Crushing and Screening Handbook Crushing plants are of great interest in reducing a particle size of rocks and ores as milling operations need to consider sustainable development Change from pressure crushing in roller mills to impact crushing in production of mineral sand Knut Sandvik Powder Technology, 19992024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage Ball Mill Is Indispensable For Lithium Ore Processing2017年7月31日 11 Mechanical screening: Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recyclingOre separation screening and classification PPT SlideShareWhether it's efficiently crushing ores, creating highquality sand for construction, or precision grinding for various applications, Choose Bellian Mining Machinery for all Horizontal ball mill and vertical Raymond mill can be used for milling of 200+ ores, with a fineness Sand Screening Plant TGM Trapezium Grinder Mill Ball MillOre Crushing, Sand Making, Grinding Machinery Bellian Mining

Copper Concentrate regrind at Sossego Plant using Vertical Mill

At the regrind or secondary grinding stages of base metal ores, the concern about energy efficiency is usually extremely important Vale is using the vertical mill on its copper projects – Sossego and Salobo, in order to optimize the regrind of Vertical stirred mills are a fine grinding equipment that covers advantages of low rotation speed, high reliability and long life cycle The significant advantages that the vertical stirred mills have over the ball mills are smaller size, less auxiliary equipment required, more simple system and more options of processing methodsVertical Stirred Mill Mineral Processing Equipment CITIC HIC2018年2月27日 Tom Schroeder Separation Experts LLC Wikipedia defines “Mechanical Screening” as: “Mechanical screening, often just called screening, is the practice of taking granulated ore material and Primer: Mechanical Screening and Separation LinkedIn5 天之前 The eccentric shaft directly drives the screen frame to make a trajectory movement in the vertical plane with an amplitude equivalent to twice the eccentricity The sieve size can reach 100~250mm It is often used in the prescreening process or the first screening process of sand and gravel materialsScreening Machines Comparison JXSC Machinery

.jpg)

The Role Of Rod Mill In Quartz Sand Beneficiation

2024年11月21日 Rod mill is an important piece of equipment in quartz sand beneficiation Quartz ore is the main raw material for producing glass, ceramic, and building materials After sorting and purifying it, it is used to make various Vertical Grinding Mill is a widely used grinding machine suitable for processing nonflammable and nonexplosive materials It is suitable for construction, mining, metallurgy, pharmaceuticals, and chemical industries The Vertical Grinding Mill is ideal for medium and smallscale industries as it requires less investment and lowpower consumption compared to a ball millVertical Grinding Mill – Shalimar EngineeringSBM will provide high quality and production capacity natural sand vertical roller mill for worldwide clients particle size less than 5 mm in rock particles, it is referred to as the natural sand Magnetic separation machine can be applied for wet dressing of ores with the size less than 3mm Raymond Mill Raymond mill is used for Natural Sand Making Machine Vertical Roller Mill for Sale from HGM ultrafine grinding mill can process nonmetallic ores with Mohs hardness less than 7 The equipment has stable operation, simple operation, long service life, low carbon and environmental protection There are 5 models of HGM ultrafine grinding mill, SBM Ore Ultrafine Grinding Mill

Mineral Screening: The Complete Guide Mining Pedia

2022年12月28日 Screening refers to the process of breaking up the material into different size pairs through one or several layers of screen surface In the screening process, the sieved raw material continuously into the screening machinery, then, less than the size of the screen hole material will be through the screen hole, this part of the material is the product of the screen; Iron Ore Dressing The iron ore dressing process is aimed at the processing of iron ore materials, which is divided into crushing and screening, grinding and classification, separation, and dehydrationCrushing and screening refers to the crushing and screening of iron ore to ensure that the particle size of crushed ore can provide ore that meets the requirements of block size Iron Ore Processing JXSC MineralFlowchart Explanation The raw ore is fed into the trommel screen for washing a few little clays and can separate the gravel or stone which needs to crushgrind to get the inside tin, the separated gravel can transfer to the next jaw crusher by the belt conveyor After the jaw crusher, goes to a cone crusher for second crushingThe output from the cone crusher goes to a Tin Ore Mining Process JXSC Mineral2023年10月30日 The selection and design of crushing equipment in the mineral processing industry are influenced by several key factors, all of which are critical for achieving efficient and effective ore processing Chief among these factors is the material's inherent characteristics The hardness, abrasiveness, moisture content, and size distribution of the ore significantly impact The selection and design of Crushing equipment Mineral

.jpg)

Barite Ultrafine Vertical Roller Mill

Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content, high degree of automation, convenient maintenance, long service life, environmental protection, and energysaving, and is an ideal equipment for largescale production of ultrafine powder2016年5月26日 Only enough water is necessary to keep the solids in full teeter As the sands accumulate in the classifier pockets the effective density of sandwater mixture increases and thumbscrews on the valve rod assemblies may Types of Classifiers in Mineral ProcessingNot only does the vertical mill have a reduced footprint compared to horizontal mills of the same size, but the compact design is optimised to eliminate backpressure problems and remove the risk of bearing seal leakage With no need for seals or filters within the mill chamber, maintenance costs and downtime are reducedVertical mills for fine grinding – FLSsand screening machine in chennai Mineral Processing EPC Dec 06, 2017 Best Selling Mining Crushing Equipment Diesel Engine Jaw Best Selling Mining Crushing Equipment Diesel Engine Jaw Crusher With Ceiso screen for a separation which classified the materials into two kinds of stone, of sand gravel base sand will feed into the sand making machine, another partsand screening machines KOOKS

How to Choose the Correct GRINDING MEDIA PCI Mag

DIFFERENT MILLS REQUIRE DIFFERENT AMOUNTS OF MEDIA •BASED UPON WORKING VOLUME OR TOTAL VOLUME •Mills such as the Immersion Mill have a fixed amount determined by size of the basket •Steel Ball Mill 333% •Open Head Sand Mill 3545% •Ceramic Pebble Ball Mill 50% •Dry Grind Batch Attritor 4560% •Wet Grind Batch Attritor 3845% •Continuous In addition, the vertical mill adopt sealed gearbox and pulley to transmit power, which greatly reduces the noise Silica sand vertical mill There are two types of silica sand grinding mills: ball mill and vertical mill Ball mill is widely used in silica sand grinding process Vertical mill is also widely used in silica sand grinding processWhat is the best for grinding silica sand ball mill or vertical millJXSC mining washing and screening equipment is commonly used in construction, gravel plants or mining plants Mainly including wheeled sand washer, spiral sand washer, trommel scrubber, trommel screen, vibrating screen, mobile gold washing plant, silica sand attrition scrubber, fine sand recovery machine, linear vibrating screen, gyratory swing vibration screen, rotary Ore Washing Screening Equipment JXSC Machinery2014年10月20日 Hematite and magnetite, the two predominant iron ores, require different processing routes Highgrade hematite direct shipping ores generally only require crushing and screening to meet the size Regrind of metallic ores with vertical mills: An overview of the

.jpg)

Crushing Screening Plant 911Metallurgist

2016年7月12日 A large wheel, up to 24 ft in diameter by 4½ ft wide, is fitted with internal buckets As the wheel revolves, the buckets lift the rock to the top of the mill where it is dropped onto stationary breaker plates The ore is thus crushed by its own impact on the plates Ore as large as 12 in is fed to the mill2016年3月11日 In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or lessCrushing Plant Flowsheet DesignLayout 911MetallurgistUnderstanding the SAG Mill in Copper Ore Mining Process Are you curious about the machinery behind copper ore mining? role in copper ore mining by efficiently breaking down large chunks of material into manageable sizes while Understanding the SAG Mill in Copper Ore Mining Screening is mainly used in the mining sector in primary and secondary crushing systems (Fig 3), coarse screening (scalping) in the preheap leaching process, fine screening and finegrain elutriation in various process stages, enrichment Advances in screening technology in the mining sector

Mobile Crushing Screening,Grinding,Sand Making Equipment

Manufacturer of Crushing Screening, Grinding Equipment Liming Heavy Industry is an innovative China mineral processing technology company with over 35+ years of experience in the quarry, mining and aggregate industries Our crushing and screening, grinding equipment is renowned worldwide for robust construction, reliability and high 2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished Limestone crushing, sand making and grinding processThe mobile vibration sand screening and conveying machine is a multifunctional equipment with a complex structureIt consists of multiple components such as a vibrating screening part, a conveying part, a support structure, a control system, and moving parts to screen granular materials such as sand and gravel It is suitable for sand and gravel separation, cinder Mobile Vibration Sand Screening Machine2024年11月21日 (3) There are a large number of vibrating screens in the sand and gravel processing system The appropriate screen hole size and screen hole form can be selected according to the mica embedding particle size in the raw Beneficiation Methods For Removing Mica From Quartz Sand

.jpg)

Vertical Shaft Impact Crusher Excellent Sand Making Machine

2022年11月3日 Vertical shaft impact crusher, also known as sand making machine, is widely used in the crushing of various rocks, abrasives, refractories, quartz stone and iron ore This article mainly introduces what is a vertical shaft impact crusherCLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, Superfine vertical grinding mill main machine and multirotor powder separator: Finished product Less than 2μm=30% output (t/h) 912: 1216: 1418: Less than 2μm=45% output (t CLUM Ultrafine Vertical Grinding MillVM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of industry mills With a decade of research of mills, vertical grinding mill is designed and manufactured based on our advanced design idea, in combination with the european technology and the market demandVM Vertical Grinding Mill Kefid2015年3月10日 Pilot scale vertical roller mill grinding tests were performed for chalcopyrite grinding successfully This situation was confirmed in an OGP test campaign for chalcopyrite ore with 18% less grinding energy consumption over to conventional ball milling circuit (Altun et al, 2015) In addition to low energy consumption, Copper ore grinding in a mobile vertical roller mill pilot plant