high fine vertical mill hollow grid

HIGmill high intensity grinding mill Metso

The Metso HIGmill™ is an advanced, energyefficient fine and ultrafine grinding solution that utilizes proven technology With the tall, narrow, vertical body arrangement, grinding media is evenly distributed and mineral particles remain Outotec HIGmills™ being based on existing, well proven stirred milling technology provide modern, sophisticated, flexible and energy efficient grinding solution for fine and ultra fine Outotec HIGmills; A Fine Grinding Technologymill size can be selected to optimize the media load and power input for specific applications Chamber volumes extend up to 50,000 liters with corresponding drives ranging up to 6,500 HIGmill™ MetsoThe Kurimoto VX Mill is designed to feed material to the center of a table, where the material horizontally rolls and moves in the peripheral direction of the table with centrifugal forceVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill

Swiss Tower Mills Minerals AG

Small footprint, expansive range of mill sizes Vertical arrangement means compact and efficient use of space From 200 to 125,000 Litres and 75kW to 12,500kW installed power We Vertical design eliminates cavitation in the grinding zone at high speeds ; Hightorque drive allows the use of grinding media with a wide range of intrinsic density ; Variable speed drive allows VXPmill for fine ultra fine grinding FLSmidthThe “flowsheet of the future” uses highpressure grinding rolls as an alternative to a semiautogenous grinding mill, and vertical stirred mills in open circuit as an alte rnative to ball Flowsheet of the Future: HighPressure Grinding Rolls, Vertical “The HMP combines Outotec’s leading fine grinding technology with faster installation and compact footprint while maintaining safety standards This standalone modular solution Introducing the Outotec® HIGmill plant a costeffective modular

A power model for fine grinding HIGmills with castellated rotors

2017年4月1日 A grinding power model has been developed to predict the power draw of Outotec’s vertical fine grinding mill (HIGmill) The model is based on a combination of The process comprises just a scalping cyclone with no circulating load, feed tank and pump, and the mill itself The benefit of high power intensity and vertical installation is a very small footprint The head room over the mill is small and HIGmill high intensity grinding mill Metso2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven 2022年7月20日 In order to study the axial compression performance for composite hollow column of steel fiber, highstrength lightweight aggregate concrete and angle steel, the axial compression tests were Experimental study on axial compression for composite hollow

Vertical mill for coal pulverizing in power plant Geckointech

Fine particles are taken away to boiler furnace, while oversized particles are separated by classifier for grinding again Vertical mill advantages Low energy consumption, 2030% lower compared with ball mill Much smaller footprint compared with The vertical roller mill has high energy efficiency and the installation space is smaller compared with tube mills These days, Grid screen To EP Coarse powder Fine powder Refined powder Raw materials First chamber Second chamber Doublerotator mill 71 6 Vertical roller mill for raw Application p rocess materials2020年5月18日 Grid Type Ball Mill VS Overflow Type Ball Mill, The ore discharge of overflow type ball mill mainly depends on the pulp itself high over the lower edge of the hollow shaft bushing 2 The overflow mill is better if the material needs to be ground to the fine products Grid Type Ball Mill VS Overflow Type Ball Mill, How to Choose 2023年10月3日 Rocker Arms: The function of the rocker arm device of the cement vertical roller mill is to transmit the pressure provided by the hydraulic cylinder to the grinding roller, so that it can be transformed into the grinding force act on the material bed The rocker arm device is mainly composed of upper rocker arm, lower rocker arm, rocker arm shaft, bearing and What is a vertical roller mill (VRM)? A Comprehensive Guide to

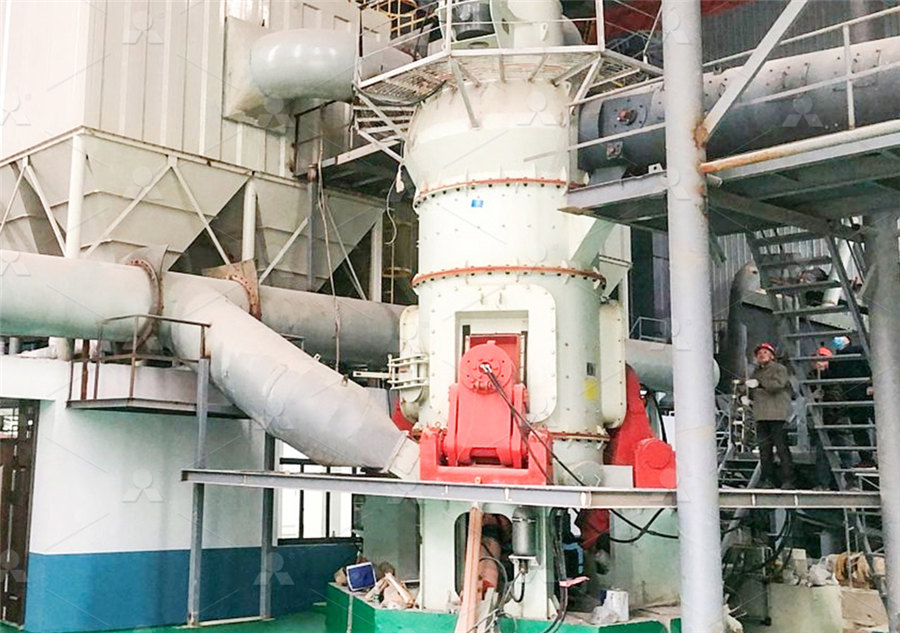

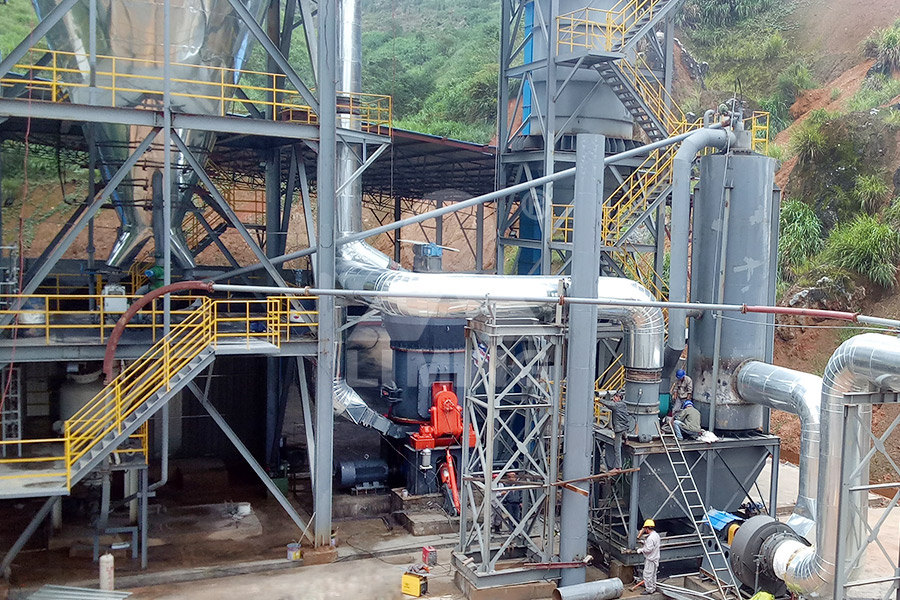

High Quality Vertical Mill for Sale Professional Manufacturer

The raw material vertical mill, as a technically mature and highperformance grinding and drying equipment, is widely used in industries such as cement, chemical, coal, and electric power This product has unique advantages, integrating drying, grinding, and powder selection, and has become the mainstream equipment in the cement grinding plex applications require adaptable equipment – and that’s what our range of vertical mill technologies offers With multiple options for mill heads, spindle configurations, mill footprint, and movement options, our high rail and gantry vertical mills and profilers can be precisely tailored to your process requirementsHigh rail vertical mills, gantries and profilers for precision 5Axis CNC Vertical Mill with 30" x 20" x 20" travels 5axis machining is an effective means to reduce setups and increase accuracy for multisided and complex parts The Haas UMC Series universal machining centers are cost UMC750 5Axis Mill 40Taper Vertical Mills – Barite ultrafine vertical roller mill is an industrial vertical grinding mill that can grind nonmetallic ore into fine powder The mill has a high production capacity, high fine powder content, high degree of automation, convenient maintenance, long service life, environmental protection, and energysaving, and is an ideal equipment for largescale production of ultrafine powderBarite Ultrafine Vertical Roller Mill

.jpg)

Tower Mill Grinding: Revolutionizing Efficiency and

The VTM series tower mill is a newly developed wet fine grinding equipment designed to address the issues of high energy consumption and high media consumption common in existing ball mill grinding operations The tower 2022年6月30日 In summary, we can draw the following conclusions Grid Type Ball Mill Advantages: The discharge speed is fast, which can reduce the overgrinding of the crushed stone, and at the same time can increase the output per unit volume, which is higher than the overflow type ball mill; Disadvantages: The structure is complex, the grid plate is easy to be OverflowTypeBallMillVSGridTypeBallMill MiningpediaCLUM ultrafine vertical mill is a new type of ultrafine grinding equipment integrating powder grinding, grading, conveying, secondary powder selection, and finished product packaging Capacity: 0245 t/h Max feeding size: 30mm Processing ability: 0245 t/h Application of CLUM ultrafine vertical mill:CLUM Ultrafine Vertical Mill2024年5月17日 Ultra fine vertical roller mill Pre grinding vertical roller mill Slag vertical roller mill A grate discharge mill has a perforated grid that allows the ground material to exit the drum while retaining the grinding media inside Use highquality lubricants to ensure effective protection and performance 3Understanding Ball Mill Parts: Essential Components for Effective

.jpg)

CLUM Ultrafine Vertical Grinding Mill

Production of coarse powder and general fine powder above 45um, stable operation, high cost performance and high noise Ring roller mill: 2um content is about 20% or more, the highest fineness is 810um, middle and highend finished powder Produce 1015um powder, stable operation, short life of wearing parts, high noise and low output Ball millOur ZGM MPS coal vertical mill uses highefficiency pulverizing technology to increase efficiency and reduce energy costs Excellent Crushing Effect The coal mills may provide more uniform and detailed coal powder to meet the product size requirement through an optimized grinding system and grinding processMPS ZGM Coal MillGrinding Equipment YingYong Machinery2024年6月28日 2 Overflowtype ball mill There is no grid lining plate on the discharge side of the overflowtype ball mill Instead, on the inner surface of the hollow shaft neck liner at the discharge end, there are spiral blades with opposite rotation directions to the mill to prevent balls or coarse ore blocks from being discharged together with the parison Between Grid Type and Overflow Type Ball MillWith years of technical innovation experience in cement and slag grinding, Shanghai Yingyong Machinery Co, Ltd has successfully developed various models of vertical roller mills Our team of specialists is dedicated to assisting customers worldwide in creating dependable, energyefficient, and highperforming solutions for vertical roller mill grindingOptimize Your Grinding Process with Our Vertical Roller Mills

.jpg)

Roller Mill SpringerLink

2024年1月1日 The vertical roller mill has the advantages of low energy consumption, high output, easy maintenance, etc, and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore MillMax Mfg Corp • 190 Pine Hollow Road, PO Box 300, Oyster Bay, NY 11771 • 5169226000 • Fax: 5169229253 • millmax PIN GRID ARRAY SOCKETS PAGE 138 IC SOCKETS / TO SOCKETS083110145165080 or 115046 DIA020 DIA015025 • High temperature PCT polyester insulator material suitable for allPIN GRID ARRAY SOCKETS MillMaxProduct Introduction PLF highfine vertical double impact crusher is suitable for crushing medium and partial Introduction Baisheng MQG Wet grid ball mill consist of feeding part, discharging part, rotary part, transmission part and Mining EquipmentProducts CenterJiangsu Baisheng 2020年11月1日 The crosssectional behaviour of high strength steel tubular sections has been investigated experimentally by a number of researchers: Jiao and Zhao [14] and Ma, Chan and Young [15] tested a series of coldformed CHS, Wang et al [16] and Meng and Gardner [17] examined hotrolled square and rectangular hollow sections (SHS and RHS), Ma, Chan and Crosssectional behaviour of coldformed high strength steel

ufgmills Air Classification ultra fine grinding

The ufgmill is an effective method of ultra fine grinding many soft to medium hard materials in the range of 1 to 50 microns The ufgmill is a dry, vertical, airswept agitated media mill The grinding action takes place on the surface of grinding media which is agitated by a Newtype Pneumatic Ultra Fine Grinding Mill (Jet Mill) Cross Jet Mill; Compact Jet Mill and Separator Combined System Kurimoto Pocket Jet; Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High GVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill Longyi makes targeted improvements on existing vertical mill's technology to develop a newtype vertical mill fit for superfine grinding of nonmetallic minerals +29 Get A Quote HomeSuperfine Vertical Mills,NonMetallic Mineral Ultrafine Vertical MillDescription Characteristics of Summit ® HeavyDuty vertical boring mill and milling (VBM) machines Summit ® HeavyDuty vertical boring mills and milling (VBM) machines offer smooth running, superior speed control, and maximum reliability in a costeffective solution Summit’s 48″ 60″ (single column) and 80″ – 120″ (double column) vertical boring mills feature closedgrain Vertical Boring Mill and Turning Machines Summit Machine Tool

CLUM Series Ultrafine Vertical Roller Mill

3 Double PositionLimiting Technology Makes Operation More Stable In the CLUM series ultrafine vertical roller mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical limiting protection technology, which can avoid the destructive impact (eg the grinding roller directly smashing the millstone) caused by machine HLM series vertical mill is a largescale, highyield, HLM ultra fine vertical mill; Specifications Capacity(t/h) Pulverized coal fineness The raw coal moisture Pulverized coal moisture Main motor power(kW) HLM1200M 6—10 R008=515% ≤15% ≤15% 110132 Energysaving and Efficient Vertical Roller Mill Fote MachineryGrinding Jars for Across International High Energy Ball Mills Ball Mill is a grinder that blends or grinds materials for various applications Impact force enables size reduction in feed materialHigh energy ball mill Across InternationalLimestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Limestone Powder Ultrafine Vertical Roller Mill

.jpg)

Vertical hammer mill Lamec

The vertical mill is a very compact machine designed to take up less space and offer the user a high level of production capacity with reduced energy consumption The advantages of using the vertical mill in production, as UK National Grid Map Reference Conversion for any location by simply rightclicking on our map Postcode finder and bulk conversion toolsGrid Reference Finder2023年6月19日 The overflow type ball mill belongs to the nonforced high material level ore discharge, and the discharge speed is slow The mineral material stays in the machine for a long time, so its overgrinding phenomenon is serious 6 Different motion state of the steel ball The speed of the gridtype ball mill is high, and the steel balls are droppedBattle of the Mill Grid Ball Mill VS Overflow Ball MillLimestone ultrafine vertical mill is a high quality ores material powder grinding mill +17 Limestone ultrafine vertical mill is the introduction of Taiwan and Germany super fine vertical grinding technology combined with Clirik’s own years of grinding machine production experience selfdeveloped out of a new type of Limestone Ultrafine Vertical Mill

Fivestand coldrolling tandem mill Download ResearchGate

Download scientific diagram Fivestand coldrolling tandem mill from publication: The Research of the Rolling Speed Influence on the Mechanism of Strip Breaks in the Steel Rolling Process Sharp Industries, Inc 3501 Challenger Street Torrance, CA 90503 Tel 3103705990 Fax 3105426162 : tries Parts: triesSharp Industries, IncA Versatile Lineup of Vertical Machining Centers (VMC) Whether you need a standard 3axis mill, a powerful 5axis machining center, or a small VMC for precision parts, there’s a Haas to do the workVertical Mills VMC Haas CNC Machines Haas AutomationThe velix ® is most commonly placed downstream of either a tra ditional horizontal ball mill or, more recently, polycom ® highpres sure grinding rolls (HPGRs) The product exiting these mills is first fed into a slurry tank 1 The fresh material is pumped to a hydro cyclone cluster 2 to separate the coarse and fine particlesIndustrial Solutions velix ThyssenKrupp