HOME→coal mill small steel ball application transformation coal mill to use small steel ball and matching lining plate coal mill small steel ball application transformation coal mill to use small steel ball and matching lining plate coal mill small steel ball application transformation coal mill to use small steel ball and matching lining plate

coal mill small steel ball application transformation coal mill to use small steel ball and matching lining plate coal mill small steel ball application transformation coal mill to use small steel ball and matching lining plate coal mill small steel ball application transformation coal mill to use small steel ball and matching lining plate

Optimization and transformation of 300MV units steel ball coal

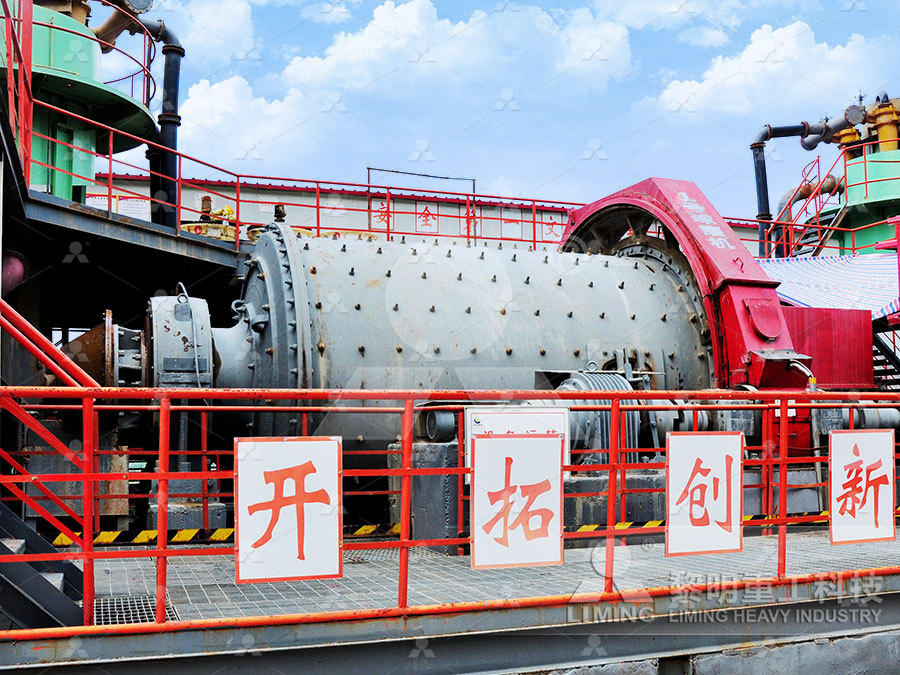

systemThe advantages of using steel ball mill are:It is safe and reliable, easy to operate and maintain coal with low grindability and high moisture contentBut it also has its 2019年10月1日 Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main operating parameters before Optimization and transformation of 300MV units steel ball coal Coal ball mill is mainly used in coal power plant or mineral calcining system Skip to content Home; The main bearing is made of cast steel, and the rotating large gear is processed by casting hobbing There are liner plates on the inner Coal Ball Mill Grinding for Different Kinds of They use steel balls to crush and grind the coal material, which is then discharged through a screen to separate the fine particles from the coarse ones The grinding process in ball mills is controlled by the rotating speed of the cylinder, which can be adjusted to achieve the desired particle size distributionWhat is a Coal Grinding Mill

.jpg)

Optimization and transformation of 300MV units steel ball coal mill

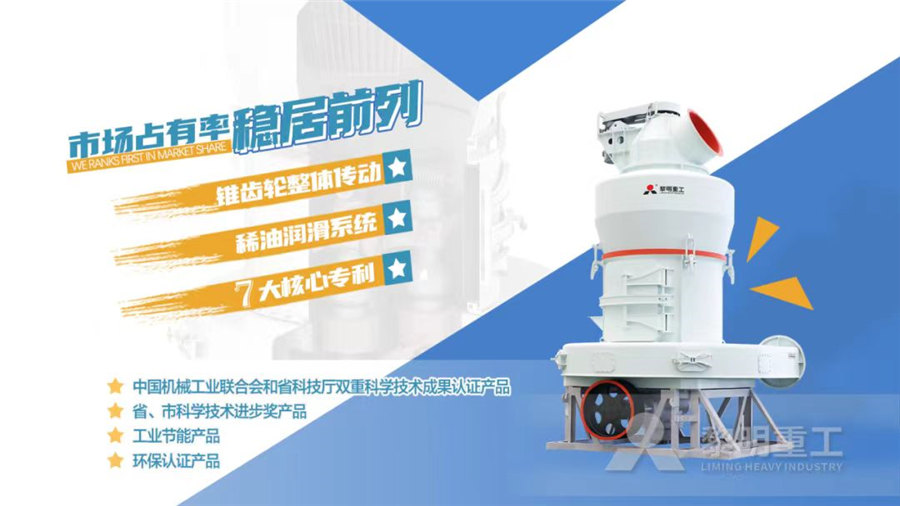

IOP Conference Series: Materials Science and Engineering PAPER OPEN ACCESS Optimization and transformation of 300MV units steel ball coal millThe small ball mill is small in size and light in weight, and is especially suitable for narrow sites or complex working environments The small ball mill adopts the optimal energysaving design, and the fuel saving rate is as high as 25% The lining plate and grinding steel ball of the mini ball mill machine are made of high chromium steelSmall Ball Mill Mini Ball Mill for Small Scale Mineral Grinding2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum GrindingThe ball mill is a device that grinds materials up to a consistent size, including pulverizing coal for combustion in power generation, cement production, and other industries The Ball Mill for Coal Pulverization The ball mill is a cylindrical drum that rotates around its axis, causing the steel balls to tumble and grind the coal into a fine How Is Coal Pulverized in a Ball Mill?

Mini Ball Mill – Mineral Grinding Small Ball Mill For Sale AGICO

Mini ball mill for sale! The mini ball mill is a type of smallscale ball mill, suitable for trial production and small batch production AGICO offers highefficiency mini ball mills at a competitive price If you are interested, please contact usGrinding media – Ball mill balls AGICO manufactures and supplies a variety of ball mill grinding media, including steel balls, short cylinders, and steel bars The ball mill mainly grinds materials by the grinding media in the grinding bin continuously impacting and extruding materials Therefore, the grinding media is one of the most easily worn accessories of the ball mill during Ball Mill Grinding Media Steel Balls for Ball Mills AGICO GroupFigure 1 Typical Arrangement of the Riley Ball Tube Mill System DESCRIPTION OF PULVERIZERS AND FUEL SYSTEMS Ball Tube Mill The Ball Tube Mill (BTM) is a cylindrical lowspeed grinding mill It consists of a steel barrel, lined with cast abrasionresistant liners and partially filled with hardened steel balls Coal and preheated primary airA Comparison of Three Types of Coal Pulverizers Babcock Power2012年11月17日 20 131Fineness Fineness is an indicator of the quality of the pulverizer action Specifically, fineness is a measurement of the percentage of a coal sample that passes through a set of test sieves usually designated at 50, 100, and 200 mesh A 70% coal sample passing through a 200 mesh screen indicates optimum mill performance The mill wear and Coal mill pulverizer in thermal power plants PPT SlideShare

An investigation of performance characteristics and

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose Introduction This article concerns itself with vertical grinding mills used for coal pulverization only (coal pulverizers), although vertical grinding mills can and are used for other purposes The 3D model in the saVRee database represents a Vertical Grinding Mill (Coal Pulverizer) ExplainedAir Swept Coal Mill ; Batch Ball Mill ; Cement Ball Mills ; Cement Raw Mill; Ceramic Ball Mill; Coal Ball Mill ; and the matching motor power is 45570KW, which can meet 14 16 t/h pulverized coal production Widely used in the preparation of coal powder in electric power, It is usually made of steel plate, Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill2024年8月5日 The "United States Steel Ball Coal Mill Market " is predicted to attain a valuation of USD xxx billion in 2023, showing a compound annual growth rate (CAGR) of xxUnited StatesSteel Ball Coal Mill Market By Application 20242031

.jpg)

Air Swept Coal Mill AGICO Ball Grinding Mill ball mill machines

The air swept ball mill is an ideal grinding machine that merges pulverizing and drying into a single It has the characteristics of high efficiency, energy saving, and environmental protection It is often used as the main equipment in the coal preparation system, which is capable to grind coal of various hardness (the fineness of pulverized coal can reach 85% and the moisture content 2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of Ball Mill Design/Power Calculation 911Metallurgist2019年10月1日 Comprehensive treatment,we should have a test on the 300 MV unit steel ball coal mill pulverizing systemAt the same time,analyze the main operating parameters before modificationTransform the pulverizing system and optimize the run mode of the pulverizing system by comprehensive treatmentSo we can control the pulverizing unit consumption under Optimization and transformation of 300MV units steel ball coal mill 2024年2月19日 The ratio of steel balls in the ball mill depends on the effective length of your mill, whether it has a roller press, the size of the feed particles, the lining and structure used, the expected sieve residue fineness and ratio, how many chromium balls to operate, and the rotation speed How much and other factors make a comprehensive judgmentBall Mill Steel Balls: Quality And Gradation JXSC Mineral

Coal Mill in Cement Plant Vertical Roller Mill AirSwept Ball Mill

The ball mill is a traditional coal pulverizer machine, which has been widely used since it was invented In the cement plant, the new dry process cement manufacturing requires the moisture content of coal powder to be 05% ~ 15%, while that of raw coal is 15% ~ 40%ZENT coal mill also called coal pulverzier or coal powder mill is a grinding mill that is used widely in coal mining industry, such as vertical coal mill, ball coal mill or coal ball mill, trapezium coal mill etc If you want to get more information about ZENT ball mill, then contact us according to : [ protected]Coal ball mill, ball mill for coal crushing processTrelleborg has been providing mill lining systems since 1920 The focus is on working with our customers to provide incremental improvement to enhance mill availability, increasing efficiency and reducing energy consumption Full lining Mill Lining Systems FluidHandling Trelleborg2019年8月14日 The Grinding Media Of Ball Mill – Steel Balls back to top The steel balls in ball mill are consumable, which need to be supplied from now and on 1 The filling rate of steel balls Steel balls undertake the main job in grinding, therefore, the number of steel balls in ball mill is highly relative with the grinding strengthThe Ultimate Guide to Ball Mills Miningpedia

Ball Mills 911Metallurgist

2017年2月13日 A ball mill efficiently operated performs a wide variety of services In small milling plants, where simplicity is most essential, it is not economical to use more than single stage crushing, because the SteelHead Ball or Rod Mill will take up to 2″ feed and grind it Confused about which type of ball mill to use for your application? Different types of ball mills available, Industrial ball mills are typically made of steel, and the lining material is selected based on the type of material being processed 20tph Coal Ball Mill For Clean Coal Powder Production Line In VietnamHow to Choose the Right Type of Ball Mill for Your ApplicationBall mill is the key equipment for grinding after the crushing process in the beneficiation plant, it is used to grind kinds of materials such as copper ore, gold ore, magnetite ore, quartz, lead zinc ore and other materials into fine powder 2075micrometerMining and Grinding Ball Mill for Gold/Copper/Ore/Cement/Gypsum/Coal This document discusses coal pulverization in power plants It covers various topics related to coal pulverizers including: Types of coal and reasons for pulverizing coal like improved efficiency and combustion control Two types of pulverizer firing systems direct and indirect Different types of pulverizers classified by speed tube mills, bowl mills, and impact mills Key Coal Mills in Thermal Power Plant PDF Mill (Grinding) Scribd

.jpg)

Modeling and control of ball mill system considering coal moisture

2016年8月1日 Fig 1 shows the structure of a duplex inlet and outlet ball mill The system is equivalent to two parallel cylinders joined together in one ball mill to achieve high milling efficiency Milling work is carried out by the collision, squeezing and grinding of the steel balls inside the mill The working principle described as follows [10]Coal is a vital source of energy in many industries worldwide From power generation to manufacturing, coal is used in various processes However, before it can be used, coal needs to be processed in a coal mill In this article, we will explore the basics of how a coal mill works Introduction Coal mills are []How does a Coal Mill Work? ball mills supplier2024年3月16日 A vertical coal mill is a type of industrial milling equipment used to crush and grind coal into powder for Particularly advantageous for medium and smallscale industries, the coal grinding mill offers distinct benefits such as requiring less initial investment and Prev Previous Application of Dry Ball Milling in Mineral How Does a Vertical Coal Mill WorkCoal water slurry ball mill (CWS ball mill) is the key equipment for coal water slurry fuel production, which is commonly used in coal water slurry power plant Coal water slurry ball mill is grinding equipment specially used for coal water Coal Water Slurry Ball Mill

.jpg)

Ball Mills Laboratory Grinding Mill Latest Price,

Usage/Application Laboratory Phase Single phase Weight (45 Kg) I Deal In New Only Motor Type Electric motor Mild Steel Ball Mill Machine, For Coal Industry ₹ 2,50,000/piece Mild steel 250 kg batch ball mill; Ball mill with The main Function of the Pulveriser in thermal power plant is to crush/grinding the raw coal coming from coal handling system through coal feeder into a predetermined size in order to increase the surface area of the coal If the coal is Pulveriser in Thermal Power Plant Bowl Mill Ball Advantages of Ball Mill Ball mill grinding machine offer several advantages, including: Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or continuous grinding, and fine or ultrafine grinding, making them Ball Mill Grinding Machines: Working Principle, Types, Parts 2023年4月23日 One of the most used tumbling mills is the ball mill This paper reviews different types of grinding media that have been developed and improved over the years and their properties(PDF) Grinding Media in Ball MillsA Review ResearchGate

.jpg)

Monitoring the fill level of a ball mill using vibration sensing and

2019年10月19日 Ball mills are extensively used in the size reduction process of different ores and minerals The fill level inside a ball mill is a crucial parameter which needs to be monitored regularly for optimal operation of the ball mill In this paper, a vibration monitoringbased method is proposed and tested for estimating the fill level inside a laboratoryscale ball mill A vibration IIForging Steel Ball 1, forged steel ball surface quality, good impact resistance, strong toughness, good wear resistance, not easily broken and out of roundIs the metal heating temperature of 7001300℃, the use of forging machinery to apply pressure to the metal billet, plastic deformation to obtain a certain mechanical properties, a certain shape and size forging Introduction and application of coal mill steel ballCoal Mill Ball Tube Detailed Info Free download as PDF File (pdf), Text File (txt) or read online for free The document provides details about the commissioning experience of ball tube mills supplied by BHEL for a 250 MW thermal power station in Dahanu, India It describes the construction and working of the mills, including components like the shell, trunions, screw Coal Mill Ball Tube Detailed Info PDF Valve Duct (Flow)Inside a ball mill, rotating cylindrical drums are filled with grinding media (usually steel or ceramic balls) As the drum rotates, the grinding media collide with the material being processed The impact, friction, and compression forces break down the material into finer particlesBall Mills – efficient grinding FLS

.jpg)

AirSwept Coal Mill of High Quality Fote Machinery

Lowspeed coal mill: Its rotating speed range is 15–25 r/min The lowspeed coal mills include cylindrical steel ball mill, steel ball mill with two symmetrical grinding circuits, etc Mediumspeed coal mill: Its rotating speed range is 50–300 r/min Flat plate mills, bowl mills, and MPS mills are common mediumspeed coal mills