Crushing roller mill

Roller Mills by SIEBTECHNIK TEMA Crushing milling

Our laboratory roller mills have an innovative app control, a continously adjustable roller gap, reversible overload protection, high fore transmission to the moving Our crushing roller mill is used to obtain a homogeneous and high quality feed structure Its rollers break the feed into small and uniform particles so that a coarse granulate is produced instead Crushing roller mill for the industry AMANDUS KAHLWilliams is an industryleading roll crusher manufacturer and designer We provide machines with high throughput capacity, minimal maintenance requirements, and low cost per ton operation Learn more about our heavy Roll Crushers Williams CrusherRoskamp delivers unparalleled expertise, superior quality and precise particle size control Roskamp roller mills and roll crushers deliver a consistent, uniform grind every time, positioning you to exceed your customers’ expectationsRoskamp CPM

Roller Mills Roll Crushers CPM

Roskamp roller mills and roll crushers deliver a consistent, uniform grind for every application imaginable Engineered to give you precise particle size control, Roskamp roller mills and crushers are built on a strong, solid foundation and Bauermeister’s Roller Mills/Roll Crushers are used for crushing a variety of soft to mediumhard products providing high throughput with narrow particle size distribution The creation of undesirable fine particles is reduced by subjecting Roller Mills Roll Crushers Flakers BauermeisterIKA introduces the world‘s first disposable grinding system for safe, instant and precise milling results Its unique and compact design makes the unit space saving and ultraportable The disposable grinding chamber eliminates the Mills Lab mills Grinding mill Crushing IKAAn early 20thcentury oilseed rollermill from the Olsztyn district, Poland A late 19th century double roller mill displayed at Cook's Mill in Greenville, West Virginia in 2022 Closeup of Barnard's Roller Mill, New Hope Mills Complex, New York Cutaway drawing of a centrifugal roller mill for mining applications, 1913 Roller mills are mills that use cylindrical rollers, either in opposing Roller mill Wikipedia

.jpg)

Roll crushers – ERC and double roll crusher – FLS

Optimise crushing efficiency – FLS Double Roll and ERC Crushers FLS double roll and ERC crushers offer efficient, reliable crushing with low maintenance and optimised wear life Choose double roll crushers for your soft to mediumhard materials, or ERC crushers for highthroughput, highefficiency crushing of hard and abrasive oresRoll crushers come in different configurations depending on the crushed material and the required output size Some standard roll crushers include singleroll, doubleroll, and tripleroll crushers They can also be designed with smooth or corrugated surfaces on the rollers to provide different levels of crushing action How Roll Crushers WorkRoll Crushers Williams CrusherThe KAHL crushing roller mill crushes feed mixtures, but also oilseeds and legumes Unlike in the hammer mill which crushes the grain by impact, specific crushing takes place in this machine The pan grinder mills work according to the pan grinder principle and are used in wood processingCrushing of individual components mixtures AMANDUS KAHLWilliams Patent Crusher understands that every crushing and grinding requirement is different We customize mill orders to ensure every machine we design and manufacture gets the job done right and meets all customer specifications From impactors and roll crushers to impact dryer mills and roller mills that grind, dry, Rock Crushers Pulverizers Williams Crusher

.jpg)

Roll Crusher HRC HAZEMAG

Further features of the HAZEMAG Roll Crusher include: Rotation and slip monitoring of the crushing rolls; Temperature monitoring of bearings, gearbox and hydraulic unit; Roller carriage for moving the roller crusher to the maintenance position; Quick exchange of crushing segments even in operating position; Adjustable scrapersDuring operation, the rotational energy of the crushing rolls and the drive components reduce the peak loads ideally and uniform power consumption is achieved A system that easily permits and transports the roll mill out from under the feed hopper; thus, permitting full access to the roll mill and its internal parts FORMER PRODUCT LINE WM;Roll Mill HRM HAZEMAGR Roller Mill Xiao Xiao1, Huang Lilong2 and Xu Kuangdi3 1Changsha Research Institute of Mining and Metallurgy, Changsha, China 2Changsha Research Institute of Mining and Metallurgy, Changsha, China 3Chinese Academy of Engineering, Beijing, China Roller mill is a type of grinding equipment for crushing materials by pressure between two orRoller Mill SpringerCrushing > Crushers > Roller crushers; Optimal primary size reduction of soft and hard, moist and dry clods of clay with or without rocks exhibiting Mohs’ hardness levels up to 6 The size of the crusher depends on the throughput and on the nature of the mill feedRoller crushers Händle

Grain Roller Mills Automatic Equipment

Our increased roll configurations in lowprofile electric roller mills allow for additional adjustment with the use of a single lever Automatic’s lowprofile electric rollers are available in 4, 65, 8, and 10 roll configurations with our Leaders in the crushing pulverizing industry since 1871 Over 500 patents and trademarks The Roller Mill will grind 2” x 0 barite, up to 4% to 5% moisture, to 97% minus 200 mesh product, dried to 02% or less surface moisture, at a product rate of 18 STPH CLIENTSWilliams Patent Crusher Pulverizer Company Since 年5月31日 The vertical roller mill (VRM), including powder separation and crushing subsystems, is used extensively for intermediate crushing of minerals in several industries such as cement, electric power, and chemical Compression crushing is also the main crushing mechanism in the VRM, but there is also shear force between grinding roller and particlesAnalysis of vertical roller mill performance with changes in During operation, the rotational energy of the crushing rolls and the drive components reduce the peak loads ideally and uniform power consumption is achieved A system that easily permits and transports the roll mill out from under the feed hopper; thus, permitting full access to the roll mill and its internal parts FORMER PRODUCT LINE WM;Roll Mill HRM HAZEMAG

.jpg)

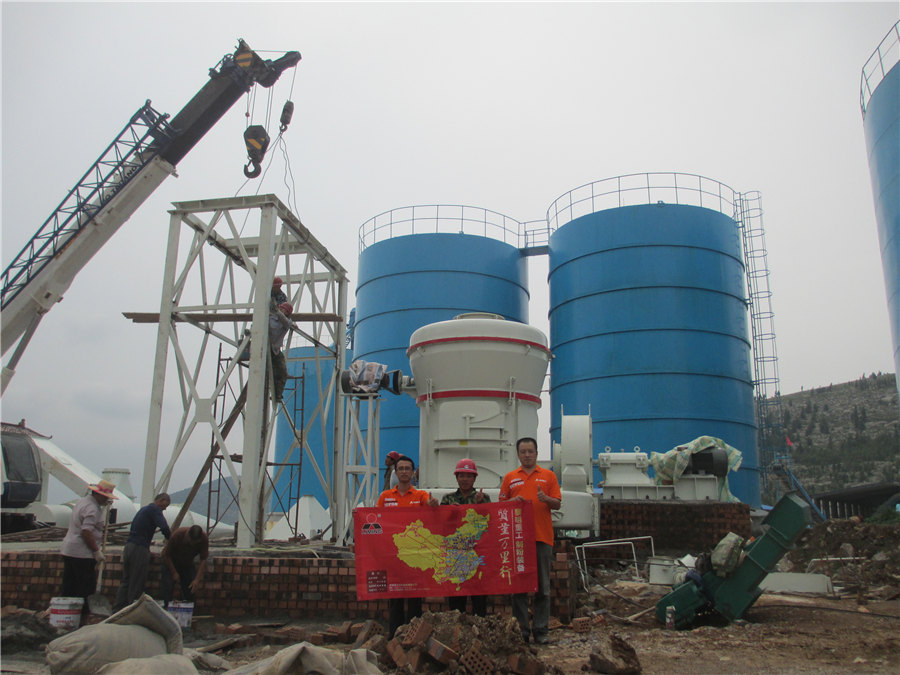

Stone Crushers, Mill and Grinding

LM Vertical Mill LM Vertical Mill integrates crushing, drying, grinding, classifying and conveying together, and it is specialized in processing nonmetallic minerals, pulverized coal and slag READ MORE 5X Pendulum Roller Grinding Mill 5X Series Pendulum Roller Grinding Mill is new mature and advanced equipment READ MOREThe material to be processed is fed into the roller mill, and as the rollers rotate, they crush or grind the material into smaller particles Standard roll crushers have a simple design and are commonly used for primary crushing applications Smooth roll crushers are usually more complex and are used for finer applicationsRoller Mills Sales, Install, 24/7 Service ABM EquipmentDefinitions This invention relates to an improved two roll sugarcanecrushing mill More particularly this invention relates to a two roll sugarcane crushing mill in which multiple feeder rollers are used, without needing a closed stationary pressure chute for compressed/compact feeding of prepared cane/bagasse mat and in which pivoted hydraulic system attached to a USB2 Two roll sugarcane crushing mill Google PatentsRoller mills perform a variety of feed mill tasks, including crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds Choose the roller mill that best fits your location's needs and gather more information by contacting companies through the form available belowRoller Mills Grain and Feed Equipment

Roller / Crusher / Bruiser Mills Danagri3S

4030 / 7530 3 Roller Mill Show Full Screen; For the crushing of dry grains, peas beans; Both Twin Roller Triple Roller models available ; Triple rollers used for pre crushing of peas beans; 3Phase 4Kw or 75Kw motor options and SinglePhase 37Kw motor ; 2022年10月15日 Roller Mill A roller mill is an awesome tool to achieve the perfect balance when crushing both the grist and husk As you’ll recall, the husk should remain intact with the kernel, however, the kernel should be thoroughly crushed for enzymatic action to take place With mill rollers, you can achieve this balance with minimal effortHow to Crush Your Own Malts: Milling Grain For Beer Sound 2019年1月15日 Crushing Malts with a Powered Roller Mill Many mills, especially the most affordable ones, rely on people power via hand cranks Unless you’re still driving a Model T and have lots of crank practice, crushing How to Crush Your Own Malts Brew CabinA crushing rate in kg/hr f fibre per unit cane Thrust area REABSORPTION 12 roller mill 33 42 47 52 15 roller mill 32 41 47 52 55 18 roller mill 32 40 47 53 50 60 • Wt of bagasse after each mill w = TCHxfbx1000 kg q • Assume bagasse density(d) after MILL DESIGN MILL OPERATION

Energysaving and Efficient Vertical Roller Mill Fote

A vertical roller mill, also known as a vertical grinding mill or vertical mill, is a comprehensive grinding equipment integrating crushing, drying, grinding, grading, and conveying Vertical grinding mills can be widely used in electric power, As the manufacturer holding the very first hammer mill patent to utilize midair impact crushing, Williams takes great pride in providing quality, rugged machines for many applications Williams Hammer Mills can reduce limestone without unwanted fines and can create cubical shaped stone with few “flats” or “slivers,” making it an ideal choiceLimestone Mills Limestone Crushers Pulverizers Williams SMOOTH ROLL CRUSHER SR11 Features Fast rotating rollers independently driven Crushing under pressure with identical roll’s speed Roller surface smoothed, grooved or welded Unique feature of roller gap adjustment by 0,1 mm Material evenly distributed along crushing gap 1 fix and 1 movable rollers, heavy hydraulic pistons Hydraulic loosen rolls in case of foreign bodies Smooth Roll Crusher CPC GmbH Crushing ProcessingTo meet customers‘ specific product requirements, there is a wide range of crushing segments available, which are quick and easy to exchange The fixed roll is mounted in selfaligning roller bearings and is secured in the housing lower section The floating roll is mounted in rocker arms, hydraulically supported against the housing lower Roll Crushers HAZEMAG

Crushing Roller Mill by KAHL

2020年6月22日 In order to meet individual requirements, the crushing roller mill is available in a singlestage, twostage or threestage design The capacity ranges from 10 to 60 t/h with a drive power of 22 to 55 kW (motor with Vbelt drive and gear)Looking for Manufacturer of Roller Grinding Mill Plant? The Malwiya Engineering Works is best Ball Mill Manufacturers in India, best Roller Crusher Manufacturers in India and Best Roller Crusher Supplier in India They provides all types of equipment like grinding equipment, crushing equipment, conveying equipment and so onManufacturer of Roller Grinding Mill Plant Ball Mill 2024年1月1日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table)Roller Mill SpringerLinkRoll crusher or roller crusher is used in secondary or fine crushing process of ores and rocks in mining, ore beneficiation, chemical industry, cement, building materials and other industrial departments Roller crusher has simple structure and few over crushing phenomenon; its tooth shape and size on the surface of roller can be changed along with the nature of materialsRoll Crusher Hongxing Machinery

.jpg)

Vertical roller mills FLSmidth Cement

For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product quality Further, our 2020年5月7日 Crushing roller mill rolls should be up to approximately 40 percent of the total roller mill length, Reduction (liso) roller mill rolls are up to 60 percent of the total roller mill lenght The average lenght of the roller mill is based on the Crushing, Grinding and Reduction in Flour MillingThe thyssenkrupp Impact Crusher produces a single stage perfect feed material for a vertical roller mill They crush mediumhard to hard material Find out more DoubleRoll Due to the arrangement of the crushing tools the fines in the Crushing Technologies thyssenkrupp PolysiusShrink fitted roll journals or throughshaft Smooth or corrugated rolls Various types of roller gap adjustment High efficiency motors Atex provisions Easy access front and back panels Easy access swing doors Various types of roll scrapers Two models of feeders with various options like magnet case Various types of distribution bining heritage, expertise and innovation Flaking mill

.jpg)

Roll Crushers 911Metallurgist

Laboratory Roll Crusher Laboratory Roll Crushers usually follow a primary crusher in the crushing section of an ore concentrating mill, Roll Crushing Action and Working Principle The tipvelocity of the slugger teeth in the Fairmountstyle crusher is from 400 to 450 ft/minute, Single Roll Crushers Single Roll Crushers are typically used as primary crushers that provide a crushing ratio of up to 6:1 They crush materials such as ROM coal, mine refuse, shale, slate, gypsum, bauxite, salt, soft shale, etc, while producing minimal finesDesigned with intermeshing roll teeth and a curved crushing plate, they are extremely effective in reducing slabby feedsRoll Crushers McLanahan2024年9月9日 Abstract: The causes of tungsten carbide roll ring breakage in the highspeed wire rod finishing mill in our factory are analyzed, and improvement measures are proposed in combination with specific actual conditions Introduction A steel rolling mill adopts a fully automatic continuous torsionfree highspeed rolling process with a design scale of 450,000 Tungsten carbide roll ring crushing roller of finishing millFIG 3A Two Roller Mill Module 2 Bottom Roll 3 Top Roll 4 Head Stocks paid (LH RH) 5 Central Axis of Top And Bottom Roll 6 Vertical Axis 7 Feed of Prepared Bagasse 8 Donnelly Chute 9 Scrapers 10 Scraper Cum Knife 11 Grooved Under Feed Roller 12 Hydraulic Loading Means FIGS 1, 2, 3B and 3C 13 Two Roller Mill Module 14 Bottom roll 15 Top roll 16 Central USB2 Two roller sugarcane crushing mill Google

Static Structural Analysis of Crushing Rollers of Three Roller Sugar Mill

opposite The DC power is given to the top roller for crushing Top roller is critical component amongst all As the drive torque, hydraulic load, crushing load is coming on the top roller The forces acting on the mill rolls give rise to shearing, bending, torsion and compressive stresses The top roller is most highly stressed, since it 2019年4月12日 Based on the current research results and industrial data, this paper compares the process flow of highpressure roller mill in metal mine and pellet pretreatment industry, Morrell S Predicting the overall specific energy requirement of crushing, high pressure grinding roll and tumbling mill circuits[J]高压辊磨机在金属矿选矿与球团预处理领域的工艺和