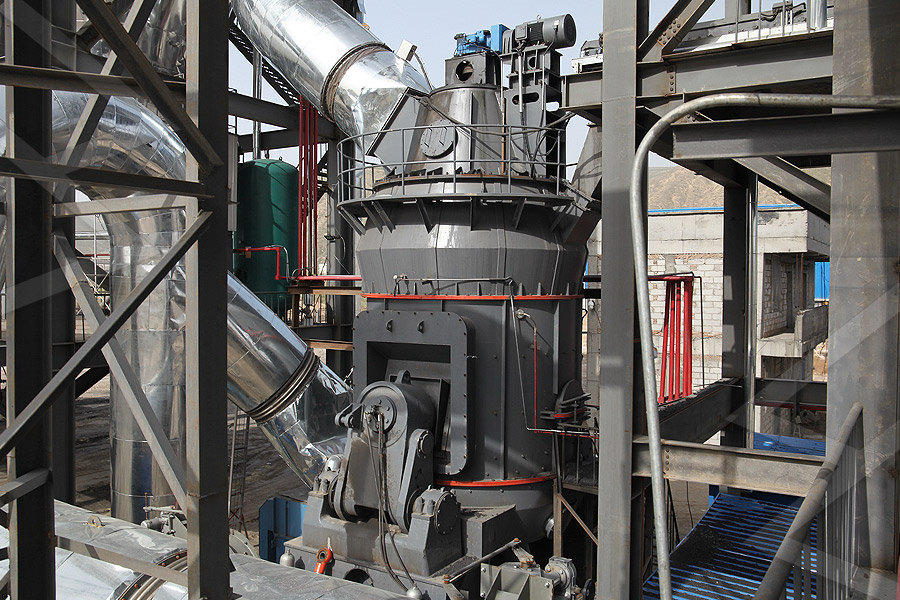

Manganese ore grinding system equipment

Optimizing Manganese Ore Process Flow and Equipment

5 天之前 Before manganese beneficiation, it is necessary to first understand the properties and composition characteristics of the ore, and JXSC support customize the best manganese ore equipment for you to maximize the beneficiation indicatorsThe key to efficient manganese ore processing is effective separation and Equipment Required To Buil2019年8月23日 The magnetic separators are easy to control, suitable for various manganese ore process The most commonly used machine is the mediumgrain strong magnetic separator, followed by the coarsegrained and Manganese Processing Equipment, Process Flow, 2024年11月21日 The key to efficient manganese ore processing is effective separation and classification equipment Manganese ore can be effectively separated and classified from impurities using advanced technologies such as Equipment Required To Build A Manganese Ore

.jpg)

Manganese ore crushing equipment processing technology

The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiationDuring the crushing process, the threestage closedcircuit crushing is the Here is an overview of the general processes involved in manganese ore mining: Manganese Ore Processing Equipment Crushers: For breaking down large pieces of ore into smaller, manageable sizes Screens: For sorting crushed Manganese Ore Processing Equipment2024年3月27日 The most common types of manganese processing equipment include crushers, screens, conveyors, and magnetic separators Crushers are used to break down large chunks A Comprehensive Guide to Manganese Processing EquipmentSBM offers processing equipment that has been time tested and proven and the solutions your application requires in the manganese ore industry SBM supplies crusher machine and SBM Manganese ore processing plant for pure mineral ores

Manganese Ore Process Plant JXSC Mineral

We provide ore process design, mining equipment production, and solutions There are many methods to process manganese, the magnetic concentration is the most widely used in manganese ore processing plantsMost manganese ore is fine grain and contains phosphorus ore, iron ore, and associated minerals According to its different principles, there are many methods to process manganese And the magnetic concentration is the most widely Manganese Ore Processing Process Hongji Mine HCM's HC1700 vertical pendulum Raymond mill, HLM series manganese carbonate vertical mill and other equipment have a high reputation in manganese ore enterprises all over the world market share, the following two types of electrolytic manganese powder grinding mill equipment will be introduced to youHow to choose the electrolytic manganese powder grinding mill equipment 2024年11月21日 Ore washing, gravity separation, magnetic separation, and flotation are all common beneficiation processes for manganese carbonate ore Skip to content JXSC Machinery Us +86 General ore washing equipment includes vibrating Through processes such as washing, crushing, grinding, gravity and What Processes For Beneficiation Of Manganese Carbonate Ore

.jpg)

Chemical composition of manganese ore fines and

Download Table Chemical composition of manganese ore fines and bentonite (mass fraction, %) from publication: Strengthening pelletization of manganese ore fines containing high combined water by 3 1 Manganese ores used in pilot sintering There are different types of manganese ore, for example hydroxide types and carbonate types In \ this research two typical types of manganese ore have been used Type 1 is a carbonate ore , of which the Sintered Manganese Ore and Its Use in Ferromanganese Production2024年3月27日 Manganese processing equipment plays a crucial role in extracting, refining, and processing manganese ore into usable products By understanding the different types of equipment available, their functions, and key considerations when choosing equipment, you can ensure optimal performance and efficiency in your manganese processing operationsA Comprehensive Guide to Manganese Processing EquipmentPrevious research has mainly concentrated on the characterization, as well as pelletizing and sintering behaviors, of pure iron ores and manganese ores with very high Mn/Fe mass ratios [15][16][17 Compositions of main minerals of manganese ore fines (mass

.jpg)

Strengthening pelletization of manganese ore fines containing

J Cent South Univ (2014) 21: 3485−3491 DOI: 101007/s1177101423264 Strengthening pelletization of manganese ore fines containing high combined water by high pressure roll grinding and2016年4月27日 The problem involved in Manganese Ore Processing deals with the production of acceptable specification grades of manganese concentrates at a maximum recovery of the total manganese from ores having variable characteristics The flowsheet provides for both gravity and flotation with a maximum recovery of the manganese values in a coarse size in the most Manganese Ore Processing 911Metallurgistused in welding, grinding and many other applications Get the equipment that you need In addition to implementing other control measures, Personal Protective Equipment (PPE) such as Respiratory Protective Equipment (RPE) is commonly required to reduce exposures and risks to workers Respiratory Protective Equipment (RPE) – filtering respiratorsHazard awareness bulletin ManganeseMain ore washing equipment includes ore This setup is for the manganese ore process: The ball mill is for grinding the 020mm materials to 01mm, then using the slurry pump to transport the 01mm materials to the spiral chute to separate the heavy mineralsManganese Ore Process Plant JXSC Mineral

.jpg)

5 Easy but Efficient Steps to Realize Manganese Ore

2023年4月10日 4 Manganese ore dressing process and equipment According to the manganese ore plant, different types of manganese ore have the different process flows To choose different beneficiation equipment: Manganese oxide 2024年4月9日 These compounds form the basis of the insoluble residue during acid leaching at the limit of wet ore grinding When wet ore grinding is combined with acid, the leaching transition of manganese into the solution during this How is Manganese Processed: An InDepth Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentoniterich ore with montmorillonite content of more than 80%This method is to dry the raw ore in the sun, air dry it naturally or dry it in the oven Bentonite Processing Methods And Required Equipment5 天之前 A single sulfide ore is usually treated by flotation process, using crushinggrindingclassificationflotationconcentration process to select a single copper sulfide ore as copper concentrate Copper ore beneficiation process The principle of priority flotation process is: crushing and screening→grinding and classification→priority flotation of copper Copper Ore Processing Plants, Flow And Equipment

.jpg)

Manganese Ore Beneficiation PlantKefid Machinery

Manganese ore beneficiation process has many large and small equipment: vibrating feeder, PE jaw crusher, JC jaw crusher, HJ jaw crusher, vibrating screen, electromagnetic vibrating feeder, ball mill, spiral classifier, hydrocyclone, high frequency screen, magnetic separator, jigger, mixing barrels, flotation machine, concentrator, filter, drying machinesCrushing Grinding Equipment; Cyanidation Equipment Chemicals; and electrolyzed into gold mud and lean carbon under the conditions of high temperature and high pressure in a closed system All 5 / Chrome Ore 0 / Copper Ore Plant Case 0 / Gold Ore Plant Case 2 / Leadzinc Ore Flotation Plant Cases 2 / Manganese Ore Case 1 / Tungsten/Tin Gold Ore CIP CIL Processing Plant Equipment Solution Dasen 2014年5月7日 Chemical studies of manganese during the 16th through 19th centuries led to the realization that the addition of manganese to iron orebased steel made it even harder In today’s world, manganese is often used for cathodic shielding in the battery industry The Basics of Manganese Mining and ProcessingManganese Mining and Processing: Everything you Need to Know2014年9月6日 Pelletization is one of useful processes for the agglomeration of iron ore or concentrates However, manganese ore fines are mainly agglomerated by sintering due to its high combined water which adversely affects the roasting performance of pellets In this work, high pressure roll grinding (HPRG) process and optimization of temperature elevation system were Strengthening pelletization of manganese ore fines containing

Grinding Classification Equipment JXSC Machinery

JXSC grinding classification equipment is the key equipment for crushing materials after they are crushed The ball mill can process various grinding minerals, nonferrous metal beneficiation, and new building materials It is often combined with a spiral classifier to form a closedcircuit ring mill, which has higher fine powder and grinding power2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process How to choose a suitable ore powder grinding mill?2020年8月21日 Manganese is considered a relatively rare metal as concentrations of it in ore of commercial importance are geographically limited In nature, manganese is found in the form of oxides, carbonates, and silicates Manganese ores are complex in the sense that they not only consist of a complex oxide mineral assemblage but these minerals are also very finely inter From Ore Body to High Temperature Processing of Complex Ores: Manganese 2024年11月21日 Among them, the ferrosilicon ore beneficiation process involves purifying and increasing the silicon content in the iron ore, ultimately improving the quality and performance of the steel Generally speaking, Siliconiron Ore Beneficiation Process Equipment

(PDF) Grinding Media in Ball MillsA Review

2023年4月23日 During the intera ction of ore and grinding media, a complex physical and chemical system is formed, causing changes in particle size, pulp chemistry, surface chemistry, and crystal structure of 2023年10月11日 Different types of grinding equipment are suited to capable of forming an independent production system for both coarse earth, illite, mica, glass, manganese ore, titanium ore Choice of Processing Equipment for Nonmetallic Mineral Grinding2011年1月1日 Reductive acid leaching of manganese ores is not selective, some amount of iron also dissolves into the solution along with Mn; hence, this process is limited to the beneficiation of high grade Hydrometallurgical Processing of Manganese Ores: A Review2023年4月23日 Manganese is a chemical element with the symbol Mn and atomic number 25 It is a hard, brittle, silverygray metal that is commonly found in the Earth's crust Manganese is an essential trace element that plays a crucial role in many biological processes, including metabolism, bone formation, and antioxidant function It is also used in various industrial Manganese (Mn) Ore Minerals, Occurrence, Deposits Geology

.jpg)

Manganese Processing Equipment, Process Flow, Cases JXSC

2019年8月23日 (4) Progress in the comprehensive recovery of polymetallic manganese ore Washing and sieving Washing is the separation of ore and mud under hydraulic, mechanical and selffriction action, which improves the ore grade Main ore washing equipment includes ore trommel screen, cylinder trommel scrubber and tank washing machines2019年8月1日 Abstract In this study, the use of XRF, XRD and other instruments found that the manganese content in the ore was 1453%, and the main forms were carbonate, iron manganese oxide and manganese oxide Because of the special magnetic susceptibility of these minerals, the magnetic separation method was chosen to improve the grade of manganese ore, and the Insight into Mineralogy of a LowGrade Manganese Ore forThe manganese ore beneficiation process involves two key stages: Feed Preparation The initial phase incorporates the utilization of diverse physical separation equipment, such as crushers, screens, and grinding mills This stage primarily focuses on size reduction to prepare the ore for concentration ConcentrationManganese Ore Beneficiation CFlo2024年10月25日 Dasen Mining is a professional ore mining machinery, equipment manufacturer, supplier and mining solution provider for gold ore, copper ore, tungsten ore, tin ore, tantalum ore, chrome ore, manganese ore, iron ore, zircon ore, leadzinc ore etcDasen: all in one ore mining machinery, equipment, solution

.jpg)

Grinding and grading equipment in beneficiation

2021年8月13日 Selfgrinding often works in conjunction with grinding equipment such as fine crushing, ball milling, gravel milling, and so on According to its connection mode, it can form a variety of technological processes Grinding Description Processes Description 1 Rough separate the highintensity magnetic ore TAYMA adopts special highintensity; Magnetic separator of manganese ore to remove impurities preliminary, then uses spiral classifier to classify rougher concentrate and rougher tailings directly discharge; At last, rougher tailings directly discharge into the tailings thickenerManganese Ore Production Line TAYMACHINERYTuXingSun Mining provides stateoftheart mining and mineral processing equipment for metallic and nonmetallic minerals We offer comprehensive services including ore testing laboratories, global ore trade, and turnkey mining technology solutions Our global expertise ensures efficient and sustainable mining operations for gold, copper, rare earths, and other mineralsTuXingSun Mining Advanced Mining and Mineral Processing Equipment 2021年10月13日 The Bond standard grindability test provides a Work Index that is widely used to estimate the energy required for ore grinding The research investigates the work index of Anka Manganese ore at (PDF) Assessing the Grindability Behaviour of Anka (Zamfara State

Various Types Of Iron Ore Beneficiation Processes

2024年11月21日 In the past, a lot of experimental research work on this type of iron ore beneficiation, including reduction roasting – weak magnetic separation process of the selection index is relatively good, but because of its technical difficulties is the need for ultrafine grinding, and the current conventional beneficiation equipment and chemicals 2024年6月17日 Shuxrat Chorshanbiev, Nuriddin Tadjiev, Abdulxamid Erkinjonov; Development of wearresistant parts from highmanganese modified steel 110G13L for oregrinding equipment AIP Conf Proc 17 June 2024; 3152 (1): Development of wearresistant parts from highmanganese 2024年2月26日 Chongqing Chengkou manganese deposit is a large carbonatetype manganese deposit in the upper reaches of the Yangtze River, located in Gaoyan Town, Chengkou County, Chongqing In order to improve the recovery rate of lowgrade manganese ore and concentrate grade index, achieve efficient utilization of mineral resources, and sustainable development of Comprehensive Study on Mineral Processing Methods and 2019年7月15日 Gravity Separation Process back to top Gravity separation process is a beneficiation method according to the difference in density of minerals, whose process can be carried out in a medium such as water or air The density of common manganese oxide minerals ranges from 3,700 to 5,000 kg/m3, the density of manganese carbonate minerals ranges from How to Extract the Manganese Ore? Miningpedia

.jpg)

10TPH Manganese Ore Processing Plant In South Africa

This set of manganese processing equipment has obvious recovery efficiency We will formulate manganese ore processing plant solutions and specific equipment models based on your ore information Contact us for more details!Manganese Ore Processing EquipmentMining manganese ore involves several steps and methods depending on the nature of the deposit Here is an overview of the general processes involved in manganese ore mining: Manganese Ore Processing EquipmentCrushers: For breaking down large pieces of ore into smaller, manageable sizesManganese Ore Processing Equipment