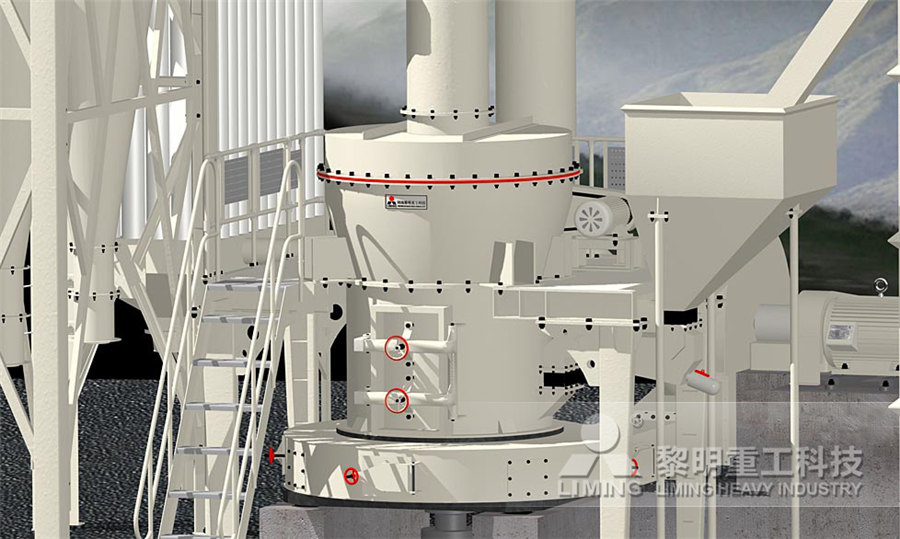

Calcite ore large crushing line

Calcite Ore Crushing Solutions DSMAC

We develop calcite crusher in stationary, portable, mobile series to meet the different calcite crushing demands As calcite (calcspar) occurs in a number of massive forms such as aragonite, marble, limestone, chalk, fibrous etcBig calcite materials are fed to the jaw crusher evenly and gradually by vibrating feeder through a hopper for primary crushing After first crush, the material will transferred to impact crusher by JoyalCalcite Processing Plant, Calcite Material Production Line, Besides the stone crushing and mineral grinding, ZENITH offers solution of metal ore processing Till now, we have built iron ore dressing, copper ore dressing and gold ore dressing and some Customer CasesCalcite crusher, as an essential machine for crushing calcite ore, has become increasingly important in the mining industry This paper introduces the working principle, structure, and Calcite Crusher

[GYQ0R)ZQ]ESS4NJ.jpg)

How calcite is mined and processed

Calcite mining and processing involve several steps to transform raw calcite into usable materials Here’s an overview of the typical process: Geologists conduct surveys to locate calcite Zhengzhou Desen Environmental Technology Co,Ltd, it is one of the hightech group company with the technology research of environmental engineering application , processing and manufacturing equipment Our traditional Jaw crusher Ball mill Rotary kiln Raymond mill – 2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers are widely used in ore crushing, aggregate Types of Crushers: Choosing the Right One for Each The processing flow for products below 400 mesh is like: raw orecrushinggrindingclassifying The purpose of crushing and grading is to produce a product that meets the fineness requirements of the application field There are two calcite grinding machine, calcite grinding mill, calcite

.jpg)

Dolomite Ore Crushing Solutions DSMAC

Dolomite crushing is in the beginning part of the whole mining process, so dolomite crushing process is quite important Like other minerals crushing process, we pull the raw dolomite explored from the mine into vibrating feeder, which feeding them continuously and evenly into dolomite crushing plant and in which dolomite raw materials get processed into the right Introduction of Stone Crushing Production Line/Stone Crusher Plant 1Stone crushing production line (stationary stone crusher plant), also known as stone crushing screening plant mainly consists of vibrating feeder, jaw crusher, cone crusher/impact crusher, vibrating screen, belt conveyor, electric control panel,dust removal equipment,etcStone Production Line HXJQJaw crusher is used to crush gypsum ore into small size less than 8 mm in the primary crushing process The vibrating screen screens out the suitable particles into the next step, while the unsuitable go back for the coarse crushingGypsum Ore Crushing Solutions DSMAC2022年8月17日 Iron ore crusher is a kind of mechanical equipment that crushes iron ore raw ore step by step, from large pieces of raw iron ore (about 500mm) to millimeterlevel fine materials +17 [ protected] The iron ore crushing production line has the characteristics of high degree of automation, high crushing rate, Iron ore crushing equipment and process flow

Crushing in Mineral Processing 911Metallurgist

2015年12月26日 In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surfaceIndonesia 200TPH 280320TPH Andesite Crushing Plant This client is from Indonesia He is a new player of quarryconstruction contractor of andesite aggregates for construction project He has contracted large numbers of road construction projects around Kalimantan ProvinceAggregate Crushing Shanghai Zenith CompanyQuartz sand is the mainly production of quartz application It is crushed by crushing plant from quartz, tridymite, cristobalite The complete quartz crushing and screening plant ensure high process efficiency, combining fieldwork with our engineering expertise results in a specific system that delivers the desired end products in a profitable wayQuartz Ore Ore Crushing Solutions DSMAC2022年4月20日 For limestone used in metallurgy and roads, the ore can be crushed and screened Coarse crushing: The jaw crusher is generally used in the coarse crushing process The jaw crusher has a large crushing force and a large feeding range It can crush large pieces of limestone into small pieces It is used for coarse crushing of many materialsLimestone crushing and grinding production line SBM Ultrafine

.jpg)

Ore Processing Concepts GT New Horizons

2024年11月24日 This shows the simplest version of a "central line" ore processing system It has one route (priority 2) and is currently useless for anything practical Gold chest = input and copper chest = output This shows the second most basic EIO ore processing setup a central line with an attached macerator round robin module2015年8月31日 3 CONE CRUSHER • Designated in size either by the gape and mantle diameter • Primary or secondary crushing • The vertical spindle is free to rotate around its own axis HXJQ • Processing capacity: 12 1000t/h • Applied material: barite, marble, talcum, calcite, dolomite, fluorite, kaoline, coal, gypsum • PRICE:$88000Aggregate Crushing Equipment PPT Free Download SlideShare2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Types of Crushers: Choosing the Right One for Each 200t/h Pebble Crushing Mobile Production Line; 150t/h Granite slag, pebble, manganese ore, limestone, iron ore, gypsum, coke, granite, coal mine, coal gangue, calcite Cone crusher was created in 1927 and officially used in Crushing Equipment Supplies Jaw Crusher, Impact

.jpg)

Limestone Aggregate Crushing JXSC Machine

1 Firststage Crushing The Limestone raw material is transported to the jaw crusher by the vibrating feeder for coarse crushing 2 Secondstage Crushing Screening After coarse crushing, the Limestone enters the impact crusher for 2023年8月25日 Calcite forms through a variety of processes in different geological environments It is a key mineral in sedimentary rocks like limestone and marble, and its formation is influenced by factors such as temperature, pressure, and the composition of fluids involved Let’s explore these aspects in more detail:Calcite : Properties, Formation, Occurrence and Uses Areas2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine crushing processing until it reaches the feed fineness of the grinding machine (1540mm) before discharge Step 2: Grind small stones into Dolomite Sand Making Plant And Grinding MachineMajor components Quartz, Calcite mohs hardness 1530 Available crusher Impact Crusher, Cone Crusher Applications Construction, CeramicShale Ore Crushing Solutions DSMAC

How to Make Fine Calcite Powder? Fote Machinery (FTM)

2019年8月29日 Fine Calcite Powder Production Line Solution Although there are differences between the two commonly used grinders, the processing process of calcite is the same, which can be divided into three stages: crushing, grinding and separating >>Crushing: the large calcite material extracted2021年10月14日 It is typically found that increasing power reduces the mechanical properties of ore, increasing energy utilization, and crushing degree, more than extending timeStudy on Magnetite Ore Crushing Assisted by Microwave IrradiationCalcite is a carbonate mineral, currently used as a decorative block Calcite drops as an item if mined by any pickaxe If mined without a pickaxe, it drops nothing Calcite generates naturally as part of the structure of amethyst geodes, between the smooth basalt and block of amethyst layers It also generates in the stony peaks in strips Calcite is currently used only for decoration Java Calcite Minecraft WikiMining machinery is mainly used for crushing and gridning various materials, such as river pebbles, granite, basalt, limestone, quartzite, calcite, dolomite, silica ore, basalt, etc Common mining machinery includes jaw crusher, cone crusher, impact crusher, ball mill plant, Raymond roller mill, etc LEARN MOREGMG Group® Official Website Mining Crushing and Screening

Crushing Machine – LEEMAY MACHINERY CO, LTD

2024年10月16日 Sand Making Production Line; Briquette Pellet Production Project; Products Crushing Machine; quartz, river pebbles, calcite, dolomite, iron ore, silica ore, basalt, etcRock: Kinds of hard stones Because of its large crushing ratio and uniform crushed size, it is particularly suitable for Impact Crusher Oct 11, 2024 SBM can offer you the whole portable gold ore crushing plant which is designed based on the conception of fully adapting various crushing condition, eliminating obstacles caused by location, environment, foundation configuration, consequently providing simple, efficient, low Mobile Gold Ore Crushing Plant, Large Scale Portable Gold Crusher Line2021年9月10日 High energy consumption in ore crushing brings great challenges to the mining industry Microwave irradiation provides a promising solution for rock breaking However, there is currently a lack of detailed Study on Magnetite Ore Crushing Assisted by The general processing technology process is as follows: mining and selection of calcite ore → crushing of calcite ore: generally using a jaw crusher to crush it to a feed fineness that can enter the grinding machine (15mm50mm) → calcite powder production: fine powder processing is generally carried out using R series grinding machines, HC longitudinal pendulum series News Calcite milling machine

.jpg)

Limestone crushing technology and equipment SBM Ultrafine

2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and 2021年8月5日 Calcite powder of different fineness is widely used in many fields such as papermaking, medicine, chemical industry, and agriculture 1 Crushing stage: Large pieces of calcite are evenly fed into the crusher by the vibrating feeder for crushing, and the crusher is equipped with a processing dust removal machineCalcite Industrial Ultrafine Powder Grinder2012年1月1日 Calcite is generally found as barren calcite veins in oremineralization areas, so that very few researchers are interested in the calcite occurrence for exploration of mineral resourcesCalcite as a tracer of oreforming hydrothermal fluids: Carbon and Calcite is a calcium carbonate mineral, widely distributed, usually white or colorless Common shapes are granular, massive, fibrous, earthy, and so on The calcite mill can grind calcite into a fine powder of 1503000 mesh, which is widely used Generally, calcite is used as industrial raw material such as chemical industry and cementCalcite Ultrafine Grinding Mill

200250tph Complete Mining Stone Crusher Plant TAYMACHINERY

Introducing the TAYMA 200250tph Complete Mining Stone Crusher Plant: Engineered for superior stone crushing efficiency This integrated system is designed to crush large stones into highquality aggregates or sand, essential for mining, quarrying, and construction applications Featuring robust jaw crushers, efficient cone crushers, advanced sand making machines, 2024年1月2日 1 Washing + Crushing: Ore is mined from the mountains, and the outer layer will contain soil and impurities, and the volume will be very large Therefore, the first step is generally to wash and crush the raw ore into smaller particles for easy entry Grinding, usually within 3 cm The equipment used is a crusher 2What is the process flow of rock grinding production line?2023年3月15日 ① HGM ultrafine grinding mill: 745 micron (2002500 mesh); D97=5 micron HGM series ultrafine mill has superior performance, stable quality, simple operation and convenient maintenance It can be adjusted arbitrarily to Serpentine crushing and grinding processing Simple structure, large feed size, and output, ideal for largescale crushing plants Large crushing ratio of 10–50, onetime crushing and shaping, eliminating primary crushing The discharging size is small, uniform, and cubic with less over Stone Crushing Equipment Fote Machinery

.jpg)

Bauxite Crushing Plant Shanghai Zenith Company

Tanzania 100120 TPH Stone Production Line; Zenith Cone Crusher Line In Indonesia; Malaysia 300TPH Impact Crushing Plant; ZENITH 300 TPH Stone Production Line in SuharLiwa, Oman; ZENITH Stationary Basalt Crushing Line In Jeddah; Linfen 250TPH Tailing Construction Waste Crushing Line; Quzhou 500TPH Granite Crushing Line; Zhoushan 1800TPH Tuff 27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so ongrinding equipment for calcium carbonate process CM Mining Thailand 1000TPD Iron Ore Crushing Line Material: Iron ore Capacity: 1000TPD Output Size: 015mm, 1525mm Product application: Shanghai Kunming highspeed rail and local large mixing station the capacity is 350 tons per hour of gravel, 150 tons of Thailand 1000TPD Iron Ore Crushing Line sbmchina2024年5月23日 In this context, the demand for calcite in the construction industry is particularly significant The role of calcite in cement production 1 Controlling cement composition and loss on ignition Cement typically requires limestone (with calcite as the main component) containing a minimum calcium carbonate content of 75%Calcite: A Key Ingredient in Efficient Cement Manufacturing

Cone Crusher For Sale Secondary Crushing Equipment

The APCC Compound Type cone crusher in AIMIX, also known as the Symons cone crusher, combines the benefits of spring and hydraulic systems to deliver enhanced crushing performance; With a high crushing ratio and substantial production capacity, it is wellsuited for largescale operations; It is capable of processing materials of varying hardness, such as The high capacity and robust design of the large scale tracked stone crushing plant make it particularly well suited for use in large quarries and in other open pit operations It is the most widely used primary unit in connection with the mobile conveyorLarge Scale Tracked Stone Crusher, Mobile Ore Crushing Plant Mobile Crushing Production Line Capacity : 85650t/h low noise, convenient maintenance, reasonable technical parameters, and large production capacity The output can be calcium carbide, coke, limestone, river pebbles, granite, etc It is not suitable for crushing flake ores General feed particle size: 501000mm Mobile Crushing Production Line Hongji Mining Machinery