What is the appropriate pressure for the grinding mill

.jpg)

Grinding Mills and Their Types IspatGuru

2015年4月9日 The general principle of operation in a fluid energy mill is that the material to be ground is fed into a grinding chamber in a high speed, high pressure and, often, high temperature jet of air (or other gas)Grinding within a tumbling mill is influenced by the size, quantity, the type of motion, and the spaces between the individual pieces of the medium in the mill As opposed to crushing, which Grinding Mill an overview ScienceDirect TopicsThe principle objective for controlling grinding mill operation is to produce a product having an acceptable and constant size distribution at optimum cost To achieve this objective an attempt Grinding Mill an overview ScienceDirect Topicssample preparation The "Art of Milling" describes the process of turning a laboratory sample into a representative part sample with homogeneous analytical fineness For this task RETSCH Retsch: The art of Milling

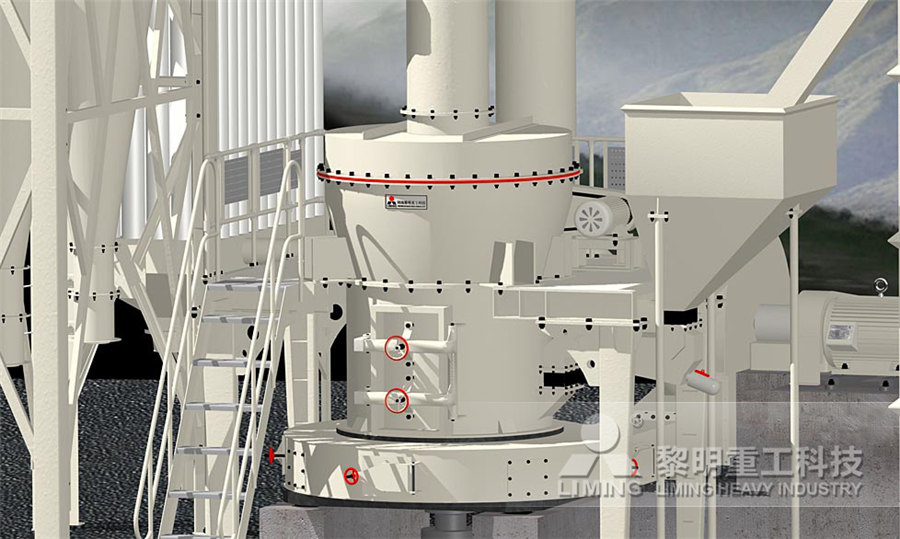

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

Mill air flow/mill differential pressure Why Realtime Control? Rapid process dynamics are a challenge to operating a vertical roller mill (VRM)o grind raw materials and cement Roller presses are used mainly in combi ion possibilities (see Figure 1) The ball mill comminution process has a high electrical energy consumption, BALL MILLS Ball mill optimisation Holzinger ConsultingThe selection of a suitable mill depends on the application: Grinding with pressure operates on the principle of applying mechanical force or pressure to break down materials This method Grinding Mills for reliable size reduction tasks RETSCH2007年1月1日 When the finest grinding is required by dry grinding, the jet milling or the attrition milling with a roller mill, a ball media mill or a powderbed attrition mill would be useful Figure Chapter 10 Selection of Fine Grinding Mills ScienceDirect

Pocket Guide to Grinding Technique Atlas Copco

Up to the limit of the tool’s dimensioned power Beyond that, excessive load or feed force (as the pressing action is called) is both ineficient and harmful to tool and operator alike The power Choosing the appropriate grinding media is essential for the effectiveness of the grinding operation Metallic Grinding Media Metallic grinding media includes carbon steel , forged steel, stainless steel, and chrome steel, which come in Mills: What are they? How are Mills used? Advantagesproduct with a particle size appropriate for the Bayer process The milltypes and configurations used for bauxite are usually limited International ICSOBA Conference, 16 – 18 November 2020 158 recommendations of the design engineers High Pressure Grinding Rolls (HPGR) is rarely considered as lateritic bauxites are too AA04 Bauxite Particle Size Requirements for the Bayer2022年5月20日 After coprecipitation of the model protein and one of the model polymer matrices, 1 g of the powder was added in the chamber of the spiral air jet mill Injector air pressure was 75 bar Grinding air pressure (GAP) was either 25 or Mechanical ParticleSize Reduction Techniques SpringerLink

.jpg)

Mill (grinding) Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist to do Often, the ball used in ball mills is oversize “just in case” Well, this safety factor can cost you much in recovery and/or mill liner Calculate and Select Ball Mill Ball Size for Optimum GrindingFortunately, the chemical method is not the only option for removing the mill scale from steel The mill scale can also be removed by blasting or grinding Although this does not have the harmful effect that chemical cleaning does, these methods for What is a mill scale and do I need to remove it Corrosion Alliance2020年8月12日 As one of the three major forces of coal mills, the grinding force exerts a significant impact on the working process of coal mills and parameters like mill current and outlet temperatureAn investigation of performance characteristics and energetic

.jpg)

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single mill2024年2月13日 If you are about to cut or mill anything with your CNC machine, understanding feed rates and RPM speeds is vital They will significantly affect your tool life, surface finish, and machining time – so this is a crucial calculation to get under your C Feeds Speeds Formula (How to Calculate Feed Rate)2023年4月4日 The Ultra Centrifugal Mill ZM 300 is an alternative mill that is entirely appropriate for cryogenic grinding as it allows larger sample volumes than the mixer mills This highspeed rotor mill is even capable of pulverizing some types of Safe and Efficient Cryogenic Sample Preparation at 196°C2014年1月1日 Two mill systems are employed for most coal grinding applications in the cement industry These are, on the one hand, vertical roller mills (VRM) that have achieved a share of almost 90% and, on (PDF) MPS mills for coal grinding ResearchGate

.jpg)

22 Speed and Feed for the Mill 311 Flashcards Quizlet

Study with Quizlet and memorize flashcards containing terms like 1What is the preferred reference source for selecting and setting cutting variables?, 2Which cutting variable has the greatest effect on tool life?, 3How do cold working and case hardening improve machinability? Cold working and case hardening: and more2023年1月28日 Generally speaking, a fine grind is best for espresso machines that apply high pressure and temperature to the beans A slightly coarser grind will work better for lowpressure and lowtemperature machines An ideal Grind Setting for Espresso: A Beginner’s Guide to the 2024年7月12日 Selecting the appropriate grinding media is essential for optimizing ball mill performance and minimizing equipment wear Consider the initial and final particle sizes, desired product size, and energy consumption when choosing grinding mediaWhat Is a Ball Mill and How Does It Work? Certified MTP Blog2015年4月15日 Bond rod mill grindability tests at 10 or 14 mesh for Work Index For each ball mill grinding step, a Bond ball mill grindability test for Work Index at one mesh size coarser than the desired 80% passing size and at the mesh size of or just finer than the 80% passing sizeWhat Ore Testing is Required For Mill Selection

What is Raymond Mill? How Does It Work? alwepo

2024年9月4日 While Raymond Mill is a valuable tool for material grinding, it is essential to be aware of potential risks that come with its operation These risks include: 1 Dust and Particle Hazards During the grinding process in a Raymond Mill, there is a notable risk of dust and fine particles being generatedHigher capacity than AG mill grinding; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feed plus 412% ball charge (ball dia100 125 mm) PRT 140: Lesson 2 Pressure; PRT 140: Lesson 3 Temperature; PRT 140: Lesson 4 Level; PRT 140: Lesson 6 Flow Measurement;AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator While mill scale can initially provide a protective layer against corrosion for steel structures, its longterm presence is often more harmful than beneficial For steel to be used in construction, manufacturing, or any application requiring durability and longevity, removing mill scale and applying appropriate protective coatings is essentialMill Scale: What It Is How To Remove It Red Label Abrasives2024年8月29日 Shanghai Clirik Machinery Co, Ltd Is excellent ore mill supplier Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consultClirik Grinding Mill Clirik Enterprise Focuses On The

%3C1PGHL[2}HK_]YT.jpg)

Grinding Mills 911Metallurgist

Grinding Mills: Ball Mill Rod Mill Design PartsCommon types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed herePhotographs of a glass ended laboratory ball mill show 2012年6月1日 mounted on an appropriate basis at both e nds which allows rotation of the vessel Hybrid HighPressure Roll Mill/Ball Mill Grinding – Powder T echnology, V ol 105, 1999, 199204 23Grinding in Ball Mills: Modeling and Process Controlpellet mill A pellet mill is not designed to pellet these materials, let alone the animal stomach to digest them The pelleting process starts with a bin (Figure 1, Item 1) in which the mixture of mash is stored From there, the mash will flow by gravity The Pelleting Process CPM2016年10月23日 Each application dictates the selection of proper feeding arrangement This depends upon whether the grinding will be open circuit or closed circuit, and dry grinding or wet grinding The size of feed and tonnage rates are also important factors Speed of Ball Mill Feeders 911Metallurgist

What is Mill Scale And How To Remove It — Benchmark Abrasives

2024年9月11日 Mill scale is something that metal workers and welders should be aware of The remaining mill scale from production can develop in all varieties of steel It must be eliminated before working with the steel because its presence can cause corrosion and impair a weld This article will define mill scale and go over a few methods for getting rid of it MILL SCALE: 2018年3月20日 A pin mill is one of the most commonly used impact mills for grinding bulk solid materials to medium fineness The mill can accept feed materials with a particle size ranging from 20 microns to 05 in and a Mohs hardness of 4, reducing particles down to as small as 10 microns, depending on the mill type and feed sizeIdentifying a Pin Mill for Optimal Performance and Minimal 2016年2月2日 The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentGrinding Circuit Startup and Shutdown Procedure2017年1月1日 The centripetal force of the spinning stone, together with the pressure from grain behind, moves the grain outwards across the grinding surface of the stone The grinding surface is dressed with ‘furrows’, or tapered grooves, that the grain moves up and along until it is sheared off by the passing stoneAll is Grist for the Mill British Columbia Organic Grower

.jpg)

Solids Choose the Right Grinding Mill Chemical Processing

There are many different types of grinding mills (Table 1) Some devices, such as ball mills, are more suitable for coarse materials These mills use "large" media, ranging in size from 20 mm in diameter and up, to produce material from about ten microns to mesh sizes Attrition mills are more appropriate for "midrange" size particles2021年4月30日 Therefore, for rail passive grinding, the appropriate grinding pressure should be selected to balance the grinding quality and the use of grinding wheel Next Article in Journal Determination of the Vertical Load on the Carrying Structure of a Study on the Effect of Grinding Pressure on Material Removal2 Grinding process description The ball mill grinding process is mainly composed of a ball mill, a hydrocyclone cluster, a sump, a slurry pump and an ore bin The schematic diagram of this process is shown in Fig 1 Fig 1 Schematic diagram of ball mill grinding process The variables of this process shown in Fig 1 are explained as follows: WIntelligent optimal control system for ball mill grinding process2020年1月13日 pressure in the system My electric bill went from about $500 a month to about $220 a month (I know at least $40 of that was lights I got rid of) I only run the pressure I need now, I cycle about 95 to 115, no need putting 140 psi in the lines when you don't need it I run 2 extra 20 gallon accumulator tanksAppropriate air supply for CNC Machine? Practical Machinist

.jpg)

Gold Extraction Recovery Processes

2016年2月29日 SAG mills, rod mills and ball mills are the classical pieces of grinding equipment employed in gold recovery plants There is an increasing trend to employ SAG mills (semiautogenous mills) in place of secondary and 2015年10月15日 Learn how to calculate the grinding capacity of your ball mill with 911 Metallurgist This guide provides essential formulas, insights, and tips to optimize your milling process and enhance production efficiencyCalculate Ball Mill Grinding Capacity 911Metallurgist2023年8月30日 For instance, when using Q235 carbon steel as the material, it can be challenging to machine threads while ensuring the desired surface roughness quality index The process of finishing is more challenging than roughing Difficult cutting processes often require higherquality cutting fluidsThe Essential Guide to Selecting Cutting Fluids MachineMFG2024年11月21日 Generally speaking, the grid type ball mill is suitable for coarse grinding, and the overflow type ball mill is suitable for fine grinding When it is necessary to grind to a uniform coarsegrained product of about 0208~0295mm (48~65 mesh), the grid type ball mill is better;Ball Mill Is Indispensable For Lithium Ore Processing

How to choose the right industrial mill? Palamatic Process

Should you choose a hammer mill or knife mill?The choice of the type of grinder will depend first of all on the nature of the raw material to be crushed, its hardness, its size and what will be done with it once it is reduced The choice of grinding technology is made in two steps First of all, it is necessary to identify the appropriate types of mills by taking into account the size of 2018年5月4日 Ventilation system: the volume of air taken in by the hammer mill (calculated in m3/min) must be approximately twice the maximum volume that can be ground by the mill, expressed in m3/h This, in turn, is about equal to the following rule of thumb: Air volume in m3/min = Screen area in dm2 x 0,70Hammer mill: parameters that affect grinding La Meccanica2022年4月21日 If you’re a welder or metalworker, mill scale is something to definitely look out for All types of steel can develop residual mill scale from production Its presence can contribute to corrosion and can ruin a weld, so it needs to be removed before working with the steelIn this article, we will discuss what mill scale is and several options for mill scale removalWhat is Mill What is Mill Scale and How to Remove It Empire AbrasivesAdvantages of Ball Mill Ball mill grinding machine offer several advantages, including: Versatility: Ball mills can perform various types of grinding, such as dry grinding ball mill or wet grid ball mill, batch or continuous grinding, and fine or ultrafine grinding, making them Ball Mill Grinding Machines: Working Principle, Types, Parts

EnergyEfficient Technologies in Cement Grinding IntechOpen

2015年10月23日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a