Graphite manufacturing process Graphite manufacturing process Graphite manufacturing process

.jpg)

Graphite Manufacturing Process – A StepbyStep Guide

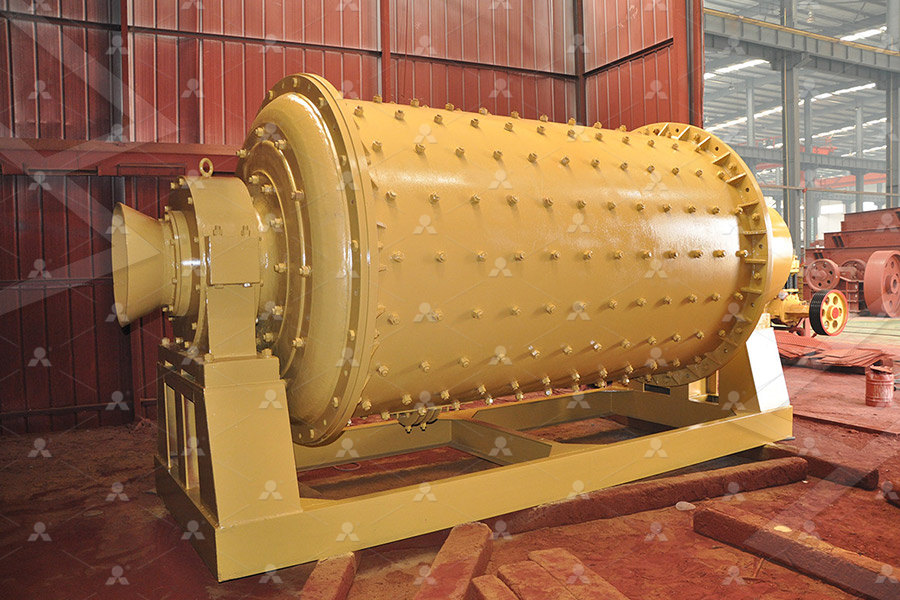

2024年9月26日 If you are interested in manufacturing graphite, understanding each step is crucial Whether you aim to produce natural or synthetic graphite, this guide breaks down The first step in graphite manufacturing involves crushing and pulverizing the raw coke materials, such as coal and petroleum, into a microfine powder This is typically done using crushers and mills that break down the raw materials into Graphite Manufacturing Process Flowchart MWI, IncBased on the properties deriving from the manufacturing methods and production stages, graphite (see box) may be used in various applications, such as: the manufacture of silicon, a critical Manufacturing artificial graphiteRebaked electrodes undergo a heat treatment process known as graphitization, where electric Joule heating is employed to raise the temperature to approximately 3000°C The graphitization process depends on furnace types, The Manufacturing Process of Graphite Electrodes

Bulk graphite: materials and manufacturing process Korea Science

This study defines artificial graphite as bulk graphite, and provides an overview of bulk graphite manufacturing, including isotropic and anisotropic materials, molding methods, and heat This research work gives a detail description of designing a manufacturing process for expanded graphite based on the observation from patents and design a continuous production line for Design of manufacturing process and production line for This review summarizes current descriptions of the science and technology of graphite manufacture The delayed coking process is outlined and mechanisms of coke formation put Science and technology of graphite manufactureThis study defines artificial graphite as bulk graphite, and provides an overview of bulk graphite manufacturing, including isotropic and anisotropic materials, molding methods, and heat treatment Graphite can be classified into natural Bulk graphite: materials and manufacturing process

Bulk graphite: materials and manufacturing process OAK

graphite and pyrolytic graphite 4 Manufacturing Process of Bulk Graphite The general manufacturing process of bulk graphite is shown in Fig 2, and a schematic diagram is presented in Fig 3 [35] The particle size and the mixing ratio are determined based on usage of the filler and binder, and mixing is performed at a tem5Baking Within the roasting road, will be “green” electrode roasting to the specified temperature, according to the requirements of process after roasting products with special dipping, density, mechanical strength, in order to Graphite Electrode Manufacturing Process HGraphiteGraphite can be classified into natural graphite from mines and artificial graphite Due to its outstanding properties such as light weight, thermal resistance, electrical conductivity, thermal conductivity, chemical stability, and high Bulk graphite: materials and manufacturing process2021年12月22日 The data are further processed via a datadriven model (Alchemite) in order to provide additional insight, and an optimized electrode was designed using a Bayesian optimization process 27 different graphite electrode formulation and manufacturing protocols (cases) were developed to optimize the cycle life performance of anode electrodes for high Formulation and manufacturing optimization of lithiumion graphite

.jpg)

Manufacturing Process of Synthetic Graphites Olmec

Manufacturing Process of Synthetic Graphites Synthetic (artificial) graphite is a petroleumbased composite used in a variety of applications requiring superior to natural graphite properties Synthetic graphite can be produced in several ways at our graphite machining workshop, all of which change the physical properties of the final graphite2023年12月13日 graphitemanufacturingprocesstxt Last modified: 2023/12/13 by dmitrikopeliovich Except where otherwise noted, this work is licensed under a Creative Commons AttributionNoncommercialShare Alike 30 LicenseGraphite manufacturing process [SubsTech]2015年9月15日 4 Manufacturing Process of Bulk Graphite The general manufacturing process of bulk graphite is shown in Fig 2, and a schematic diagram is presented in Fig 3[35] The particle size and the mixing ratio are determined based on usage of the filler and binder, and mixing is performed at a temperature higher than the softening point of the binderBulk graphite: materials and manufacturing process Korea The need to create a production plant begins with design of the manufacturing process Designing a desired manufacturing process for a specific application with a special raw material property is a challenging task There is maximum probability in production failure if anyone of the parameters are not properly balanced with the systemDesign of manufacturing process and production line for expanded graphite

.jpg)

Graphite electrode manufacturing process

Graphite electrodes are an essential component in the steelmaking industry, and they play a critical role in the production of steel Raw Materials Used in Graphite Electrode Manufacturing The first step in the graphite electrode manufacturing process is sourcing the right raw materialsIf baking process is carried out in a short time, cracks and pores could occur due to volatile substances included in the pitch or shrinkage Because of that, a controlled baking and cooling process is carried out over a duration of The Manufacturing Process of Graphite Electrodes2024年3月10日 Isostatic graphite is a kind of highperformance material obtained by a special process In the manufacturing process, the internal structure of the graphite material is refined and densified using isostatic StepbyStep: Exploring the Manufacturing Process Graphite Electrode Manufacturing Process Graphite electrode is a kind of hightemperature resistant graphite conductive material produced by a series of processes, such as mixing and kneading, molding, roasting, impregnation, graphitization and mechanical processing, using petroleum coke and needle coke as aggregate and coal pitch as binderGraphite Electrode Manufacturing Process Prominer (Shanghai)

.jpg)

From Powders to Parts: Carbon Graphite manufacturing Process

Graphitization is a postprocess that transforms carbon graphite into graphite It is often used to improve the material’s oxidation resistance and selflubricating ability During this process, carbon graphite is heated to approximately 5,000°F in a controlled atmosphere for over a weekThe manufacturing process of graphite electrodes involves several key steps, from raw material preparation to the final product Here is an overview of the typical manufacturing process: Raw Material Selection: The process begins with the careful selection of highquality raw materialsWhat is the process of manufacturing graphite electrodes?Point Requirement; 1 Graphite electrodes should have a smooth surface with a maximum of two pieces or voids and no transverse cracks If there are longitudinal cracks, they should be no wider than 03mm10mm, and their combined length should not exceed 5% of the electrode’s circumference, with a limit of two cracksGraphite Electrode Manufacturing Process and Usage Jinsun 2023年6月1日 Correlating the input/output parameters of the manufacturing process aims to understand the link between the different steps of the LithiumIon Battery (LiB) electrodemaking processImpact of the manufacturing process on graphite blend

.jpg)

Impact of the manufacturing process on graphite blend

2023年10月1日 Interdependencies between the manufacturing parameters, such as graphite (Gr) content, coating gap, and calendered porosity (ε), with the output electrodes properties we believe that these manufacturing process data and parameter correlations are very useful for calibrating and validating physical and machine learning The general manufacturing process of bulk graphite is shown in Fig 2, and a schematic diagram is presented in Fig 3 The particle size and the mixing ratio are determined based on usage of the filler and binder, and mixing is performed at a temperature OAK 국가리포지터리 OA 학술지 Carbon letters Bulk formulation and manufacturing process predicted The electrode manufactured using the model process shows excellent cycle life and capacity agreement to prediction The data model can be used to predict and design the formulation and manufacturing process to produce thick, highcoatweight, graphitebased electrodes INTRODUCTIONFormulation and manufacturing optimization of lithiumion graphite 2 天之前 Recently, due to the rapid increase in the demand for artificial graphite, there has been a strong need to improve the productivity of artificial graphite In this study, we propose a new efficient process by eliminating the carbonation stage from the existing process The conventional graphite manufacturing process usually involves a series of stages: the pulverization of needle A Shortened Process of Artificial Graphite Manufacturing for

Bulk graphite: materials and manufacturing process Korea

2015年9月15日 4 Manufacturing Process of Bulk Graphite The general manufacturing process of bulk graphite is shown in Fig 2, and a schematic diagram is presented in Fig 3[35] The particle size and the mixing ratio are determined based on usage of the filler and binder, and mixing is performed at a temperature higher than the softening point of the binderWithin graphite powders, one can distinguish two main families based on the origin: natural and synthetic graphite (see Fig 1) Fig 1 Main steps of the synthetic and natural graphite manufacturing process Natural graphite results Manufacturing Processes and Properties of 2021年3月31日 In this paper a manufacturing process is introduced to treat the bulk surfaces of surfaces via graphite powder blasting to directly produce an adherent layer of graphene Subsequently, the study aims to correlate optical, thermal and electrochemical modifications with treatment parameters such as blasting pressure, nozzle distance and number of passes After Manufacturing process design of highpressure graphite 2023年8月23日 Synthetic Graphite (SGBAM) Manufacturing: Crafting Precision Through Transformation The process of producing Synthetic Graphite (SGBAM) for lithiumion battery anode materials is a symphony of Synthetic vs Natural Graphite: Unveiling the Manufacturing

GRAPHITE ELECTRODES Manufacturing Process LinkedIn

2019年4月10日 1 RAW MATERIALS Coke (approximately 7580% in content) Petroleum coke is the most important raw material, and it is formed in a wide range of structures, from highly anisotropic needle coke to Raw Material StorageRaw coke materials are typically stored in large storage silos before being inserted into the production process Crushing The first stepGraphite Manufacturing Process YouTubeGraphite is mainly used in large amount Aluminum Graphite is used for billet casting machine and casting of Al alloys The amount of graphite usage is relatively large Gold, platinum, silver and other rare metals Graphite is also used but production amount of metal is small Our main customers are casting copper alloys!Isotropic graphite manufacturing process and features for Manufacturing Process of Pencil Factories manufacture pencils using large quantities of wood, graphite, and clay Machines like mechanical saws, lacquer sprayers, and giant kilns are used to make pencils out of these materials The following are the detailed steps in the pencil manufacturing process Step1: How To Make Wood from Forest TreesThe Best StepbyStep Guide To The Pencil Manufacturing Process

.jpg)

Graphite sheet manufacturing process optimization :rotary die

Graphite sheets are commonly used as a thermal interface material for effective heat dissipation The manufacturing process of graphite sheets plays a crucial role in determining their properties and performance In this article, we will discuss the optimization of the graphite sheet manufacturing process using a rotary die cutting machine2024年1月22日 The pursuit of industrializing lithiumion batteries (LIBs) with exceptional energy density and toptier safety features presents a substantial growth opportunity The demand for energy storage is steadily rising, driven Engineering Dry Electrode Manufacturing for > Manufacturing Process Isotropic Graphite (Special Graphite) We have a wide range of products from the nuclear power field, which requires high reliability, to the electric discharge machining field, which requires extreme precision, and Manufacturing Process|Isotropic Graphite (Special Graphite Manufacturing Process Free download as Word Doc (doc / docx), PDF File (pdf), Text File (txt) or read online for free The graphite manufacturing process consists of powder preparation, shape forming, baking, and Graphite Manufacturing Process PDF Graphite

.jpg)

Graphite ANZAPLAN

Processing steps in the development of a flowsheet targeting the concentration and downstream processing of graphite will involve physical, thermal and chemical processing steps Main physical processing steps applied: Comminution; Flotation; Micronization; Spheroidization (spherical graphite) Intercalation (expandable graphite)2023年5月12日 Amorphous graphite ore processing flowsheet Amorphous graphite ore has a high grade (generally containing 60% to 80% carbon), but the particles of graphite ore are extremely small and often embedded in clay, making flotation separation impossible Therefore, many graphite mines directly pulverize and grind the mined raw ore to sell graphite Graphite Ore Processing: Optimal Processes and EquipmentImprovements in process technology reduce the amount of energy required to produce key Focused on sourcing clean power for its manufacturing sites Industry Leading (GWP) relative to conventional anode grade synthetic graphite produced in Inner Mongolia, China and ~30% decrease in GWP when compared to the anode grade natural Our Process NOVONIX2020年12月1日 The total plate area has a decisive influence on the manufacturing process of the plate The larger the plate area, the larger the machines In the case of metallic plates, this is usually achieved by a welding process Graphitebased BPPs can be glued or only joined by inserting a sealA comprehensive comparison of stateoftheart manufacturing

NANOXPLORE UNVEILS A LARGESCALE DRY PROCESS FOR MANUFACTURING

Montreal, Quebec — November 22, 2023 – NanoXplore Inc (“NanoXplore” or “the Corporation”) (TSX: GRA and OTCQX: NNXPF), a worldleading graphene company, proudly announces an interesting achievement in graphite exfoliation with the successful development of a novel dry graphene manufacturing process The dry process centers on an advanced exfoliation The invention provides a graphite anode manufacturing process Three graphite blocks are assembled to a graphite block component in an existing method Graphite powder and sodium silicate are mixed to form oildag The oildag is filled in a gap between roots of each two adjacent graphite blocks of the graphite block component A piece of graphite cloth coated with the CNA Graphite anode manufacturing processDownload scientific diagram Overview over the production process of natural graphite from publication: Environmental and socioeconomic challenges in battery supply chains: graphite and lithium Overview over the production process of natural graphite