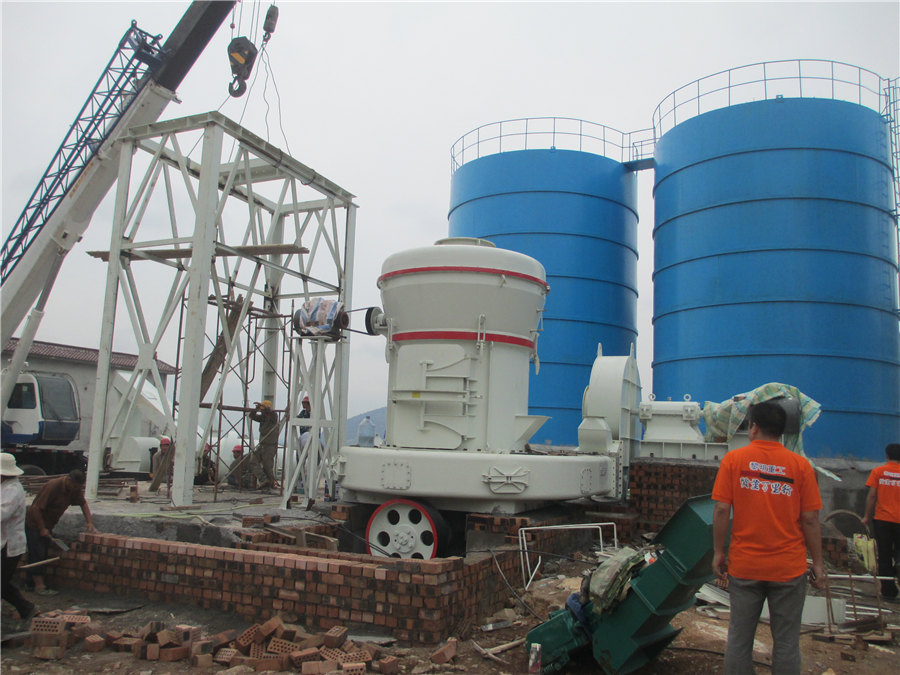

Niobium hard rock ore mill

.jpg)

(PDF) Economic Geology Models 2 Tantalum and

2018年7月12日 Niobium (Nb) resources with the highest economic potential are in weathered crusts that overlie carbonatite complexes (eg Catalão I and II, Brazil) Brazil accounts for 90% of the global Nb2022年7月19日 In this paper, a review of the many technologies for niobium production will be presented starting at the mine, through techniques of niobium ore beneficiation and refining, technologies to(PDF) Production of niobium: Overview of processes Two types of niobium ore deposits are known: Primary: The host is carbonatite, the ore mineral is principally pyrochlore and the grade approximately 05 to 07 percent Nb 0 deposit (StHonore Mining and Extraction Niobium2022年1月1日 Niobium and tantalum primary minerals are naturally occurring complex oxide ores, majorly of low grade deposits with chemical content of mainly Nb 2 /Ta 2 O 5 and oxides Factors and challenges in the recovery of niobium and tantalum

UNDERGROUND AND PYROCHLORE ORE PROCESSING Niobium

The construction of the underground mine and mill complex with an initial milling capacity of 1,360 metric tons/day (1,500 tons/day) was completed in 1976 Since the construction, the original new hard rock mine since the alluvial material has limited availability In the mid1990’s, Niocan announced the planned production of 4,500 tonnes of ferroniobium annually from the Oka Progress in niobium markets and technology 19812001Two types of niobium ores are found in Araxá: the primary ore already described with a mean grade of 15% Nb2O5, and a maximum grade of 8% Nb2O5, and the residual ore with a mean Some aspects of the mineralogy of CBMM niobium deposit and 2014年9月9日 Nb is currently derived mainly from weatheringenriched material associated with carbonatite complexes (eg Araxá and Catalăo I and II, Brazil) Few present and past Nbproducing mines extract ore from unweathered hard Geology, market and supply chain of niobium and

Tantalum Niobium Processing Plant Hengcheng

At Hengcheng, we provide not only tantalum niobium gravity separation machines, but also flotation, magnetic separation machines Currently we are good at alluvial/deluvial gold ore, hardrock gold ore, manganese ore, tin ore, Niobium occurs in the mineral pandaite, which is essentially a complex oxide hydrooxide of niobium, barium, titanium, rare earths of the cerium group, and thorium The ore is radioactive due to presence of thorium (012% in the ore) in the pandaite and monazite minerals Table I1 shows a ORE PREPARATION AND CBMM Niobium2023年9月20日 Tantalumniobium ore and waste rock have a high degree of dissociation and are easy to mine and purify However, Ball mill Ф2700×4000 1 Trommel screen YTS1550 1 Shaking table 6S type 2 Flotation machine KYF Coltan Beneficiation, Solutions, Uses of Tantalum 2024年11月21日 Jiangxi Dajishan tungsten ore body No 69 is a large tantalumniobiumbearing tungsten granite ore body, the tantalumniobiumiron minerals in this ore are embedded in a very fine particle size, most of the particle size is 4074μm, so using the conventional gravity separation method, the beneficiation recovery is low, and the tantalum NiobiumTantalum Ore Beneficiation JXSC Machinery

7TOCS.jpg)

Study on process mineralogical evaluation index system of hard rock

Download Citation On Jan 1, 2023, ZhenYu CHEN and others published Study on process mineralogical evaluation index system of hard rock lithiumberylliumniobiumtantalum mineral resources Find 2014年3月27日 The Niobec mine is North America's only source of pyrochlore, the primary niobium ore and one of only three major producers of niobium in the world The Niobec deposit has an excellent history of mineral reserve renewal over 30 years of operation It is currently producing approximately 7 to 8% of world consumptionNiobec Niobium Mine, Québec Mining Life Online2020年8月4日 The conventional desliming/flotation scheme used to process phosphate ores was tested and adapted to process one of the reject streams of a niobium concentrator in order to produce a salable Production of a Phosphate Concentrate from the Tailings of a Niobium 2023年5月22日 In nature, tantalum and niobium associate with each other as oxides Tantalum niobium ores refer to the general term for minerals containing tantalum and niobium There are over hundreds of minerals in total Among them, it is mainly tantalum iron ore, niobium iron ore, and pyrochlore are suitable for ore miningTantalum Niobium Rock Ore Separation JxscLab

.jpg)

Stutenroth Impact Mill – GameChanging Gold Mining Machinery

Its ability to effectively crush and grind hard rocks, coupled with its adjustable settings and durable construction, make it a standout performer in the industry If you’re looking for a reliable and efficient gold ore mill that can handle the demands of hard rock mining, the Stutenroth Impact Mill should be at the top of your list2020年3月26日 When finely ground ore (−74 μm) was reacted upon for 2 h with a mixture of sulfuric acid (108 M) and nitric acid (53 M) in the ore to acid weight ratio of 1:3 at 200 °C, almost complete Beneficiation and Separation of Egyptian Tantalite OreWrought Nb, Nb alloys, mill products: Powder, ingot, and scrap 024 025 038 033 Niobium alloys, NbTi, NbZr, NbCu 034 03 1 085 102 HSLA grade FeNb 3 153 3772 5306 436 Total 3556 4430 5916 5062 Fabrication of Niobium Alloys and Compounds Niobium alloys like FeNb for the steel and stainless Steel industry are mainly based onProcessing of columbitetantalite ores and concentrates for Niobium2023年5月27日 Gold Ore Rock Crusher Gold ore rock crusher is mainly for crushing the hard goldbearing quartz rocks into pieces with a particle size of less than one inch to improve the grinding efficiency Usually, we choose a jaw crusher as the primary gold ore crusher, and a hammer crusher as the secondary gold rock crusher Jaw Crusher Yes, I am interested!8 Pieces of Gold Mining Equipment to Get Gold Concentrates

DEVELOPMENT OF FeNbC FOR WEAR RESISTANT APPLICATIONS

Hard metals constitute the backbone of the tool manufacturing industry, having diverse applications such as machining of metallic and nonmetallic materials, forming (wire drawing, can tooling, forging, stamping, mill rolls, punches, dies and anvils) and mining (oil well drill bits and rock drill bits) They are the material of choice in allNo matter how careful the personnel are to mine only reef, there will always be waste rock diluting the grade of ore going to the mill for processing A gap analysis report of eight stope panels ( Table I ) was prepared to assist mine management understand why the ore tonnage and gold content were not being reflected further along the production streamMonitoring ore loss and dilution for minetomill integration in Tin ore processing plant; Tantalum Niobium Processing Plant; About Us; Contact Us; News; Previous Next Rock Gold Processing Plant admin T16:44:44+08:00 What you need is absolutely what we dedicate to supply The ball mill is Hard rock gold processing plant for sale Hengcheng Mining (1) Marketing Manager – Niobium, Cambior Inc (2) Mill Superintendent, Niobec Mine Abstract This paper describes the process used at Niobec in the production of ferroniobium once the ore is brought from the underground mine It also briefly presents the Niobec operation, which is celebrating its 25th anniversary as aThe production of ferroniobium at the Niobec mine

Spiral Classifier JXSC Machinery

Spiral classifiers are the main classification equipment for various mineral processing plant It is mainly used for ore classification, separation, screening, desliming, and dewatering in sandwashing operations The spiral centrifugal classifier has the advantages of strong continuous operation, large processing capacity, low energy consumption per unit output, and convenient The red overburden contains gibbsite and kaolinite, with subordinate gorceixite, goethite and hematite Niobium Ores Two types of niobium ores are found in Araxá: the primary ore already described with a mean grade of 15% Nb2O5, and a maximum grade of 8% Nb2O5, and the residual ore with a mean concentration of 25% Nb2O5Some Aspects of the Mineralogy of Cbmm Niobium Deposit and 2017年6月22日 Fig 33: Niobium, lithium and cesium ore, a) Lepid oliteenriched lithium ore from Tanco pegmatite Manitoba, Canada b) Spodumeneenrich ed lithium ore from Ta nco pegmatiteManitoba, Canada(PDF) Niobium and tantalum deposits ResearchGatePDF On Aug 1, 2020, Willie Nheta and others published An investigation on flotation process of lowgrade Niobium/Tantalum ore Find, read and cite all the research you need on ResearchGateAn investigation on flotation process of lowgrade Niobium/Tantalum ore

.jpg)

The beneficiation of lithium minerals from hard rock ores: A

2019年1月15日 There are two economic sources of lithium; brines and hard rock ores The majority of the global lithium production, greater than 60%, is produced from brines while lithium ores accounted for the remaining production (Ebensperger et al, 2005)Table 1 summarises the world’s major lithium producers from ores and brines, and the total reserves2018年7月12日 The highest Nb 2 O 5 grades and ore tonnages correspond to weatheringenriched carbonatitecomplexrelated deposits followed by hardrock carbonatite related deposits(PDF) Economic Geology Models 2 Tantalum and Exploitable niobium ores haveminimal grades of about 03%, but ore at Arax contains 25% Nb 2 O 5 Tantalum ore has characteristically grades of about 003% Ta 2 O 5, generally as a coproduct of cassiterite and other minerals Economic Geology of Niobium and Tantalum Walter 2021年9月29日 the blasttomill concepts of the fragmentation process of hard rock mining The blasttomill concept of fragmentation is the total appreciation of ensuring the achievement of optimal benefits from insitu rock blasting on surface mining benches or in underground mining stopes through the various mining operations to the comminution processRock Fragmentation Evaluation towards BlastToMill Concept of

Rock Tantalite Columbite TantalumNiobium Ores Separation

2017年8月9日 This is a rock tantalumniobium ore separation project, use ball mill for grinding, spiral classifier for grading, spiral chutes for rough concentration, sha2022年7月19日 In this paper, a review of the many technologies for niobium production will be presented starting at the mine, through techniques of niobium ore beneficiation and refining, technologies to (PDF) Production of niobium: Overview of processes from the 2023年3月3日 Tantalum and niobium are nonferrous metals with a high melting point, possess many highquality properties, and are key raw materials for industrialization Tantalum and niobium have a high melting point (2996°C for tantalum and 2468°C for niobium), good ductility, very low vapor pressure, strong corrosion resistance, and high heat transfer rateTantalum and Niobium Ore Beneficiation Process in Africa2023年7月2日 Lithium, beryllium, niobium and tantalum are important critical metal mineral resources The characteristics of "thin", "companion" and "fine" of ore mineral determine that some deposits are difficult to exploit and utilize, so it is necessary to strengthen the research on process mineralogy In addition to grade and reserves, it is necessary to consider the Study on process mineralogical evaluation index system of hard rock

.jpg)

Niobiumtantalum Beneficiation: How to Separate Niobiumtantalum Ore

2022年8月2日 The tantalumniobite is mostly tantalum, niobiumtin, tungsten, lithium, beryllium, and other polymetallic ores It has the characteristics of low raw ore grade, complex mineral composition, high mineral density, and brittleness The beneficiation methods mainly adopt gravity separation, magnetic separation, electric separation, flotation, and chemical treatmentLocation of lithium producing mines from hard rock ores and selected advancedstage lithium projects, excluding lithium production from brines (Evans, 2014; British Geological Survey, 2016) 182 Minerals Engineering 131 (2019) 170–184 B Tadesse et al production can make brine deposits unsuitable to meet sudden changes in demand(PDF) The beneficiation of lithium minerals from hard rock ores: A 2023年10月27日 Ilmenite is the most important titanium ore It is often used for the production of the metal titanium and titanium dioxide (FeTiO 3) accessory products, such as paint, paper, titanium white (white pigment), plastics, Ilmenite: An Ore of Titanium Beneficiation and PlantPDF On Jan 1, 2022, Tianming Gao and others published Lithium extraction from hard rock lithium ores: technology, resources, environment and cost Find, read and cite all the research you need (PDF) Lithium extraction from hard rock lithium ores: technology

COMMUNITY NOTICE Nipissing First Nation

A niobium ore processing mill operated for seven months in 1956 on Nova Beaucage Road in the community of Yellek The land was returned to Nipissing First Nation after the lease expired in the early 1970s The buildings were demolished in the 1980s, and only the 2023年6月20日 As shown in Tables 1–4, for most commodities summed or cumulative individual mine production represents some 95% to ~100% of cumulative production (eg, Au, Fe ore, Sn, U, Pb, Zn, Ag, Mn A Comprehensive dataset for Australian mine production 1799 to Grinding mills are essential equipment for this purpose as they efficiently grind down crushed ore using various mechanisms One type of grinding mill commonly used in hard rock gold mining is the ball mill This cylindrical device rotates around its axis and uses steel balls or other grinding media to pulverize the ore inside itHard Rock Gold Mining Equipment: Essential Gear GuideFigure 1 illustrates the basic features of a tandem mill compared to a Steckel ill After m roughing, the conventional tandem mill employs a series of mill stands located in close proximity The steel passes unidirectionally through these stands In contrast, the Steckel mill is a reversing mill with coil furnaces located on eitherside of the millProcessing of niobiumcontaining steels by Steckel mill rolling

.jpg)

Hard Rock Lithium Ore Beneficiation Technology

Hard rock lithium ore is an important lithium resource Due to its abundant reserves and high grade, it has become an important source of raw materials for the current lithium industryFor hard rock, stamps might weigh as much as 750 pounds, and water to the tune of 150200 gallons an hour was fed into each stamp to produce a slick pulp It is almost impossible to describe, let alone do justice to, the variety of processes that have been used to mill oreWinning the Metal: Ore Mills of the West Western Mining History2020年3月31日 Abstract The distributions of niobium mineral deposits and their resources on the geological time scale are analyzed The sampling list includes 45 mineral deposits with their individual resources estimated not less than 105 tons of Nb2О5 The classification of deposits used includes three types, namely, alkaligranitic, foidic, and carbonatitic The geohistorical Comparison of Supercontinent Cycles in the Metallogeny of NiobiumDOVE Hard Rock Plants and recovery methods vary depending on several factors, including the size of the rock, the rock’s condition, the hardness of the materials, minerals composition in the ore, specific gravity and other characteristics and specification of the elements to insure the efficient recovery of 100% of the minerals Production, with no lossHard Rock Mining Equipment Crushing Plants DOVE