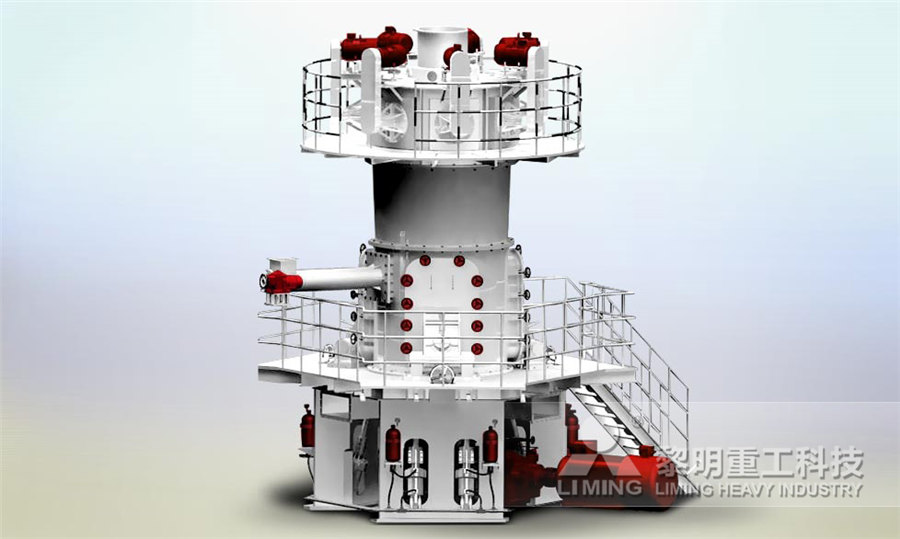

Chongqing coal mill lubricating oil cooling system

CNU Lubrication cooling system of coal grinding mill

The utility model discloses a lubrication cooling system of a coal grinding mill The lubrication cooling system comprises an oil box, an oil pump communicated with the oilIn this study, the influence mechanism of lubricating oil on the heat transfer of CO2 flow boiling was investigated from a mesoscopic perspective A multiphase and multicomponent latticeXiaoxiao LI Lecturer Doctor of PhilosophyThe CJC ® System solutions fit all coal mill pulveriser systems regardless of oil volume, and we can deliver globally where required In close cooperation with technical organizations, we help coal mill pulveriser lube oil CJC2014年1月13日 The document discusses the hydraulic lubrication system of a SAG mill It provides definitions and discusses the importance of lubrication in reducing friction and wear between moving parts It describes the various Mill Lubrication System PPT Free Download

.jpg)

Coal mill bearing lubrication system Semantic Scholar

2013年12月2日 The utility model relates to a coal mill bearing lubrication system, and aims to solve the problems that in the prior art, when a coal mill bearing lubrication system operates, 2021年10月1日 To design these systems, this article introduces one of the most advanced models of lubricated cold rolling since it combines the following features in a single model: An advanced model of lubricated cold rolling with its The objective in modeling is to design a coolant system that delivers sufficient volume of coolant onto the roll surface in an optimally sized cooling area such that there are uniform Fundamentals of Roll Cooling and Control of Flatness at LechlerDepending of the type of rolling mill, dedicated roll cooling systems are required to fulfill the required functions Examples are suitable roll cooling and lubrication systems to fully utilize the GENERAL ASPECTS OF ROLL COOLING FOR HOT COLD

Oil/Air Lubrication Systems for Steel Production Facilities

Compared to conventional lubrication used in steel mill applications, oil/air lubrication reduces environmental pollution, increases lubricating and sealing performance, improves the high 2019年1月1日 Researchers use water based coolant in conventional cooling method, mixture of oil or water based coolant with air passed thorough controllable flow in minimum quantity A Review On Cooling Systems Used In Machining Processes2019年7月19日 Main Engine: Main bearing, Gear drive and Piston Cooling Lubricating oil system The main or crankcase lubrication system is supplied by one of two pumps, one of which will be operating and the other is on standby, Ship’s Main Engine Lubrication System Explained2024年2月1日 The lubricating oil system of the turbine realizes the circulation, filtration, cooling, distribution and monitoring of the lubricating oil through the synergistic action of the oil pump, oil filter, cooler, distributor and other Turbine lubricating oil system composition and

.jpg)

Ball Mill Trunnion Bearing Lube System

2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and Manufacturer of Oil Filtration Systems Transformer Oil Conditioning Machine, Lubricating Oil Purifier, Gear Oil Purifier and Lubrication Oil Purify System offered by Minimac Systems Pvt Ltd (NSICSSI Regd Unit), Pune, MaharashtraOil Filtration Systems Transformer Oil Conditioning Machine Hayden's Lube Oil Cooling Systems typically range from 18’’ x 18’’ up to multiple bays that are 15’ wide by 65’ long They are also customizable for any project you may have at hand Our product can withstand oil temperatures up to 400°FLube Oil Cooling Systems Oil Cooler Hayden Industrial2023年12月20日 The oilhydraulic oil radiator is used for heat exchange with the fuel system The fuel used for heat dissipation in the fuel system comes from the oil tank 3 After being pressurized by the oil supply pump, the fuel first flows through two oilhydraulic oil radiators, and then through two oillubricating oil radiatorsFast Dynamic Simulation Analysis of the Thermal Environment

RollGap Lubrication for Cold Rolling Mills with MQL Metals

2016年9月1日 Fig 4: Improvement of stripsurface cleanliness with MQL on stand 1 of a 4stand tandem coldrolling mill The MQL technology package A pretested MQL technology package consisting of spray bars, an oilsupply unit and a process unit with a defined interface to the mill automation system is available to customers2023年7月28日 The oil cooler is a cooling equipment for turbine oil that is used in conjunction with the steam turbine in power systems It operates by exchanging heat between the hot lubricating oil and the cool cooling water Coal mill lubricating oil station cooler; Control oil station oil cooler;Unveiling the Mystery: What Exactly is an Oil Cooler?25 Fig32 Main Engine Lubricating Oil Circulating System of Wärtsilä RTflex 60C 26 001 Main engine RTflex60C 002 Lubricating oil drain tank 003 Heating coil 004 Suction filter 005 Lubricating oil pump 006 Lubricating oil cooler 007 Automatic temperature control valve; constant temperature at engine inlet 45°C 008 Lubricating oil filter 009 Reduction piece (only when Analyzing lubricating oil used onboard and modern main The faults of lubricating oil system will directly affect the safety and reliability of aeroengine, thus online health monitoring and fault diagnosis are important to the lubricating oil system Aiming at a certain type of a civil aeroengine, the lubricating oil system simulation model is established in MATLAB/Simulink And the simulation model is optimized and its accuracy is verified using Modeling and Fault Diagnosis of Aeroengine Lubricating Oil System

Oil and air lubrication systems SKF Lincoln SKF

In oil and air lubrication systems, a volumetrically metered quantity of oil is pulled apart by a continuous air flow in a tube It is carried along the tube wall in the direction of compressedair flow The quantity of oil is fed into the air flow in China Lubricating Oil Purifier System catalog of Top Newly Advanced Waste Lubricating Oil Purification Machine Chongqing TOP Oil Purifier Co, Ltd Chongqing, Maintain The Oil′s Quench Speed and Cooling Rates, Reduce The Chance of Fire FOB Price: US $6,00050,000 / Piece Min Order: Lubricating Oil Purifier System Chongqing TOP Oil Purifier An example of a circulating oil system Circulating oil systems or lube skids provide continuous flow of lubricant to bearings, gearboxes and blowers They lubricate machinery used to pump stormwater, circulate fresh air into mines, Circulating Oil Systems: What You Should Know2020年9月12日 As the water flows through the shell side of the cooler, it picks up heat from the lubricating oil through the tubes This cools the lubricating oil and warms the cooling water as it leaves the cooler The lubricating oil must be maintained within a specific operating band to ensure optimum equipment performanceThe Operation of a Temperature Control System for lubricating oil

.jpg)

TYA Lubricating Oil Purifier Machine

TYA Lubricating Oil Purifier Machine, find complete details about TYA Lubricating Oil Purifier Machine, TYA Lubricating Oil Purifier Machine Chongqing TOP Oil Purifier Co,LTD +8623 +86 sales@topoilpurifierAircraft reciprocating engine pressure lubrication systems can be divided into two basic classifications: wet sump and dry sump The main difference is that the wet sump system stores oil in a reservoir inside the engine After the oil is circulated through the engine, it is returned to this crankcasebased reservoirAircraft Reciprocating Engine Lubrication SystemsIn addition to cooling, the oil flushes bearings and gearboxes, removing contaminants from friction points Helping to assure accurate and reliable oil flow to each lubrication point, SKF CircOil systems include a wide range of customized and turnkey solutions for Oil circulation lubrication systems SKF Lincoln SKFlow pressure oil coats the journal and other bearings surfaces, helping with oil wedge formation when rotation has been achieved The high flow circuit will deliver the filtered and cooled oil to the bearing LIFT LUBE SYSTEMS Individual Jacking and Lubricating circuits can be combined in one “Lift Lube” system ComOil Circulating Systems for Ball Mills Bijur Delimon

.jpg)

Main Lubricating Oil System YouTube

The main purpose of this section is to give all operation personnel a basic understanding of :• The engine most essential functions• How the Main Lube Oil SThe CJC ® System solutions fit all coal mill pulveriser systems regardless of oil volume, and we can deliver globally where required In close cooperation with technical organizations, we help select the most fitting solution depending on system type and conditions in the environmentcoal mill pulveriser lube oil CJC2021年8月1日 310 The low lubricating oil pressur e of the coal mill caused the trip of the coal mill Cause analysis : ( 1 ) Insufficient output of oil pump ( 2 ) The filter screen is seriously (PDF) Fault analysis and optimization technology of HPAutomatic oil circulation lubrication systems SKF oil circulation systems are designed to lubricate as well as cool highly stressed bearings in nearly every size of machine Additionally, the returning oil removes and ilters out wear particles from friction points and prevents corrosion damage by removing air and waterAutomatic oil circulation SKF

.jpg)

Experimental study of oil cooling systems for

2015年1月22日 The present study focuses on the use of lubricating oil as a coolant for electrical motors Oil is introduced at each side of a 40 kW test machine to directly cool the stator coil endA CN35A CN3A CNA CN A CN A CN A CN 35 A CN35 A CN 35A CN 3 A CN3 A CN 3A CN A CN A CN A Authority CN China Prior art keywords oil oil pump CNA Safety guarantee mechanism in coal mill lubricating CHONGQING NAKIN ELECTROMECHANICAL CO, Ltd is jointstock hightech enterprise from Chongqing China We are professional in various oil purifier equipment manufacturing, main products cover vacuum transformer oil purifier, turbine oil treatment, hydraulic oil filtration, waste engine oil regeneration system etcTransformer Oil Purifier Manufacturer, Lubricating Oil Purifier, Introduction to Cooling Water System Fundamentals Cooling of process fluids, reaction vessels, turbine exhaust steam, and other applications is a critical operation at thousands of industrial facilities around the globe, such as general manufacturing plants or mining and minerals plantsCooling systems require protection from corrosion, scaling, and microbiological fouling Cooling Water Systems Fundamentals Handbook ChemTreat

Lubrication Systems HYDAC

Amongst our lubrication system range, we can design, manufacture and test the following: Lube Oil Systems, Mill Lube oil Systems, Crusher Mil Lube Systems, and Sag Mill and Ball Mill Lube oil systems Whether you’re looking for a new solution or an upgrade to an existing oil lubricating system, HYDAC is your professional partnerOil cooling is the use of engine oil as a coolant, typically to remove surplus heat from an internal combustion engineThe hot engine transfers heat to the oil which then usually passes through a heatexchanger, typically a type of radiator known as an oil coolerThe cooled oil flows back into the hot object to cool it continuouslyOil cooling Wikipediathe oil cooling system illustrated in FIGURE requires that the entire fuel flow for the engine pass through the fuel control means 88, so that any failure of the fuel bypass system 97 to the secondary boiling cooler 94 would be less likely to interfere with the engine operation Further, since all of the fuel passes through the exchanger 90 before vaporization, undercooling of oil Engine lubricating oil cooling systems for turbojets or the like2017年6月10日 4 Necessity of Cooling The cooling system is provided in the IC engine for the following reasons: • The temperature of the burning gases in the engine cylinder reaches up to 1500 to 2000°C, which is above the melting point of the material of the cylinder body and head of the engine (Platinum melts at 1750 °C, iron at 1530°C and aluminum at 657°C)cooling and lubrication system PPT Free Download SlideShare

DESIGN CALCULATION FOR EQUIPMENT AND

2017年6月30日 The lubricating oil system for a tug boat whose transmitting power is about 955KW was calculated mathematically to obtain the flow rate of the shaft line bearing cooling oil, stern tube bearing 2009年9月23日 This system may be used where the AT of the gas is less than 150°F and discharge gas temperature is less than 210°F Forced coolant systems using a mixture of glycol and water are the most common for natural gas compressors Normally, the compressor cylinder cooling system and compressor frame lube oil cooling system is combinedReciprocating Compressors – Cylinder Cooling Oil Gas Industrial Oil Filtration System, Industrial Oil Filtration System Suppliers and Exporters at Chongqing TOP Oil Purifier Co,LTD +8623 TYA A Fully Automatic Lubricating Oil Purifier Inquire Add to Basket TYA W Enclosed Hydraulic Oil Purifying UnitIndustrial Oil Filtration System, Industrial Oil Filtration System 515 Coal mill and motor foundation mounting plate, embedded parts and candle anchor bolts 516 Lubricating oil system 517 Hydraulic oil system 518 The slag discharge box is equipped with inlet and outlet shutoff plates and movable pebble coal scuttle 519 Self use maintenance platform and ladder 5110ZGM type Mediumspeed Rolling coal millpower plant equipment

.jpg)

Cooling Oil an overview ScienceDirect Topics

Industrial Wastewater Treatment Technologies, Recycling, and Reuse Iyyanki V Muralikrishna, Valli Manickam, in Environmental Management, 2017 131144 InPlant Control Measures In a sugar mill, for example, cooling oil used in roller mills for tandem cooling can be collected in a sump filled with bagasse, which is solid waste from the same industry Bagasse absorbs To support this, Bijur Delimon has developed the DS405 Lubrication Monitor; a highly configurable product that can be used on Oil Recirculation Systems and Total Loss Oil or Grease Systems respectively Oil Recirculation Systems are realtime monitoring of the flow rate of oil, typicaly through an oval gear flowmeterOil Circulating Lubrication Systems (OCS) Bijur DelimonA simple energy balance model of the coal mill is derived in (Odgaard and Mataji 2006), this model is based on a more detailed model found in (Rees and Fan 2003)In this model the coal mill is seen as one body with the mass m mThe following variables are defined: T(t) is the temperature in the coal dust flow in the mill, ṁ PA (t) is the primary air mass flow, T PA (t) is Coal Mill an overview ScienceDirect TopicsWe Provide Professional Oil purifiers, Oil Filtration, Oil Purification, Transformer Oil purifiers, Testing Equipment, Topoilpurifier Is An Excellent Manufacturer Of Oil Purifiers, Welcome To Contact Us!Oil Purification, Transformer Oil Purifier, Testing Equipment

.jpg)

Oil circulation automatic lubrication systems SKF Lincoln

Automatic oil circulation lubrication systems System description SKF oil circulation systems are designed to lubricate as well as cool highly stressed bearings in nearly every size of machine Additionally, the returning oil removes and filters out wear particles from friction points and prevents corrosion damage by removing air and water from bearings Thus, a continuous oil Dozens of fins and coolant tubes quickly dissipate excess heat Also known as oil coolers, these heat sinks cool hydraulic fluid and lubricating oil in cylinders and compressors Cooling and flow capacities are based on 50 SSU oil, 1, 000 feet per minute of air, a 50° F initial temperature difference, and a 10 psi pressure drop Heat sinks with a bypass prevent damage to the Oil Coolers McMasterCarr