Single roller ore mill

Roller Mills SIEBTECHNIK TEMA

Singleroller mill With the singleroller mills, brittle, soft to mediumhard materials can be reduced in size with a reduction ratio of approx 1:5 to 1:5 The stepped arrangement of the crushing jaws on the crushing wall enables any material rolling off being minimised, so that, compared to the doubleroller mill, coarser material can be This straightthru ultracompact unit rectifies flow properties of heavy sludge, slurries and solidsladen streams The PIPELINE DELUMPER® alleviates blockages, works the stream to free flow and improves processing It can prevent damage to pumps, piping, valves, nozzles and downstream equipmentSingleroller crusher Pipeline Delumper® DirectIndustryThe dry milling of ore in LOESCHE vertical roller mills has shown significant process advantages, as well as economic and ecological benefits To demonstrate these a mobile oregrinding plant the OGPmobile has been developedMills for minerals and ores Loesche2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill combines crushing, grinding, classification and if necessary drying operations in one unit and enables to decrease number of equipment in grinding Operational parameters affecting the vertical roller mill

.jpg)

Roller Mill SpringerLink

2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding bodies (balls, rollers) and a track (plane, ring, and table)2001年10月1日 LOESCHE vertical roller mills are widely used for the comminution of raw materials in the cement industry, for the comminution of clinker and blast furnace slag and for the production of pulverized coal for cement kilns, blast furnaces and power plantsLoesche vertical roller mills for the comminution of ores and 2012年9月1日 Mills (VRM) installations and summarises the main benefits of the dry compressive Loesche grinding technologies in Airflow and OverflowMode Some of these benefits are optimised energy efficiency of the grinding classifying circuits, increased mineral recoveries and decreased OPEX costs, at a parallel simplification of the process routeLatest Installations And Developments Of Loesche Vertical Roller 2015年3月10日 Vertical roller mill (VRM) technology was developed based on that and attracted interests of both manufacturers and researchers It has been used mainly for cement raw meal grinding applications where crushing, grinding, classifying and drying operations were combined in Copper ore grinding in a mobile vertical roller mill pilot plant

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

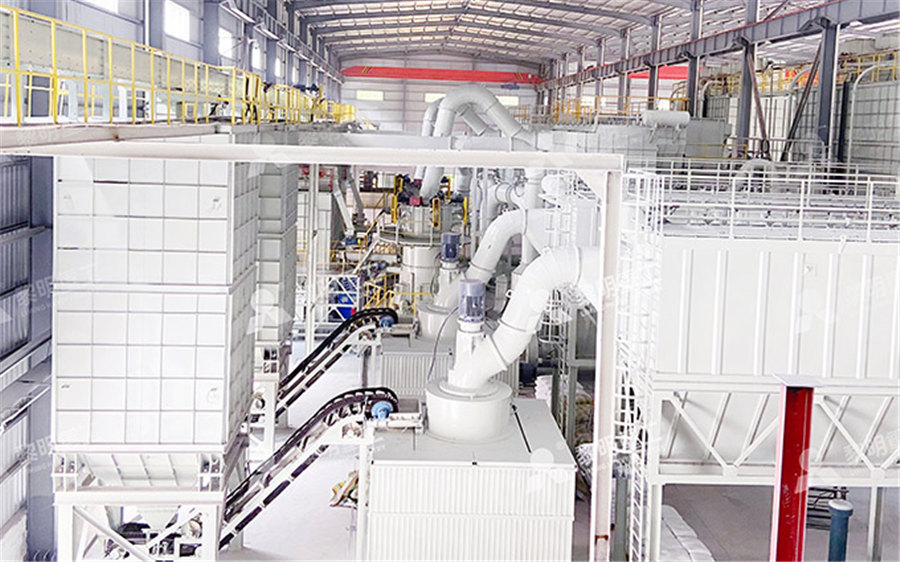

Vertical Roller Mills used for the comminution of mineral ores

Vertical roller mill (VRM) is an established technology in cement and slag grinding applications and Boliden and Gebr Pfeiffer have been collaborating on the application of this technology in the minerals processing industryRoller Mill + Crusher: Complete package : Ksh 385,000/= Usually a single motor is used to power two rollers that will be rotating at a faster speed while a system of pulleys is used to allow easy rotation of the other rollers If the system has three rollers in line, the third pair of rollers in the system is operated using a different motorHow it Works Roller MillThe Double Roller Mill is the same as the single Roller Mill with the following exceptions:Dimensions Unpacked – height 1100mm, length without motor 700mm, and width without auger 870mm Power Requirement – 55 kw Wetmore Roller Mill Grain Roller Mill Livestock Single HI M Roller Mill Iidwpdf MODEL M FR00pdf The FerrellRoss M Series Roller Mills are designed to provide an economical solution for medium duty particle size reduction The M Series Mills are widely used for cracking or grinding grains and oilseeds in lower capacity applications that do not require continuous operationSingle HI M Roller Mill AT Ferrell

6F Single Roller Mill SHANDONG XINGFENG FLOUR

The structure of a single roller mill mainly includes: roller mill frame, roller, feeding roller, cover, transmission mechanism, etc It uses a compound horizontal constantspeed toothed roller (or smooth roller) and uses gears, chains or synchronous belts to transmit the force on the fast roller to the slow roller to achieve unequal and relative rotationimportant feature for a roller mill to have if it is going to have a long service life P) 9134223000 F) 9134227220 Box 395, Bonner Springs, Kansas 66012 USA P) 9134223000 F) 9134227220 H C DAVIS SONS Manufacturing Co, Inc Single High Roller Mill BrochureKRIMPER KRACKER ROLLER MILLS SINCE 1894 HC DavisDESIGN OF SINGLEPASS RUBBER ROLLER TYPE RICE MILL Machine Design Submitted to the Department of Agricultural and Food Engineering College of Engineering and Information Technology Cavite State University Indang, Cavite In partial fulfillment of the requirements in AENG 85 Agricultural Machine Design HANA PEARL A DESCARTIN ROSELY D EMELO Design OF RICE MILL 123 DESIGN OF SINGLEPASS RUBBER ROLLER 2015年11月21日 CRUSH, GRIND and CLASSIFY in a single pass! YOU Will save time, money and labor with the Gibson combination Elliptic Roll and Ball Mill• It is the first successful mill put on the market that will take the mine run of ore Crush grind and classify in a single pass • Horsepower consumption over one third less than ordinary ball millsGibson Roll Ball Mill 911Metallurgist

Roller Mill Sudenga Industries Inc Request a Quote

Sudenga’s Roller Mill is available in single, double, and triple pair high setups with capacities up to 36 TPH at 500 microns Available with roll gap automation and load compensating controls Specifications; Photos; Sudenga ROLLER GRINDER (RGS2020) Product Details2016年10月29日 It does not appear to be used anywhere either as an amalgamator or to prepare ore for amalgamation, but is described here for convenience In December, 1904, 34 Griffin mills and 14 Huntington mills were in use in Western Australia preparing ore for cyaniding Among other roller mills, the Bryan Mill is one of the most successful It resembles Roller Mills 911MetallurgistFind your ore mill easily amongst the 42 products from the leading brands (Fritsch GmbH, Retsch, Eriez, The POITTEMILL pendulum roller mill is a vertical mill that works by compressing the material bed The Taskmaster Titan Duplex features two dual shaft grinders powered by a single motor and drive This unit’s unique Ore mill, Ore grinding mill All industrial manufacturers100A Roller Mill with Oversized Intake Hopper and Enclosed Discharge Area 100A Roller Mill With Angle DischargeAuger 200A Roller Mill VBelt Drive Side 400AP Portable Roller Mill with 54 12x52 Solid Forged Rolls 100A Roller Mill Roller Mills HC Davis Web Site

Comparing Hammer Mills and Roller Mills Horning

Are you thinking of getting a mill for your farm or feed operation? You probably know something about hammer mills and roller mills, the two main kinds of mills But it’s possible you are new to agriculture and aren’t familiar with these mills 【What’s the double roller crusher】 The Doule Roller Crusher, also known as roll crusher, or toothed roll crusher, is suitable for fine crushing medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, Double Roller Crusher JXSC Machine2023年1月26日 Single Pair Mill vs Double Pair Mill From a functional standpoint, the difference between a single pair mill (or a 2 roller mill) and a double pair mill (or a 4 roller mill) is pretty minor With a single pair, a single set of two rolls is being used to crush your grain A double pair essentially does the same thing but with four rollsSingle vs Double Pair Mill RMS RollerGrinderRequest PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

.jpg)

Single Pair Mills RMS RollerGrinder

Roller Mill Accessories; Typical micron targets for a single pair mill range from 3,000 to 1,200 microns These mills are diverse enough to handle any course grind applications Contact our team today to discuss your specific needs Single Pair Roller Mill – #2 Yellow CornSBM Ore Ultrafine Grinding Mill Discharge fineness: 1503000 mesh Feed size: 20 mm The fineness of the finished product can reach 2 microns, and the single product qualification rate can reach 90% The grinding efficiency is Models: HGM ultrafine grinding mill, CLUM vertical roller mill, LXMC ultrafine wet stirring mill etc Send us SBM Ore Ultrafine Grinding Mill2015年3月10日 Within the scope of the study ore grinding performance of the vertical roller mill was investigated with mobile pilot plant In this context, chalcopyrite ore of a plant having rod and ball milling circuit was ground under different operating modes eg, air swept and overflow, and process conditions, then samples were collected around the systemCopper ore grinding in a mobile vertical roller mill pilot plant2018年4月16日 Request PDF Comparing Vertical Roller Mill Performance on Two Different Precious Metal Ores The vertical roller mill (VRM) is a comminution device in which crushing, grinding and Comparing Vertical Roller Mill Performance on Two Different Precious

Roller Mills Grain and Feed Equipment

Roller mills perform a variety of feed mill tasks, including crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds Choose the roller mill that best fits your location's needs and gather more information by contacting companies through the form available belowRoller diameter 250mm or 300mm in the same chassis; Single drive for each grinding roll; Vertical division of the roller mill; Additional roll changing package, including roll changing carriage; ProfiNET connection; Sensors to detect hot surfaces and smoldering spots in the mill outlet; Temperature monitoring of the grinding rollersMIAG GmbH Roller Mill2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE 2017年9月25日 A drum roller, also referred to as a road roller or smooth drum roller, is a heavyduty machine used for compacting and leveling surfaces such as soil, gravel and asphalt These machines are commonly found in construction Single vs Double Drum Roller: When to Use Each

Roller Mills SIEBTECHNIK TEMA

Singleroller mill With the singleroller mills, brittle, soft to mediumhard materials can be reduced in size with a reduction ratio of approx 1:5 to 1:5 With the doubleroller mill, all brittle materials, such as, for example, ores, clinker, limestone, gypsum, aluminium oxide, glass, MSE PRO Single Tier 2Jar Lab Roller Mill, Jar Capacity 10L15L $ 4,649 95 Add to Cart Request a Quote Continue Shopping SKU: 1234 Quantity+ Price $00 Delete Total Price: $000 Contact Information Thank you for trusting MSE Supplies Your quote will be ed to you momentarilyRoller Jar Mills and Roller Milling Equipment MSE Supplies LLCThe Pfeiffer pilot mill used in this study is a semiindustrial vertical roller mill of type MVR with a table diameter of 400 mm The mill can be equipped with different classifiers for specific applications The process layout of the plant (Figure 2) corresponds to that of an industrial plantVertical Roller Mills used for the comminution of mineral oresAvailable From Stock Used and Rebuilt Roller Mills Single Roll PROCESSCO Main Menu Home; About us; Products; Links; Testimonials; Conversions; Quotation; Contact us; Français November 29 2024 04:40 PM Single pair ROLLER MILL with magnet and diff drive 75 HP main Motor Model 9x12Single Pair Stock #: RM14864 Stock: 1 Used Roller Mills Single Roll PROCESSCO

Roll Crushers Williams Crusher

Roll crushers come in different configurations depending on the crushed material and the required output size Some standard roll crushers include singleroll, doubleroll, and tripleroll crushers They can also be designed with smooth or corrugated surfaces on the rollers to provide different levels of crushing action How Roll Crushers WorkSAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY AUTHOR: FO VERRET, G CHIASSON AND A MCKEN SGS KEYWORDS Comminution, grindability, grinding, SAG mill, AG mill, milling, HPGR, work index, pilot plant INTRODUCTION The resistance of ore samples to breakage (or hardness) is SAG Mill Testing Test Procedures to Characterize Ore GrindabilityFind out all of the information about the Franklin Miller, Inc product: singleroller crusher Delumper® L Contact a supplier or the parent company directly to get a quote or to find out a price or your closest point of sale Highperformance grinding Delumper® L Singleroller crusher by Franklin Miller, Inc 2023年5月31日 Roller adjustment device; A roller adjustment device adjusts the roll gap in rolling mill equipment so that the rolled piece may attain its required size The upper adjustment roller is also called a ‘pressing device,’ designed A Definitive Guide to Rolling Mills: All You Need to

Triple Roller Mill: Principle, Construction, Working

2023年12月27日 A triple roller mill consists of three rollers of equal diameters and is made up of hard abrasionresistant material (stainless steel usually) These rollers are arranged parallelly and are horizontally fixed to a rigid frame The Fiveroll mill and singleroll mill are included in these In a singleroll mill, the material is passed between a cement, etc, and nonferrous and ferrous metals' ore dressing Ores and other materials, dry or wet, can be ground by the Three Roll Mill and The Potential Applications6 Vertical Roller Mill: Vertical roller mills combine crushing, drying, and grinding processes in a single machine They are suitable for gold ores with high moisture content and can produce finer particles compared to traditional ball millsWhat are the models of gold ore ball mills?Korte 700 Output 1016 tonnes/hour; 2mm fluted rollers process all cereal and pulses down to 45% moisture; 3m chain and flight discharge elevator; Learn moreCrimpers and Rollers Kelvin Cave

Wet Pan Mill JXSC Mineral

Our Wet Pan Mill Roller Material: 6% manganese alloy steel, which can last at least 3 years Ring Material: Optional casting steel, casting iron, and manganese steel Thickness: Standard 85mm Steel Steel stand: A2 standard steel frame Basin: 5mm thickness steel plate Gearbox: Specially designed for wet pan mill, 1year quality guarantee Motor: Simens or China 1st level standard 2023年7月4日 Roller mill is a type of grinding equipment for crushing materials by pressure between two or more rolling surfaces or between rolling grinding and has been widely applied in cement, steel and power industry, the preparation of nonmetallic ore ultrafine powder, manganese ore fine grinding, and other fields Horizontal Cylinder Roller Mill SpringerLinkIron Ore Pellets Roller Screen for the Balling Line; Iron Ore Pellets Roller Screen (Removal of Undersize Pellets); Iron Ore Roller Screen (Removal of Oversize Pellets); Available for Chain Driven or Individual Gear Motor type Roller Feeder (Screen) at the Feeding Station; Iron Ore Pellets Single Deck Roller Feeder (Screen), Iron Ore Pellets Double Deck Roller Feeder What Is the Iron Ore Pellet Roller Screen? CVICroller mill tests of your material in the manufacturer’s test facility with various roll corrugation styles and under conditions that duplicate your operating environment Figure 1 Particle size distributions: Roller mill versus other grinding methods Other grinding methods Roller mill Overs Target particle size Fines Figure 2Roller mills: Precisely reducing particle size with greater efficiency

Roller Mills Pelleting Technology Netherlands

The new PTN Roller Mill series HE is developed to break or structurize various materials, such as grains, oilseeds, biomass products and/or others Herewith an optimum result and low energy requirements is achieved