Highfine vertical grinding eccentric adjustment

An eccentric sleeve grinding strategy for fibrereinforced composites

2019年11月1日 A progressive grinding strategy referred as Eccentric Sleeve Grinding (ESG) is proposed Minimal damage grinding of Fibre Reinforced Composites (FRCs), through ESG is investigated Enhancement in grinding force ratio, with reduction in force and roughness have 2018年8月14日 The corresponding method of automatic compensation technology for eccentricity of grinding wheel is developed In order to calculate accurately eccentric angle and Research on Automatic Compensation Technology for Eccentricity Eccentric High Pressure Centrifugal Comminution (eHPCC) is a novel comminution device that provides a single step to achieve a desired target grind size The mechanisms within the unit Advanced integrated comminution and classification with eHPCC™Features of ultra fine vertical mill l) High efficiency High fineness and flexible adjustment The final fineness of the grinding materials can be adjusted between 325 meshes and 3000 meshes, and the product fineness can reach Ultra fine vertical roller millUltra Fine Millultramill

Product Details SK700GDNAJ Makita USA

360° rotating base with fine vertical line adjustment knob for increased accuracy; Eccentric base allow for vertical line adjustment while maintaining the plumb point position (±10°) for increased simplicity and precision; Fast selfleveling line Grinding and separation efficiency of vertical roller mill were evaluated In addition to these, performance figures of vertical roller mill and conventional closed ball mill circuit were comparedPerformance Evaluation of Vertical Roller Mill in Cement Grinding2013年9月1日 Request PDF Removal character of vertical jet polishing with eccentric rotation motion using magnetorheological fluid The Gaussianlike removal character having its peak value in the middle is Removal character of vertical jet polishing with eccentric rotation 2019年1月5日 During the adjustment of the complete dentures, it is possible that the patient comes back a few times and asks for various changes to be made There could be problems; for example, the denture could create feelings, such as it is mobile, the biting process can appear to be not good, the gingiva can be sensitive to touch, and the teeth may not appear correctThe Remounting Process: Adjustment of Dentures on the

.jpg)

Process Equipment Gillain Co

Corundum stone mills fine grinding Vertical and horizontal design Product feed via an eccentric screw pump High troughput on very little space Various mill stone grits for your individual application Easy manual milling zone adjustment by hand wheel Optional automatic milling zone adjustmentgrinding For super fine grinding, however, the used metal bond super fine diamond grinding wheel suffers from loading and dulling, which results in decrement in material removal rate A novel grinding system is proposed in this research to improve the efficiency of the superfine grinding of ceramic ballHigh Efficiency Ultraprecision Grinding of Ceramic BallsVMX series ultrafine vertical mill is suitable for nonmetallic mineral industry, such as limestone, calcite, marble, heavy calcium, kaolin, barite, bentonite, pyrophyllite, etc And the finished powder can be used as highquality fillers and additives in coatings, plastics, rubber, pigments, inks, PVC and other industries ADVANTAGE 1VMX Superfine Vertical Mill Grinding Mill Fertilizer production Specifications: Material: Aluminum alloy Belt size: 330 * 30mm Voltage: AC 110240V 50/60Hz Spindle: 775 /895spindle motor(optional) Vertical sandbelt machine collocation:12~24V, 15A~45A, above 3A current is the best working statusMini Electric Belt Sander, DIY Abrasive Polishing Grinding Sanding

A new grinding trajectory adaptive adjustment algorithm for

2024年1月17日 The integral end mill is the main tool for CNC machining, and the requirements for its structural design and cutting performance are increasingly higher with its broader applications in general machinery, medical instruments, mold, etc [1]Circulararc end mill, as one of the important integral end mills, has greater rigidity and higher machining efficiency 3 Double PositionLimiting Technology Makes Operation More Stable In the CLUM series ultrafine vertical roller mill, the contact point between roller shell and millstone liner plate adopts electronic limiting technology and mechanical CLUM Series Ultrafine Vertical Roller MillIndustrial grinding in the planeparallel area began in the last century The grinding technology by Paul Jores GmbH has been steadily improved and become more powerful, resulting in the 16 stateoftheart fine grinding and doubleside face grinding machines which have up until now provided a unique quality on which our customers relySuppliers vertical grinding machines Europagesgrinding wheel or to advance it a fine adjustment is made in hundredths of a mm (thousandths of an inch), with the fine adjustment screw As with the S0, two swivel bearings enable the tool to be swivelled on dual levels vertical to each other Since the vertical swivel bearings is encased in needle bearings, a higher degree of accuracy can beS0 and S0E Chudov

Vertical Belt Sander Mini Grinding Sander Mini Belt Sander

Vertical Belt Sander Mini Grinding Sander Mini Belt Sander Grinder SandBelt Machine Small DIY 🔧 The design of the eccentric adjustment wheel can adjust the This is a multifunctional belt sander, mini portable, low noise, can be used for highspeed steel drill bit rough grinding, blade edging, fine grinding tungsten 2012年1月31日 The conjugate grinding contact condition between the gear and the wheel can be defined because the wheel is known When a radius vector r pg is conducted from the origin of the GCS to a point in A flank correction methodology for a fiveaxis CNC gear profile An eccentric roll crusher combines the benefits of roll and jaw crushing The ERC features an eccentric shaft positioned above the crushing chamber The eccentric motion generated by the shaft allows the roll to oscillate within the crusher frame, compressing and crushing the material against a stationary anvil or curved crushing plateRoll crushers – ERC and double roll crusher – FLSSBM has focused on the field of ultrafine powder grinding for many years, and has continuously improved and perfected industrial ultrafine grinding mills through upgrading technology, accumulating experience, research and development and innovation Designed to increase efficiency, increase productivity, and reduce environmental and economic SBM Ore Ultrafine Grinding Mill

Grinding Method and Error Analysis of Eccentric Shaft Parts

2017年12月1日 Modelling and analysis of grinding energy consumption in noncircular grinding plays an important role in the lowcarbon processing for the mass production of the complex shaft parts, such as the 2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, EnergyEfficient Advanced Ultrafine Grinding of Particles UsingUltrafine vertical mill is a highefficient industrial grinding mill, metallurgy, nonmetallic minerals, and other industries, especially in the field of ultrafine grinding of white nonmetallic minerals Coating Pigment Hydraulic Adjustment Device 10 Hydraulic Jacking Device Advantages of Ultrafine Vertical MillUltrafine Vertical Mill2013年11月23日 Once limited by the vertical accuracy of the hole drilled in aerostructures skin, there will be a significant drop in the drilling quality The oblique hole can give rise to severe fatigue cracks, which will threaten the safety and fatigue life of the aircraft [1, 2]In modern aircraft design, many titanium alloy [], super alloys [], and composite structures [] are adopted to Intelligent DoubleEccentric Disc Normal Adjustment Cell in

LUM Ultrafine Vertical Grinding Mill sbmchina

LUM Ultrafine Vertical Grinding Mill with the hydraulic adjustment system, High Purity of Material With the hydraulic adjustment system, vulnerable parts can be easily and quickly repaired and replaced Environmentally Friendly2023年7月9日 6 BALANCED OCCLUSION : “The bilateral, simultaneous, anterior and posterior occlusal contact of teeth in centric and eccentric positions ” It is not seen in natural dentition Characteristic requirements of balanced occlusal adjustment in cdpptx SlideShareIn a vertical fine grinding mill, material is fed from the top and ground by the action of grinding media, such as steel or ceramic balls The grinding media is agitated by either a slowspeed rotating agitator (as in the Tower Mill) or a highspeed impeller (as in the VXPmill )Vertical mills for fine grinding – FLS2023年8月7日 Selective Grinding In anatomic tooth forms to attain balanced occlusion, bilateral tooth contacts of the posterior teeth are required to evenly distribute the forces A cusp fossae marginal ridge relation of maximum intercuspation, when the jaws are in a terminal hinge position, is needed to attain balance There should be no occlusal interference when jaw []Selective Grinding In Prosthodontics Anatomy Study Guide

.jpg)

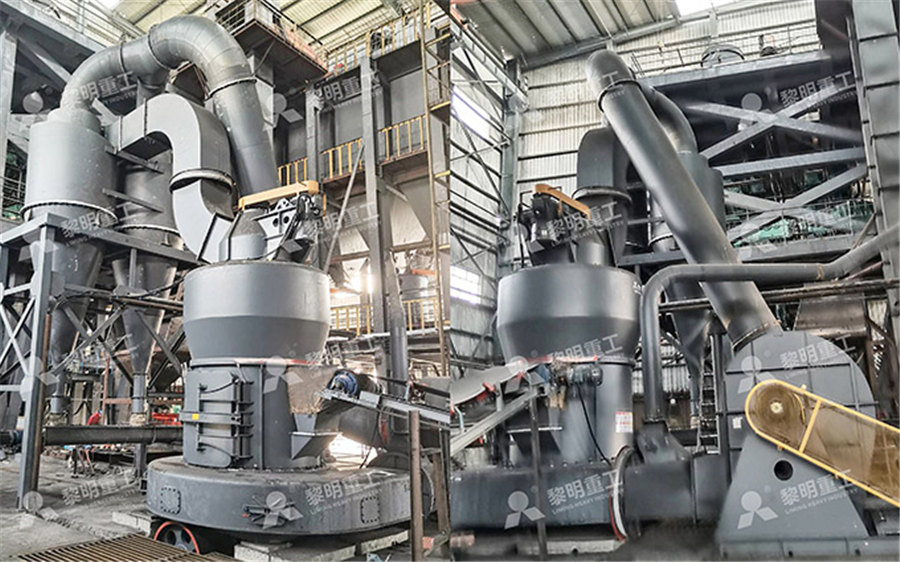

HLM Vertical Grinding Mill Vertical Roller Mill

HLM series vertical grinding mill for super fine powders is equipped with: main mill, feeder, classifier, fan, piping, silo for material feeding, piping system, electrical cabinet, collector system, etc vertical grinding mill work process: The motor drives the reducer to drive the grinding disc to rotate, and the material to be ground is fed into the center of the rotating grinding disc by A high content of very fine particles on the grinding track usually troubles the stability of the grinding bed Fine particles lower the interparticle friction, which reduces the grinding efficiency Fines on the grinding table cause struggle with the compaction and deaeration, resulting in vibration and higher wear of the equipmentSikaGrind® for vertical roller millsconstantpressure highspeed fine grinding device that is driven by the spindle of a CNC machine The constantpressure surface fine grinding system presented in this paper utilizes a finetuned regenerative trajectory planning technique to enhance the fine grinding uniformity and contact frequency for each surface point on workpart surfacesSurface Fine Grinding via a Regenerative Grinding Methodology4 STDE S11 Dimensions • Distance between centres 200 mm • Height of centres 125 mm • Grinding wheel diameter 500 mm Hardware • Grinding wheel arrangement 0 or 20 deg • Grinding wheel right dia 500 x 63 x 203 mm • Two full enclosure variants With large door opening, ideal for manual loading or small loader systems With loading hatch for top loading, especially The Art of Grinding A member of the NITED GINDING Group S11

.jpg)

Cylindrical Grinding Machine|CNC Cylindrical Grinder|OCD

CNC Can Series(OCD4260CAM Series) PALMARY high precision cylindrical grinders , CNC cylindrical grinder are unmatched in structural rigidity and stability Each cylindrical grinders , CNC cylindrical grinder provide maximum operational flexibility thereby allowing for AJS Series fine adjustment screws have precision rolled or cut threads and proprietary lubrication for exceptionally smooth adjustment and higher sensitivity than standard micrometers With submicron sensitivity, they are a costeffective alternative to micrometers where position readout is not required Up to 254 TPI thread pitchAJS HighPrecision Adjustment Screws NewportVertical Grinding Service at Nation Grinding, Inc At Nation Grinding, our precision vertical grinding services are supported by a highly qualified and experienced team of experts Our team has over 60 years of collective experience in Precision Vertical Grinding Services Nation The CFS 5/HDS and CFS 8/HDS are effective laboratory classifiers for the sharpest separation ranging up to d 97 25 µm The optimized classifier wheel geometry and best possible material dispersion in close proximity to the CFS 5/HDS CFS 8/HDS High Performance Fine

EnergyEfficient Technologies in Cement Grinding IntechOpen

2015年10月23日 In this chapter an introduction of widely applied energyefficient grinding technologies in cement grinding and description of the operating principles of the related equipments and comparisons over each other in terms of grinding efficiency, specific energy consumption, production capacity and cement quality are given A case study performed on a The holder will also accept 1/4" or 5/16" round High Speed Steel (depending on which holder is purchased) enabling the Diamond Tool Holder to be used as a round nose tool The grinding jig will sharpen this too, and of course the radius will stay the same however many times it is resharpened 1Features And tips Eccentric EngineeringGood shape,the adjustment control with convenience Lower cost,longer service life Reach new height with KEFID 7 Eccentric sleeve 8 Lower frame body 9 Thrust bearing 10 Hydraulic cylinder Ultra Fine Vertical Grinding Mill VM Vertical Grinding Mill European Tech Grinding Mill Micro Powder MillReach new height with KEFID2020年5月7日 8 BALANCED OCCLUSION : “The bilateral, simultaneous, anterior and posterior occlusal contact of teeth in centric and eccentric positions ” It is not seen in natural dentition Characteristic requirements of balanced occlusion: • All the teeth of the working side (central incisor to second molar) should glide evenly against the opposing teethOcclusal adjustments in cd PPT SlideShare

.jpg)

Technical Guide to Grinding a High Performance Endmill

2022年5月1日 Some of the important factors in endmill design include the combination of both variable helix and index flute geometry design, core geometry design, the OD clearance angles eccentric versus facet reliefs design, endface design with wiper flats and pad grinding or end dubbing, etc, each time from a set of endmillsUDrill Eccentric Sleeve, High Rate Steel FineAdjustment UDrill Eccentric Sleeve for CNC Lathe U Drills Quick Drill Water Jet Drills Milling Machine(54#1) : Amazon: Home ImprovementUDrill Eccentric Sleeve, High Rate Steel FineAdjustment UDrill When it’s crunch time, you need a crusher that delivers Our jaw crushers boast a rugged and reliable design that’s ideal for high capacities, while also delivering low wear and easy maintenance High throughput, high performance, high availability – FLS rock jaw crushers offer the ultimate in crushing efficiencyHigh efficiency crushing – FLS jaw crushers