Plant plan of limestone calcite powder processing plant

Limestone Quarrying and Processing: A LifeCycle Inventory

Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Figure 2In some lime plants, the resulting lime is reacted (slaked) with water to form hydrated lime The basic processes in the production of lime are: (1) quarrying raw limestone; (2) preparing 1117 Lime Manufacturing US EPA2024年1月17日 The design of a limestone processing plant is a complex process that requires careful consideration of a number of factors By carefully planning the design, plant operators Limestone Processing Plant DesignThis report deals with plant design of calcium chloride chemical powder known as calcium chloride dihydrate from limestone and acid chloride solution The PLANT DESIGN REPORT OF CALCIUM CHLORIDE

A LifeCycle Inventory of Limestone Dimension Stone Quarrying

Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Contribute to lbsid/en development by creating an account on GitHublimestone powder processing plant systemmdThis article covers the methodology of planning, incorporating the study of the detailed status of the resource inventory, demand for limestone, exploration of new deposits, and calculating andPlanning and operating a lime plant ResearchGateLimestone is converted into lime through heating in a kiln, a process known as calcination When limestone is subjected to high temperatures, it undergoes a chemical decomposition resulting Lime Production: Industry Profile

Limestone Quarry Production Planning for Consistent Supply of

Abstract—A long term production planning of limestone quarry is presented to supply consistent quantity and quality of limestone to a cement plant A case study from Indian cement industry The ZeroCAL process demonstrated herein establishes a near processemissionsfree pathway for decarbonizing portlandite and PC production, using limestone as a feedstock In situ ZeroCAL: Eliminating Carbon Dioxide Emissions from Limestone’s 2024年1月11日 Limestone Sand Making Plant Flow Limestone enters the primary jaw crusher for coarse crushing The crushed material enters a belt conveyor and goes to a fine jaw crusher(impact crusher or hammer Limestone Crushing And SandMaking Plant2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone Mining

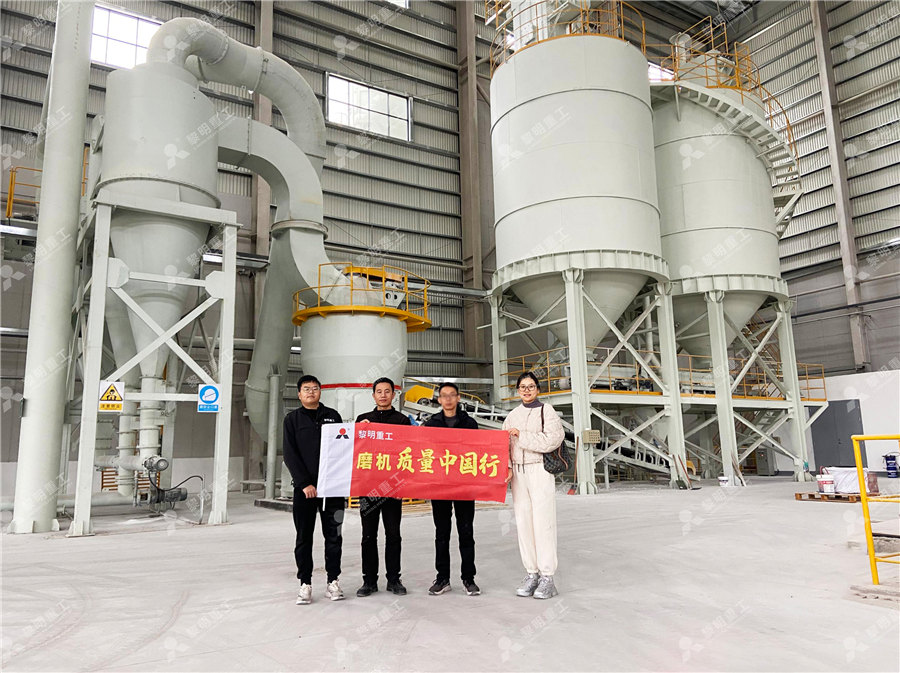

Limestone Processing Plant, Limestone Grinding

Production Process First stage: limestone chunks are transported by special vehicles to raw materials bin, after the forklift / artificial then delivered to the jaw crusher for crushing by forklift or man Second stage: Crushed limestone is This report deals with plant design of calcium chloride chemical powder known as calcium chloride dihydrate from limestone and acid chloride solution The (PDF) PLANT DESIGN REPORT OF CALCIUM CHLORIDE MANUFACTURING FROM LIMESTONE AND ACID SOLUTION BY ACIDIFICATION PROCESS Michael Subroto AcademiaPLANT DESIGN REPORT OF CALCIUM CHLORIDE MANUFACTURING FROM LIMESTONE 2018年8月18日 Limestone coarse crush This is a first step of limestone powder processing ,these limestone equipment can be choose:Jaw crusher, hammer crusher,cone crusher, impact crusher and so onHow to start a limestone processing plant, and what LinkedInComplete Calcium carbonate processing plant Generally, calcium carbonate can be divided into heavy calcium and light calcium Heavy calcium: Heavy calcium carbonate, also known as ground calcium carbonate, referred to as heavy calcium, is produced by physical methods using natural calcite, limestone, dolomite, chalk, shells, etc as raw materials4 Steps to Build a Calcium Carbonate Processing Plant Zenith

.jpg)

Limestone Quarry Production Planning for Consistent Supply of

Keywords: Long range planning, cement plant, limestone, mixed integer programming, block aggregation DOI: 101134/S50174 INTRODUCTION The success of cement plant operation is largely depends of the availability of quality raw materials at desire quantity The main raw material for the cement plant is the limestone and the2017年7月7日 Limestone – Its Processing and Application in Iron and Steel Industry Limestone is a naturally occurring and abundant sedimentary rock consisting of high levels of calcium carbonate (CaCO3) in the form of the mineral calcite Some limestones may contain small percentage of magnesium carbonate (MgCO3)Limestone – Its Processing and Application in Iron andCalcium Carbonate (GCC) produced from chalk, limestone, calcite or marble have developed in recent years from just being a simple cheap filler to highest quality functional additives GCC is used as dry powder or slurry in many industrial applications for plastic, paint, rubber, sealants or Calcium Carbonate (GCC) Hosokawa Alpinesettingup of a processing cost model that re ects xed and variable cost components is recommended Once established, the model can then be used over a range of processing rates and re ned as the project develops Table 1 shows typical sources of scoping level processing cost estimates For projects where a concentrate would be producedGuidelines for mineral process plant development studies AusIMM

calcite grinding machine, calcite grinding mill, calcite processing plant

Calcite Processing Plant Calcite is rich in resources globally, and the highquality calcite resources with calcium carbonate content ≥97% are also large Calcitelimestone ultrafine powder making plant 100,000 TPY calcite, limestone; 12501600 mesh; GCC; Contact Us2024年1月17日 The specific equipment and processes used in a limestone processing plant will vary depending on the desired end product However, the basic steps outlined above are common to all limestone processing plants Design Considerations There are a number of factors to consider when designing a limestone processing plant These include:Limestone Processing Plant DesignWe can modify the project capacity and project cost as per your requirement If you need any customized project report and BANKABLE project reports as per your requirement, Click here to CONTACT US Or Call us at +91, +91, +91 011 , , for quick response All reports are prepared by highly qualified DOLOMITE POWDER PLANT Engineers India Research Institute2013年11月15日 In addition to this, the calcite bands were observed at 1440, 1797, 2516 cm −1 The calcite bands at 1797 and 2516 cm −1 are attributed to the (ν 1 + ν 4) combination mode of CO 3 2− group [23] On the other hand, concentrate sample consists of calcite as major mineral as observed by its main absorption bands at 715, 872 and 1440 cm −1Beneficiation of limestone plant rejects for value addition

.jpg)

9 important Uses of limestone powder ZME ( Zohdy Minerals

2024年1月23日 Limestone powder is a byproduct of limestone quarrying and processing It is obtained by crushing limestone rocks into smaller pieces Limestone Lumps ( Calcite ) 5 Silica Sand ( Glass Grade ) 6 Foundry Sand; 7 Frac Sand – Fracture Sand ( Proppant Sand ) 8Limestone powder processing plant in Egypt Limestone and its powder application Limestone is a sedimentary rock composed of calcium carbonate Its main mineral is calcite and contains dolomite, siliceous, iron ore and clay As calcium carbonate changes with time, it will crystallizeLimestone powder processing plant in Egypt2013年5月8日 The two most important constituents are calcite and dolomite Limestone frequently contains Limestone powder is one of the most important fertilizers Hydrated lime (either dry or as a slurry) has a number of miscellaneous applications in the steel plant and further processing of the steel products It is normally Limestone and Dolomite and their Use in Iron and Steel Plant2013年1月15日 Later, due to the complexity of several ores, few modifiers and depressants were employed to facilitate the flotation process The commonly used modifier was sodium silicate (Prasad et al 1994 Beneficiation of limestone plant rejects for value addition

Limestone Ultrafine Mill Machine SBM Ultrafine Powder

2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etc2008年6月10日 Limestone Nutrient Content There are four types of carbonatebased limestone that are available Calcite is pure calcium carbonate (CaCO 3, 40 percent Ca)Calcitic lime is composed of mostly CaCO 3 (> 30 percent Ca) with some MgCO 3 (5 percent) than calcitic limeUnderstanding Plant Nutrition: Limestone, Calcium And 2024年6月18日 After selecting the appropriate type of aggregate material, the next step is to focus on designing the aggregate processing plant Step 2: Design for the aggregate plant Proper processing of aggregates is important to maintain their desirable qualities They are mined, crushed, cleaned, and separated into powder or lumps of different diameters5 Steps to Build a Profitable Aggregate Processing Plant2020年3月13日 Reducing CO2 emissions is a key task of modern society to attenuate climate change and its environmental effects Accelerated weathering of limestone (AWL) has been proposed as a tool to capture Reducing CO 2 Emissions of a CoalFired Power Plant via

.jpg)

Micronized Calcite Powder Manufacturing Plant IMARC Group

Report Overview: IMARC Group’s report, titled “Micronized Calcite Powder Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a micronized calcite powder manufacturing plant It covers a comprehensive market overview to microlevel 2015年10月30日 A Review of Desulfurization Technology using Limestone in Circulating Fluidized Bed Boiler Type Power Plant October 2015 Journal of the Korean Institute of Resources Recycling 24(5):314(PDF) A Review of Desulfurization Technology using Limestone in Also flexibility of the plant design and layout has to be considered 4 Milk is a food item, which has to be consumed, especially by children and old people Hence, PLANT HYGIENE is the important factor in plant layout and design 5 Effluent disposal of dairy plant is essential as the volume and BOD value of the dairy effluent is highDAIRY PLANT DESIGN AND LAYOUT AgriMoonGrinding plant,Powder processing plant,Powder Grinding plant,Stone Grinding plant Bucket elevator is used to vertically lift limestone, coal, gypsum, clinker, dry clay, Calcite powder manufacturing process typically involves several stages, Grinding plant,Powder processing plant,Powder Grinding plant

.jpg)

Evaluation of the Efficiency of Limestone Powder in Concrete and

2018年2月21日 The major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of We execute lime Processing plant manufacturers and suppliers including hydrated lime plants, quick lime plants, lime processing plants, lime kilns, lime is cooked/calcined at 800°c in a kilnWe are providing shafts kilns and rotary kilns for calcining of limestone/lime sludge with multi fuel options Prior to calcination, Hydrated, Quick, and PCC Lime Processing Plant ChanderpurLimestone (CaCO 3), in the form of calcite, alone represents about 15% The distribution between 'silica' and 'limestone' seems to be balanced; altitude), the presence of other plant species (competition) and the consequences of human activities (livestock farming, chemical fertilizers, acid rain, Limestone and calcium in plants Soin de la Terre2021年10月22日 (7) Powder conveying and bulk packing; (8) Compressed air station and pipe network: (9) Weighing system; (10) Water supply and processing unit; (11) Electrical automation system; (12) Spare parts and maintenance center The project process is shown in the figure below: Layout of the production plant 1) Use the altitude difference of floor of siteConfiguration and design of 1000tph limestone aggregate production plant

Assessment of waste eggshell powder as a limestone alternative

2024年11月6日 The decarbonization of the concrete industry is an ongoing pursuit One solution towards this goal is the use of limestone powder in portland cement Waste eggshell has tremendous potential as an alternative calcite filler in cement due to its similarities with limestone In this research, the feasibility of adding 15% and 35% ground eggshell in portland cement to Its raw materials include calcium carbonate (calcite, marble, limestone, chalk), kaolin, bauxite, dolomite, barite, quartz, etc The calcium carbonate powder produced by the ball milling production line can play the role of filling, reduce Calcium Carbonate Ball Mill Plant DASWELLARL OPTIM’X, lime/limestone, power plant, WDXRF, XRay fluorescence Water Vapor Gypsum out +95% SO2 captured Limestone and SO2 mix to form gypsum, CaSO4 Flue Gas Booster Fans Limestone in LIMESTONE PREPARATION Lime / Limestone ARL OPTIM’X XRF Spray Tower Flue Gas Desulfurization Unit in a Coal Fired Power Plant Element/ Oxide Concentration Analysis of limestone for flue gas desulfurization in a power plantreserves of limestone are spread around Indonesia Figure 2 Indonesian Limestone Reserve Area (Blogdetik, nd) 2 Limestone Mining To produce limestone is quite simple, just separate the limestone from the quarry Separating the BUSINESS STRATEGY OF LIMESTONE PROJECT DEVELOPMENT

Limestone Powder Processing Machine MadeinChina

China Limestone Powder Processing Machine wholesale Three Dimensional Design Powder Processing Machine for Pyrophyllite Mineral Phosphorite Marble Limestone Quartz Graphite Calcite Feldspar Fluorite Powder Plant US$ 6000065000 / Piece 1 Piece (MOQ) Shanghai Clirik Machinery Co, App Store Google PlayIntroduction A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such Limestone Grinding Mill Plant TAYMACHINERYWe can modify the project capacity and project cost as per your requirement If you need any customized project report and BANKABLE project reports as per your requirement, Click here to CONTACT US Or Call us at +91, +91, +91 011 , , for quick response All reports are prepared by highly qualified MICRONIZED POWDER OF CALCITE (CaCO3) Engineers India 2023年4月26日 If grinding 601000 mesh calcite super fine powder, use a superfine mill The mill has comprehensive crushing performance such as rolling, grinding, impact, etc It is an excellent equipment in the fine powder market Calcite processing plant Calcite is an important raw material for calcium carbonate and its further processed products3 Incredible Flows to Win Calcite Processing (Without Failing)

.jpg)

(PDF) Geochemical assessment of a siliceous limestone

2011年3月1日 According to (Bouazza et al, 2016;Van Oss and Padovani, 2002;Temitope and Olubunmi, 2015), the cement clinker product must be a hydraulic material composed primarily of twothirds calcium