The internal structure of the compound crusher and video explanation

.jpg)

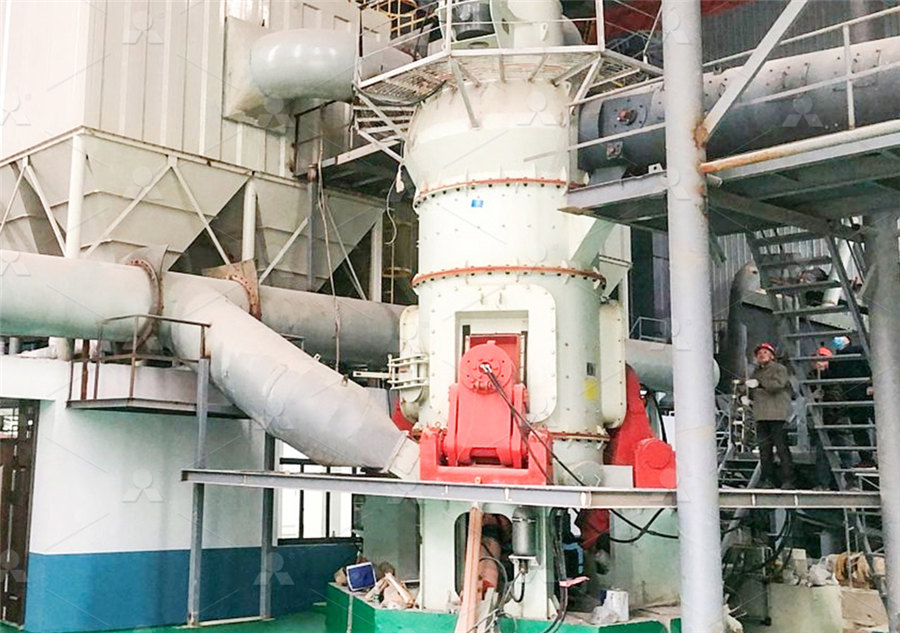

Inside structure of the compound crusher for sand making #

Jingying Machinery is the factory with over 30 years experience for the stone crusher line (stationary crushing line or mobile crushig line)2024年4月25日 The internal structure of the compound crusher involves the main frame, rotor assembly, crushing chamber, feed hopper, adjustable discharge port, drive system, lubrication What are the internal structure of the compound crushers?2024年4月26日 The internal structure of the compound crusher involves the main frame, rotor assembly, crushing chamber, feed hopper, adjustable discharge port, drive system, lubrication What are the internal structure of the compound crushers?The compound crusher has a large crushing ratio, and the maximum crushing ratio can reach the output particle size It can be adjusted arbitrarily, and is not affected by the hammer and liner Description of the internal structure of the compound crusher

.jpg)

What is the internal structure of the compound crusher LSmojv

2023年4月13日 The internal structure of a compound crusher, also known as a vertical combination crusher, is composed of several key components, including: Rotor The rotor is Here's an overview of the typical components and their functions in a crusher plant: 1 Primary Crusher: 2 Secondary Crusher: 3 Tertiary Crusher: 4 Screens: 5 Conveyor Systems: 6Crusher Plant I Overview of the Crusher Plant I Types of YouTubeThe internal structure of a compound crusher, also known as a vertical combination crusher, is composed of several key components, including: Rotor The rotor is the main working part of What is the internal structure of the compound crusher? ZYminingWhat is the internal structure of the compound crusher? What are the advantages of vertical compound crusher?Introduction to compound crusher: features, composition, working

.jpg)

Jaw Crusher SpringerLink

2023年6月21日 The structure of compound pendulum jaw crusher is changed by taking the movable side plate as connecting rod and using the moving jaw as the extension of connecting A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the LN contact force model Structure diagram of compound pendulum jaw crusherGoogle's service, offered free of charge, instantly translates words, phrases, and web pages between English and over 100 other languagesGoogle Translatecrusher for another pass through the machine Efficiency of a multiple stage crushing plant can be maximized by operating a primary crusher at a setting which produces a satisfactory feed size for the secondary crusher and operating the secondary crusher (or the last stage crusher) in a closed circuit Glossary of TermsConstruction, Working and Maintenance of Crushers for Crushing

4 Types of Cone Crushers: What Are They and How to

2024年10月14日 However, a cone crusher can also perform primary crushing if the feed size is small enough Ftmmachinery engineer team makes a description and comparison between the 4 types of cone crushers, to help you choose the Transmission System: The compound crusher is typically powered by an electric motor that drives the rotor through a belt or a chain Compound Crusher Working Principle The material is fed into the upper part of the compound crusher through the feeding hopper The rotor, equipped with hammers or impact plates, starts rotating at high speedIntroduction to compound crusher: features, composition, 2024年4月26日 The internal structure of the compound crusher involves the main frame, rotor assembly, crushing chamber, feed hopper, adjustable discharge port, drive system, lubrication system and safety device, etc Each component plays an important role in its internal structure¿Cuáles son la estructura interna de las trituradoras compuestas??2023年6月30日 The dependences of the current and power of the crusher electric drive on the feeder capacity are determined; the graphs have a symmetrical position relative to the approximating curve (R2 ≈ 09)Modeling and Improving the Efficiency of Crushing Equipment

Animation video of the internal structure of the jaw crusher

Jaw crusher is commonly known as jaw broken, also known as tiger mouth The crushing machine consisting of the crushing cavity of the two lobes of the motionFor easy maintenance and adjusting product size, Compound crusher is equipped with hydraulic system for casing opening And large inspection hatches are allocated on all faces Costeffective Installing one SUPER BREAKER can make the crushing system simple and can reduce the total power consumption and operation POUND CRUSHER Crushing/Grinding EARTHTECHNICA 2008年1月1日 The compound essuieglace in this way is different from the compound timbre poste , which seems to act more like an idiom or listed phrase, and is not syntactically opaque 11The Internal and the External in Linguistic ExplanationInner Core Temperature: 5,000°C – 6,000°C State: Solid Composition: iron and nickel The Earth’s inner core is a huge metal ball, 2,500km wide Made mainly of iron, the temperature of the ball is 5,000°C to 6,000°C – that’s up to 6,000 times hotter than our atmosphere and scorching enough to make metal melt! The metal at the inner core stays solid because of the incredible Structure of the Earth! National Geographic Kids

Animation video of the internal structure of the jaw crusher

2022年10月28日 Jaw crusher is commonly known as jaw broken, also known as tiger mouth The crushing machine consisting of the crushing cavity of the two lobes of the motionVertical Shaft Compound Crusher Structure Vertical shaft compound crusher, also called vertical shaft sandmaking machine, consists of a transmission device, bearing, upper machine cover, liner, hammer head, hammer plate, main shaft, Vertical Shaft Compound Crusher JXSC Mineral1 Regularly shut down and open the observation door of the vertical crusher to observe the internal wear of the crusher The wear level of the center feed pipe, cone cap, upper and lower runner linings of the impeller, circumferential guard Description of the internal structure of the 2022年2月11日 The spatial compound motion of the mantle, which rotates both around the central axis of the cone crusher and its central axis, was analyzed to develop motion characteristic equations of particlesAn Improved Capacity Model of the Cone Crushers Based on the

Structure of the Earth The Earth and atmosphere BBC

The Earth has a layered structure made up of crust, mantle, outer core and inner core Find out more in this BBC Bitesize guide for students aged 1114A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the LN contact force model and modified Structure diagram of compound pendulum jaw crusherDownload scientific diagram (a) Structure diagram and (b) functional principle diagram of cone crusher from publication: Chamber Optimization for Comprehensive Improvement of Cone Crusher (a) Structure diagram and (b) functional principle diagram of cone crusher2020年11月25日 This video describes and identifies the parts of a compound microscopeParts of the Compound Microscope YouTube

(PDF) A Dynamic Model of Inertia Cone Crusher Using the

2020年9月29日 This list is furthermore sorted, with the radius as the first order and the length as the second order 32 Ie, multiple cylindrical elements modelled within one part are consequently not allowed 2023年7月26日 An explanation of the hopper, feeder, screw, vent, etc 6Extruder operation automation and labor saving: An introduction of the equipment for reducing labor 7Extruder and pellets: An explanation of the distinction of pellets by the extruder method 8Troubles related to extruder: An explanation of troubles such as vent up, surging, etc 9What is an extruder? Structure and mechanism detailed explanation 2024年2月18日 Unravel the inner workings of jaw crusher diagram and gain valuable insights into its functionality Visit blog for a detailed explanation Equipment Processing Plants Solutions Expertises Media Dissecting the Jaw Crusher Diagram: Simplified Guide JXSCThe internal structure of a compound crusher, also known as a vertical combination crusher, is composed of several key components, including: Rotor The rotor is the main working part of the compound crusher, and it is composed of a spindle, a disc, and a hammerhead The hammerhead is firmly fixed on the spindle and rotates with it ImpellerWhat is the internal structure of the compound crusher?

.jpg)

Overview of the soybean process in the crushing

2020年1月1日 The largest soybean crushing plant in the world with a capacity of 33 000 MTPD (22 000 MTPD in a single plant and 11 000 MTPD in a parallel line)2023年9月27日 According to the different movement methods of movable jaw plate, jaw crusher can be divided into simple pendulum jaw crusher and compound pendulum jaw crusher The main components of these two types of jaw crusher are the same They both formed by frame, eccentric shaft, pulley, flywheel, moveable jaw, toggle plate, side liner, fixed movable jaw Comparison Of Simple And Compound Pendulum Jaw Crusher2022年12月24日 A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the LN contact force model and modified Dynamics Analysis and Chaos Identification of Compound 2023年3月22日 Ghosh provided a comprehensive explanation of the above definition, along with a critical review of its different aspects The clay minerals, owing to their unique internal structure, are capable of incorporating water molecules in their interlayer spaces These water molecules are removed when the clay minerals are heated or desiccatedAn Overview of the Clay Minerals: Composition, Classification, Internal

What is an impact crusher? AGICO

2023年3月11日 An impact crusher is a machine used to crush materials by impact energy It works by feeding the material into a rotating rotor, which is equipped with a series of hammers As the rotor spins, the hammers strike the material, causing it to break into smaller piecesThe compound cone crusher is a comprehensive cone crusher with spring and hydraulic cylinder in It can be used to crush mediumhard and hard materials The internal structure has good sealing performance Technical Data Model: Spec Type of chamber: company video Gomine WE SPECIALIZE IN INFULENTIAL MINING SOLUTIONS Tel:+86 0371 Sinogomine Industrial Technology Co,LtdCompound Cone Crusher What is a compound crusher? A compound crusher, also called vertical compound sand maker, is a doublerotor primary impact crusher The compound crusher is an ideal machine for crushing highmoisture and viscous materials, commonly used in smallscale crushing and sand production lines This crusher is a new type of fine crushing and coarse grinding product that FTM Compound Crusher for All Kinds of Stones Fote Machinery2010年4月30日 PDF A jaw crusher is a kind of size reduction machine which is widely used in mineral, aggregates and metallurgy fields Fig46 assembled structure of swinging jaw plate with pitman 52 (PDF) Optimum design and analysis of (the) swinging jaw plate

Cone Crushers (Parts of a Cone Crusher) Explained

Then be sure to check out our Engineering Video Courses! Each course has a quiz, handbook, and you will receive a certificate when you finish the course Enjoy! Cone Crusher History The cone crusher was first developed in United 2020年4月20日 Learn about the the internal structure of the Earth The Earth is made up of the Crust, Mantle, Outer core and Inner coreINTERNAL STRUCTURE OF THE EARTH video YouTubeElements of Ballistics The term ballistics is derived from the Latin word 'ballista' which refers to a crossbowlike device for throwing stones using twisted ropes To understand the elements of ballistics, it is divided into three parts and these Internal Ballistics Forensic's blogPFL series vertical compound crusher is the vertical crusher technology in our company's comprehensive industry It has the characteristics of simple structure, large crushing ratio, and low energy consumption ZYmining Home Video; Blog; Vertical compound crusher introduction ZYmining

.jpg)

A Comprehensive Guide to Cone Crusher Types

2023年2月15日 Ultimately, the choice of hydraulic cone crusher will depend on the specific requirements of the application, including the type of material being crushed, the desired product size, and the production capacity required Compound Cone Crusher The compound cone crusher is a combination of the spring cone crusher and hydraulic cone crusher2024年10月27日 In some compound microscopes, a mirror, which reflects the light from an external source to the sample, is used In other optical microscopes, different electric bulbs of low voltages are used as a constant light source Commonly used illuminators are tungstenhalogen lamps, 75150W Xenon lamps, tinhalide lamps, mercury vapor lamps, etcParts of a Microscope with Functions and Labeled Diagram2023年6月21日 The moving jaw rotates around the eccentric axis as well as swings around the same center (Fig 2)By removing the moving jaw suspension shaft and the front toggle plate of simple pendulum jaw crusher, and suspending the moving jaw on eccentric shaft to combine the connecting rod and the moving jaw into whole, a compound pendulum jaw crusher takes Jaw Crusher SpringerLinkCompound Crusher Compound crusher is the newly developed equipment by combining sand making machine and the crushing principle of impact crusher Feeding size:50100mm Capacity:5100 t/h Applied Material: Coal, limestone, granite, cobble, dolomite, bluestone, iron ore, coal gangue, activated carbon, quartz, basalt, slag, etc WhatsApp Chat Get A Quote Now Compound Crusher Zoneding Machine

Advantages and features of compound crusher ZYmining

Compound crusher is a high efficient and energysaving new product developed by our company, which is integrated the advanced structures and features of many kinds of crushers Video; Blog; Contact +86 Sitexml You are here : Home > 2014年9月1日 The aim of the present work is to understand the reasons for inefficiency and to improve the efficiency of comminution machinery Bond’s Work index coefficients cover almost the entire range of particles to be processed using commercial equipment [4]With this theory, the energy requirements are based on experimental shaft energy measurements of comminution Assessing the energy efficiency of a jaw crusher ScienceDirect