Guangzhou roasted spodumene mill steel mill steel slag mill vertical mill market

2 µm 5 µm Loesche

slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as steel slag combines all the advantages of conventional processes: • Efficient and costeffective metal recovery in the coarse range • Virtually 100% metal recovery down to the finest fractionsLoesche Mills for Metal Recovery and Filler Production from Steel 2007年11月1日 With over 2000 MPS vertical roller mills in use around the world today for grinding cement raw material, coal, clinker, granulated blast furnace slag (GBFS), pozzolana, MPS vertical roller mills for slag and slag cementsThe core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock Loesche has developed and built the largest and most efficient PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

.jpg)

How is the steel slag vertical mill grinding process?

After meeting the grinding grain size requirements and reducing the iron content in the steel slag, the advantages of vertical grinding immediately show: high output, low power consumption, The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder Capacity: 200,0001,500,000t/a Steel Slag Vertical Mill CHAENGCHAENG steel slag vertical mill has complete models and strengthens the iron dressing process, with the feeding size of ≤ 5mm 【Product capacity】: 200,0001,500,000t/a 【Specific surface Steel Slag Vertical Roller MillChina Vertical Roller Mill wholesale Select 2024 high quality Vertical Roller Mill products in best price from certified Chinese Powder Grinding Machine manufacturers, Grinding Mill suppliers, Vertical Roller Mill MadeinChina

.jpg)

Vertical Steel Mill MadeinChina

China Vertical Steel Mill wholesale Select 2024 high quality Vertical Steel Mill products in best price from certified Chinese Steel Factory manufacturers, Steel Custom suppliers, wholesalers Consult Xinxiang Great Wall Machinery Co, Ltd's Slag Vertical Roller Mill brochure on DirectIndustry Page: 1/1Slag Vertical Roller Mill Xinxiang Great Wall Machinery Co, Ltd 2014年10月24日 This latest triumph involves the largest slag mill in the world, which already produces 255 t/h blastfurnace slag meal in Taiyuan, northern China Loesche hands over world’s largest slag mill Loesche hands over world’s largest slag mill – LM 633+3The coal vertical mill, also referred to as the vertical roller coal mill, is an advanced equipment developed by our company It combines modern technology with our extensive experience in powder manufacturing This coal pulverizer HighEfficiency Vertical Coal Mill Enhancing Coal

.jpg)

Cement grinding Vertical roller mills VS ball mills

Vertical roller mills and ball mills represent two clearly distinct technologies However, with proper adjustments to the operational parameters of the vertical roller mill almost identical cement properties can be achieved by the two mills Almost 30 years ago LOESCHE introduced the first vertical roller mill to grind both, cement clinker and granulated blast furnace slag, in one process The concept of M and Srollers was established in 1992, which is one of the most cost effective and Cement Blast Furnace Slag LoescheSince 2007, SINOMALY has begun to develop and manufacture vertical slag mill, which has been successfully applied in the market, with a output range from 45t/h to 300t/h that can satisfy the slag powder production lineSlag Mill Vertical Slag Mill Provider SINOMALYand dry processing of steel slag Loesche Mill type LM 15200 under construction Loesche Mill type LM 15200, Wolica, Poland, 2009 3 1 10 11 2 12 3 13 4 14 5 15 6 16 7 17 8 18 9 19 of slag with the Loesche vertical mill 1 Wheel loader 2 Conveyor belt 3 Jaw crusher 4 Impact crusher or cone crusher 5 Conveyor beltLoesche Mills for Metal Recovery and Filler Production from Steel Slag

What is a vertical roller mill (VRM)? A Comprehensive Guide to

2023年10月3日 Founded in 1958 Zhejiang Tongli Heavy Machinery Co, Ltd is an equipment manufacturer very famous in China domestic market for making ball mill, vertical roller mill, rotary kiln and all sorts of cement fertilizer production equipment, even though not as famous as FL Smidth, but Tongli is constantly improving to provide toptier product and service to global Introduction of GGBS vertical roller mill GGBS (Slag product applications) vertical roller mill is the equipment to grind Ground Granulated Blast furnace Slag (GGBFS) into small particlesGGBS (fineness:42004500cm2/g) produced by vertical roller mills are being used to substitute clinker in conventional cement manufacturing, for which the percentage of GGBS usage is typically at Introduction of GGBS vertical roller mill Great WallCHAENG+Slag vertical mill+steelcement industry+High efficiency and environmental protection 4 Pages CHAENG+Perumin34 Mining Convent+CementMine industry+Energy saving 6 pieces of slag pots are shipped again to broaden the international market of CHAENG 3 Pages The kiln tyre and the kiln support roller of CHAENG were successfully The difference between vertical roller mill and ball mill2023年1月10日 Slag Vertical Roller Mill Author: SBM Recently, the installation and commissioning of the production line with an annual output of 80,000 tons of slag powder built by SBM has been completed!Slag Vertical Roller Mill

.jpg)

TRM SERIES SLAG VERTICAL ROLLER MILL TRM SERIES SLAG

trm型矿渣辊磨的型谱 type spectrum of trm slag mill 4 trm型矿渣立式辊磨 ag r mill 磨机规格 trm32 trm43 trm45 trm50 trm53 trm56 磨盘直do,mm 3200 4300 4500 5000 5300 5600Vertical Coal Mill, also known as coal mill, for superfine grinding of raw coal, soft coal specifically for cement, power plant, steel mill and other fields Its special design structure and production process creates the higher production Vertical Coal Mill Great Wall2007年2月1日 Granulated blast furnace slag is moist, abrasive, fine grained and difficult to grind It also needs to be ground very finely There are several grinding systems on the market meeting the requirements for slag grinding, but no other grinding system has gained so much importance during the last decade as the vertical roller mill Polysius roller Slag grinding with the Polysius Roller Mill in ChinaProcess introduction The GRMK cement vertical roller mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions It can save 30% of power per ton compared with traditional ball mill At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little Vertical Cement Mill

.jpg)

Coal vertical roller millVertical roller millPRODUCTTongli

Grinding Rollers: Grinding roller is the main part for crushing and grinding materials The grinding roller is composed of cast steel roller sleeve, forging shaft and wearresistant surfacing bushing The grinding roller is installed on the rocker arm of the coal vertical roller mill, under the action of external force, it is pressed tightly on the material of the grinding table, as the Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mineVertical Roller Mill Great WallVertical Roller Mill for Cement, Clinker, Slag, etc See Carbon black grinding mill, processing line See details Release time 18/12/2014 Clirik Newest super fine HGM100 vertical powder grinding mill See Jaw Crusher gold separator Nitrile Gloves Production Line CG Safety China Freight Elevator Cuplock Scaffolding Steel Rail vertical roller mill clirikultrafine vertical mill, Raymond vertical 2022年5月17日 When processing steel slag, when the specific surfa ce area of the vertical mill reaches 4500cm2/g, the average grinding capacity of each steel slag vertical mill is maintained at 90t/h If a ball mill is selected, at least 6 sets of ball mill systems are requiredShould steel slag grinding choose vrm or ball mill?

Vertical Cement Mill Great Wall

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production This vertical cement mill is widely used in the grinding of cement raw meal, cement clinker, slag, raw coal and other raw materialsSteel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500㎡/kg, which is widely used in cement and concrete admixture, realizing the highvalue resource utilization of steel slagSteel Slag Grinding Plant CHAENG2023年12月4日 In processing plants, size reduction of raw materials is an energyintensive operation A vertical roller mill is a grinding equipment for many industries such as minerals, cement, and ceramics It is also used to grind slag and nonmetallic oresNumerical Investigation of Vertical Roller Mill Operation Using The MPS mill also grinds, dries, calcines, and classifies gypsum without any problem, all in a single machine, for any fineness requested and considering individual requirements The MPS vertical roller mill built to last, reliable and Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

.jpg)

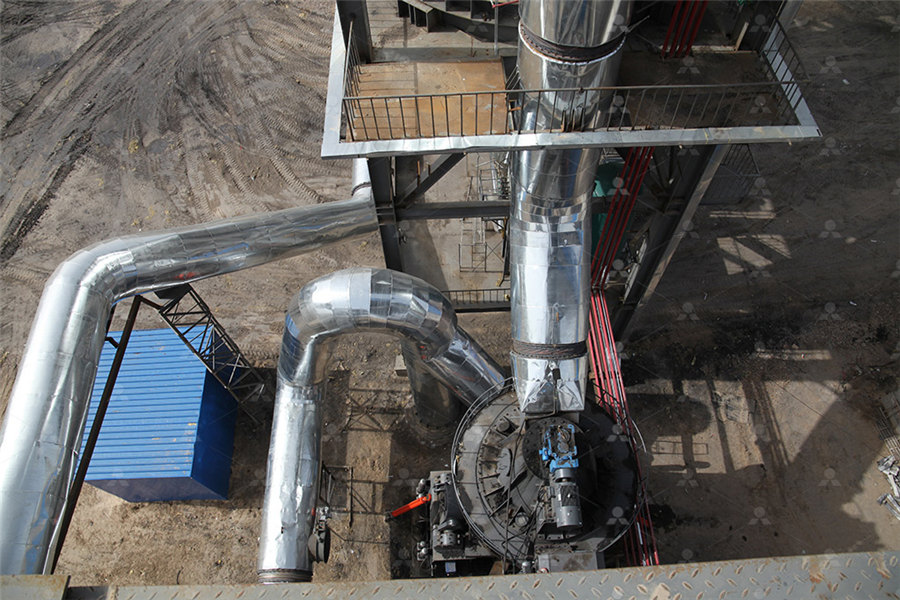

Slag vertical mill

Slag vertical mill is mainly applied in metallurgical and cement industries and is the highend round billet, square billet, etc as well as ladle turret for domestic key steel iron making cranes serve the major domestic steel plants and over 30 foreign metallurgic enterprises and always maintain higher market share CHAENG GRMR Vertical Raw Mill is a type of highefficiency, energysaving, and environmentally friendly grinding equipment for cement raw mill grinding system +79Vertical Raw Mill CHAENGIntroduction : Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesVertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these materialsVertical Raw Milla Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, Brazil2 µm 5 µm Loesche

.jpg)

Vertical Roller Mill MadeinChina

China Vertical Roller Mill wholesale Steel Casting Vertical Roller Mill Hub Cement and Coal Mill Supplier US$ 200010000 / Ton 1 Ton (MOQ) Rotationl Speed: Slag Vertical Mill Application: Construction Materials: Slag Vertical Mill 1 / 6 Favorites China We can provide different types of vertical roller mills in different industries such as cement, steel, and mining The production capacity is 30250 t/h More>>cement plant,ball mill,vertical mill,rotary kiln,slag grinding mill Project One cement factory in China purchased GRMK5341 cement vertical mill from CHAENG in 2012 This vertical mill is the first and the largest cement vertical mill in China, adopting new efficient powder separator, easy to operate and operating stably Its designed output is 220t/h, and the actual output is up to 260t/hVERTICAL CEMENT MILL Xinxiang Great Wall Machinery Co, 2007年11月1日 The first industrialscale vertical roller mill for slag cement, an MPS 3750 C, went into operation in Hannover 25 years ago 1 and is still in operation today (Figure 3) The capacity of this mill ranges from 60t/h slag with 4100cm²/g to 70t/h CEM III A or 45t/h CEM III B with slag content between 50–80% and fineness of 3600cm²/g and 4300cm²/gMPS vertical roller mills for slag and slag cements

.jpg)

vertical roller mill, vertical slag mill, vertical coal mill, Superfine

Vertical Roller Mill Vertical roller mills are mainly engaged in three major fields of coal powder, slag and nonmetallic ore Divided into: vertical coal mill, vertical slag mill, vertical roller mill, and ultrafine vertical mill (ultrafine powder processing) One machine is multipurpose, it can be used for grinding, grading, crushing, drying, etc2023年3月15日 SBM has launched the LM Vertical Grinding Mill which integrates five functions of crushing, grinding, powder selection, Operations such as steel plates’ cutting, bending, planing, Vertical Slag Mill Series LM Vertical Grinding Mill SBM Mill Crusher2007年3月1日 The various solid wastes in the form of slags and sludges that are emerged from steel plants are blast furnace slag, blast furnace flue dust and sludge, Linz–Donawitz (LD) converter slag, LD sludge, LD dust, mill scale, mill sludge, acetylene sludge, etc The solids and liquid wastes generated from a steel plant are shown in Table 1An overview of utilization of slag and sludge from steel industries2011年1月1日 Steel mill slag produced from electric furnaces or open hearths typically contains onethird to onehalf nonhydrated lime (primarily CaO with some MgO) The lime is added as a fluxing agent during steel production Lime can absorb water through hydration for many years after the slag has been createdSteel Mill Slag At Your Construction Site? GeoEngineers

.jpg)

Vertical Roller Mill CHAENG Great Wall Machinery

Steel Slag Vertical Mill The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder Integrating crushing, transporting, grinding and 2012年2月8日 To evaluate the energy potential of steel mill slag, the volume of BF iron and steel production has been examined Figure 2 (elaborated with data from IISI 2009; WSA 2011) shows the evolution of worldwide production of BF primary iron and steel It can be seen that there is an increasing tendency for both products during the last 10 yearsSteel mill slags energy potential: the case of the steel factory of Projects More than 100 customer cases of vertical mill production lines CHAENG vertical roller mill is applied in many large production lines, playing an important rolls in slag, cement and other material production lines, such as: Shanghai Baosteel 1,500,000 tons /year composite powder (slag, steel slag) production line, Henan Meng Electric Group 1,000,000 tons/year GGBFS Vertical Roller MillsChina Steel Rolling Mill wholesale Select 2024 high quality Steel Rolling Mill products in best price from certified Chinese Hammer Mill manufacturers, Ball Mill suppliers, wholesalers and factory on MadeinChinaSteel Rolling Mill MadeinChina

Slag Grinding Vertical Milling Machine Vertical Mill Manufacturer

Our slag vertical mill is designed with a vertical structure, covering a small area and saving production space Its compact design makes the equipment arrangement more flexible and adaptable Additionally, the slag vertical mill adopts sturdy and durable materials and a precise manufacturing process to ensure the stability and long life of the equipmentGrinding Rollers: Grinding roller is the main part for crushing and grinding materials The grinding roller is composed of cast steel roller sleeve, forging shaft and wearresistant surfacing bushing The grinding roller is installed on the rocker arm of the water slag vertical roller mill, under the action of external force, it is pressed tightly on the material of the grinding table, as the Water slag vertical roller mill