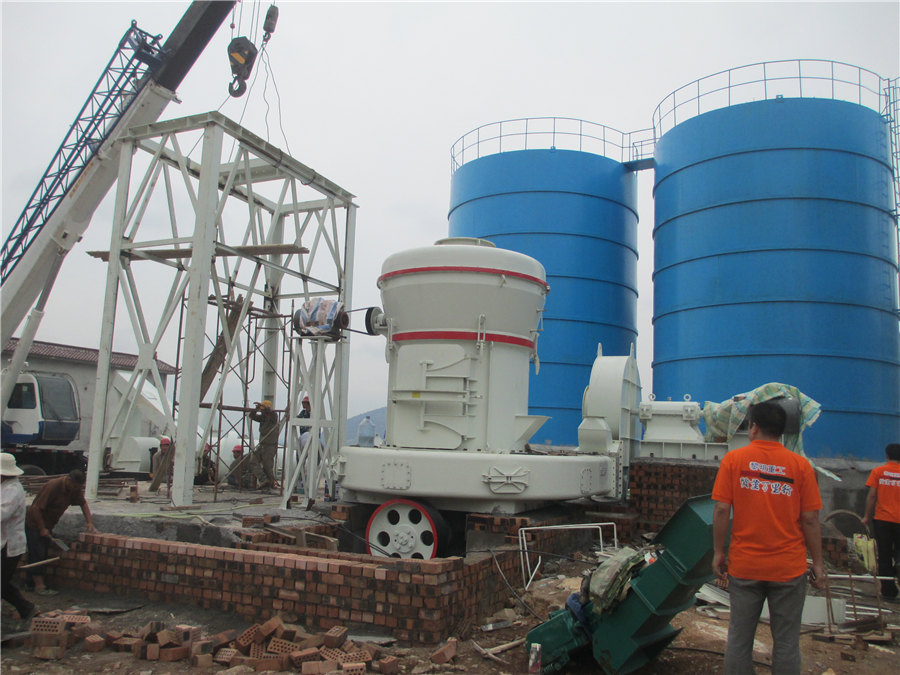

Activated carbon high fine vertical mill

Activated Carbon Ultrafine Vertical Mill

CLUM series activated carbon ultrafine vertical mill is an industrial ore pulverizer that integrates the functions of grinding, powder separation, 展开2024年4月1日 Vertical roller mill is particularly suitable for grinding materials with high moisture content, such as activated carbon Principle of Operation: Vertical roller mill utilizes the Grinding Mills For Activated CarbonActivated carbon Raymond Mill is used to grind activated carbon into fineness between 80400 mesh Guilin Hongcheng has activated carbon cases that use Raymond mills, the Raymond Raymond Mill Machine for Activated Carbon Powder Production2024年6月5日 Working principle of Ultrafine Vertical Mill: The grinding disc is driving by motor through reducer The material falls to grinding disc from the feed opening The materials are High Efficiency Vertical Grinding Roller Mill for Activated Carbon

China Activated Carbon Vertical Mill Manufacturers and Factory

Activated Carbon Vertical Mill Manufacturers, Factory, Suppliers From China, Home; About Us Company Profile; Brand Story; Development History; Corporate Responsibility; Company Activated Carbon Vertical Mill Manufacturers, Factory, Suppliers from China Adhering to the principle of "quality, service, efficiency and growth", we have gained trusts and praises from China Activated Carbon Vertical Mill Manufacturers and Factory HCM provides various types of grinding mills for 800 mesh activated carbon powder, which is a specialized equipment for fine powder production The HCH ultrafine mill and HLMX super Selection Of Grinding Mill Equipment For 800 Mesh Activated Activated carbon requires high pretreatment of water, and the price of activated carbon is expensive Therefore, in wastewater treatment, activated carbon is mainly used to remove trace pollutants in wastewater to achieve the purpose Activated Carbon

Activated Carbon Raymond Mill

The activated carbon Raymond mill should be selected according to the fineness and output of the mineral powder you produce If the output is 035 tons of 80 mesh to 325 mesh powder HCMilling (Guilin Hongcheng)‘s small 200mesh ultrafine mill is mainly a new type of activated carbon Raymond mill represented by the HC series, which is also an ideal equipment choice Application of small 200mesh activated carbon ultrafine mill in 2020年12月30日 Activated carbon Raymond Roller Mill has excellent dependability and economy in maintenance especially in medium fine and fine powder processing The mill equipped with automatic and dustless Activated Carbon Grinding Plant 4 Rollers Raymond Vertical mill merges fine crushing, drying, grinding and powder selecting into a single, which simplifies the production process It has the advantages of high grinding efficiency, low power consumption, large feed particle size, easy Vertical Mill In Cement Plant Cement Vertical Mill

What is a vertical roller mill (VRM)? A Comprehensive Guide to

2023年10月3日 Rocker Arms: The function of the rocker arm device of the cement vertical roller mill is to transmit the pressure provided by the hydraulic cylinder to the grinding roller, so that it can be transformed into the grinding force act on the material bed The rocker arm device is mainly composed of upper rocker arm, lower rocker arm, rocker arm shaft, bearing and Table 3 Power Consumption Of Roller Press Grinding System Overall, we can conclude the three tables: After the longterm operation, although unit raw material grinding power consumption of the cement roller press grinding system is still low, the indexes of the vertical roller mill grinding system are very close to it, among which the output power of the vertical mill and the roller Comparison Of Vertical Roller Mill And Roller Press MillVERTICAL ACTIVATED CARBON FILTER PACKAGED ACTIVATED CARBON FILTER UNIT (PACVSERIES) Based on chemical absorption, Activated Carbon is able to remove LowLevel Odour contaminants and impurities from Sewage Odour The requirement of air leakages and FRP fabrication will be based on AMCA, ASTM, NBSPS69 and other international standardsVERTICAL ACTIVATED CARBON FILTER PURITEQHLM Vertical Mill for Carbon Model: Grinding table median diameter (mm limestone, calcite, feldspar, activated carbon, barite, fluorite, gypsum, clay, graphite, kaolin, wollastonite, quicklime, manganese ore lower energy consumption The power consumption is 40% 50% lower than ball mill The single unit has high throughput, Best HLM Vertical Roller Mill Manufacturer and Factory

.jpg)

Ultra Fine Grinding Mill Ultra Fine Powder Grinder AGICO

What Is Ultra Fine Grinding Mill The ultrafine powder grinding system is a new product independently developed by our company, mainly used to grind and classify various nonmetallic ores in cement plants, such as the grinding of limestone powder, deep processing of pulverized coal, etcThis system is composed of an elevator, airlock device, superfine vertical mill (ultra Why Choose FTM Henan Fote Heavy Machinery Co, Ltd, has been in existence for more than 40 years since its establishment It has four production bases in China and its products are sold to more than 160 countries around the world, including South Africa, Tanzania, Nigeria, Botswana, Uganda, United Arab Emirates, Ghana, Sierra Leone, India, Indonesia, Singapore, Australia, Vertical Roller MillFote Machinery2022年5月24日 Activated carbon Raymond mill Activated carbon Raymond mill, also known as YGM high pressure Raymond mill, is widely used in the grinding and processing of mineral products in the fields of metallurgy, building materials, chemical industry, mining, etcThe fineness of the finished product is 613 microns to 44 microns Discharge particle size: 613 microns44 Coconut Shell Activated Carbon Grinding Mill Machine2023年5月10日 Activated carbon has long been used for filtering contaminants, thanks to its large surface area for adsorption This, and other properties has led to a growing interest in activated carbon and a Activated Carbon: Fundamentals, Classification, and Properties

Preparation and characterization of activated carbon from paper mill

2022年4月27日 Activated carbon is mainly an adsorbent material and for its versatile application in material science, it’s received much attention in recent years Activated carbon can be prepared using different methods such as physical or chemical activation or physicochemical activation As a precursor Paper Mill Sludge was used to prepare activated carbon by direct chemical 2023年4月6日 A general term for carbon materials with strong specific adsorption capacity 2 What equipment is used for the activated carbon pulverizer? Grinding activated carbon is generally in the range of 80400 mesh, and the common fineness is generally 200 mesh and 325 mesh The output is 23 tons per hour For such equipment, we can choose the What is an activated carbon grinding millCocoanut shell activated carbon Vertical mill is mainly applied to noninflammable, nonexplosive and brittle materials with Mohs’ hardness scale under seven Cocoanut shell activated carbon Vertical mill has the similar working principle as High pressure suspension grinding equipment, but its grinding device is fixed with 10001500kg Cocoanut shell activated carbon machineryYGM Vertical millPREPARATION AND CHARACTERIZATION OF ACTIVATED CARBON FROM WASTE SAWDUST FROM SAW MILL D Shrestha, G Gyawali and A Rajbhandari (Nyachhyon) Journal of Institute of Science and TechnologyPREPARATION AND CHARACTERIZATION OF ACTIVATED CARBON

.jpg)

China Activated Roller Mill, Activated Roller Mill Wholesale

China Activated Roller Mill wholesale Select 2024 high quality Activated Roller Mill products in best price from certified Chinese Rice Mill manufacturers, Roller Machine suppliers, wholesalers and factory on MadeinChina2006年11月1日 The chemically activated carbons were characterized by measuring iodine and methylene blue number and specific surface area The activated carbon prepared from char of paper mill sludge in this study had maximum iodine and methylene blue number of 7260 mg/g and 1520 mg/g, and specific surface area of 1,0020 m2/g, respectively[PDF] Preparation of activated carbon from paper mill sludge by Materials: Raymond mill grinds minerals like gypsum and limestone, while ball mill processes metal ores and cement clinker b Output: Raymond mill produces less than ball mill but uses less power c Dust pollution: Raymond mill has cleaner dust control, whereas ball mill is larger, harder to manage, and causes more dust pollution dHighefficient Raymond Mill Fote MachineryActivated carbon (also called activated charcoal, activated coal or active carbon) is a very useful adsorbent Due to their high surface area, pore structure (micro, meso and macro), and high degree of surface reactivity, activated carbon can be used to purify, dechlorinate, deodorize and decolorize both liquid and vapor applicationsActivated carbon, what is activated carbon, applications

Coconut shell activated carbon processing and grinding mills

2022年5月26日 Coconut shell activated carbon mills 1 Coconut shell activated carbon Raymond mill Coconut shell activated carbon Raymond mill also known as YGM high pressure suspension grinding mill is suitable for processing various nonlammable and nonexplosive mineral materials with Moh's hardness less than 6 and humidity less than 6%LUM ultrafine vertical mill is designed for nonmetallic mineral ultrafine grinding equipment For limestone, SBM has developed all kinds of coarse, fine and ultrafine grinding mills to meet customers'demands for powder production from coarse powder(03mm) Activated carbon processing Activated carbon Slag processing SlagGrinding Mill ultrafine grinding mill, vertical ultrafine mill Coconut shell activated carbon uses coconut shell as raw material It is made by carbonization, activation, and grinding process Activated carbon grinding mills can grind coconut shellactivated carbon into fine and ultrafine powderCoconut shell activated carbon preparation process and coconut Activated Carbon Rotary Kiln Kiln Body Length: 40 – 95 m Production Capacity: 180 – 10,000 t/d Motor Power: 55 – 950 * 2 kW/h Application: Activated carbon production, carbonization, activation, waste activated carbon reactivationActivated Carbon Rotary Kiln Carbon Reactivation

.jpg)

Application of Vertical Roller Mill in Cement Production

This article will explore the application of vertical roller mills in the cement industry, including their benefits, efficiency, and ecofriendly features Understanding Vertical Roller Mill Technology Vertical roller mill (VRM) is a The crushed small pieces of activated carbon are sent to the silo by the elevator, and then sent to the mill grinding chamber for grinding evenly and quantitatively by the vibrating feederFine powder processing can choose LM vertical mill, MTW European mill, 5X European intelligent mill; The ultrafine powder processing generally adopts LUM ultrafine vertical mill, MW ring roller Activated carbon processing plant, Activated carbon grinding 2022年9月30日 Recycling carbon black grinding mills (pyrolysis carbon black mills) include Raymond mills, pendulum mills, vertical mills, and ultrafine vertical mills If the rCB of 80325 mesh is processed within 20 tons in one hour, it is recommended to choose an economical pulverizer (Raymond mill, pendulum pulverizer)Recovered Carbon Black rCB Processing Grinding Mill Machines2020年3月1日 Activated carbon (AC) is a notable adsorbent for the treatment of wastewater owing to its pronounced porous structure, diverse functional groups, high surface area, high adsorption capacity Solventfree synthesis of magnetic biochar and activated carbon

.jpg)

Methods for preparation and activation of activated carbon: a

2020年1月4日 Activated carbon refers to a wide range of carbonised materials of high degree of porosity and high surface area Activated carbon has many applications in the environment and industry for the removal, retrieval, separation and modification of various compounds in liquid and gas phases Selection of the chemical activator agent is a major step controlling the The uses of activated carbon grinding machine: Activated carbon grinding machine is mainly used in mining, building materials, chemical, metallurgical and other industries It can process stone materials that moisture content less than 5%, Mohs hardness under 6 levels, such as kaolin, limestone, talc, barite, dolomite, calcite, marble, activated carbon, bentonite, mica, graphite, Activated Carbon Grinding Machine MillWe have several decades of experience in manufacturing super fine grinding mill HLMX series super fine mill is independently developed by our engineers which is used for large scale production of nonmetallic powders This 2500 mesh superfine powder grinding mill using static and dynamic separators which is able to produce adjustable fineness HLMX 2500 Mesh Superfine Powder Grinding MillDownload scientific diagram Five types of vertical roller mills: Quadropol, FRM, MPS, Atox or OK mills that can be used to grind aluminosilicate precursors [71,105108] from publication: A Five types of vertical roller mills: Quadropol, FRM, MPS, Atox or

.jpg)

High Efficiency Vertical Grinding Roller Mill for Activated Carbon

High Efficiency Vertical Grinding Roller Mill for Activated Carbon Shell Coconut Shell Bamboo Carbon Black Powder Production Line, Find Details and Price about Ultra Fine Vertical Roller Mill Grinding Mill from High Efficiency Vertical Grinding Roller Mill for Activated Carbon Shell Coconut Shell Bamboo Carbon Black Powder Production Line Shanghai Clirik Machinery Co, LtdThe crushed small pieces of activated carbon are sent to the silo by the elevator, and then sent to the mill grinding chamber for grinding evenly and quantitatively by the vibrating feederFine powder processing can choose LM vertical mill, MTW European mill, 5X European intelligent mill; The ultrafine powder processing generally adopts LUM ultrafine vertical mill, MW ring roller Activated carbon processing plant, Activated carbon grinding 2023年9月1日 Viable sources for biochar and activated carbon (AC) due to high carbon content at elevated temperatures to form minuscule threedimensional structures with a lateral extension of 2–5 nm and a vertical height of 12 nm (turbostratic crystallites) The feedstock type A combination of fine and large pores can be observed in Production of biochar and activated carbon from oil palm AGICO is a professional manufacturer of activated carbon making machines We can provide customers with EPC solutions from five aspects: biomass carbonization, carbon activation, activated carbon regeneration, activated carbon acid washing and water washing, and crushing and screening! We mainly use the physical production process, taking air and water vapor as Activated Carbon Plant Activated Carbon Machine For Sale

Best HLM Vertical Roller Mill Manufacturer and Factory

HLM Vertical Mill for Carbon Model: Grinding table median diameter (mm limestone, calcite, feldspar, activated carbon, barite, fluorite, gypsum, clay, graphite, kaolin, wollastonite, quicklime, manganese ore lower energy consumption The power consumption is 40% 50% lower than ball mill The single unit has high throughput, a Corresponding author: paat77@gmail Burner Characteristics for Activated Carbon Production Supaat zakaria1,a, AM Leman1, Dafit Feriyanto1 ,Azmarini A Nazri2, NM Sunar1 and Mohd Najib Mohd Salleh3 1Faculty of Engineering Technology, Universiti Tun Hussein Onn Malaysia (UTHM) 86400, Parit Raja, Batu Pahat, Johor, Malaysia 2Department of Mechanical Burner Characteristics for Activated Carbon Production2022年5月24日 The optimal coal gasification fine slag activated carbon (GCFSAC) has large BET surface area of 11518 m2/g and high total pore volume of 0923 cm3/g Owing to the hierarchical porous structures with large mesopore volume, CGFSAC exhibits high charge storage capacity and energy density, as well as excellent cycling stabilityPreparation of hierarchical porous activated carbons for high AGICO is a leading manufacturer of activated carbon making machines We are experienced and specialized in supplying production solutions for customers, such as biomass carbonization, carbon activation, activated carbon washing, activated carbon regeneration, etc The activated carbon rotary kiln is our major product and the key equipment for activated carbon productionRotary Kiln For Activated Carbon Production

.jpg)

Vertical Grinding Mill: How it Works, Application And Advantages

Vertical Grinding Mill’s are used to grind various insulation materials, phosphate rocks, cement, activated clay or carbon, limestone, marble, glass, plaster, etc It enables the grinding and processing of more than 280 kinds of nonflammable and nonexplosive materials with a hardness lesser than 7 and humidity less than 6%The vertical cement mill is largescale cement grinding machine With advantages of energyefficient and stable quality, vertical roller mill is widely applied to many industries, such as cement, power, metallurgy, chemical and nonmetallic mining industry and etc As a typical type of Cement Mill, vertical cement mill set crushing, drying, grinding, grading transportation in one, it grind Vertical Cement Mill