Steel slag grinding production process

Comprehensive utilization of steel slag: A review ScienceDirect

2023年5月15日 Steel slag is the main solid waste produced in the process of steelmaking Chinese steel slag has the characteristics of large output and low utilization Most of the steel Steelmaking slag, or steel slag, is a byproduct from the production of steel during the conversion of hot metal to crude steel in a basic oxygen furnace, or during the melting of scrap in an EAFSteelmaking Slag an overview ScienceDirect Topics2007年3月1日 Great amounts of slags from steel plants are produced through basic oxygen furnace and LD furnace The main purpose of LD process is to convert the molten pig iron and An overview of utilization of slag and sludge from steel industries2023年8月22日 It is found that the removal rate of hardtogrind minerals in steel slag is the highest when steel slag enters magnetic separation particle size of 1 mm and magnetic field The Effect of Removing HardtoGrind Minerals from Steel Slag on

The Steelmaking Transformation Process and Its Consequences for

2024年8月19日 The main challenge of the European steel industry for the next decade is the steel production transformation process Many steel producers aim to avoid their CO 2 2004年5月14日 This paper reviews the production, processing, and characteristics of steel slag, and its use as a cementing component in different cementing systems The chemical Steel Slag—Its Production, Processing, Characteristics, and 2019年10月29日 Iron slag (slag of blast furnace BF) and steel slag (slag of basic oxygen furnace BOF, and electric arc furnace, EAF) are two types of slag generated during iron and steel production processes The composition of the The potential utilization of slag generated from ironThese metal constituents can be recovered from slags by employing mineral processing techniques like crushing, grinding, magnetic separation, eddy current separation, flotation, leaching, and/or roastingAn Overview of Precious Metal Recovery from Steel

.jpg)

Comprehensive Utilization Technology of Steel Slag

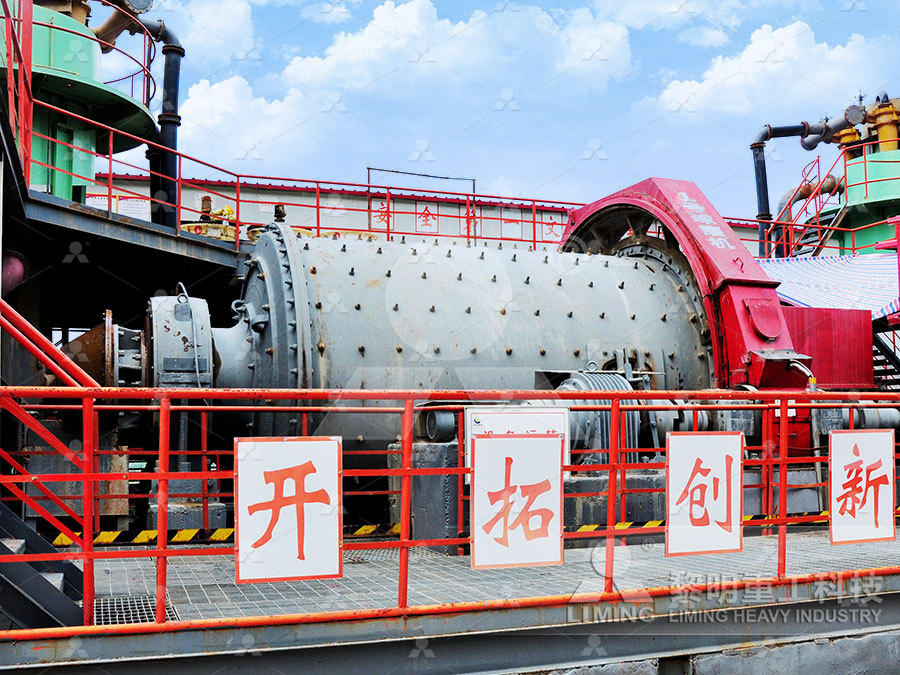

2019年5月23日 Fine grinding of steel slag is helpful for “exposing” iron particles in steel slag, and these are magnetically separated to achieve the purpose of reducing the amount of iron in Steel slag is a solid waste of the steel industry, produced during steel production Three types of slag, namely electric arc furnace (EAF), basic oxygen furnace (BOF), and LinzDonawitz processed slag (LDslag) are the steel industry An Overview of Precious Metal Recovery from Steel Wet process: The dryprocess steel slag production process does not need to consume precious water resources After the steel slag is crushed, rod milled, and magnetically separated, the slag steel can be selfgrinding to obtain grade A and B scrap steel The iron content of the slag powder can reach more than 55%Steel slag recycling crushing and grinding production line2023年8月25日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the continuous use of residue yards Application of Steel Slag as an Aggregate in Concrete

.jpg)

Chemical, Mineralogical, and Morphological Properties of Steel Slag

2011年10月26日 The slag generated from a steelmaking cycle is later processed, and the final product after processing is referred to as basicoxygenfurnace slag (BOF slag) The chemical reactions occurring during the removal of impurities determine the chemical composition of the basicoxygenfurnace slag [ 1 , 3 , 5 ]2016年10月28日 In order to determine the HGP in the grinding process, the steel slag powder after 10, 20, 30, 40, 50, 60, and 70 min grinding were screened with a 09 mm squarehole(PDF) Comparison of Grinding Characteristics of Converter Steel Slag 2016年10月28日 The converter steel slag cannot be widely used in building materials for its poor grindability In this paper, the grinding characteristics of untreated and pretreated (ie, magnetic separation) steel slag were compared Additionally, the grinding property of pretreated steel slag was also studied after adding grinding aids The results show that the residues (ie, oversize Comparison of Grinding Characteristics of Converter Steel Slag 2024年3月12日 The global steel industry, as per the International Energy Agency (IEA), consumes about 20% of industrial energy Projections indicate a 30% increase in global steel consumption by 2050, resulting in a continual surge in global steel slag production Steel slag recycling brings significant economic and environmental benefits to societySteel Slag Recycling: The Definitive Processing Solution

A Visual Guide: Steel Making Process Chart Cabaro Group

2024年3月17日 The steel making process chart is a graphical portrayal that details each stage of steel production, turning abstract sequences into a tangible roadmap for comprehensive understanding It serves as a guide for those looking to grasp each integral step in turning raw materials into finished steel2023年5月15日 Steel slag is the main solid waste generated in the steelmaking process, accounting for 15 to 20% of crude steel output [1]China's crude steel output in 2021 was 1035 billion tons [2], more than half of the global crude steel output (19505 billion tons) [3], and the steel slag output exceeded 120 million tonsIn contrast, the comprehensive utilization rate of Comprehensive utilization of steel slag: A review ScienceDirectTable 1 Production and sales of steel slag (2010Fy) Production Sales Japan NSC Japan NSC Pig iron 82,915 32,180 Crude steel 110,792 32,716 Production Blast furnace Air cooled 5,085 1,495 4,362 1,000 The iron/steel slag processing flow is schematically shown in Fig 2Processing and Reusing Technologies for Steelmaking Slag2023年9月1日 Ever wondered how steel, a cornerstone of modern civilization, is made? This comprehensive guide dives into the intricate steel production process, from raw materials to finished products Discover how elements like Steel Production Process: The Comprehensive Guide

.jpg)

Iron and Steel Slag USGS Publications Warehouse

crude (pig) iron production and steel furnace slag may be estimated to be 10% to 15% of raw steel production In 2020, world iron slag production was estimated to be between 310 million and 380 million tons, and steel slag production was estimated to be between 180 million and 270 million tons World Resources : Not applicable Substitutes :Global crude steel production in 2018 was approximately 18071 Mta 708 % of the current crude steel production is accounted for by the BOF process, 288 % by the EAF process (Fig 3) and only 04 % by other processes such as the Slag recycling recovery2013年9月1日 The specific surface area of steel slag is generally between 300 and 500 m 2 /kg when it is used as a mineral admixture for cement or concrete production Some studies showed that, in this range, increasing the specific area of steel slag was beneficial to its activity [26], [27], [28]It is interesting to know the activity of steel slag with even higher specific surface areaCementitious properties of superfine steel slag ScienceDirectTypical morphology of steel slag [](a) BOF steel slag(b) EAF steel slag(c) LF steel slagBOF steel slag is the solid waste produced in the converter steelmaking process, and its discharge is approximately 100–150 kg per ton of BOF steel [20,21,22,23]BOF steel slag commonly has a grayishwhite appearance and a vesicular nature, with many noninterconnected pores []Application of Steel Slag as an Aggregate in Concrete Production

.jpg)

Global Slag Knowledge Base

Paper 18: Dry granulated BF sand: A groundbreaking and sustainable Innovation – Production process, product grinding and building materials investigations: Alexander Fleischanderl: Thomas Fenzl (speaker): Primetals; Holger Wulfert Paper 2 Economic Aspects of steel slag processing with Slag Atomizing Technology: Sangtae Cha: Ecomaister 2023年7月21日 Introduction China is the world's largest steel producer, with the China Iron and Steel Association estimating that the country's crude steel production in 2022 will be 935 million tonnes [Citation 1]Steel slag mainly refers to the blast furnace slag and converter slag produced in the process of iron making and steel making, and with the increase of steel production, the Comprehensive utilisation of blast furnace slag Taylor Francis 2021年6月7日 The main mineral composition of steel slag is olivine, merwinite, C 2 S, C 3 S, C 4 AF, C 2 F, RO phase (CaOFeOMnOMgO), fCaO and Fe Due to the presence of C 2 S, C 3 S, C 4 AF and C 2 F, steel slag could show a weak cementitious performance, which could be considered as supplementary cementitious material after processing However, the bad grind Effect of wetgrinding steel slag on the properties of Portland 2024年2月26日 Steel slag and GBFS are wastes generated during the steel and iron smelting process, characterized by their considerable production rates and extensive storage capacities After grinding, they are often used as supplementary cementitious materials However, the intrinsic slow hydration kinetics of steel slag–GBFS cementitious material (SGM) when Feasibility of Preparing Steel Slagndash;Ground Granulated Blast

What is a ultrafine slag grinding plant? ultrafine slag grinding

2023年10月19日 In late July 2023, Guangxi Guigang Hengyao steel Co, Ltd successfully completed the production and acceptance inspection of their annual 300,000ton ultrafine highperformance cementitiousSteel slag is a byproduct generated during the steelmaking process As the largest steel producer in the world, China produces over 100 million tons of steel slag annually, accounting for approximately 15–20% of crude steel production (Rui et al 2022, Shi et al 2022)After steelmaking, the slag is placed in a slag heap and subjected to magnetic separation to recover Activation technology of steel slag for concrete exposed to 2024年1月31日 Kang W, Xiaoli L, Chao J, et al Optimal tracking control for slag grinding process based on adaptive dynamic programming Acta Automatica Sinica 2016; 42: 1542–1551 Wang K, Li X, Jia C, et al Tracking control of slag powder production process based on adaptive dynamic programming Acta Automatica Sinica 2016; 24: 1542–1551Intelligent process control system for predicting operating Events, Trends, and Issues: The availability of steel slag is tied closely to the rates of raw steel production and the cost consideration of recovering slag for use in lowvalue downstream applications The majority of US steel slag production is from electric arc furnaces, which accounted for approximately 71% of US steel production in 2021IRON AND STEEL SLAG USGS Publications Warehouse

.jpg)

Steel Slag Processing Plant Equipment Selection

2023年12月27日 The purpose of the steel slag process is to recover useful ironcontaining components, including bulk iron, granular iron, Prev Previous Feldspar Powder Crushing Grinding Production Line Equipment Next Limestone Crushing And SandMaking Plant Next Contact Us Now Your Name Your Phone/WhatsApp Project Location 2020年9月24日 With the rapid development of China’s steel industry, rising rates of steel production have led to the increase of steel slag emissions Steel slag is a kind of industrial solid waste produced in the process of iron and steel smelting, and its emission is about 15 wt%–20 wt% of crude steel output []According to the data released by the World Iron and Steel Sustainable Utilization of Steel Slag from Traditional Industry and In the production process, slag ball mill can not only grind the slag separately, but also mix grinding with cement clinker and gypsum It has been widely used in cement industry For the grinding equipment of slag materials, we also produce watergranulated blast furnace slag ball mill and steel slag ball mill, which are used for grinding Blast Furnace Slag Ball Mill2024年6月1日 Steel slag, particularly EAF, KR, and BOF slags, exhibits poor grinding efficiency compared to BFS and LF slag due to metalFe, FeO, and Fe 2 O 3 [112] Notably, metalFe poses a significant challenge, as it can damage milling machines due to its high strength [70] Consequently, grinding steel slag typically consumes more energy than BFSUtilization of steelmaking slag in cement clinker production: A

.jpg)

Pilot production of steel slag masonry blocks University of

Figure 1 shows the steel slag in slag yard at the plant The chemical compositions of steel slag obtained by the Xray fluorescence (XRF) spectrometry are shown in Table 1 The main oxides are calcium oxide, iron oxide and silica oxide 22 Steel slag grinding Steel slag needs to be fine enough in order to be able to react with carbon dioxide2016年2月5日 The quality of raw materials (iron ore, coal, and coke) has a clear impact on the carbon emissions of the hot metal production in steel making So far, very little work has been done to measure and quantify this impact Yet for benchmarking, technology choice and general carbon optimization are important elements The total slag production of a blast furnace gives The Carbon Cost of Slag Production in the Blast Furnace: A2018年9月26日 Because of the high hardness and poor wear resistance of steel slag, the potential cementing property of steel slag can not be effectively exerted, and the utilization rate of steel slag Is low In order to improve the performance and grinding efficiency of steel slag powder, different grinding aids were added in the process of steel slag grinding in laboratory Research of the Effect of Different Dosage of Grinding Aids on and dry processing of steel slag Loesche Mill type LM 15200 under construction Loesche Mill type LM 15200, Wolica, Poland, 2009 3 1 10 11 2 12 3 13 4 14 5 15 6 16 7 17 8 18 9 19 proportion of finely ground dust as defined filler product Dry grinding Loesche DGL Complete dry grinding of the mineral matrix, (metal recovery: > 95 %) Loesche Mills for Metal Recovery and Filler Production from Steel Slag

.jpg)

Slags from steel production: Properties and their

2013年7月1日 During steel production a considerable amount of slags is produced In addition to its usual processing, as recycling in device for steel production and preparation of aggregates, it is also 2021年12月7日 After this grinding process is complete, parts are passed over by a highdensity steel wire brush, removing any remaining sharp edges and leaving behind a beautifully finished product every time If you want to fully capitalize How to Remove Slag From Steel Slag Removal The Effect of Removing Hard‑to‑Grind Minerals from Steel Slag on Ecient Grinding and Hydration Activity Jianqi Zhao1,2 Wentao Hu 1 Wen Ni 1 Jiuchuan Guo1 Wan Zhu 1 Steel slag (SS) is a byproduct of steelmaking process, accounting for 15–20 wt% of crude steel [, 21] Statistics show that the global crude steel The Effect of Removing HardtoGrind Minerals from Steel Slag 2021年10月1日 Steel slag is a solid waste derived from the steelmaking process, which accounts for approximately 15% of the total crude steel output (Furlani et al, 2010; Pang et al, 2016)By 2016, approximately 832 million tons of steel were produced in China with an annual output of more than 100 million tons (Hasanbeigi et al, 2016), which exceeded half of the total Use of steel slag as sustainable construction materials: A review

(PDF) Feasibility of Preparing Steel Slag–Ground Granulated Blast

2024年2月26日 Steel slag and GBFS are wastes generated during the steel and iron smelting process, characterized by their considerable production rates and extensive storage capacities2023年8月25日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the (PDF) Application of Steel Slag as an Aggregate in Concrete Production 2024年4月24日 16th Global Slag Conference, Exhibition Awards 2024 23 24 April 2024, Dubai, UAE The 16th Global Slag Conference has successfully taken place in Dubai, UAE, with 175 registered delegates from 32 countries, two field trips to slag grinding plants and the Global Slag Awards dinner at a spectacular camp on the edge of the Arabian DesertReview of 16th Global Slag Conference 2024GGBS(Granulated Blastfurnace Slag) cement It is produced by grinding premium quality Granulated Blastfurnace Slag, a byproduct of steel manufacturing process,consisting essentially of silicates and aluminosilicates of calcium and other bases, is formed when molten iron blastfurnace slag is rapidly chilled (quenched) by immersion in water It is a granular product with Slag Grinding Plant Great Wall

.jpg)

Granulation and Heat Recovery from Metallurgical Slags

2019年12月9日 Production Rates Table 1 summarizes the slag rates for pyrometallurgical production of various metals, together with their enthalpy values, estimated based on data available for the year 2016 As seen, the production of slag has exceeded 750 million tonnes per year, of which 85% is only from the iron and steel and related industries