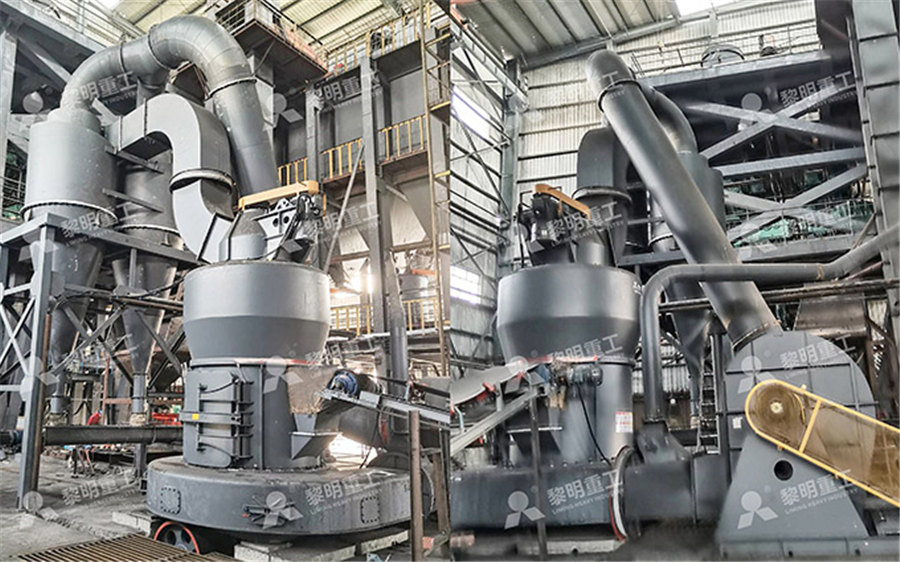

Lithium ore grinding machine limestone production line

Lithium Ore Production Line TAYMACHINERY

Lithium ore production lines are crucial for extracting and processing lithium, which is vital for various applications, particularly in modern technology and energy sectors Here are the 2021年5月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically Processing of lithium ores: Industrial technologies and case studies The two primary production methods for lithium – brine evaporation and hard rock (eg spodumene) processing – come with their own unique set of challenges We have more than Lithium processing technology Complete solutions that FLSmidthThe production line for roasting and acidizing lithium ore with lepidolite, spodumene and other raw materials configured by our company has excellent product performance, stable production Lithium Extraction Lithium Production Line Lithium Calcination

Processing of lithium ores: Industrial technologies and case studies

2021年2月1日 In modern Russian realities, roasting and hydrometallurgical processing of ores and concentrates using sulfuric acid and limesoda methods seem to be practically 2021年5月1日 This paper focuses on the research progress of extracting lithium from spodumene, lepidolite, petalite, and zinnwaldite by acid, alkali, salt roasting, and chlorination Processing of lithium ores: Industrial technologies and case studies 2024年4月8日 So, what equipment is good for crushing, grinding, and separating lithium ore? When crushing lithium ore, it usually uses a jaw crusher (coarse crushing) and a singlecylinder hydraulic cone crusher (medium and Selection Of Lithium Ore Processing Plant EquipmentThe lithium ore beneficiation process includes crushing and screening, grinding and grading, sorting, concentrate dehydration and other stages In this article, we will take you to understand the beneficiation equipment required for each A Comprehensive Guide to Lithium Processing

Lithium Ore Production Line TAYMACHINERY

Here are the primary uses of lithium ore production lines: 1 Battery Manufacturing Lithiumion Batteries: The most significant use of lithium is in the production of lithiumion batteries, which power electric vehicles (EVs), portable electronics (smartphones, laptops, tablets), and renewable energy storage systems2023年4月23日 Lithium (Li) ore is a type of rock or mineral that contains significant concentrations of lithium, a soft, silverwhite alkali metal with the atomic number 3 and symbol Li on the periodic table Lithium is known for its Lithium (Li) Ore Minerals, Formation, DepositsHere are the primary uses of lithium ore production lines: 1 Battery Manufacturing Lithiumion Batteries: The most significant use of lithium is in the production of lithiumion batteries, which power electric vehicles (EVs), portable electronics (smartphones, laptops, tablets), and renewable energy storage systemsLithium Ore Production Line TAYMACHINERY2022年4月20日 Or further grinding to form limestone powder, which is widely used in building materials, highways, metallurgy, chemical industry and other industries +17 Limestone crushing and grinding production line 20/04/2022 admin Kalium ore powder grinding mill machine Hot News PEX Jaw Crusher; Ultra Fine Powder Mill Limestone crushing and grinding production line SBM

.jpg)

Limestone Grinding Mill Plant TAYMACHINERY

The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing 2024年1月23日 550TPH Granite Aggregates Production Line in Henan; 450TPH Limestone Gravel Production Line in Mexico; 300TPH Feldspar Gravel and Sand Production Line in Gansu; 200TPH Basalt Aggregate Production Line in Sri Lanka; 300TPH Coal Gangue Crushing Production Line in Colombia; 180TPH Waste Rock Crushing Production Line in AustraliaLimestone crushing and screening production line introduction2023年10月9日 The processing of lithium ore involves several steps, from mining and extraction to refining and purification The machinery and equipment used in a lithium ore processing plant may vary depending Lithium ore processing plant machinery and equipment LinkedInComplete Spodumene Lithium Ore Crushing Grinding Equipment Concentration Plant Lithium Ore Processing Line Gold Mining Separator Processing Plant Copper Ore Production Line Flotation Machine $10,00000 $40,00000 Min order: 1 set 500TPD Mini Cement Clinker Grinding Plant For Limestone Production Plant $40,00000 $75,00000 Complete Spodumene Lithium Ore Crushing Grinding Equipment

Selection Of Lithium Ore Processing Plant Equipment

2024年4月8日 The lithium processing plant equipment includes a jaw crusher, a fine jaw crusher, a storage bin, a ball mill, a hydraulic cyclone, a mixing tank, and a flotation machine The hydraulic cyclone and ball mill constitute a closed circuit grinding and classification cycle, which improves the efficiency and fineness of classification grindingLITHIUM PRODUCTION LINE Processing capacity: 100020000 t/a Raw material: Spodumene, lepidolite, lithium ore Rotary kiln diameter: 1545m The production line for roasting and acidizing lithium ore with lepidolite, spodumene and other raw materials configured by our company has excellent product performance, stable production condition and easy operation, which has Lithium Extraction Lithium Production Line Lithium 2022年12月26日 Lithium ore generally needs to be processed by crushing, grinding, flotation and some auxiliary equipment to get finished products The specific processing process is: lithium ore enters jaw crusher for coarse crushing and then the material is crushed by cone crusher for a second time, and then enters the vibrating screen for screeningLithium ore is how to process crushing, grinding equipment?Spodumene ores are typically consolidated from ore comprising 1–15% Li20 to a concentrate of about 6–65% Li20 To achieve this, the ore passes through a typical concentratortype plant, flowing from crushing and grinding, to gravity separation and DMS, to flotation, and then to the final dewatering of the concentrateLithium processing technology Complete solutions that

.jpg)

Production Line of Lithium Carbonate Used Calcium

Product Introduction Grinding Mill machine Application: Feed Size: 1020mm Finished Size: 1503000mesh Capacity: 0430T/h Materials: HGM series of Limestone mining machine is mainly applied to the processing of Mohs Project Name: Ultrafine Vertical Limestone Powder Production Line Finished fineness: 1500 mesh Finished product use: The main filler in rubber industry, plastic industry, paper industry, paint industry, coating and feed industry Optional equipment: Limestone ultrafine vertical mill, Crusher, Bucket Elevator, Vibrating Feeder Project Benefits 1 Highquality particle shapeChina Henan limestone ultrafine vertical mill production lineThe barite grinding production line is a production line specially used to process barite raw ore into fine barite powder; it has the advantages of simple configuration, stable operation, high output, low energy consumption, and the fineness of the finished product meets the requirements Barite is a pure natural stone with high practical value in mining, machinery, metallurgy, Barite Grinding Production Line TAYMACHINERYThe graphite ore mining production line plays a crucial role in efficiently extracting and processing graphite, ensuring its availability for various industrial, technological, and consumer applications The versatility and unique properties of graphite make it Graphite Ore Mining Production Line TAYMACHINERY

.jpg)

Processing of lithium ores: Industrial technologies and case studies

2021年2月1日 Although lithium extraction from salt lake brine in China has shown a rapid growth trend in recent years, its lithium production is still dominated by ores (spodumene and lepidolite), accounting 2024年1月18日 Limestone is the primary raw material for manufacturing cement, lime, and carbide and is an essential flux limestone in the metallurgical industry Highquality limestone, after ultrafine grinding, is widely used in the production of paper, rubber, paint, coatings, pharmaceuticals, cosmetics, feed, sealing, bonding, polishing, and other productsHow to choose a limestone grinding mill SANDMINE2024年7月9日 SBM's lithium ore grinding machines are mainly divided into four categories: Raymond mill, ultrafine mill, ball mill and vertical mill +17 [ protected] Different types of mills are suitable for different ores and production requirements Lithium OreLithium Ore Grinding Mills SBM Ultrafine Powder Technology2023年12月6日 Advantages of HGM series ultrafine grinding production line Focus on high production capacity and output requirements (1) PLC intelligent frequency conversion control cabinet is fully controlled, and intelligent frequency regulation ensures continuous 24 Limestone ultrafine grinding production line customer site

Limestone Powder Production Line Buy Limestone,

Limestone Powder Production Line, find complete details about Limestone Powder Production Line, Limestone, mining machine, Grinding Mill Guilin Hangda Mining Machinery Co, Ltd Home; And then, the crusher breaks 2023年6月19日 There will be three raw material bins in the system: Limestone clay, pure limestone, sand and Iron ore 06Raw material grinding and exhaust gas treatment A vertical roller mill with an exterior circulating system is 2000T/D Cement Production Line GHANAPrice Silica Quartz Sand Making and Washing Production Line The capacity of it generally is from 100t/h to 250t/h Materials: granite, basalt, barite, limestone, quartz, marble, sandstone, cobble stone, iron ore, copper, gold, bauxite Sand production line Zoomjo Group2024年1月29日 As limestone powder has numerous applications across various industries, selecting the appropriate limestone grinding machine is essential The choice depends on several factors Firstly, it's important to clarify your processing requirements, including the desired fineness of the powder, production capacity, and quality standardsHow to choose limestone grinding mill? SANDMINE

.jpg)

Limestone crushing, sand making and grinding process

2022年7月20日 Process flow of limestone sand production line 1 Process flow of limestone manufactured sand Sand making: Through the crushed limestone, part of it is directly sent to the stockpile as a finished product, and the other part is crushed and made sand by the sand making machine Screening: The vibrating screen is also responsible for distinguishing the finished 2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine 2023年9月19日 Limestone grinding mill Material: Limestone Finished product particle size: 01730044mm Processing capacity: 8176t/shift Applicable materials: calcium carbonate crushing processing, gypsum powder processing, power plant desulfurization, nonmetallic ore pulverizing, coal powder preparation, etc Main limestone grinding machines Vertical roller Limestone Grinding Mill That You Need To Know Mortar PlantLimestone grinding mill production line and the grinding workshop of the limestone grinding machine can basically realize unmanned operation, In addition to ultra fine grinding mills, we can provide the configuration of the entire ore milling production line All accessories, crushers, powder modifiers, Limestone Ultrafine Grinding Mill

.jpg)

Ball Milling in Lithium Ore Processing: A Comprehensive Guide

2023年5月27日 Overall, the role of ball milling in lithium ore processing is crucial to the production of highquality lithium products With its ability to improve the efficiency of lithium extraction and purification, as well as its potential in the synthesis of lithiumion batteries, ball milling is a promising technology that will continue to play a key role in the future of lithium The process flow of the sulfuric acid method lithium carbonate vertical roller mill production line is as follows: ① The spodumene or lepidolite ore is transformed and roasted, and after cooling, it is transported to the vertical roller mill for fine grinding to achieve a certain concentrate particle ②The ground powder is mixed with concentrated sulfuric acid with a certain acidtoore Process Flow Of Lithium Carbonate Vertical Roller Mill Production LineStone crushing production line is a combination of special equipment used for manufacturing building materials or industrial materials, including vibrating feeder, jaw crusher, cone crusher, impact crusher, hammer crusher, sand making machine, vibrating screen, belt conveyor and other equipment The maximum designed output can reach 3000t/dStone Crushing Production Line2024年1月20日 Our factory can provide the complete the solution with complete equipment for high grade lithium carbonate production from lepidolite ore, the grade of lithium carbonate as shown below:Equipment Machines For Lithium Extraction From

Limestone Ultrafine Mill Machine SBM Ultrafine

2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone directly into the Circulating Fluidized Bed (CFB), thus eliminating costly material handling, Limestone Mills Williams CrusherLimestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone There are two main types of limestone grinding mills: MTW European Type grinding mill and LM vertical roller mill powder selection and conveying together It focuses on nonmetallic ore, 200,000TPY Limestone desulfurizer production line 1316TPH Limestone powder production lineLimestone Grinding Mill, Limestone Mill,Limestone Grinding Machine

Flow chart of lithium ore crushing, grinding and screening process

2022年12月27日 Lithium ore from mines is lumpy The maximum size of ore blocks from open pit mining is 1000mm~1500mm, and the maximum size of ore blocks from underground mining is 300mm~600mm The ore with such a large lumpiness cannot be sorted directly, because the lithium ore in it is closely symbiosis2024年1月11日 Equipment Configuration Of Limestone SandMaking Plant The equipment for the limestone sand production line mainly includes a vibrating feeder, jaw crusher, sand making machine, circular vibrating screen, sand washing machine, etc The vibrating feeder is responsible for evenly and quantitatively delivering raw materials to the stone crusherLimestone Crushing And SandMaking Plant Eastman Rock China Limestone Grinding Mill wholesale Gold Mining Machine Professional Mining Ore Gold Copper Lead Manganese Iron Slag Sliver Aluminum Limestone Gypsum Powder Grinding Wet and Dry Ball Mill Price Calcium Carbonate Production Line Gypsum Limestone Kaolin Graphite Powder Grinding Mill US$ 800025000 / Set 1 Set Limestone Grinding Mill MadeinChinaGrinding Classifying: In order to ensure that lithium minerals are fully dissociated from gangue mineral monomers, a closedcircuit grinding and classifying process can be adopted, using ball mill + classifying machine According to the ore properties of different lithium ores, some lithium ores may need to be deslimed after the grinding stageLithium Processing Plant, Equipment JXSC Machinery