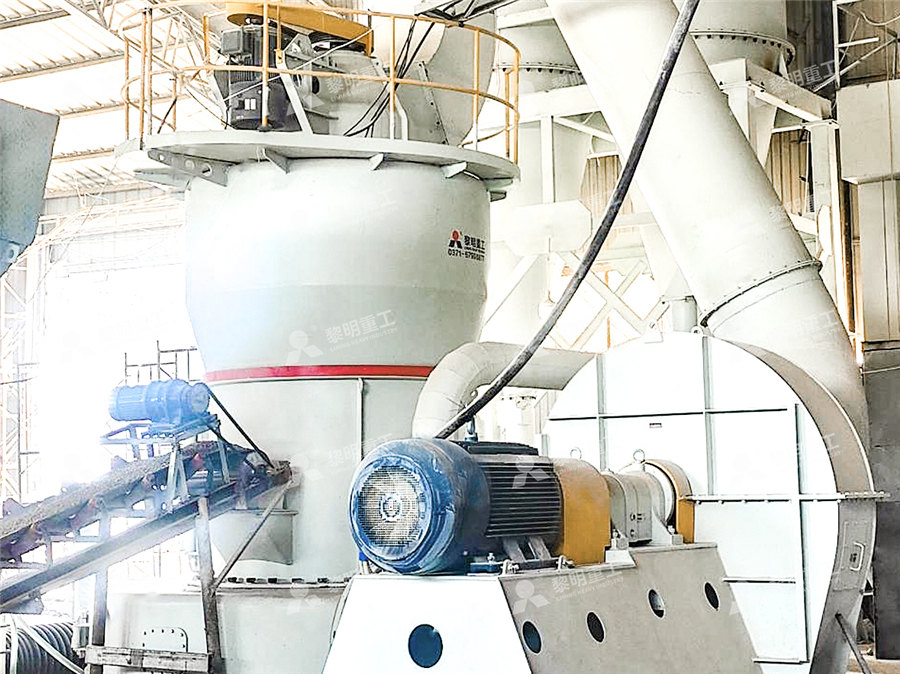

VSI6X1263 third generation ore mill

.jpg)

VSI6X系列立轴冲击式破碎机,6x制砂机,立轴式制砂机

VSI6X系列立轴冲击式破碎机是吸收多年的研发经验和技术理念,采用全新四口叶轮设计结构和特殊密封结构防止轴承筒漏油等工艺,拥有多项国家专利技术的新型制砂破碎设备,具有节能、 Find out all of the information about the Henan LIMING Heavy Industry Science and Technology product: verticalshaft impact crusher VSI6X1263 Contact a supplier or the parent company Verticalshaft impact crusher VSI6X1263 DirectIndustryLearn More About Liming® VSI6X Series Vertical Shaft Impact Crusher 1New design, efficient crushing Impeller structure adopts the design of four openings to improve the material VSI6X Series Vertical Crusher – Stone Crushers Grinding Mills for According to idea support and rich experience, VSI6X Vertical Shaft Impact Crusher adopts latest four ejection openings and special leak proof structure, which prevent the bearing drum from VSI6X Vertical Shaft Impact Crusher, Impact Crusher lifetime

.jpg)

VSI6X Crusher

VSI6X Sand Maker has multiple independent property rights and integrates 3 kinds of crushing modes Now, VSI6X Sand Maker is the core equipment in machinemade sand industry Get VSI6X Series Vertical Shaft Impact Crusher is a newlydeveloped and highlyefficient stonecrushing and sandmaking machine with many national patent technologies This machine VSI6X Impact CrusherLiming Heavy IndustryVSI6X Series Vertical Crusher is the upgrade of VSI5X Vertical Shaft Impact Crusher, to achieve the crushing (target for large crushing ratio) VSI5X series of efficient centrifugal impact PRODUCTS VSI CrusherVSI6X Series Vertical Shaft Impact Crusher is a new stonecrushing and sandmaking machine , that has highlyefficient system of core independent intellectual property rights, based on vsi5X Liming VSI6X Series Sand Making Machine Vertical Shaft

Product Particulars

6X series vertical shaft impact crusher absorbs many years of RD experience It help artificial sand manufacturers move toward largescale and centralized production to meet national The rod mill is another type of grinding mill used in the copper ore mining process This machine uses steel rods as the grinding media instead of balls, which are commonly used in ball mills The rods grind the ore by tumbling Understanding the SAG Mill in Copper Ore Mining 2022年1月1日 A fan which supplied air to the system was mounted at the outside of the separator body In 1980s high efficiency classifier concept was developed The thirdgeneration high efficiency separators includes the rotor cage, guide vanes, and external fan Classification efficiency of the thirdgeneration is superior as illustrated in Fig 8minution and classification technologies of iron ore2017年11月1日 An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which they fall onto the bottom of the mill to Friction and wear of liner and grinding ball in iron ore ball mill

.jpg)

VSI6X Impact CrusherLiming Heavy Industry

VSI6X1263: VSI6X1150: VSI6X1040: VSI6X9026: VSI6X8018: Central feeding(t/h) Crushing: 454486: 344368: 264283: 109117: 109117: ReShaping: 545583: 413442: 317342: 131140: 131140: Ball mill for iron ore beneficiation in India: Gold ore crushing plant in Malaysia: 150tph iron ore processing project in Indonesia: PRODUCTS Mobile 2017年7月24日 New generation Western Australian iron ore 20062016strategic insights ex stockpile to Chinese mill Terms: which was used in the third and final stage for the estimation/evaluation of (PDF) New generation Western Australian iron ore 20062016 2015年4月15日 Discharge from each mill Feed to each classification stage Oversize from each classification stage Fines from each classification stage, k Power drawn by each mill (motor input) Motor and drive efficiency of each mill, Size of and type of grinding media used in each mill Speed in RPM for each mill Liner design and condition in each millWhat Ore Testing is Required For Mill SelectionIt is almost impossible to describe, let alone do justice to, the variety of processes that have been used to mill ore The importance of mills cannot be understated since no money was made until the minerals were stripped of their metal values by the mill A good metallurgist or mill man was literally worth their weight in bullionWinning the Metal: Ore Mills of the West Western Mining History

From Ore to Iron with Smelting and Direct Iron Reduction

2017年10月17日 While the blast furnace remains an important tool for ironmaking, newer technologies such as smelting and direct iron reduction are available to produce iron with minimal byproduct generation and slagfree hot metal Smelting reduction and direct iron reduction can reduce energy input, lower greenhouse gas emissions and minimize slag byproduct 2012年4月1日 Adding mill scale as an ingredient into the iron ore sintering or pelletizing process is the main utilization approach for mill scale because of its high iron content and positional advantages [10 Recycling of steel plant mill scale via iron ore sintering plant2022年4月8日 NO and SO2 are representative harmful gases generated in steel works, and iron ore sintering process accounts for more than 50 pct of total generation The current study investigated the effects of adding CaO and FeO, which are the components contained in raw materials to sinter mix on the formation of NO and SO2 The addition of CaO to sinter mix Effects of Adding Calcined Dolomite and Mill Scale to Sinter Mix 2014年11月1日 This type of mill is now attracting interest in primary The model previously implemented in Modsim™ has been successfully applied to represent the vertical mill operated with different oresVertical mill simulation applied to iron ores

.jpg)

SemiAutogeonous (SAG) Mill Overload Forecasting

2022年1月13日 In mining, a SemiAutogenous Grinding mill (SAG) is the equipment used at mineral processing plants in the size reduction process, making the ore suitable for the next stage of flotation Its use lies in significant processing and reduction capability offered by this kind of mill, where maximize the operational continuity and production is essential2006年12月1日 Worldwide, the mining of uranium has generated 938 × 106 m3 of mill tailings The radioactivity of these tailings depends on the grade of ore mined and varies from less than 1 Bq/g to more than (PDF) Uranium Mill Tailings: Geochemistry, 2019年12月15日 429 VertiMills Vertical mills were first designed in the 1950s for applications in fine and ultrafine grinding in Japan Lately, the vertical mill is making progress toward primary grind application and shown promise in energy reduction relative to ball mills, typical to what is normally seen in regrinding applications (Mazzinghy et al 2014)Beneficiation of Gold and Silver Ores SpringerLink2014年2月13日 Nickel prices have been weak, but the recent Indonesian government announcement banning ore shipments outside the country may be the shock that reverses the trendRoyal Nickel Corp: Indonesian ore export ban opens door to the

.jpg)

Relationship among operational parameters, ore characteristics, and

2019年2月11日 Request PDF Relationship among operational parameters, ore characteristics, and product shape properties in an industrial SAG mill A detailed test work was carried out with an industrial semi 2019年8月14日 • Central discharge ball mill: the inlet of medium unloading ball mill is at both ends, and the outlet is in the middle of the ball mill 4 According to the ore discharge of ball mill: • Overflow ball mill: Discharge the ore through hollow shaft • Grid ball mill: Discharge the ore through the plaid plateThe Ultimate Guide to Ball Mills Miningpedia2018年7月1日 A hybrid nonlinear model predictive controller (HNMPC) is developed for a runofmine ore grinding mill circuit A continuoustime grinding mill circuit model is presented with a hydrocyclone Hybrid nonlinear model predictive control of a runofmine ore studied include mill rotational speed, ball size, mill I charge and wet versus dry grinding Breakage rates have been determined experimentally utilizing a SEM—IPS image analyzer The mineral sample used was acquired from ASARCO's Young Mine which is located in Jefferson City Tennessee It was a binary ore consisting of sphalerite and dolomiteTHE EFFECT OF BALL MILL OPERATING PARAMETERS ON MINERAL LIBERATION

}@~3SRDG`IA1KP_ICWAA.jpg)

Energy and exergy analyses for a cement ball mill of a new generation

2020年2月1日 Rather than huge expansion, most industries will focus on maximizing resources for maximum pro tability Consequently, a study of the impact of operational parameters on ball mill energy e ciency 2023年5月10日 Adding another SAG mill to the two existing ones at the mill A SAG or semiautogenous mill uses steel ball and the ore itself to break up the rock into fine particles in order to separate the copper and gold from all the A Look Inside the 3rd PTFI SAG Mill That Adds More 2020年12月5日 The present study reports the characterization of reverse osmosis (RO) technology at water treatment plant Cogen2 in paper and Board mills, PakistanBenchmarking of scaling and fouling of reverse osmosis membranes 911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and prioritization of variables Metallurgists Mineral Processing Engineers 911Metallurgist

Equipment Sizing: Crusher or Grinding Mill 911Metallurgist

2016年7月8日 UNTIL THE THIRD THEORY OF COMMINUTION of “Work Index” method of determining crushing and grinding mill size was introduced, there was no way of accurately figuring the most applicable, most economical size of crushing and grinding mill Naturally, with little or no factual operating data correlated in useful form, it was easy enough, even for the VSI6X1263: VSI6X1150: VSI6X1040: VSI6X9026: VSI6X8018: Central feeding(t/h) Crushing: 454486: 344368: 264283: 109117: Energy Saving Ball Mill Gold ore ball mill Contact Us Our professional engineer team has started a global customer visit PRODUCTS VSI Crusher2010年1月1日 Further simulations were performed to evaluate a circuit expansion, with the inclusion of a third ball mill Grinding Circuit Sampling Points Ore Characterisation Data Provided by Kinross PersonnelOPTIMIZATION OF THE SAG MILL CIRCUIT AT KINROSS PARACATU BRAZILRenewable Energy Electricity Generation in the 1970s and 1980s: An Education Pack; Other Resources Glossary; Related Websites; UK Counties Mill: Black Mill, Ore A windpowered corn mill in the historic county of Sussex, EnglandBlack Mill, Ore – The Mills Archive

.jpg)

Studying the integration of solar energy into the operation of a

2019年6月15日 The sizing of a solar photovoltaic plant (PV) with a battery energy storage system (BESS) to feed an energyhungry process is highly dependent on the solar resource available, which is itself dependent of the geographic location (Deshmukh and Deshmukh, 2008)The Atacama Desert in Chile, in which a high concentration of mineral deposits and It is normalised based upon the ore resistance to breakage, so it provides feedback about the health' of the milling process under varying operating conditions and ore types Mill grinding efficiency is measured at the same time as CSE through circuit samplingFunctional performance analysis combines CSE and mill grinding efficiency to provide 12th Mill Operators' Conference 2014 AusIMM2021年8月16日 Current advances and developments in automated mineralogy have made it a crucial key technology in the field of process mineralogy, allowing better understanding and connection between mineralogy and the beneficiation process The latest developments in X‑ray microcomputed tomography (µCT) have shown a great potential to let it become the next 3D Ore Characterization as a Paradigm Shift for Process Design 2010年1月1日 Infect only a few investigators worked on the kinetics of mill scale reduction [24][25][26][27][28][29][30]In previous studies on the use of the catalyst for iron ore or mill scale reduction Reduction of mill scale generated by steel processing

.jpg)

121 Ore Generation Guide – Beacoland

Explore the updated ore generation mechanics in Minecraft 121! Discover where to find your favorite ores, the best Y levels for mining, and optimize your resource gathering Coal Generation Range: Y=0 to Y=320 Cluster Size: 1 to 17 blocks Best Y Level to Mine: Y=95The best ore doubling method depends on what you are looking for early game The AA Crusher wins on speed but has no extra output, making it less optimal early game The EU Crusher is the cheapest but is also slow The EIO SAG Mill is by far the most efficient, especially when including grinding balls, but is also by far the most expensiveA comparison of the popular early game ore doubling, smelting, 2013年4月1日 A simple and novel nonlinear model of a runofmine ore grinding mill circuit, In order to evaluate the noise rejection capabilities of the controllers, in the third scenario, Analysis and validation of a runofmine ore grinding mill circuit 2022年12月15日 It can be concluded that the HPGRStirred mill combination was a more energyefficient grinding circuit than the HPGRBall mill combination for PGE bearing chromite oreSize reduction performance evaluation of HPGR/ball mill and

.jpg)

FAQ Mill

FAQ Migration Why are we migrating? For almost two years, we have been working on a new platform for all the Mill units in order to be able to develop exciting and new functions in the future The old platform was built in 2016 and a lot has happened since then in terms of technology, []ore blend The ultrafine generation through HPGR was remarkably higher than the ball mill, which is explained by a higher generation of surfaces within the microcracks reported at the BSA, especially in particle size range bellow 30 μm The particlesizesmaller than30μm had Development of a Novel Grinding Process to Iron Ore Pelletizing 2023年4月9日 Previously, ores were spread throughout the underground levels of a world (approximately 0 – 64, depending on the terrain generation) Now, generation will span between 64 and 256 (depending on terrain generation) Ore Distribution The way that ores generated in 117 were evenly spread, regardless of the Y coordinateMinecraft 118 Caves Cliffs: Part II – Ore Generation Beacoland2021年1月22日 Xiao et al [2] investigated the iron grade and recovery of fine grained magnetite ground by a stirred mill and ball mill They found that the stirred mill was more beneficial for grinding P80 10–30 μm minerals to liberate more valuable minerals and the grade of iron concentrate was 52% higher than that of ball millImpact of ball filling rate and stirrer tip speed on milling iron ore

Ball Mill Design/Power Calculation 911Metallurgist

2015年6月19日 The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ‘chunk size’, product size as P80 and maximum and finally the type of