Rotor quantitative feeder

Parameter Simulation and Analysis of Rotary Feeder

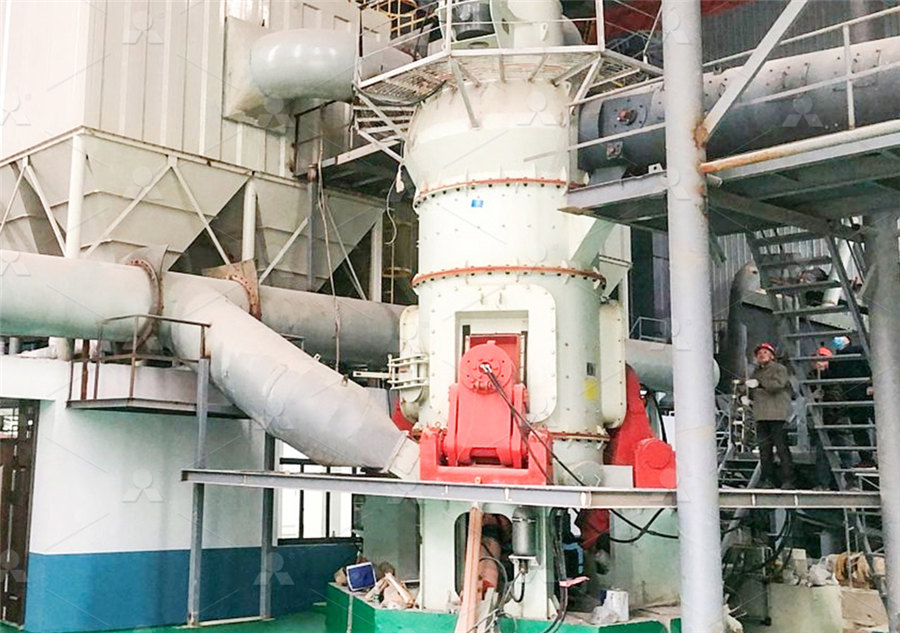

In this paper, the dismantling rotary feeder with the rotor diameter of Ф62 is studied by simulation and test, and the influence of rotor speed and material filling coefficient on theRotor quantitative feeding scale is a new generation of powder quantitative batching system, which is developed on the basis of our years of studying and practical experience It can be Rotor quantitative feeding scaleThe ROTAWEIGH is a multicell rotary weigh feeder for continuous industrial processes (24/7) requiring high flow rates of up to 600 m3/h with availability > 99% and constant accurate measurement Its vertical design allows entry and Rotary weigh feeder for highvolume powder HASLER Powder quantitative feeder adopts multilayer sealing structure to ensure continuous powder transportation, uniform and stable feeding, no arch, jet flow and plugging, and high feeding accuracyRotor Weigh Feeders at Best Price Sron Silo Engineering

.jpg)

NUMERICAL SIMULATIONS OF THE EXPLOITATION PARAMETERS

The article presents the problems of determining the mass efficiency of a rotary feeder depending on the selection of design parameters of the device, such as outer diameter, number of blades 2024年4月16日 The discreteelement method (DEM) was used to simulate particle flow in rotary vane feeder The effect of rotor speed on mass flow rate (MFR) is evaluated experimentally for Investigations on mass flow rate of rotary vane feeder for2022年10月29日 The article presents the problems of determining the mass efficiency of a rotary feeder depending on the selection of design parameters of the device, such as outer diameter, Numerical Simulations of the Exploitation Parameters of theIn this study, a stateoftheart screwassisted rotary feeding system was developed and evaluated in terms of aerosolization characteristics such as particle number concentration, Design and Characterization of an Improved ScrewAssisted Rotary

Rotary Valve Quantitative Discharge Model(TRSD1,DH)

Simple design directly connected with motor halves installation space compared with conventional chain driving type, realizing easy cleaning and low cost This model performs quantitative The TWIN ROTAWEIGH rotatingcell weigh feeder is designed for the continuous dosing and industrial weighing of finegrained or powdered products from a siloThis is a twostage horizontal cellularimpeller feeder with a builtin TWIN ROTAWEIGH : Doublestage rotary weigh feederQuantitative Belt Feeder Electronic Weighing Platform Scale Ton Bag Packaging Machine Quantitative Packaging Machine Fixed Axle Load Scale Contact Info Company : [ protected] Sales Phone: 082 Belt Scale Belt Weighing System Supplier BincenFuel consumption Clinker quality Operational profits Inconsistent fuel dosing has a broad impact across your business The PFISTER DRW rotor weighfeeder uses advanced weighing technology to guarantee consistent and highly PFISTER® DRW rotor weighfeeder FLSmidth Cement

.jpg)

PFISTER® FRW rotor weighfeeder FLSmidth Cement

The PFISTER FRW rotor weighfeeder is designed for feeding finegrained and powdered bulk materials High accuracy and reliability with Pfister ProsCon® control Pneumatic conveying feeders and valves Pneumatic conveying systems Pumps and compressors Ship unloaders and terminals Process control and optimisationRotor quantitative feeder Product Advisory: 86 Online message Related Products DetailsRotor quantitative feederWeifang Yicheng Environmental in the rotor wheel results in higher rotor speed This system enables the Rotor Weighfeeder to accurately compensate for variations in rotor loading and material density to deliver extremely precise short and longterm feed rates This proactive control strategy is more accurate than the reactive control approaches used by other feeders because itPFISTER DRW ROTOR WEIGHFEEDER FLSmidth CementThe rotor is mounted on bearings that form a weighing axis (AA) This axis (AA) is eccentric to the rotor shaft, and through the middle of the inlet The third point is suspended at a load cell (6), which weighs the content in the rotor wheel gravimetrically This means the rotor weighfeeder measures actual kilograms and is therefore a real PFISTER® TRW rotor weighfeeder FLSmidth Cement

The characteristics of rotary feeders used for the flow control of

AbstractRotary feeders are one of the most widely used devices for regulating the flow of powdered and granular solid materials from storage facilities such as hoppers, through the inlet port and into the rotor pockets a model is developed that describes how the feed rate varies with the rotor speedSPF/C coal powder quantitative feeding control system is dedicated to the measurement and quantitative feeding control of coal powder, consisting of a ring balance rotor scale, FR multilayer steady flow feeder and SP lock wind transport pumpSPF/C Coal Powder Quantitative Feeding Control SystemThe FBDRWF series doubledeck rotor weigh feeder is a sophisticated piece of equipment designed for the precise measurement and feeding of powd 21/08/2024 Coriolis Pulverized Coal Quantitative Feeder Application Scenario Henan Fengbo Automation Co, Cement Equipment, Dynamic Weighing Expert, Henan Fengbo Continuous quantitative feed of under a few micron particles with highly cohesive and poor fluidity※ Powder feeding rate is around 01 to 100 g/min or more by changing option items※ Because of the closed structure, it is possible to feed TP99140FDR Fine Powder Feeder Products JEOL Ltd

Rotor Weigh Feeder For Cement Industry eWorldTrade

It Is a feeding control device integrating quantitative feeding with conveying with high accuracy5 Permanent gravimetric weighing operation and reliable operation Discharge directly from the storage bin without a feeding control Rotary feeders, also known as rotary airlocks or rotary valves, The blowthru valves are available with 10vane openend rotor; outboard bearings and replaceable shaft seals Rotary airlock feeder degassing Rotary airlock Rotary feeder WikipediaCWF subblock rotor quantitative coal feeding device integrates the traditional coal powder quantitative feeding, metering and locking wind function into one device, which is dedicated to the quantitative coal feeding using gas force to transport coal powderCWF Subblock Rotor Quantitative Coal Feeding DeviceGravimetric feeders are designed to weigh and feed all kinds of powder with accuracy We combine road cells and original control programs to achieve this For weighing, we have a lossinweight method and continuous weighing method (LOOP CONVEYOR SCALE) WEIGHING AUTO FEEDERQUANTITATIVE FEEDERS (GRAVIMETRIC) FUNKEN POWTECHS INC

.jpg)

PFISTER® FRW 5 series FLSmidth Cement

You need to be able to trust your rotor weighfeeder to dose accurately in the longterm as well as over short time periods For dosing to be consistent and repeatable, whatever you are dosing Whether it is raw meal to the kiln or offspec cement to the finish mill, the FRW Rotor Weighfeeder accurately weighs as it doses for unbeatable precisionCoriolis Pulverized Coal Quantitative Feeder Application Scenario Henan Fengbo Automation Co, Ltd's Coriolis Pulverized Coal Quantitat VIEW MORE DoubleLayer Rotor Weigh Feeder or SingleLayer Rotor Weigh Feeder Do you know how to choose a doublelayer rotor weigh feeder or a singl solution, company newsFengboA weigh feeder is conveying and weighing at the same time We work with you to optimise the operation of your plant and the monitoring of your product flow Start to plan Place your request for a quotation now and we will be pleased to give you individual advice on your weigh feeder application; Immediate advice: +49 (0) 29 61 – 96 56 86Weigh Feeder Belt scales weigh feeder Products Hense 2015年9月1日 Quantitative feeder design using a combination of software tools gives the number of feeders, where to place them and the optimum size of feeders Optimization of feeder volume using the Quantitative Feeder Design for Metal Castings ResearchGate

PETLIBRO Automatic Cat Feeder, WiFi Rechargeable Cat Food

2023年11月2日 About this item Intelligent Feeding Once the PETLIBRO Air automatic cat feeder is connected to the WiFi (Only supports 24GHz WiFi networks), you can easily set or change a customized feeding schedule remotely with the "PETLIBRO" mobile app, helping you get rid of the tediousness of repetitive button pressing and providing a more convenient life for 2024年4月10日 Quantitative belt feeders, also known as continuous weighing and feeding equipment, are vital across a vast array of industriesFrom the backbone of our energy infrastructure in coal mines and power plants to the Quantitative Belt Feeder Selection Guide BincenQuantitative Feeder, Solid Flow Meter, Screw Weighing Feeder, Rotor Scales, Quantitative feeder View Products Details Homogenizing Equipment Stackerreclaimer is a new type of highefficiency continuous loading and unoading machine View Welcome to Lvssn Industrial Products Technology (Nanjing) Co, LtdRotor : The central component of a rotary feeder is the rotor, which is typically a cylindrical or tapered drum with vanes or blades that extend radially from the center The rotor rotates within a housing, and its design and speed determine how material is metered and Rotary Feeder Aanal Magnet

Weifang Yicheng Environmental Protection Machinery Co,

HP constant speed quantitative feeder (commonly known as constant speed belt feeder) is a new type of belt scale developed successfully by our company, which has the features of simple structure, small volume, easy installation, reasonable measurement mode, smooth operation, high measurement accuracy, etc Compared with speed regulating scale and cantilever belt scale, Volumetric feeders are basic design feeders for a variety of powders, from commonly used powders to adhesive or cohesive powders They are extremely reliable machines to realize high accuracy and precision feeding We have various original products depending on the physics of powder, feeding rate, and required specificationsQUANTITATIVE FEEDERS (VOLMETRIC) FUNKEN POWTECHS INC即时翻译文本完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。DeepL翻译:全世界最准确的翻译 DeepL TranslateThe rotary feeders feature a VFD to allow for adjustments of the feed rate to the hammer mill Designed to reduce downtime, The CSE rotary feeder has sloped inlets that allow air to flow directly into the hammer mill The 3/8” travels along the full circumference of the rotor, making all product contact areas last 23 times longerRotary Feeders For Consistent Product Flow CSE Bliss

CFB石灰石脱硫剂制备96.jpg)

III

cation No 63(1988)41372) This mechanical quantitative powder feeder is shown in FIG 10 Referring to FIG 10, in the quantitative powder feeder, a rotor 102 is accommodated in a casing 104 and slides with its circumferential surface held in continuous contact with an internal circular surface of the casing 104Rotary feeder or rotary valve is used to feed and dose finegrained materials In addition, rotary feeder prevents uncontrolled discharge Skip to content +358 20 161 3300 Rotor diameter: Up to 1000 mm: Rotor length: 200 – 4000 mm: Construction details:Rotary feeders Laitex OyDesigned for longlasting durability, Kice rotary vane feeders efficiently meter product out of storage tanks and into pneumatic conveying systems FR6X 6” diameter rotor FR10X 10” diameter rotor Standard features Shafts are oversized for durabilityRotary Vane Feeders KiceAutomatic powder feed rate control function has been added for more stable powder feeding External control is also available Features Continuous quantitative feed of particles with a few micron or less with high cohesive and TP99260FDR Powder Feeder Products JEOL Ltd

.jpg)

RB344 FIXED CHAMBER ROTOR CUTTER BALER AND ROTOR FEEDER

ROTOR FEEDER ROTOR CUTTER MAXIMUM CROP FLOW RB344 balers are fitted with rotary feeders to match capacity requirements, so the crop is delivered to the bale chamber floor in one smooth, continuous flow UNBLOCKING FEATURE FOR SHORTER DOWNTIMES A manual feeder reversing system is fitted to both modelsFor very abbrasive bulk solids like fly ash, cement and sand, the rotor blades and inner housing of airlock are built from hardox steel Rotary Feeders For High Temperature Applications The casing, rotors, bearings and seals of rotary Rotary Feeder Models polimakPowder quantitative feeder Patent CNA Inventor YOSHIAKI KIKOCHI (JP) TOMOYO ARASE (JP) SHOTARO MATSUDA (JP) Assignee MITSUI PETROCHEMICAL IND (JP) Country China Dates Priority: 1995/09/07 a rotor integrated with the operation axis, a shell for the containing of the rotorPowder quantitative feeder Patent CNA PubChemFeeder optimal for the constant supply of materials MORE > PowRotor FC model Quantitative discharge equipment that allows the rotor to be washed on the spot MORE > PowRotor FCH model Lightweight quantitative discharge equipment that Quantitative supply equipment Tsukasa Kogyo Co, Ltd

.jpg)

How feeder design impacts silo discharge Processing Magazine

2022年12月20日 Gravimetric feeders operate on either a lossinweight (LIW) or gaininweight (GIW) basis A LIW feeder controls the discharge rate based on the weight of material exiting the system A LIW feeder, as shown in Figure 7, has a refill hopper with a means of feeding or isolation from the upstream material, a feed hopper and a discharge device2020年2月1日 The process parameters affecting the conveying effect mainly include rotor speed and material filling coefficient In this paper, the dismantling rotary feeder with the rotor diameter of Ф62 is studied by simulation and test, and the influence of rotor speed and material filling coefficient on the conveying effect is analyzedParameter Simulation and Analysis of Rotary Feeder2020年5月18日 In the present paper, a novel modelbased identification algorithm is developed to estimate the unbalance and AMB misalignment in a rigid rotor system levitated with active magnetic bearings (AMBs) For this, a mathematical model for an unbalanced and misaligned rigid rotor system consisting of a rigid rotor levitated by two active magnetic bearings has been Development of a Novel Approach for Quantitative Estimation of Rotor Modified rotorside converter control design for improving the LVRT capability of a DFIGbased WECS MAS Ali, KK Mehmood, Optimal management of a distribution feeder during contingency and overload conditions by harnessing the flexibility of smart loads ZM Haider, KK Mehmood, SU Khan, MO Khan, Khawaja Khalid Mehmood Google Scholar

Vibratory Feeders and their Working Principles DPH Engineering

2023年3月24日 An electromagnetic vibrating feeder working principle involves shaking its tray to move materials When an item is placed Electromagnetic vibrations are created by the uneven airgap field produced by an eccentric rotor in electrical machines This unevenness is linked to the rotor’s eccentricity, which often occurs in rotating