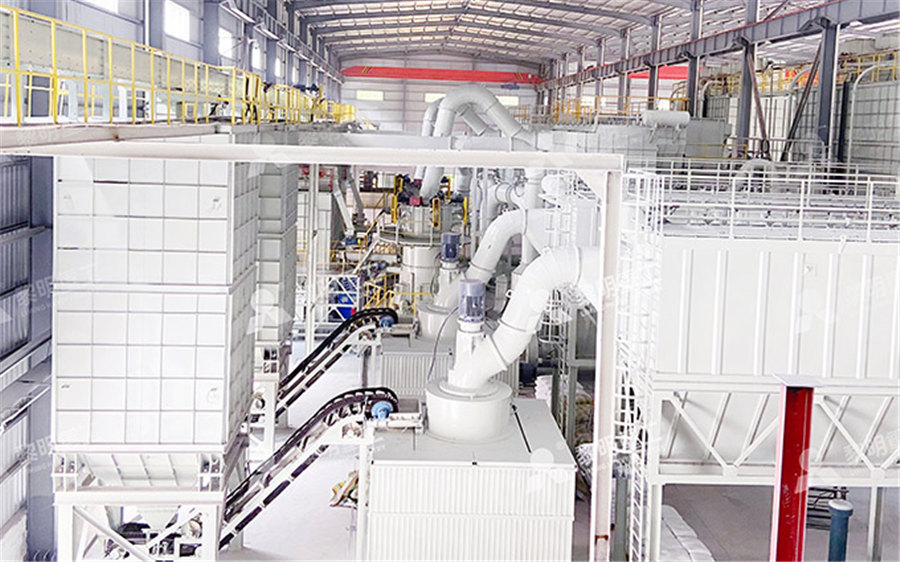

Wet mold comprehensive fine sand powder equipment

.jpg)

Machines systems for molding sand preparation

More than 1,500 EIRICH sand preparation systems worldwide process sand for gray iron, steel and aluminum casting lines from all major manufacturers, delivering leadingedge quality, The sand wet by the liquid catalyst makes it difficult to increase the molding speed and apply artificial sands which have excellent refractoriness to the sand molding using AM technology Additive Manufacturing Technology by Furan Sand Mold Using 2024年6月1日 Voxeljet launched various sandmold printing equipment, with models from VX200 to VX4000 They also developed a bidirectional sandspreadingbased printing Advances in Digital MultiMaterial Composite SandMold Binder Wahal has been the the market leader in the wet milling industry over the years Our sophisticated machines and process know how honed over the years can handle a wide range of dissolved Wet Dispersion Grinding Wahal Engineers

Maximize Efficiency and Productivity in Green Sand Moulding

To unlock the full potential of any green sand molding plant, Simpson offers a comprehensive portfolio of advanced, energyefficient technologies tailored to the unique needs of each KW offers a full knowhow package in all process sectors required for reliable sand preparation – including sieving, cooling, premixing, storage and homogenisation, inprocess checks, mixing, SAND PREPARATION – KÜNKEL WAGNERThe green casting technology of digital frozen sand mold is a method to produce sand mold by freezing cutting and printing, and to obtain typical parts by mold assembling and pouring In Research on Green Casting Technology and Equipment of Digital Most recently EMI has partnered with Savelli, a global leader in the design and installation of highly customized and high performance “Green Sand” molding machines, sand preparation, Green Sand Molding Solutions Equipment Manufacturers

Advances in Digital MultiMaterial Composite SandMold Binder

2024年6月1日 Sandmold 3D printing technology has been a consistent focus of research in China and other countries [31]Most studies have focused on optimizing the process parameters, whereas others have focused on improving alternative or model design methods for 3D printingbased sandmold casting [32, 33]To support the rapid application and development of BJ 2022年5月23日 Fine sand powder can effectively prolong the setting time and improve the rheological properties of OAASGM When the amount of fine sand powder was 10% (OAASGM10), the fluidity was 14 s, the operability time was 45 min, and the initial yield stress and plastic viscosity of OAASGM were 0699 Pa and 1997 Pas, respectivelyEffect of fine sand powder on the rheological properties of one » Dry wet granulation » Tablet reclaim rework » Dry ingredient blending » Ingredient check sifting Chemical » Clay mineral screening » Metal powder blending » Classifying of EPS (Expanded Polystyrene Beads) » Classifying of SAP (Super Absorbant Polymers) Environmental » Sorbent grinding » Frac sand screeningPowder Processing Equipment Systems QlarThree vibratory screens are used to scalp oversized silica sand particles in a wet screening application Sand and water are fed from a water separator onto the screen’s surface All sand particles larger than 40 mesh are scalped off and removed from the flowSilica Sand Wet Scalping Screen Tinsley Equipment Company

Sand Casting Recipes: A Comprehensive Guide

2022年10月31日 Learn how to make your own casting sand at home from easytosource ingredients 3 different formulas for you to try! The process of sand casting has been around for a very long time, one of the oldest castings is of a copper frog, believed to be made around 5000 years ago (3200 BCE) in Mesopotamia While the process of sand casting commercially has 2021年1月1日 The working performance and durability of medium and low strength machinemade sand concrete with different stone powder contents were studied, and the optimal range of stone powder content in Research on the Performance of Manufactured Sand Concrete 2023年10月10日 Step 3: Start with Coarse Sandpaper With your surface prepped, it’s time to set up your orbital sander For the first round of sanding, use 80grit sandpaper, which is coarse enough to efficiently remove the powder coating without damaging the underlying materialHow to Sand Off Powder Coating: A Comprehensive Guide2023年3月6日 With so many different types of media on the market for sandblasting, it can be hard to know what abrasive will be right for the equipment and job Whether you're planning on removing paint, surface contaminates from metal surfaces, or specialize in rust removal, selecting the appropriate abrasive is important to maintain efficiency, conserve media, and protect any A Guide to sand blast Media Dustless Blasting

The 3 Types of Sand Used for Sand Casting Patriot Foundry

2017年9月19日 Sand casting, or sand mold casting, is a popular method of producing nonferrous alloy casts Invented over 6,000 years ago, this process has undergone a number of changes and modernizations over the years, but the basic principals have remained the same2023年10月31日 A: Some of the most common types of sandblast media include silica sand, crushed glass, brown aluminum oxide, steel shot blast media, and garnet media Q: What is silica sand used for in sandblasting? A: Silica sand is commonly used as an abrasive in sandblasting It is known for its hardness and ability to strip away coatings from various The Ultimate Guide to Choosing the Right Sandblast Media for 2024年7月20日 A comprehensive guide to sandblaster maintenance, covering all essential aspects to maximize performance and prolong the lifespan of your equipment 899 Sheridan Dr, West Chester, Pennsylvania Mon – Sat: Sand Blaster Maintenance: A Comprehensive Guide Wet Sand Blasting Machine Application: It is applied for the products which need surface cleaning or renovating, wet blasting is widely for Electronic parts, Hypodermic needles, Precious metal finishing, Jet engine turbine blades, Wet Sand Blasting Machine Dustless Blasting Cabinet

.jpg)

Fine Sand Recycling Equipment JXSC Mineral

Fine sand recycling equipment is powerful, not only can it recover fine sand, but it also can desliming, dewatering, and demediation of slurry The main role is to recover the lost fine sand, to solve the problems of unreasonable sand gradation and coarse fineness modulus, to improve the quality of sand, and to increase the revenue of enterprisesHome » Related Equipment » Fine Sand Recovery Machine Fine Sand Recovery Machine Applied Materials: kaolin, mud, sand and gravel aggregate, artificial sand, coarse slime, concrete mixing station and other fine materials recycling and reuse Applications: It is used for mud purification, sand aggregate aggregate system, raw material processing system, artificial sand Fine Sand Recovery Machine Fodamon Machinery即时翻译文本完整的文档文件。为个人和团队提供准确的翻译。每天有数百万人使用DeepL进行翻译。DeepL翻译:全世界最准确的翻译 DeepL TranslateSieve analysis equipment is used to characterize and classify sand, aggregate, soils, coal, grains, and many types of fine powders With our large inventory and wide range of ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) Test Sieves, Gilson is the best source for your sieves and particle size analysis equipmentSieve Analysis Equipment Particle Sizing Gilson Co

Sand Casting: A Comprehensive Guide

Mold Making involves creating a mold by packing sand around the pattern The mold is divided into two halves: the cope (top half) and the drag (bottom half) Once the pattern is removed, the cavity left behind forms the mold for the casting Molding Sand: A mixture of sand, clay, and water (green sand) or chemically bonded sand2019年6月17日 After the sand type hardens, the mold sand does not need high wet strength, the sand has good fluidity, the sand type has high strength, the deformation is small, the tooling is simplified, the shape is simple, the sand type does not need to be dried, and the dimensional accuracy of the casting is significantly improved, which can reach CT8~ Level 10, casting Sand casting method and technical parameters LSmojvCasting Equipment Cleaning Engraving Tools Files Flexshafts Rotary Gauges Measuring Sand1 An ultrafine, moldable clay/sand mixture for casting or replicating detailed objects in gold, silver, ProCraft® Yellow Ochre Powder, 1/2 lb 6" x 6" Red Brass Sheet 26 Gauge Sand Casting PMC SuppliesWhen the sand washing machine washes the sand, it will inevitably cause the loss of fine sand The lost fine sand may be contained in the sedimentation tank, and the fine sand may flow along the river However, the existence of the fine sand recovery machine is to recover fine sand particles of less than 016mm that will flow away from the Fine Sand Recycling Machine JXSC Machinery

(PDF) Effect of waste glass powder and recycled fine aggregate in

2023年9月30日 Effect of waste glass powder and recycled fine aggregate in sustainable concrete September 2023 Journal of Structural Engineering Applied Mechanics 6(4):343年8月28日 This gives the sand the additional properties it needs to become an effective moldmaking material What is the Sand Casting Process? 1 Build a Pattern The sand casting process doesn’t start with the sand Trying to sculpt Sand Casting 101: What It Is, How it is Done What It Mold Sand Castings Excellence in Aluminum Castings: tailored to produce detailed and highstrength components, complemented by T6 heat treatment, CNC Machining, and comprehensive finishing services like Powder Coating Aluminum Permanent Mold Sand Castings – CMT There are two different ways for using our OBBSand Either our sand is used only for the first layer, then it will mix with the usual moulding sand and can not be recovered Or our OBBSand is used as a unique sand, it is then possible to reclaim the sand with OBBOil and Paste Properties Compression strength (g/cm²) 1250Petrobond Foundry Supply Source

Explore Powder Coating Textures A Comprehensive Guide

2022年12月8日 There are several reasons textured powder coating can be the better choice over wet painting for metal fabricators One of the main reasons to choose powder coating is that it's much more durable Wet paint is generally not very durable on its own and requires multiple coats to get the desired results2024年6月7日 Sandblasting is an effective method for removing mould from contaminated surfaces It involves using a blasting machine to force sand or other abrasive materials through a nozzle at high velocity, removing unwanted materials such as Sandblasting: Mold Removal's Secret Weapon ShunToolIn traditional wet process of manmade sand, is almost incontrollable Fine sand recycling equipment reduces the flow away of fine sand effectively, and put it under the control of 510% It well resolves the problem of coarse fineness module of manmade sand, low proportion of stone powder in aggregate processing system 2The spiral Fine Sand Recycling Machine Sand Recovery and Sand WashingAbout wet mold sand process Coated sand process About coated sand process 1 1 2 2 3 3 burning loss, fine powder quantity, casting inspection, etc Processing workshop equipment Read more Process flow Read more Physical and chemical analysis and testing Read more KEBOER NEWS Anhui Ningguo Keboer Foundry Base, to be put KBR Group : Shanghai keboer Casting Group Co, LTD

.jpg)

Fine Sand Recycling Machine JXSCTeam

In the traditional wet process of manmade sand, desoil and dehydrate by the spiral sand washer, the loss of manmade sand (especially fine sand) is almost uncontrollable Fine sand recycling equipment effectively reduces the flow away of fine sand and puts it under 510% controlSilica sand, mixed with a suitable bonding agent, is by far the cheapest of all mold materials Sand molds are relatively easy to make and the partrelated investments of sand casting are low Wooden, plastic, or metal “patterns” are used to form molds containing a negative of the shape of the casting: the mold cavity (Figure 36)Another plus for this method: it can deal with all Sand Mold an overview ScienceDirect TopicsWhen it comes to the component manufacturing industry, metal sand casting is one of the most popular processes in the production of steel, iron, and aluminum parts In fact, it’s extensively used in the steel foundry industry, where large Metal Sand Casting: Process Cycle, Design, and 2023年7月7日 Sand binder jetting is useful in the foundry industry (credit: ExOne) Binder jetting is particularly wellsuited for processing sand materials, such as silica sand and synthetic sand Sand parts produced using binder Binder Jetting: A Comprehensive Guide to the

.jpg)

The 6Step Process of Sand Casting: A StepbyStep Guide to

2024年2月22日 Molten metal is then poured into the mold cavity, where it solidifies and takes the shape of the pattern Once the metal has cooled and solidified, the casting is removed from the mold and cleaned II Key Components in Sand Casting Pattern: A replica of the final part used to create the mold cavity in the sand2024年7月3日 Garages have broad entrances that permit both vehicles and water to enter during heavy precipitation, making the garage more vulnerable to mold growth 3 Wet Items Stored Inside the Garage It is common to store wet items in the garage You may be storing wet yard equipment, such as lawn mowers and snowblowersHow To Get Rid Of Mold From Garage Walls? A Comprehensive 2023年9月5日 The resulting powder is extremely fine and pure, but the process is costly Industrially, it’s primarily used to produce fine and ultrafine powders of nickel and iron, as well as alloy powders of FeNi, FeCo, NiCo, and others 215 Chemical Displacement MethodMetal Powder Preparation Methods and Principles: A Comprehensive 2023年12月11日 Laboratory tests are one of the most fundamental and crucial methods in rock mechanics and engineering research Natural rock specimens are challenging to acquire, and traditional casting methods involve prolonged curing times and cannot produce rocklike specimens with complex internal fractures Furthermore, 3D printing technologies such as Characteristics and mechanism of time on sand powder 3D

.jpg)

Sand Casting Metal Casting Resources Reliance Foundry Co Ltd

2024年8月16日 Sand molds can be formed to create castings with fine exterior detail, inner cores, and other shapes Nearly any metal alloy can be sand cast Hollows are made in moistened sand, filled with molten metal, and left to cool The ability of a sand mold to permit the escape of gases and steam during the casting process Moisture Content2024年10月22日 3 Sand washing equipment Get a Quote Sand washing machine is a key auxiliary machine in sand making and washing production lines It is used to clean and remove dirt, dust, and other impurities from manufactured sand The most commonly used sand washing equipment in sand plants includes wheel washers and spiral washers a) Wheel Sand WasherA Comprehensive Guide to Sand Making Plants and MachinesPlastic molding process is a widely used technology in the manufacturing industry, used to manufacture various plastic products This comprehensive guide will explore different types of plastic processing and molding methods, commonly used materials, equipment involved, quality control measures taken to ensure production consistency, and the industry's increasing Plastic Moulding Process: Types, Materials, Equipment