Efficiency of hydraulic mill

.jpg)

Reconstructing the hydraulics of the world’s first

2020年10月21日 Carbonate incrustations that formed on the woodwork of the mills were used to reconstruct its structure and function, revealing a sophisticated hydraulic setup unique in the history of water2017年8月1日 Simplified view of a 180kW Francis turbine manufactured in 1882 by the Humphrey Machine Company and installed at the Tremont Suffolk mills in Lowell, replacing From the water wheel to turbines and hydroelectricity2023年10月1日 In this paper, a hydraulic depressurization model of the JMB is developed based on the theory of the jet pump, and a hydraulic cuttings cleaning model of the JMB is developed Hydraulic modeling and optimization of jet mill bit considering the 2020年6月26日 The maximum hydraulic efficiency (80%85%) is constant for rotational speeds below the critical speed, whereas the efficiency linearly decreases at higher rotational speeds due to the(PDF) Performance Optimization of Overshot Water

.jpg)

(PDF) The repowering of vertical axis water mills

2021年8月17日 Optimization of water mills' benefits is not only important for sustainable/regenerative development but is also costefficient, particularly for small farms2021年8月17日 Throughout most of the 20th century, the vertical axis water mill (VAWM) was usually thought to be the earliest (oldest) stage of hydraulic grinders when compared to the The repowering of vertical axis water mills preserving their cultural Throughout most of the 20th century, the vertical axis water mill (VAWM) was usually thought to be the earliest (oldest) stage of hydraulic grinders when compared to the more efficient and The repowering of vertical axis water mills preserving their cultural 2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate that grindingAn investigation of performance characteristics and

.jpg)

A Review of the Efficiency Improvement of Hydraulic

2023年6月14日 Figure 1 shows that methods to improve the efficiency of the hydraulic turbine optimize the hydraulic turbine mechanism, optimize the configuration of the device and adjust the system operating parameters A mechanical/hydraulic efficiency of 100 percent would mean if the pump was delivering flow at zero pressure, no force or torque would be required to drive it Intuitively, we know this is not possible, due to mechanical and fluid friction Hydraulic Pumps and Motors: Considering EfficiencyKaplan turbine and electrical generator cutaway view The runner of the small water turbine A water turbine is a rotary machine that converts kinetic energy and potential energy of water into mechanical work Water turbines were Water turbine Wikipedia2020年11月5日 A typical pulp and paper mill will use 30 percent of their energy usage to drive pumps Hydraulic efficiency factors are the largest hindrance This is the sum of all the fluid friction losses in the pump, including disc friction How to Define Measure Centrifugal Pump

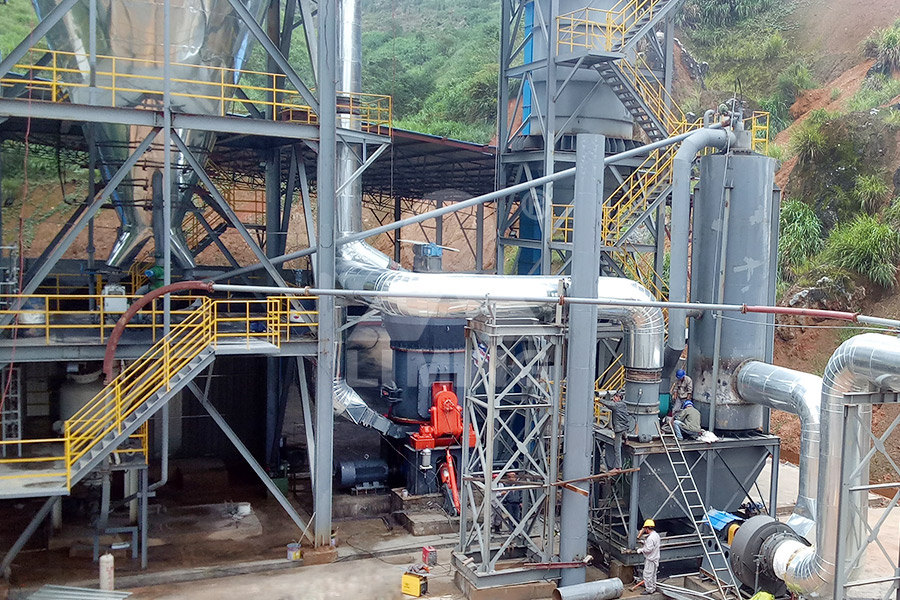

MillType Welded Hydraulic Cylinder Manufacturing Process

Milltype welded hydraulic cylinders are essential components in hydraulic systems, providing power and control for a wide range of applications These cylinders are known for their robust construction and high load capacity, making them ideal for heavyduty operationsdemonstrates a hydraulic efficiency increase between 3 and 6 percent in this bench test As temperature and pressure increase, the efficiency benefit increases This demonstration shows the impact that fluid formulation and physical characteristics can have on overall hydraulic efficiency But hydraulic efficiency is not an end goal in and of Hydraulic efficiency Mobil2021年8月17日 (VAWWs) (24 – 29%) was low in comparison to the efficiency of hydraulic turbines (Pujol et al , 2010 ) This is the reason why most of Spanish water mill owners converted the water(PDF) The repowering of vertical axis water mills preserving their NORMAL MILL PRACTICES Not to monitor lift of top roller It is assumed that top roller lifts only that value considered during mill setting calculations Normally actual lift of top roller during operation is higher than considered in mill setting calculation Higher thickness of cane/bagasse blanket passes through mills due to excessive lift of top rollerMILL DESIGN MILL OPERATION

.jpg)

Hydraulic Three Roll Mill: Revolutionizing Material Processing

2 Efficient and HighThroughput: Equipped with highquality rollers, the Hydraulic Three Roll Mill provides remarkable milling efficiency The rollers are designed to facilitate maximum material transfer and minimize particle agglomeration, resulting in a finely dispersed output2017年8月5日 11 EFFICIENCY Hydraulic ram has two types of efficiencies namely D’Aubuisson’s efficiency and Rankine’s efficiency 1 D’Aubuisson’s efficiency: Let, Q = discharge from supply tank to valve chamber q = discharge from valve chamber to delivery tank H = height of water in delivery tank raised above the chamber h = height of water in the supply tank Hydraulic ram PPT Free Download SlideShareIncrease the efficiency of a mill tandem by adjusting the operating parameters to the extraction area, according to the standard indicators Specific objectives The hydraulic pressures and torque applied to the upper hub can range from 2100 to 2500 pounds per square inchImprove the extraction efficiency of a tandem sugarcane milFeatures of the Mill Duty Hydraulic Cylinder Below are the amazing features of Zenith’s advanced “Mill Duty Hydraulic Cylinders Robust, HeavyDuty Designs: Engineered to withstand harsh industrial environments; Bolted Head and End Mill Duty Hydraulic Cylinder Zenith Hydromatics

.jpg)

The repowering of vertical axis water mills preserving their cultural

hydro plants and electric motors, and because the efficiency of vertical axis water wheels (VAWWs) (24–29%) was low in comparison to the efficiency of hydraulic turbines (Pujol et al, 2010) This is the reason why most of Spanish water mill owners converted the water wheels into turbines (see, eg RojasSola and LopezGarcıa, 2007)Download scientific diagram The layout of the coal mill with a rotary classifier from publication: An investigation of performance characteristics and energetic efficiency of vertical roller The layout of the coal mill with a rotary classifier2018年3月21日 The indicator of sugar mill efficiency is the yield represented by sugar mill performance (technical efficiency), sugar cane plantation (sugar cane quality), and productivityPRODUCTION AND PRODUCTIVITY IMPROVEMENT THROUGH EFFICIENCY SUGAR MILLIn the realm of hydraulic systems, milltype welded hydraulic cylinders play a pivotal role in ensuring optimal performance and efficiency These specialized cylinders are meticulously designed and crafted to withstand the rigors of heavyduty applications, offering unparalleled strength and durabilityMillType Welded Hydraulic Cylinder Manufacturing Process

.jpg)

How To Calculate Hydraulic Cylinder Efficiency Power Motion

2016年8月15日 And mechanicalhydraulic efficiency during retraction is: 1 (500/5000) = 1 01 = 090 = 90% Overall efficiency is simply the product of volumetric and mechanical/hydraulic efficiency In a modern hydraulic cylinder, where volumetric efficiency approaches 100%, overall efficiency equals mechanical/hydraulic efficiency: 095 x 1 = 095 = 95%2013年7月15日 mill circuits closed with hydraulic classifiers, with the vast majority being cyclones Metso PTI investigations into the effect of cla ssification efficiency on ball mill circuit capacity (PDF) Energy Efficient Ball Mill Circuit – Equipment Sizing Research on the Efficiency of Ball Mill Based on Finite Element Analysis Zhiqiang Xu Department of Physics and Technology, Kunming University, Kunming, , China Since the pinion gear is connected to the hydraulic motor through an acceleratorhe torque T transmission efficiency is 95%, the torque transmitted to the pinion gear is Research on the Efficiency of Ball Mill Based on Finite Element mill 2 – 1168 x 2134 mm, mills 3 to 5 – 1069 x 1981 mm Mill 1 was added to the tandem for season 2018 The tandem is fully automated, being driven by electrohydraulic drives which allow the Considering that total efficiency of the electro BENEFITS OF HYDROSTATIC TRANSMISSIONS APPLIED AS SUGAR MILL

Energy Efficiency and Dynamic Analysis of a Novel Hydraulic

2020年1月3日 At present, increased attention has been given to energy efficiency promotion and energy saving of manufacturing equipment and systems Hydraulic system is widely used in engineering machinery industries; however, the high energy consumption and low energy efficiency of which limit its development and application On the basis of previous research on 2020年3月9日 The average efficiency of these fluid power systems is 21% Could fluid optimization reduce energy consumption and improve the efficiency of hydraulic systems? Efficiency Basics Hydraulic systems convert rotary Getting the Most Efficiency Out of Hydraulics Power The integration of these systems into the rolling mill contributes to a more streamlined and responsive manufacturing process Energy Efficiency Solutions: Energy efficiency is a crucial consideration in modern rolling mills to reduce Modern Rolling Mill Technology and Their AdvantagesIt is reported that the first hydraulic ram pump was built by Whitehurst (1775), which operated manually by the opening and closing of the stopcock This hydram was able to raise water to a height of 49m The first automatic Design and Construction of a Hydraulic Ram Pump

OPERATION OF SUGAR MILLS WITH INDIVIDUAL VARIABLE SPEED DRIVES

Operation of sugar mills with individual variable s peed drives corresponds to propulsion of each roll of the sugar mill independently by ele ctrohydraulic variable speed or electromechanical variable frequency drives This paper pr esents the results of the tests carried out in Santa Isabel sugar mill in Brazil, when each four roll mill of four mill tandems was driven by four hydraulic 2021年5月1日 Improving Energy Efficiency at Palm Oil Mill Industries To cite this article: Zamri Noranai et al 2021 J Phys: Conf Ser 1874 View the article online for updates and enhancementsImproving Energy Efficiency at Palm Oil Mill IndustriesHence, pump efficiency is a measure of the effectiveness of a pump in using energy to move fluid from one location to another— higher efficiency indicates less energy wastage and improved performance Pump efficiency is defined as the ratio of the hydraulic power imparted on the fluid to the electrical power input required to operate the pumpPump Efficiency Explained EngineerExcel2021年8月17日 Throughout most of the 20th century, the vertical axis water mill (VAWM) was usually thought to be the earliest (oldest) stage of hydraulic grinders when compared to the more efficient and powerful horizontal axis mill (Curwen, 1944, p 134), but archaeological findings contradict this hypothesis and show that the VAVM is three centuries younger than the The repowering of vertical axis water mills Emerald Insight

Hydraulic Mill Roll Stand Dongguang Chenxiang Machinery Co,

We sell our Hydraulic Mill Roll Stand to brand manufacturers, wholesalers, etc all over the world Feel free to contact us! This helps to minimize waste and improve production efficiency 4 Speed control: Hydraulic mill roll stands can also be used to 2024年1月21日 The productivity and capacity release of hotstrip rolling is severely limited by pendular vibration Previous studies on mill vibration have investigated the influence of rolling parameters on vertical vibration; however, the influence of dynamic stiffness compensation factors on vertical vibration has not yet been considered owing to the limitations of modelling Study on the effect of rolling mill dynamic stiffness on coupled 2018年7月13日 In other words, the machine designers failed to properly consider all four sides of what I call The Power Efficiency Diamond of a hydraulic machine The PowerEfficiency Diamond Power efficiency means the ratio of power out to power in Ninety kW out from 100 kW in is an efficiency of 90% Ninety kW out from 110 kW in is an efficiency of 82%The Four Pillars of Hydraulic Machine Efficiency Power Motiondesigns applied, the separation efficiency seldom surpasses 60% The end result is that most grinding circuits closed by hydrocyclones operate with high circulating loads that range between 230 and 450% (See Figures 5–8 for circuit types) Picture 4 Typical crowned deck configuration Figure 5 Primary rod mill followed by secondary ball Implementing strategies to improve mill capacity and efficiency,

Boost Your Grinding Efficiency with Turbo Mill Solid Equipment

Discover how our Turbo Mill can enhance your grinding processes, improve productivity, and achieve finer particle size distributions Us 8669485406Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational masses The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading One method for increasing the energy efficiency of ball mills is to optimize their drive systems This article looks at two Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems2021年3月24日 Y Jiangang, Modelling and analysis of step response test for hydraulic automatic gauge control, Journal of Mechanical Engineering (2015) 115–122 L Fan, M Fang and Y Liu, Sliding mode control of strip rolling mill hydraulic AGC system, International Journal of Control and Automation, 7(8) (2014) 43–54Design of control system for steel striprolling mill using 2019年1月1日 Invasion of natural habitats by alien trees is a threat to forest conservation Our understanding of fundamental ecophysiological mechanisms promoting plant invasions is still limited, and hydraulic and water relation traits have been only seldom included in studies comparing native and invasive tre Less safety for more efficiency: water relations and PubMed

.jpg)

Development of highefficiency hydraulic separators Springer

tor to maintain a high efficiency (Heiskanen, 1993) Excessive turbulence or changes in flow conditions can result in the unwanted misplacement of particles and a corresponding reduction in separation efficiency Unfor tunately, current hydraulic separators use a feed injection system that discharges directly into the main separation chamber2015年1月1日 Hot rolling mill hydraulic gap control (HGC) thickness control improvement January 2015; January 2015; We prove the technological efficiency of using the proposed control method on Mill 5000(PDF) Hot rolling mill hydraulic gap control (HGC) thickness 2020年5月14日 Smallscale farming with different varieties of rice is common in the rural areas in Thailand This can complicate the milling process and affect the production yield In addition, a high logistic cost to the commercial mill is another barrier To cope with the problems and to support selfreliance, a compact and highly efficient smallscale rice mill machine has been Design and development of a compact and highly efficient small 2020年11月1日 In the present investigation, we have reported detail analysis related to heatmass transfer and thermal efficiency calculation of Wire Rod mill at SCSC (Siam Construction, Steel Company; located in Rayong province, The gap can further be reduced to 50 mm if the hydraulic system is upgradedIncrease in energy efficiency of a steel billet reheating furnace by

.jpg)

Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems

Figure 5 Startup of the LSPMSM SMH1732T motor with a filled ball mill after two hours of downtime: (a) active power, (b) current intensity, (c) voltage "Energy Efficiency Analysis of Copper Ore Ball Mill Drive Systems"