Can limestone crusher be used to produce high calcium powder from smelting waste slag

.jpg)

A review on use of limestone powder in cementbased materials

2018年8月30日 Incorporating superfluous fine limestone powder or coarse limestone powder increases the porosity of cementbased materials due to dilution effect The chemical effect of 2021年3月28日 The LSP0 specimens exhibit the highest drying shrinkage This result is expected due to the high calcium content in slag It was reported that in an alkaliactivated Effect of limestone powder on mechanical strength, durability and 2017年1月5日 While the supplies of many alternatives to OPC (such as fly ash or slag) may be limited, those of limestone and silica powders produced by crushing rocks seem virtually endless(PDF) Limestone and Silica Powder Replacements forSlag from steel mills in ferrous smelting is designed to minimize iron loss, which gives out the significant amount of iron, following by oxides of calcium, silicon, magnesium, and aluminiumSlag Wikipedia

Production, characterisation, utilisation, and beneficial soil

2021年10月5日 The high residual amounts of lime and iron in steel slag, as shown in Table 3, can be reused as a substitute for raw materials and a flux for sintering and smelting Large iron 2023年3月6日 Recycled smelter slags can be used in both in situ and ex situ treatment However, their application has some limitations One of the challenges is how to handle spent slag adsorbents, as they contain the accumulation of Recycled Smelter Slags for In Situ and Ex Situ Water 2021年12月10日 ALDs can prevent limestone from undergoing “armouring” under anaerobic conditions The alkalinity released by limestone can increase the pH value of AMD while Formation mechanism of carbide slag composite sustained PDF On Jan 1, 2011, Mauricio Mancio and others published Use of highcalcium Ladle slag as a partial limestone substitute for clinker manufacturing with reduced CO2 emissions Find, read Use of highcalcium Ladle slag as a partial limestone substitute for

Steelmaking Slag an overview ScienceDirect Topics

Steelmaking slag, or steel slag, is a byproduct from the production of steel during the conversion of hot metal to crude steel in a basic oxygen furnace, or during the melting of scrap in an EAFThe slag is generated as a melt and is a complex solution of silicates and oxides that solidify upon cooling 11 Depending on the specific steel production process, three different types of steel 2020年9月24日 Shan et al used the principle that steel slag and blast furnace slag can activate each other to promote hydration and added a 25% steel slag and 25% blast furnace powder as an admixture to increase the strength of the cement, with results showing that the 28 day bending strength and compressive strength of cement was 212 MPa and 550 MPa, respectively, Sustainable Utilization of Steel Slag from Traditional Industry and 2020年5月8日 Limestone that has been crushed can be used to refine and smelt metals When used for smelting, the calcium carbonate rock reacts with impurities in the metal, combining with them, and the combination removed in the form of 25 uses of limestoneChina is the largest producer and consumer of calcium carbide in the world The calcium carbide industry is an indispensable industry to support the basic life of people The huge production capacity of calcium carbide is accompanied by a large number of solid waste carbide slag Due to the immature treatment technology of carbide slag, a large number of carbide slag are stacked Resource utilization of solid waste carbide slag: a brief review of

Extraction of iron IGCSE Chemistry Revision Notes Save My Exams

2024年11月4日 calcium carbonate → calcium oxide + carbon dioxide The calcium oxide formed reacts with the silicon dioxide, which is an impurity in the iron ore, to form calcium silicate This melts and collects as a molten slag floating on top of the molten iron, which is tapped off separately calcium oxide + silicon dioxide → calcium silicateWhen calcium carbonate decomposes as a result of the high heat inside the furnace, it reacts with sandy impurities to form what is known as slag Carbon in the form of coal is delivered to steelmaking plants, and before it is mixed with limestone and the iron ore, known as hematite, to form the charge, it must be heated to a high temperature in an ovenLesson Explainer: Extracting Iron Nagwa2019年5月23日 Carbide slag is used to substitute limestone to produce many chemical products, which require Ca(OH) 2 These products include calcium oxide, bleaching powder, and calcium carbonate Carbide slag is dehydrated, dried, and burnt at 800–900 °C to prepare highactivity calcium oxide, which can be used in fields, of building prehensive Utilization of Carbide Slag SpringerLinkImpurities are further removed by adding flux if not already present in ore (if gangue is acidic basic flux is added, if gangue is basic acidic flux (ie, SiO 2) is used Smelting separates the material to separate into 2 layers (copper matte: bottom layer containing molten sulfides of Fe and Cu and silicate slag: top layer formed by reaction 232: Principles of Extractive Metallurgy Chemistry LibreTexts

.jpg)

SlagWhat is it Good for? US Geological Survey

2017年6月29日 Ferrous slag is currently underutilized Although the construction industry does use some slag as an aggregate, most is simply discarded However, slag could be used to treat acid soils or acid mine drainage Doing so would both offset the cost of restoring abandoned mine areas, as well as decrease steel manufacturers’ current waste footprint2018年2月5日 Piles of steel slag, a solid waste generated from the iron and steel industry, could be seen due to no utility found for the past century Steel slag has now gained much attention because of its new applications The properties of slag greatly influence its use and thus had got varied applications The chemical composition of steel slag varies as the mineral composition Review on the innovative uses of steel slag for waste minimization2023年11月25日 In response to the pressing global issue of reducing carbon emissions and the crucial technical challenges of fully utilizing steel slag, researchers have been studying an accelerated carbonation process that entails the carbonation of basic oxides in steel slag to store CO2 However, despite its promising potential, the process has yet to see widespread A review of use of metallurgical slag for its carbonation products 2024年9月10日 Since limestone is primarily made of calcium carbonate, a base substance, it can be used to neutralize acidity in industrial waste and runoff Limestone can also be used to reduce soil acidity for agriculture Other Limestone can be used in pigmentmaking and as a filler for more expensive paints Paper is also manufactured using limestoneLime vs Limestone Rock: Types and Uses of Each

Evaluation of the Efficiency of Limestone Powder in

2018年2月21日 The major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of 2023年2月4日 What is lime Lime, also known as quicklime or burnt lime, is mainly composed of calcium oxide, molecular formula CaO, which is a white block or powder cubic crystal The lime commonly used in industry will be dark gray due to impurities such as magnesium oxide, aluminum oxide and ferric oxide The relative density is 325338g/cm3, the true density is Lime/quicklime for metallurgy – how producing and briquetting2024年7月17日 Fine Crusher Fine crushers use highspeed hammers and impact plates to crush materials, while softer materials like limestone and coal can opt for impact crushers or hammer crushers fine crushers or compound crushers in tertiary crushing to produce fine sand or powder 4 Capacity requirementsTypes of Crushers: Choosing the Right One for Each Stage2023年3月16日 The term “slag” is used for different materials which result from solidification of a meltSometimes it refers to pyroclastic rocks [], sometimes to ashes, eg from waste incineration, which have undergone sintering due to partial melting [], but mostly for pyrometallurgical residues which result from the reaction of slagforming agents with gangue or impurities in the metal in Mineralogy of Metallurgical Slags SpringerLink

Life cycle assessment of melting reduction treatment for iron and

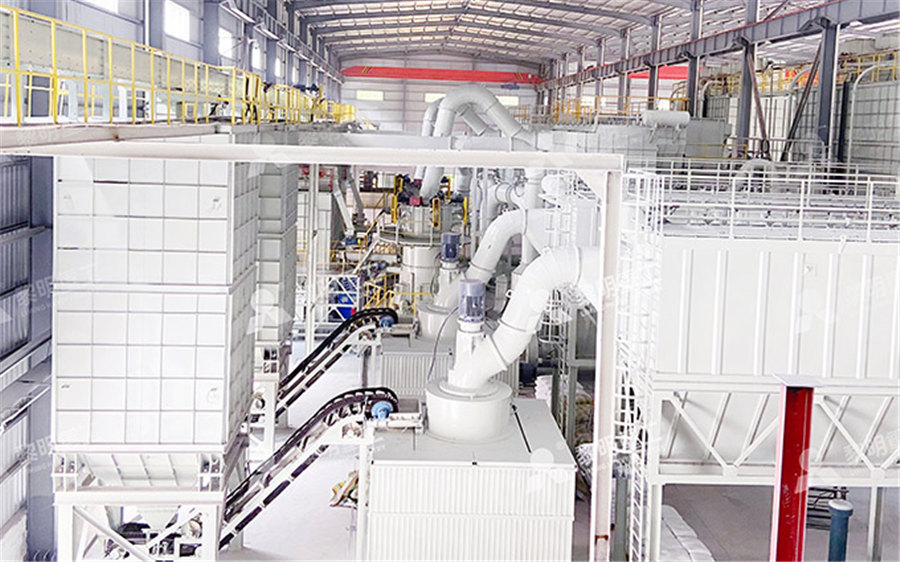

2022年11月1日 China has the largest output of steel and iron in the world (Zhang et al, 2022)In 2021, China's average annual pig iron output arrived at about 869 million ton (Stewart et al, 2021) and crude steel arrived at about 103 billion tons (Zhao et al, 2022)Meanwhile, the output of steel solid waste keeps at a high level and generally the production of one ton steel will generate 2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more environmentally friendly, and has a low investment 1503000 mesh calcium carbonate powder can use SBM calcium carbonate ultrafine grinding Calcium Carbonate Grinding Mill Powder Modify SBM Ultrafine Powder Slag processing George C Wang, in The Utilization of Slag in Civil Infrastructure Construction, 2016 53 Blast furnace slag processing Iron blast furnace slag results from the fusion of iron ore, fluxing materials, and coke; the reduction reactions; and the separation of iron from the ore As indicated in Chapter 2, the term blast furnace slag is used often to refer to iron blast furnace Blast Furnace Slag an overview ScienceDirect Topics2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcLimestone Ultrafine Mill Machine SBM Ultrafine Powder

Comprehensive Utilization of Carbide Slag Springer

furization system can also treat wastes Moreover, carbide slag is used to produce ordinary chemical products and prepare nanocalcium carbonate Keywords Carbide slag Comprehensive utilization Cement Flue gas desulfurization 71 Generation and Chemical Composition of Carbide Slag and Its Effect on the Environment 711 Source of Carbide Slag2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and Limestone crushing technology and equipment SBM Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) Limestone Mills Limestone Crushers Pulverizers2018年8月1日 In addition, the high content of CaO, MgO, and MnO in steel slag means that it can be used as a substitute for limestone, dolomite, and manganese ore to reduce the cost of iron and steelmaking (Shen et al, 2003)Steel slag in China: Treatment, recycling, and management

.jpg)

Smelting: Types, Process, Uses, Challenge, Effect Science Info

2023年9月20日 Processes of smelting It often includes the following steps: The process of reducing metal using carbon; Impurity Removal through Slag Formation; The heat required for the process is produced within the furnace by the combustion of carbon (C) in the presence of a hightemperature stream of air2023年5月3日 High calcium limestone is preferred for agricultural lime because it contains high levels of calcium and low levels of magnesium Magnesium can be toxic to plants in high concentrations, so it is important to use a lime source that is low in magnesium In addition to its use in agriculture, high calcium limestone is also used in the production Unlocking the Potential of High Calcium Limestone: Soil Carbon dioxide sequestration using steel slag—modeling and experimental investigation Smitha Gopinath, Anurag Mehra, in Carbon Dioxide Sequestration in Cementitious Construction Materials, 2018 41 Introduction Steel slag is an industrial waste that is generated during the production of steel In the production of steel, oxides of metal impurities in the iron combine Steel Slag an overview ScienceDirect Topics2013年1月25日 Calcium carbide Slag is from CaC2 hydrolysis reaction and will do harm to land and make pollution Calcium carbide slag can be a substitute for limestone to produce clinker with a high portion of CaO as an excellent calcium raw material As a kind of industrial wastes, the properties of calcium carbide slag differentiate from that of natural limestone In the present Using Calcium Carbide Slag as One of Calcium Semantic

Precipitated Calcium carbonate production, synthesis and properties

2017年1月1日 Waste seashells from aquaculture are a massive source of biogenic calcium carbonate (bCC) that can be a potential substitute for ground calcium carbonate and precipitated calcium carbonate2016年5月16日 Reduce, reuse, and recycle are important techniques for waste management These become significant for improving environmental and economic condition of industries Integrated steel industries are generating huge amounts of steel slag as waste through the blast furnace and Linz–Donawitz (LD) process Presently, these wastes are disposed by dumping in Sustainable Approaches for LD Slag Waste Management in Steel 2007年12月21日 The industrial process of lime production can be chemically expressed as thermal decomposition of calcium carbonate (CaCO3) into calcium oxide (CaO) and carbon dioxide (CO2), with a heat Lime and Limestone: Chemistry and Technology, Production and 2023年8月1日 Copper slags are a byproduct generated from copper extraction Rich in iron oxide, silica, calcium oxide, and alumina, copper slags are mostly stockpiled or used in landfill applications These slags consist of a substantial amount of valuable metals in an entrained metallic, sulphide or dissolved oxidized form, copper being one of themA comprehensive review on the recovery of copper values from copper slag

.jpg)

Lime Powder Making Machine

2021年12月21日 About Lime Powder Lime powder is a white powdery substance with calcium carbonate as the main component The application range is very wide, the most common is calcium carbonate used in the construction A plot of the temperature dependences of the free energies of these reactions, superimposed on similar plots for the oxygen removal reactions \(\ref{24}\) is called an Ellingham diagram (Figure \(\PageIndex{2}\)) For a given oxide MO to be smeltable, the temperature must be high enough that reaction \(\ref{24}\) falls below that of at least one of the oxygenconsuming reactions232: Pyrometallurgy Chemistry LibreTexts2020年4月1日 It can be categorized by either the process in which it was generated (basic oxygen furnace slag (BOFS), electrical arc furnace slag (EAFS), ladle refining slag (LFS)), or by the type of steel produced in said process (carbon steel slag or stainlesssteel slag) (Yi et al, 2012, Liu and Wang, 2017, Ndlovu et al, 2017)Basic oxygen furnace slag: Review of current and potential uses2020年6月3日 Smelting slag is a typical hazardous waste generated in the smelting and metallurgy industry 1,2Slag contains high concentrations of heavy metals, such as Cu, Zn, Cr and Ni, which are harmful if Highpurity recycling of hematite and Zn/Cu mixture from waste smelting

.jpg)

Limestone Quarrying and Processing: A LifeCycle Inventory

Limestone can also be chemical in origin as is the case with travertine Chemical limestone forms when calcium and carbonate ions suspended in water chemically bond and precipitate from their aquatic sources Because of its high calcium content, limestone is usually light in color, although many variations exist1 Introduction The basic oxygen steelmaking (BOS) process produced over 70% of the global crude steel in 2018, [] generating 100 to 150 kg of slag (“BOS slag”) for every tonne of crude steel produced BOS slag, a product of hot metal element (eg, Si, Mn, Fe, P) oxidation and flux (eg, lime, dolomite) dissolution, plays a critical role in the production of highquality crude steelBasic Oxygen Steelmaking Slag: Formation, Reaction, and Energy 2020年11月22日 The hightemperature process, known as calcination, converts calcium carbonate (CaCO 3), the principal component of limestone, to calcium oxide (CaO), or lime, releasing CO 2Alternative materials could shrink concrete’s giant carbon footprint2022年5月1日 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coalbased CaC 2CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are generated annually in China, among which only a Recycling and utilization of calcium carbide slag ScienceDirect