Fly ash production technology Fly ash production technology Fly ash production technology

.jpg)

Fly ash properties, characterization, and applications: A review

2021年9月1日 Fly ash can be modified or transformed into new materials for heavy metal ions adsorption The high content of Al 2 O 3 and SiO 2 in class F fly ash make it suitable for 2023年4月10日 Coal fly ash (CFA) management has become a global environmental concern due to their impact on the environment and the quantities of the waste generated However, Valorization of coal fly ash (CFA): a multiindustry review2023年6月15日 Utilizing waste fly ash for producing valueadded products has gained significant interests Therefore, in this work, we reviewed the current implementation of fly ashderived Emerging wastetowealth applications of fly ash for 2021年7月1日 In this article, significant properties, characterization methods and, applications of FA were summarized Number of publications of fly ash per year from 2000 to 2019 according Fly Ash properties, characterization, and applications: a review

.jpg)

Examining the endpoint impacts, challenges, and opportunities of

2023年10月25日 High fly ash replacement for normal and highstrength concrete has a greater reduction in all endpoint categories than for lowstrength design Recommendations are 2024年11月26日 The application of incineration fly ash (IFA) sintering technology has brought a large amount of secondary fly ash (SFA) rich in heavy metals and chlorides, and its treatment has attracted much attention A unique Innovative Technology for Secondary Fly Ash Full Fly ash and bottom ash are the two types of coal combustion leftovers that are blended and disposed of directly into the ponds/lagoons in both dry (Mound ash) and wet (Pond ash) State of the art review on physiochemical and engineering 4 天之前 Rotational molding is an ideal method for producing hollow, stressfree plastic products with minimal waste Linear lowdensity polyethylene (LLDPE) is frequently used as a base Fly AshLinear Low Density Polyethylene Composites for

.jpg)

Photothermal Synergistic Hydrogen Production via a

5 天之前 1 Introduction Photothermal synergistic catalytic water splitting technology enables the direct harnessing of the full solar spectrum for hydrogen production within an integrated 2018年9月1日 Finally, the important needs, pertinent to the optimal and broad utilization of fly ash as an integral part of sustainable construction materials, are identified for further research and development, where largescale application studies, further classification of fly ash, advanced characterization tools and technology transfer to biomass fly ash are recommendedCharacteristics and applications of fly ash as a sustainable 2024年3月22日 Utilizing microbialinduced carbonate precipitation technology and carbonation for recycling municipal solid waste incineration fly ash in the production of bricks Author links open overlay panel (MICP) is excellent and sustainable Chahal and Siddique [23] used fly ash and silica fumes to partially replace cement in the Utilizing microbialinduced carbonate precipitation technology The focus of this study is to critically review the physiochemical and engineering properties of the fly ash and its applications in various fields The utilization of fly ash has become a widespread area, but the amount of utilization is still a serious issue It has many beneficial qualities (such as pozzolanic property, fineness, spherical shape, lightweight, etc), which enhance its State of the art review on physiochemical and engineering

.jpg)

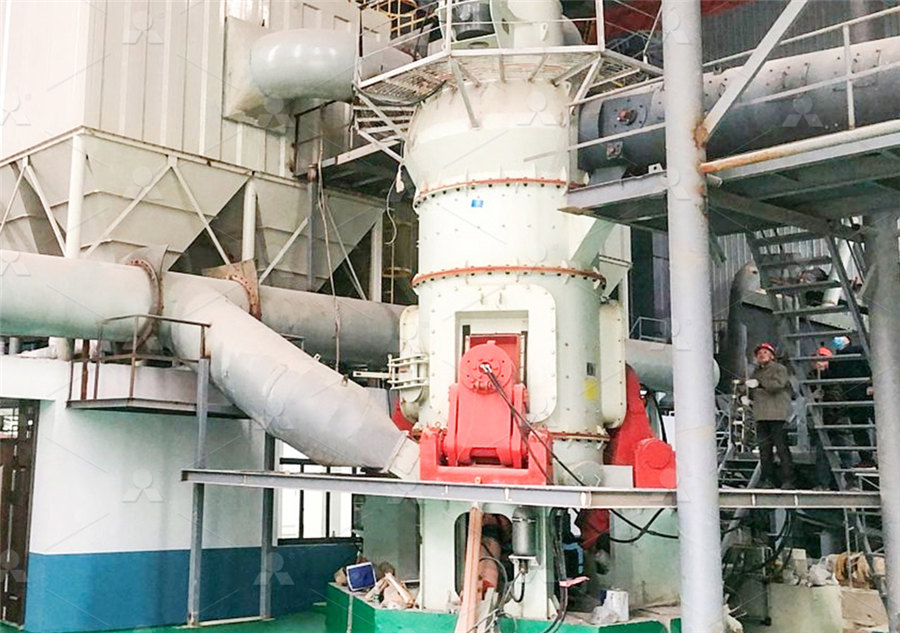

Fly ash drying technology Indian Cement Review

2015年2月28日 Dry fly ash can be directly mixed in to the final product, PPC Capacity of the grinding mill does not need to be increased to get enhanced production Advantages of fly ash drying plant in power plant premises: Wet fly ash can be easily sourced since, abundantly available with nearby TPPs Logistics of wet and dry fly ash becomes economical4 Coal fly ash production across different countries According to the investigation by Olarewaju (Citation 2016), India is the primary biggest nation for the production of CFA worldwide with the production of 112 million tons every year and use of 38%, trailed by China having around 100 million tons with 45% useFull article: A comprehensive review on coal fly ash and its Fly ash (FA)a coal combustion residue of thermal power plants has been regarded as a problematic solid waste all over the world India has some of the largest reserves of coal in the worldFly ash production (million tonnes/year) in different countries 2016年8月19日 Increasing production and disposal of coal fly ash (CFA) is a matter of serious environment concern However, CFA contains various beneficial metals and mineral matters whose demand is increasing in the industrialized world, while natural supplies are diminishing Therefore, recovery of these potential resources from CFA can be an alternative way to save Recovery of metals and other beneficial products from coal fly ash

.jpg)

Fly ashbased geopolymer: clean production, properties and applications

2016年7月1日 Due to the cost and availability of oil and natural gas, coalfired power plants will be still run for a long period, especially in the coalrich countries, for example, China, the USA, India and Australia (Lior, 2010)Under such a circumstance, the generation of fly ash remain significant and thus its economic and green utilization technology of fly ash are desired (Fig 1 a)2006年6月1日 Therefore, disposal and utilization of fly ash needs careful assessment to prevent conversion of arable land into landfills and accumulation of toxic metals in soil (Petruzzelli, 1989) and use it as an ameliorant for problem soilsRestoration and utilization of fly ash dumps for biomass production will be an adjunct to these effortsFly ash as a soil ameliorant for improving crop production—a Increased Fly Ash Sales Decreased Cost Profile and Footprint The innovative EnviroSource fly ash beneficiation technology uses a proven thermal process that reduces loss on ignition (LOI), ammonia, activated carbon, mercury and other contaminants making your formerly unusable fly ash in current production or legacy ash stored in ponds or landfills immediately marketableEnviroSource Fly Ash Beneficiation Technology CharahFly ash bricks' mechanical attributes are superior to those of regular brick According to the study, fly ash from electrostatic precipitators (ESPs) used in the chemical industry can be used to make bricks The use of fly ash in brickmaking helps reduce waste and will also aid in the preservation of natural resources including air, water, and A CASE STUDY ON ECO FLY ASH BRICKS USING ALKALI ACTIVATION TECHNOLOGY

.jpg)

Industrial Production of Fly Ash and SandBased Geopolymer

2023年6月26日 The world is inundated with millions of tons of industrial wastes such as fly ash, ground granulated blastfurnace slag (GGBS), and mining tailings The best method to utilize these wastes is to make different types of building materials and include them in structural parts, reducing the carbon footprint In developing countries such as India, the population explosion 2021年5月11日 Thus, the ash production from the abovementioned seven power plants by 2025 would be about 20 million metric tonnes per annum, out of which about 90% would be fly ash and the rest are bottom ash The ash production from coalfired power plants will grow further beyond the year 2025 as some of the pipeline projects will be put into operation after 2025Coal Fly Ash Utilisation and Environmental ImpactOPTIMIZING FLY ASH USE IN INDIA: CHARACTERIZATION AND APPLICATIONS Material Science and Technology 555 fine residue made up of of approximately 810 percent As a result, fly ash production will reach 100 million tonnes per year by the year 2000, and 125 million tonnes by 20032004OPTIMIZING FLY ASH USE IN INDIA: CHARACTERIZATION AND Fly Ash Bricks: Brick production using flyash from thermal power plants in India Background Information As the second most populated country in the world, urbanization in India is taking place at a high rate As a result, the country is dealing with a great housing shortage Twentyfiveper cent of the population doFly Ash Bricks: Brick production using flyash from thermal

(PDF) Utilization of Fly Ash in Construction ResearchGate

2019年9月3日 In year 2016, Malaysia produce about 68 million tonnes of fly ash from six coal fired electric power station and this figure will increase due high demand of electric production2006年6月30日 3 Fly ash as a soil ameliorant for improving crop production—a review 4 Sudha Jala, Dinesh Goyal 5 Department of Biotechnology and Environmental Sciences, Thapar Institute of Engineering and Fly ash as a soil ameliorant for improving crop production2024年2月20日 A novel process for the production of angularshaped high strength fly ash aggregates from an energetic, and environmental perspective is presented in this paper and compared with the production of natural aggregates This study is significant because there is an increasing demand for aggregates and no published research addressing the environmental Comparative environmental life cycle assessment of artificial fly ash In year 2016, Malaysia produce about 68 million tonnes of fly ash from six coal fired electric power station and this figure will increase due high demand of electric productionFly ash production in different countries [22] ResearchGate

Production Process and Technology in Fly Ash Bricks Plants

Here’s an overview of the typical production process and the technology involved in fly ash brick plants: 1 Raw Material Preparation: The primary raw material for fly ash bricks is, as the name suggests, fly ash, which is a byproduct of coal combustion in power plants Fly ash is collected, stored, and transported to the brick manufacturing Fly Ash: Production and Utilization in India An Overview Aadil Yousuf 1 , Shahzada Omer Manzoor 1 , Mudasir Youssouf 2 , Zubair A Malik 3, * and Khawar Sajjad Khawaja 4Fly Ash: Production and Utilization in India An Overviewfly ash bricks Generally, the machine consists of a raw material mixing chamber, mixture conveyor, moulds for the brick, a hydraulic system, and electronic control panel The operational of the fly ash brick machine is simple The first step is to mix all of the materials (Figure 2), consisting of sixtytwo per cent of fly ash,Fly Ash Bricks: Brick production using flyash from thermal 2022年11月25日 Both fossil and renewable fuel sources are used widely to produce electricity around the globe The dependency on fossil fuels for energy leads to the depletion of reserves and various forms of pollution Coal fly ash Status of CoalBased Thermal Power Plants, Coal Fly

Examining the endpoint impacts, challenges, and opportunities of fly

2023年10月25日 Fly ash has been widely used as a cement substitute to improve the sustainability of concrete Although the advantages of fly ash have been extensively documented, there is a gap in understanding Figure 2: Fly ash production process of refuse incineration plant The collection method of fly ash from garbage incineration plant is: the fly ash generated from the three links of the mixing waste heat boiler, spray tower and dust collector is collected together, as shownResearch and Application of Detoxification and Harm Reduction 2022年12月15日 MSWI ashes are divided into MSWI bottom ash (MSWIBA) and MSWIFA And MSWIFA accounts for 166–20 % of MSWI ash residue (Tang et al, 2015)During incineration, heavy metals or heavy metal chlorides in MSW usually evaporate in the hightemperature environment and are subsequently deposited in the crystal lattice of MSWIFA (Dou et al, 2017)Resource utilization of municipal solid waste incineration fly ash 2023年12月10日 The use of fly ash for the preparation of cement, fly ash bricks, and concrete all three resource utilization pathways have carbon emission reduction benefits The use of fly ash replaces part of the primary resources and reduces the energy consumption for its mining and production Thus, an indirect carbon emission reduction benefit is generatedSynergetic benefits of pollution and carbon reduction from fly ash

.jpg)

Prospective Utilization of Coal Fly Ash for Making Advanced Materials

2021年5月11日 20244 Bricks Manufacturing The synthetic pozzolanic character of FA is because of the constituents accomplishing amorphous silicate minerals Usually pozzolanic ash does react with slaked lime and water to form the complex, ie, CaO–Al 2 O 3 –SiO 2 –H 2 O (Çiçek and Çinçin 2015)The fired clay type bricks have been used on masonry constructed 2012年1月1日 production of bricks made of 100 % fly ash, International Ash Utilization Sympo sium, 2001, Center for Applied Energy research, U niversity of Kentucky, paper # 84 Pimraksa,K, Kurzweil J and A Brief Overview of Fly Ash Brick Production ResearchGate2019年5月23日 524 Composition of Fly Ash Particles The fly ash particles are composed of a mixture of various particles Therefore, the quality of fly ash mainly depends on the composition of various particles, and the quality is affected by the change in composition []Scanning electronic microscope (SEM) observation shows that fly ash includes spherical particles, slag particles, Comprehensive Utilization of Fly Ash SpringerLink2022年5月12日 Currently, the high pollution derived from the production of Portland cement is a major problem, therefore the development of alternative cements obtained by processes with lower gas emissions and low energy consumption is a new line of research of worldwide interest It is proved that geopolymers can replace Portland cement in some application in the Use of fly ash in the production of geopolymers: a literature review

.jpg)

Fly Ash: Production and Utilization in India An Overview

Fly ash particles generally fall in silt range and are typically finer as compared to lime and Portland cement The size of fly ash particles varies from 10 to 100 microns having a spherical shape •! Colour of fly ash principally depends on the mineral composition of coal source, it may have a dark or black shade or tan colour2021年6月5日 Ash circulation technology could be used to return secondary fly ash to the melting furnace and finally convert to slag (Okada and Suzuki, 2013) Such ash circulation promoted the condenzation of PTEs in the secondary fly ash for future metal recoveryTreatment of municipal solid waste incineration fly ash: State 2022年8月15日 Fly ash (FA), a type of solid byproduct, is produced during coal combustion in power plants [9], [10], [11]Due to the low cost and abundant availability of coal, the colossal use of coal to meet the demand of growing energy has generated an exponential increase in the amount of FA [10], [12]Estimates indicate that global annual production of FA has reached Fly ashbased artificial aggregates synthesized through alkali 2022年12月1日 Methods of sampling fly ash: 2021: Japan: JIS A 6201: Fly ash for use in concrete: 2015: United Kingdom: BS EN 4501: Fly ash for concrete Definition, specifications and conformity criteria: 2012: BS EN 4502: Fly ash for concrete Conformity evaluation: 2005: PD CEN/TR 15840: Evaluation of conformity of fly ash for concrete Guidelines for Fly ash for sustainable construction: A review of fly ash concrete

.jpg)

COSTEFFECTIVE ASH BENEFICIATION TECHNOLOGY Charah

fly ash, in the production of concrete products and Portland cement manufacturing are well documented Concrete products manufactured with fly ash are less permeable, last longer, are stronger and more durable, and are easier to handle and finish Moreover, using fly ash is an environmentallyfriendly solution dueCoal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), [1] are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls: Diagram of the disposition of coal combustion wastes Fly ash is captured after coal combustion by filters (), Coal combustion products Wikipedia2019年9月1日 With fast urbanization and continued increases in the standard of living of 13 billion people, generation of MSW has grown rapidly in China, posing a significant disposal challenge (Hoornweg and BhadaTata, 2012; Zheng et al, 2014)The total volume of MSW generated in China had increased from 313 million tonnes in 1980 to 2036 million tonnes in Municipal solid waste (MSW) incineration fly ash as an Firstly, fly ash is mixed and reacted with the hot acidic scrubber liquid; this leads to the neutralisation of the scrubber effluents and the formation of a salt brine including metals in solution Secondly, the fly ash particles with a size over 1 mm are removed; they represent less than 1 wt% of the fly ash and are returned to the WtE WastetoEnergy fly ash valorisation

(PDF) Assessing the suitability of fly ash and rice husk ash from

2022年1月12日 Fly ash (FA) and rice husk ash 2 College of Technology, University of Science and Technology of Southern P hilippines, Lapasan, Production of Fly Ash/Rice Husk Ash Bricks