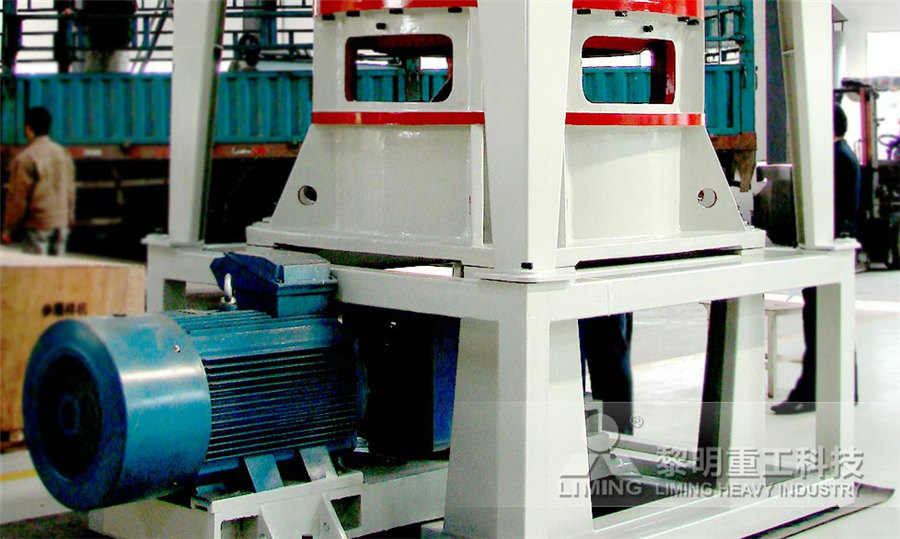

Tangzhang ore grinding mill

高压辊磨机在金属矿选矿与球团预处理领域的工艺和

2019年4月12日 高压辊磨机能量利用率高,目前已在水泥行业、金属矿山、冶金球团等领域广泛应用。 结合当前研究成果及工业现场数据,本文对比了高压辊磨机在金属矿山和球团预处理 2023年7月20日 According to the different grinding medium, the grinding mill is divided into three types: (1) ball mill – it is used widely, and almost all materials can be triturated by ball mill; (2) Ore Grinding SpringerLink2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral Processing 2023年11月24日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the Grinding Media in Ball Mills for Mineral Processing

Grinding mills for mining and minerals processing Metso

Customized grinding mill parts including heads, shells, trunnions and liners, main bearings, gears and pinions, and more! Metallic, PolyMet™, Megaliner™, Rubber and Orebed™ mill liners for Ore grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the separation of the Ore Grinding Methods and Process of Ore Grinding2017年9月1日 The objective of this work is to assess the influence of fine grinding in ball mills and stirred mills on valuable mineral liberation and particle shape characteristics of UG2 ore, a Fine grinding: How mill type affects particle shape characteristics 2014年10月20日 In Brazil, during the last 10 years, regrind P80 sizes of approximately 40 to 20 μm have been necessary in all new iron and copper plants The use of conventional ball mills, Regrind of metallic ores with vertical mills: An overview of the

.jpg)

Effect of Ball Mill Parameters’ Variation on the Particles of a

2021年10月21日 Grinding/milling the ore/mineral prior to the leaching process enhances the surface area and the distorted structure which helps speed up the rate of reaction by Two basic types of UFG mills are available, the vertical stirred mill and the horizontal stirred mill Both use rotating stirrers within a stationary mill shell to impart kinetic energy to a fine media Ultra Fine Grinding A Practical Alternative to Oxidative Treatment 2023年7月20日 Therefore, the rod mill is mostly used for coarse grinding of the previous period of ball mill, or grinding of brittle materials and materials against overcrushing, such as tungsten and tin ore before gravity separation; and (3) autogenous mill – it refers to the materials which themselves are collided and ground mutually to be crushed when the grinding mill rotates, and Ore Grinding SpringerLink2022年1月1日 The mass of grinding media (m GM) and feed (m P) was added into the grinding chamber of the stirred mill using the following formulae below, Impact of ball filling rate and stirrer tip speed on milling iron ore by wet stirred mill: Analysis and prediction of the particle size distribution Powder Technol, 378 Effect of operating conditions on the particle size distribution and

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 The choice of grinding mill depends on factors such as the desired product size, capacity requirements, and energy consumption b Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) 2023年10月17日 3 Ultrafine Powder Grinding Mill Ultrafine powder mill (threering / fourring mediumspeed micropowder mill) feed particle size ≤25 mm, production capacity 0545 t/h, production fineness 1503500 mesh,it is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process How to choose a suitable ore powder grinding mill?2024年9月1日 Fine grinding is a milling method of crushing materials to less than −01 + 001 mm by using grinding, impacting, shearing and other forces within the mill (Kumar et al, 2023)The purpose of grinding is not only to provide a suitable feed size for further processing but also to release valuable minerals from the gangue, which is tightly combined in the oreEffect of different mills on the fine grinding characteristics and 2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parametersAnalysis and Optimization of Grinding Performance of Vertical

.jpg)

Grinding Mill an overview ScienceDirect Topics

A crushing plant delivered ore to a wet grinding mill for further size reduction The size of crushed ore (F 80) was 40 mm and the SG 28 t/m 3 The work index of the ore was determined as 122 kWh/t A wet ball mill 1 m × 1 m was chosen to grind the ore down to 200 micronsSpeed also plays a role in ore grinding; too high of a speed can cause damage to the mill gears and other components, while too low of a speed can cause excessive wear on these same components It is important to find a balance between these two variables in order to achieve optimal grinding performanceFactors affecting ores grinding performance in ball mills2022年1月1日 A pilotscale grinding technology of ceramic medium stirred mill was proposed in this study Based on the specific productivity and grinding efficiency, the appropriate grinding parameters were ascertained as follows: material ball ratio of 07, ceramic ball medium size ratio (10 mm: 15 mm: 20 mm = 3:2:5), stirring speed of 110 rpm, grinding concentration of 50%, Highefficiency and energyconservation grinding technology using 2014年10月1日 In a test performed in the Loesche test center in Germany, copper slag grinding saved 229% energy in an airswept model and 344% energy in an overflow model [13,14]Copper Ore Grinding in a Mobile Vertical Roller Mill Pilot Plant

.jpg)

(PDF) Grinding Media in Ball MillsA Review

2023年4月23日 grinding media in a grinding mill with about 2630 wt% chrome by Chen et al [37] using a phosphate ore in a modified ball laboratory ball mill whose electrochemical potential could be controlled1 Grindability: The grindability of the ore affects the efficiency of the grinding mill Harder ores require more energy and longer grinding times, which can impact the mill's performance and operational costs 2 Media andliner Wear: The condition of the grinding media and liners affects the mill's efficiencyUnderstanding the operation of grinding mills in the mining and 2013年8月3日 In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Calculate and Select Ball Mill Ball Size for Optimum 2017年10月26日 The following are factors that have been investigated and applied in conventional ball milling in order to maximize grinding efficiency: a) Mill Geometry and Speed – Bond (1954) observed grinding efficiency to be a function of ball mill diameter, and established empirical relationships for recommended media size and mill speed that take this factor into Factors Affecting Ball Mill Grinding Efficiency

Effect of Water Density on Grinding Mill 911Metallurgist

2015年7月29日 As you increase the volume of the through put, the time that the ore has to react to the grinding media is lessened As you add ore to the mill you are also adding WATER and changing density which affects the slurry rheology and workings of the grinding action inside that mill This water is one of the main controls that you have over your grindAbout 200 kg of each ore type was homogenized using the coning and quartering method to obtain a representative sample weighing approximately 50 kg The 50 kg samples were stage crushed to 100% passing 3350 µm (a suitable feed size for the laboratory ball mill) using a laboratory jaw crusherEffect of mineralogy on grindability A case study of copper oresSBM ultrafine powder technology co,ltd Is China's excellent ore mill supplier Our main products include ultrafine vertical roller mill, ultrafine ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected] language >Shibang Industry Technology Group, Shanghai Ultrafine Powder Tech SBM Ultrafine Powder Technology Industrial Grinding Mill, 2024年11月21日 The grinding and grading stage of lithium ore is to ensure that lithium minerals are fully dissociated from gangue mineral monomers Therefore, lithium ore extraction is inseparable from ore grinding, and the common equipment for lithium ore grinding is ball mill Onestage closedcircuit grinding and grading process can be adopted, and the onestage Ball Mill Is Indispensable For Lithium Ore Processing

Population balance model approach to ball mill optimization in iron ore

2014年1月1日 An analysis of the kinetics of dolomite grinding in a dry ball mill reveals that the following approximations apply for the parameters of the batch grinding model: the size discretized selection 2008年12月1日 Overload in mill is a worksituation fault that commonly occurred in grinding processes This worksituation fault may cause the deterioration of the product quality and even a total collapse of Intelligent monitoring and control of mill load for grinding processes 2015年3月10日 DOI: 101016/JMINPRO201410002 Corpus ID: ; Copper ore grinding in a mobile vertical roller mill pilot plant @article{Altun2015CopperOG, title={Copper ore grinding in a mobile vertical roller mill pilot plant}, author={Deniz Altun and Carsten Gerold and Hakan Benzer and Okay Altun and Namık A Aydogan}, journal={International Journal of Copper ore grinding in a mobile vertical roller mill pilot plantAt Bellian Mining Machinery, we specialize in crafting advanced solutions for ore crushing, sand making, and grinding processes Whether it's efficiently crushing ores, 200+ Ore Milling Ball Mill Raymond Mill Horizontal ball mill and vertical Raymond mill can be used for milling of 200+ ores, with a fineness of 1002500 meshOre Crushing, Sand Making, Grinding Machinery Bellian Mining

.jpg)

Fine Grinding as Enabling Technology – The IsaMill

Table 1: Power Intensity of Different Grinding Devices Ball Mill is a 56m D x 64m L @ 26MW Tower Mill is a 25m D x 25m L @ 520KW Table 2: Mill Comparison of Media Size, Power Intensity, number of grinding media The ability to use smaller media is probably the dominant impact on grinding efficiency It2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM2016年11月7日 In Fig 13 is shown a large ball mill, designed for the dry grinding of limestone, dolomite, quartz, refractory and similar materials; this type of mill being made in a series of sizes having diameters ranging from about 26 in to 108 in, with the corresponding lengths of drum ranging from about 15 in to 55 inGrinding Mills Common Types 911Metallurgist2020年12月1日 During the process of mineral grinding, mill load parameters (MLPs) determine the information of the mechanical signals So, online MLPs detection is one of the key factors for improving the Expand Highly Influenced 4 Excerpts; Save Fault Diagnosis of Rolling Bearing Based on CBAMICNNExperimental analysis of wet mill load parameter based on

Grinding Mill Design Ball Mill Manufacturer 911Metallurgist

2017年2月20日 All Grinding Mill Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material When choosing primary autogenous grinding, run of mine ore up to 200300 mm in size is fed to the mill When using a crushing step before the grinding, Xiaolong Zhang's 21 research works with 443 citations and 8,915 reads, including: Enhanced iron extraction from highphosphorus waste limonite ore via suspension magnetization roasting: A pilot Xiaolong Zhang's research works Northeastern University 2013年4月16日 ABSTRACT In this study, ultrafine grinding of a refractory silver ore tailings was studied A laboratory scale pintype vertical stirred mill and ceramic beads were employed for the grinding testsInvestigation of some parameters affecting the Ultrafine grinding 2023年12月1日 The precise control of multijoint manipulators presents significant challenges in the context of replacing internal liners of large grinding machines These chTerminal sliding mode control based on recursive stochastic

.jpg)

Ball Rod Mill Density – How Water Impacts Grinding

2015年8月6日 It affects retention time and helps distribute the ore throughthe mill so each piece of rock will come in contact with the surface of the rods The % solids by volume of the rod mill discharge Rod mill grinding efficiencies have been shown to increase in the range of 5 to 15% with more dilute discharge slurry (ie, SAG MILL TESTING AN OVERVIEW OF THE TEST PROCEDURES AVAILABLE TO CHARACTERIZE ORE GRINDABILITY AUTHOR: FO VERRET, G CHIASSON AND A MCKEN SGS KEYWORDS Comminution, grindability, grinding, SAG mill, AG mill, milling, HPGR, work index, pilot plant INTRODUCTION The resistance of ore samples to breakage (or hardness) is SAG Mill Testing Test Procedures to Characterize Ore Grindability2015年8月6日 In conventional milling, the ore is crushed to, plus or minus, 3/8 of an inch, before it is put into a mill for grinding In a autogenous mill the ore is fed directly into the mill from either the primary crusher or the mine itself The size AG Autogenous Grinding 911Metallurgist2015年4月15日 For each ball mill grinding step, a Bond ball mill grindability test for Work Index at one mesh size coarser than the desired 80% passing size and at the mesh size of or just finer than the 80% passing size If 50 mm x 75 mm (2″ x 3″) ore lumps are available an impact crushing Work Index testWhat Ore Testing is Required For Mill Selection

Physicochemical Problems of Mineral Processing Investigation

2017年3月20日 An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studiedWet Pan MillWet Pan Mill, also called Wet Pan Mill, is mainly working for preliminary grinding for gold, silver, lead, zinc, iron, and copper ore concentration, but also one of the main milling machines to replace of ball mill Our pan mill is suitable for smallscale gold mining, transportation inconvenience, and lackWet Pan Mill Hengcheng Mining Equipment Co,ltd2023年12月4日 A vertical roller mill is a grinding equipment for many industries such as minerals, cement, and ceramics It is also used to grind slag and nonmetallic ores The VRM decreases the number of equipment in the grinding circuit by combining the drying, crushing, grinding, and particle segregation in one unit Numerical Investigation of Vertical Roller Mill Operation Using CLUM series of ultrafine gypsum powder vertical grinding mills are a new type of ultrafine industrial ore grinding equipment that integrates grinding, grading, powder collection and conveying +17CLUM Ultrafine Vertical Grinding Mill

Mill (grinding) Wikipedia

A mill is a device, often a structure, machine or kitchen appliance, that breaks solid materials into smaller pieces by grinding, crushing, or cutting Such comminution is an important unit operation in many processesThere are many different types of mills and many types of materials processed in them Historically mills were powered by hand or by animals (eg, via a hand crank), 2016年6月6日 Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughputSAG Mill Grinding Circuit Design 911Metallurgist