Choice of vibration direction angle of vibrating conveyor

.jpg)

Analysing the vibrating conveyor ScienceDirect

1978年1月1日 Several possible vibrating conveyor designs—the “sealskin” conveyor, the “jerk” conveyor, the conveyor with inclined motion and the conveyor with outofphase motion—are first discussed and their relative performances are comparedVibrating conveyors have the carrying element often directly connected to the frame by either leaf springs or through an inertia element aiming on reactive dynamic power minimization The leaf A MECHANICAL MODEL OF THE VIBRATION CONVEYOR TULMost vibratory conveyors throw their contents forward in small increments, which can cause delicate items to break or bruise By contrast, our horizontal motion conveyors replace the How to Choose the Proper Vibratory Conveyor for Your Needs2022年1月1日 It is generally accepted that the angle of the direction of vibrations, the frequency of vibrations and the amplitude of vibrations are the design parameters of the vibratory The results of the study of the vibratory conveying ScienceDirect

.jpg)

Movement Regimes and Determining the Main Parameters of

2021年2月25日 Vibrating conveyors (Fig 62), provide material transport through a gutter driven in a harmonic oscillating motion, which repeatedly throws the material from the gutter to the Increasing the angle of disphasing of the vibrators can entail a rotation of their resultant force and an increase in the amplitude of transverse vibrations (in the x direction) of the conveyor body Apart from emergency situations, such as the Influence of vibratory conveyor design parameters on 2023年2月5日 At the initial stage of data processing, the spheroid movement mode with a diameter of 3 mm along the vibratory conveyor surface was evaluated with the following pre Application of Mathematical Methods to Evaluate Vibration 2024年11月19日 How to Choose the Proper Vibratory Conveyor for Your Needs At Triple/S Dynamics, our goal is to match every single client to a conveyor system that meets their A Guide to Selecting a Vibratory Conveyor for Your Application

Vibratory conveying—analysis and design: A review

1979年1月1日 When the track is vibrated the bristles act as cantilever springs which push the material in the forward direction Short vibratory feeders used to discharge bulk materials from Difference 2#: Working principle The vibrating conveyor uses the reciprocating vibration of the conveying trough to convey the material There are two ways of conveying the material in the trough, which is the sliding motion and the Vibrating Conveyor vs Vibrating Feeder: Top 7 ei ˚ ei = ˜ ˚ ˛ ˝Modelling of transverse vibration of conveyor belt in aspect of 2022年12月7日 Vibrating conveyors are used in places where cleanliness and low maintenance are very important, Because of their durability and low maintenance requirements, these conveyors are a good choice for Vibrating Conveyors : Their Types and Function DPH

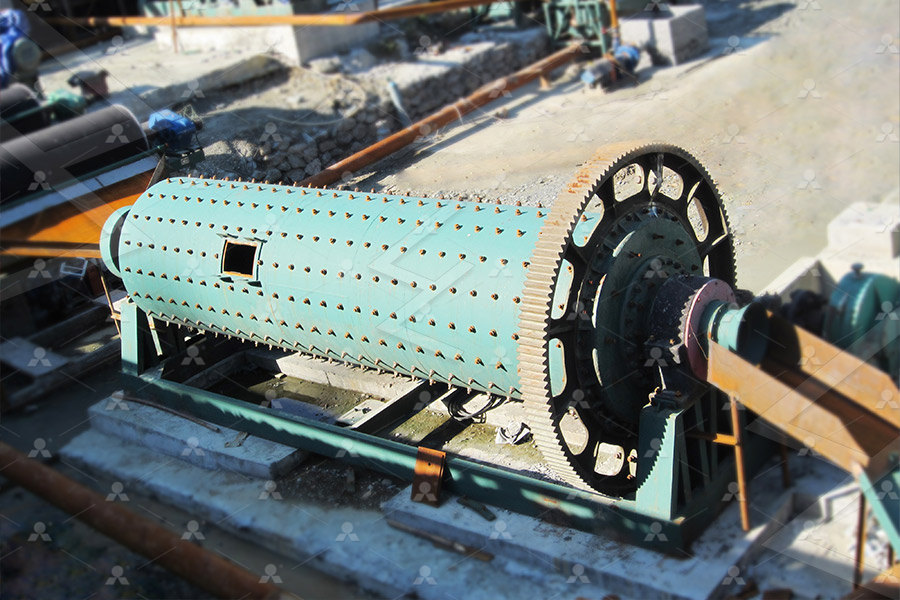

CFB石灰石脱硫剂制备64.jpg)

The Mathematical Model of Motion of Particles in Vibrating Conveyors

Oscillating inertial conveyors, oscillating vibrating conveyors, continuous movement of the point, harmonic oscillations, friction force I INTRODUCTION Vibration in technology usually has undesirable effect [1, 2] However, there is a whole class of machines and mechanisms that have the basic principle of the vibration process [3, 4]When it comes to moving bulk materials from one place to another, vibrating conveyors are often used as an efficient and reliable option Vibrating conveyors are known for their ability to move materials in a gentle, fluidlike manner, helping to reduce degradation and breakage while minimizing noise and energy consumption In this article, we will Read More »Exploring the Different 4 Types of Vibrating Conveyors and their ProsVibra Screw’s line of Vibrating Conveyors offers a simple and efficient means to meter and convey your dry bulk material Skip to content Phone: 9732567410 : info@vibrascrewVibrating Conveyors Vibrating Conveyor Vibra Screw 2019年10月28日 brating conveyor machine for multistage processing of products with mechanical combined vibration excitation Note: 1 flexible belt; 2, 3, 4, 5, 9 supporting (PDF) Substantiation of regime parameters of vibrating conveyor

Modelling of transverse vibration of conveyor belt in aspect of

2023年11月14日 The transverse vibration of conveyor belts is a crucial aspect in their proper and safe design, as the correct determination of vibration frequencies is essential to avoid unsafe operating 2023年11月14日 Introduction Vibrations of conveyor belt are a common dynamic phenomenon that occurs during the normal operation of the conveyor 1The vibration characteristic is extremely important factor for the proper and uninterrupted operation of the conveyor 2, 3, and incorrect vibration conditions can lead to failure 4, 5These vibrations can be classified as longitudinal or Modelling of transverse vibration of conveyor belt in aspect of Download scientific diagram Dynamic model of vibrating screen from publication: Study of the dynamics and analysis of the effect of the position of the vibration motor to the oscillation of Dynamic model of vibrating screen Download Scientific Diagramconveyors, if their axes of rotati on form a small angle with the dire ction of conveying [12] When this condition is not satisfied, they begin to roll down the trackDynamics of Cylindrical Parts for Vibratory Conveying

Numerical simulation and analysis of vibration screening

2011年5月1日 Download Citation Numerical simulation and analysis of vibration screening based on EDEM In order to find the best kinematical parameters (amplitude, frequency, vibrating direction angle), to The vibrating conveyor usually works in a nearresonance state When the main vibration spring deforms, it stores energy and releases energy when the deformation decreases However, during the working process of the vibrating conveyor, part of the energy will be lost, which must be replenished by the exciter or the transmission partstructure characteristic of singlemass vibrating conveyorVibrating conveyors are a critical component of many material handling systems They use vibrations to move materials from one place to another in a safe, efficient, and costeffective manner A vibrating conveyor consists of several components that work together to maintain the necessary vibration and transport the material Components of a Vibrating Conveyor Summary Understanding the Components of a Vibrating ConveyorKeywords: Vibration, Noise, Conveyor belt Introductions Tube and belt conveyors are most commonly used for transporting loose and small solid materials Like any machinery, even belt and tube conveyors are the source of noise An important source of noise is the roller, which leads the conveyor belt Another noise is emitted by theNoise and Vibration Analysis of Conveyor Belt Manufacturing

.jpg)

How to Calculate the Capacity of a Vibrating Conveyor

Formula for Calculating the Capacity of Vibrating Conveyors The capacity of a vibrating conveyor can be calculated using the following formula: q = Kd x a x n x v x 60 x t x Φ / 2 x 1000 Where: q = the capacity of the vibrating conveyor (kg/m) Kd = coefficient of friction; a = crosssectional area of the material on the belt (m²) n 2021年2月25日 Vibrating conveyors (Fig 62), provide material transport through a gutter driven in a harmonic oscillating motion, which repeatedly throws the material from the gutter to the desired direction of advancementAfter each throw a jump follows, and when the component parts of the material return, it is in a position where a new throw followsMovement Regimes and Determining the Main Parameters of Potravinarstvo Slovak Journal of Food Sciences Volume 13 754 No 1/2019 In order to select effective operating conditions, an analysis of the dynamics of the vibration excitation powerSUBSTANTIATION OF REGIME PARAMETERS OF VIBRATING CONVEYOR 2019年1月4日 Vibratory conveyors are very important elements of production lines Very often there is a need to change the feed transport velocity, especially in the case of feeders, or to alter the transport direction in the case of symmetric production lines The transport possibilities of the new vibratory conveyor, allowing fast changes of the velocity and direction of transporting, Control of the transport direction and velocity of the twoway

.jpg)

How to Choose the Proper Vibratory Conveyor for Your Needs

Horizontal Motion Conveyor is the closest approach to a zeromaintenance vibration conveyor Nothing to adjust No critical rubber parts Replacement parts are bearings, seals, and timing gears How to Choose the Proper Vibratory Conveyor for Your Needs sssdynamics sales@sssdynamics 2148288600 3PDF On Oct 24, 2019, Frantisek Klimenda and others published Noise and Vibration Analysis of Conveyor Belt Find, read and cite all the research you need on ResearchGateNoise and Vibration Analysis of Conveyor BeltVibration Conveyor Fedor A Kipriyanov, PhD in Engineering, along a vibrating conveyor surface has been carried out to further optimize the design parameters of the conveyor The RungeKutta (oscillation direction angle), 𝜉( )=𝐴 𝑖 𝜔 Application of Mathematical Methods to Evaluate Vibration ConveyorWorking principle of vibrating conveyor The vibrating conveyor uses two vibration motors as the excitation source Using the principle of selfsynchronization, when the vibration motor rotates in the opposite direction, the balance frame at the Structure and Working Principle of Vibrating Conveyor

Description of the vibrating conveyor: 1main frame, 2middle

Download scientific diagram Description of the vibrating conveyor: 1main frame, 2middle frame, 3upper frame, 4tilting frame, 5transparent transport trough, 6hopper, 7opening flap, 8 2023年9月18日 tory conveyors in general motion, Journal of Theoretic al and A pplie d Mechanics, 58, 2, 513524 7 Czubak P, Gajowy M , 20 22, Influence of selected physical parameters on vibroinsulation of(PDF) Selfsynchronization of drive vibrators of an antiresonance 2022年8月2日 The main vibration spring and the vibration isolation spring are the elastic elements in the vibrating conveyor system The function of the main vibration spring: the main vibration spring supports the conveying trough, which is usually installed obliquely, and the inclined angle is ß (vibration angle) , making effective use of vibration energy5 Important Components of Vibrating Conveyorsthe material horizontally ie with vibrating conveyors, feeders or when it is necessary to control the feed rate by variable speed controllers This type of motion is also necessary for compacting materials However, as shown in the following figure, two synchronous motors rotating in the same direction will produce torsional vibrationConstruction, Working and Maintenance of Electric Vibrators and

.jpg)

Wood pellets transport with vibrating conveyor: experimental

2021年8月16日 To analyse, in detail, the vibration transport of the samples (R and P) and to compare real measurements of the transport speed of pellets and wood rods, the vibrating conveyor was scanned during DOI: 101177/52603 Corpus ID: ; A new study on dynamic adjustment of vibration direction angle for dualmotordriven vibrating screen @article{Chen2020ANS, title={A new study on dynamic adjustment of vibration direction angle for dualmotordriven vibrating screen}, author={Bing Chen and Jiwei Yan and Zhong Jun Yin and Kumar K Tamma}, A new study on dynamic adjustment of vibration direction angle Vibrating conveyors are installed to transport mainly granular goods; they are supported or suspended by springs The troughs are driven and controlled by connecting rods, eccentric masses, or electromagnets, to perform a vibrating motion at a high frequency with a small amplitude, transporting the goods by microbouncesTheory of Vibrating Conveyors bulkonline2018年10月30日 Hydraulic systems are equipment widely used in stationary industrial equipment and in moving agricultural equipment and construction machines Currently, the rotation of the vibrating conveyor belt of the peanut diggerinverter is triggered by the tractor power takeoff Considering that for the equipment to operate at its optimal, the tractor engine Development of an electrohydraulic drive system for the vibrating

Vibrating conveyors Qlar

Vibrating conveyors also include vibrating spiral conveyors, or vibratory feeders ideal for sorting individual parts How it works The vibrating conveyor moves upwards at a sinusoidal angle in the direction of transport With each forward feed it lifts the material depending on the cast parameter and pushes it in the desired direction2021年8月2日 Vibrating screen is a screening equipment used in the production of coal mines, building materials and other industries According to different trajectories, vibrating screens can be divided into linear vibrating screens, circular vibrating screens, etc Among them, the linear vibrating screen uses a vibrating motor as the vibration source, so that the material is thrown The working principle and structure of the linear vibrating tray is the nature of the vibration effect: frequency, amplitude, direction of oscillation There arises the task of constructing a model of the motion of particles of granular medium in the chute of a vibrating conveyormixer Figure 1 shows a diagram for solving the modeling problem the cross section of the tray in the form of an arc of a Simulation of the process of movement of bulk material in a vibrating Fig 65 Constructive solutions of vibrating conveyors (principle diagrams and model) Number of masses operated in the vibration movement: with a single drive vibrating mass (cases 11–14), with two masses but only one drive mass (21–24), with two driven masses (31–34); Number of vibrating mechanisms: with one or two vibrating Movement Regimes and Determining the Main Parameters of

.jpg)

Vibrating Conveyor Applied Vibration

Driven by vibrator motor drives, an Applied Vibration vibrating conveyor is suited to applications with high throughput conveying rates Skip to content 01827 318 020 nload scientific diagram Test bed of double driving vibrating screen with comparison from publication: A new study on dynamic adjustment of vibration direction angle for dualmotordriven Test bed of double driving vibrating screen with comparisonSpecifications Applications: Foundries, recycling industries, concrete and cement, glass manufacturing, coal power generators, petfood, fastener coin production; Features: Utilizes linear vibrations for gentle and consistent material flow, ensuring minimal material degradationWith Electromagnetic drive it’s possible to variable the feed rate control from 0% Vibrating Conveyors SKAKO A/S2020年8月19日 For a dualmotordriven elliptical vibrating screen, the driving frequencies of the two motors are studied in this paper and it exposes the significant influences of different driving frequencies on the vibration direction angle of the selfsynchronous systemA new study on dynamic adjustment of vibration direction angle

.jpg)

Analysing the vibrating conveyor ScienceDirect

1978年1月1日 Several possible vibrating conveyor designs—the “sealskin that criteria for the choice of conveyor type and of its design parameters can With ~ = 06, vf can rise to 22 m/s2 More interestingly, equations (9) and (10) yield the vibration angle for best performance as a function of the coefficient of friction, ie