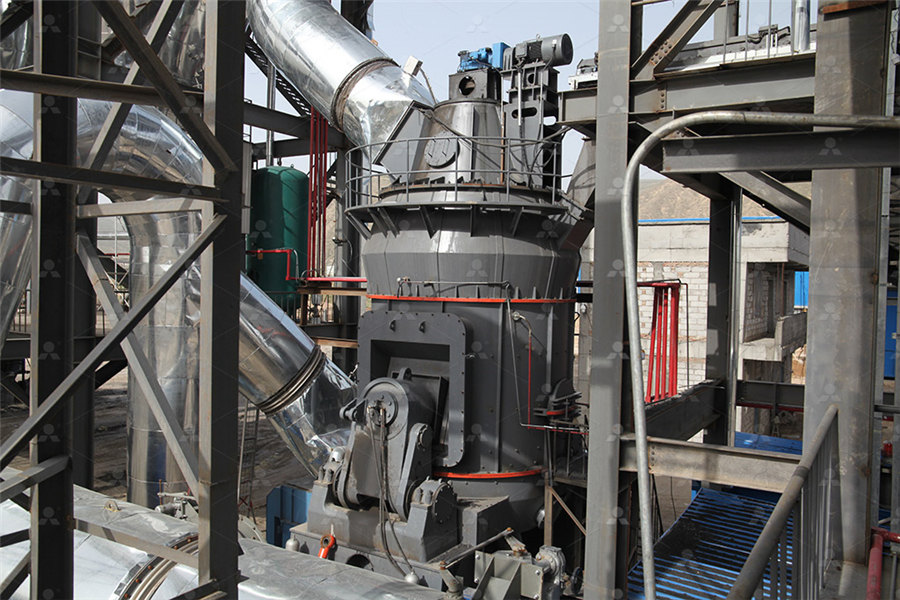

Calcium carbide slag vertical roller mill solution

.jpg)

2 µm 5 µm Loesche

slag in roller grinding mills (vertical airswept grinding mills) is a technology introduced by Loesche The first use of a Loesche mill, with a grinding track diameter of only 11 metres, was used as 2022年5月1日 CCS is physically purified by hydrocyclone and chemically separated by NH 4 Cl treatment to obtain 999% calcium chloride solution During lowtemperature carbonization, the Recycling and utilization of calcium carbide slag ScienceDirectMaterials: Calcium carbonate, limestone, barite, heavy calcium carbonate, etc Capacity: 300,0001,000,000 t/a Equipment: GRMR vertical roller mill + auxiliary machines, etc the production limestone grinding plant CHAENG2022年1月10日 Calcium carbide slag or mixture with NaOH solution were used as alkali activators Hightemperature curing can significantly improve the properties of the CWAAMs Mechanical, microstructure and reaction process of calcium

.jpg)

Grinding Process Optimization Featuring Case Studies and

Vertical roller mills have been used successfully for the combined drying and grinding of cement raw material, coal, cement clinker, blastfurnace slag and composite cements forHighquality slag vertical roller mill manufacturer The slag vertical mill is a grinding equipment for granulated blast furnace slag developed by Tongli Through integrated grinding and powder Slag Vertical Roller Mill CEMENTLUsing the solid waste carbide slag produced by the calcium carbide industry to absorb CO 2 and convert it into useful products not only improves the utilization value of carbide slag but also Resource utilization of solid waste carbide slag: a brief review of 2022年7月14日 The test results show that carbide slag and limestone have almost the same desulfurization effect The kinetics of carbide slag desulfurization process conforms to pseudo Desulphurization mechanism and engineering practice of carbide

Comprehensive Utilization of Carbide Slag SpringerLink

2019年5月23日 Carbide slag (acetylene sludge) is the industrial residue, which is discharged when the hydrolysis of calcium carbide is undertaken to prepare acetylene The slag mainly 2021年12月10日 The suggested optimum preparation conditions for the particles are as follows: bentonitetocarbide slag mass ratio of 3:7, Na 2 CO 3 dose of 10 wt%, and calcination Formation mechanism of carbide slag composite sustained 2022年5月1日 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coalbased CaC 2CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are generated annually in China, among which only a Recycling and utilization of calcium carbide slag ScienceDirectThe GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel Calcium carbonate, limestone, barite, heavy calcium carbonate, etc Capacity: 300,0001,000,000 t/a Equipment: GRMR vertical roller System Solutions ball mill roller press + ball mill vertical roller mill; System Steel Slag Vertical Mill CHAENG

Picture: Loesche GmbH, Germany CEMENT SikaGrind® FOR VERTICAL ROLLER MILL

(granulated blast furnace slag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller pressCarbide slag has uniform composition and high calcium content which is a highquality cement raw material It is the most thorough method to replace limestone to produce cement The production of cement from carbide slag usually adopts the process of “wet grinding and dry burning” or predrying “dry grinding and dry burning”News Carbide Slag Grinding Plant HLM Vertical MillNickel Slag Grinding Plant Materials: Nickel Slag Main Equipment: GRMSS Slag Vertical Mill Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse Steel Slag Grinding Plant Materials: Steel slag Main equipment: GRMSS Steel Slag Vertical Mill Applications: Roads, building materials, soil amendments, Vertical Lime Kiln CHAENGLimestone is the main raw material for the manufacture of cement, lime and calcium carbide, Main Equipment: GRMSS Slag Vertical Mill Matching Equipment: Vertical Roller Mill: Power Consumption kwh/t: 40: 45: 28: Fineness: 200400: 40400: 200600: Advantage:limestone grinding plant CHAENG

Grinding Process Optimization Featuring Case Studies and

Fig 2 Modular Vertical Roller Mill 5000 R4 Installed in Canada Fig 3 Modular Vertical Roller Mill 5000 R4 Installed in Canada V Operational Experience with Modular Vertical Roller MillsThe rocker arm is one of the main components of the vertical roller mill Each set of rocker arm includes an upper rocker, a lower Calcium carbonate, limestone, barite, heavy calcium carbonate, etc Capacity: 300,0001,000,000 t/a Equipment: GRMR vertical roller mill Solutions Slag Grinding Plant Steel slag grinding plant Active lime Vertical mill rocker arm CHAENGslag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller millsGetting started; Vertical Roller; Vertical Roller China Manufacturers, Factory, Suppliers We take pleasure in an extremely fantastic standing among the our prospects for our great product top quality, competitive cost and the finest support for Vertical Roller, Coal Milling Machine, Quartz Stone Grinding Machine, Cement Limestone Grinding Mill,Cement Production PlantVertical Roller China Manufacturers, Factory, Suppliers

.jpg)

Flyash Slag Calcium Carbonate Cement Coal Vertical

Type: Vertical Roller Mill Motor Type: AC Motor Motor Power: 135kw Rotationl Speed: 1315r/min Application: Mine Materials: Coal, Slag, Flyash, Cement, Calcium CarbonateVertical roller mill Vertical cement mill is a large cement grinding equipment Tongli has successfully developed various models such as ZJTL vertical ultrafine powder roller mill in the field of cement and slag grinding with technological innovation over the years In 2016, Tongli developed the largest limestone raw material vertical mill and cement clinker vertical mill with a Vertical roller mill CEMENTLSteel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500㎡/kg, which is widely used in cement and concrete admixture, realizing the highvalue resource utilization of steel slagSteel Slag Grinding Plant CHAENGHCM Machinery solid waste grinding mill learned that the "National Climate Change Plan (20142020)" pointed out that "the cement industry should encourage the use of calcium carbide slag, paper sludge, desulfurization gypsum, fly ash, metallurgical slag tailings and other industrial waste residues and volcanic ash and other noncarbonate raw materials instead of traditional Substitution of cement raw materials: How to use paper sludge?

News How Is Silicon Carbide Powder Produced? Production

Silicon carbide powder can be seen in concrete, refractory and other industries, and its application is very extensive Its products have also achieved success in engineering boards, wearresistant floors, coatings, functional mortar, etc There are also developments in other fields, such as using silicon carbide powder to manufacture corresponding products under the condition of Type: Roller Mill Motor Type: AC Motor Motor Power: 145430kw Rotationl Speed: 1322r/Min Application: Mine Materials: Limestone Slag Coke Gangue CoalRaw Material Slag Calcium Carbonate Vertical Roller Mill MachineThis vertical mill machine is applied in electric power, metallurgy, chemical and nonmetallic industries, such as portland cement and blended cements, limestone, slag, manganese, gypsum, coal, barite, calcite etc HLM vertical grinding mill has proven to be a versatile grinding tool that exhibits many advantages over traditional ball milling, it is also faster to install than a traditional Best HLM Vertical Roller Mill Manufacturer and FactoryGetting started; Phosphorite Vertical Mill; Phosphorite Vertical Mill Manufacturers, Suppliers, Factory from China We consistently execute our spirit of ''Innovation bringing progress, Highlyquality ensuring subsistence, Administration advertising and marketing gain, Credit history attracting buyers for Phosphorite Vertical Mill, Gypsum Powder Production Line Manufacturer, China Phosphorite Vertical Mill Manufacturers and Factory,

2 µm 5 µm Loesche

a Loesche mill, with a grinding track diameter of only 11 metres, was used as long ago as 1935 However, the breakthrough in grinding this type of material on the vertical roller mill did not take place until the beginning of the 1990’s 1935 The first Loesche mill for grinding cement clinker, an LM 11, was commissioned in Joao Pessao, BrazilHCMilling(Guilin Hongcheng), as the manufacturer of calcium aluminate powder production equipment, our HLM series calcium aluminate vertical roller mill, HC series large calcium aluminate Raymond mill, and HLMX series calcium aluminate superfine vertical roller mill provide the calcium aluminate powder production line with the support of grinding equipment at various News Calcium Aluminate Powder Production Equipment Calcium First stage: broken The bulk material of calcium carbonate is crushed by the crusher to the incoming fineness (15mm50mm) which can enter the millcalcium carbonate grinding mill, calcium carbonate 2023年10月3日 Founded in 1958 Zhejiang Tongli Heavy Machinery Co, Ltd is an equipment manufacturer very famous in China domestic market for making ball mill, vertical roller mill, rotary kiln and all sorts of cement fertilizer production equipment, even though not as famous as FL Smidth, but Tongli is constantly improving to provide toptier product and service to global What is a vertical roller mill (VRM)? A Comprehensive Guide to

.jpg)

Effects of calcium carbide slag on properties and carbon

2024年6月1日 CO 2mixing by directly injecting CO 2 into fresh cementbased materials is a burgeoning technology to produce lowcarbon cement products The objective of this study is to investigate the influence of the calcium carbide slag (CCS) content on the properties and carbon sequestration efficiency of cement pastes mixed under direct CO 2 injection conditions2019年5月23日 This way, Ca 2+ concentration in Ca(OH) 2 solution is higher than that in CaCO 3 solution Among the carbide slag desulfurization methods, in the spray reaction section of the desulfurization tower, Chen CL, Li SY (2013) Production of green low carbon cement from calcium carbide slag Shihezi Sci Technol (3): 25–28 Google ScholarComprehensive Utilization of Carbide Slag SpringerLink2024年10月15日 Carbide slag (CS) is a typical alkaline solid waste with Ca(OH) 2 as its main component, exhibiting a high capacity for CO 2 mineralization Currently, the methods for CS mineralization of CO 2 include direct and indirect mineralization which the initial pH of the reaction system plays a crucial role in the mineralization process In this study, we explored the effects Optimizing carbonation reaction parameters of calcium carbide slag 2024年2月26日 With the increasing accumulation of alkaline industrial solid waste, the mineralization of CO2 using alkaline industrial solid waste has broad application prospects Carbide slag is highly alkaline and contains a large amount of calcium elements, making it an excellent material for CO2 mineralization Our idea was to acquire qualified products and fast Research on Utilizable Calcium from Calcium Carbide Slag with

Four factors Affecting the Grinding Efficiency of Raymond Mill

The particle size of automatic Raymond mill products can be 0180038mm according to different requirements It is widely used in production of papermaking, coatings, plastics, rubber, ink, pigments, building materials, medicine Customer's site of RSeries Roller Mill RSeries Roller Mill Max feeding size: 1540mm Capacity: 0320t/hVertical Roller Mill Steel Slag Vertical Mill Ball Mill Raw material mill Coal Mill Slag Mill Cement agriculture, calcium carbide, environmental protection and chemical industries Features of the production line Mainly complete the automatic weighing compensation Solutions Clinker Grinding Unit Lime Production Line Cement Plant Media Vertical Lime Klin Great WallType: Vertical Roller Mill Motor Type: AC Motor Motor Power: 135kw Rotationl Speed: 1315r/min Application: Mine Materials: Coal, Slag, Flyash, Cement, Calcium CarbonateHigh Efficiency Ultrafine Calcium Carbonate Coal Slag Cement Vertical slag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller mills

.jpg)

Solution Grinding Mill, mineral mill, limestone mill, calcite mill

7TPH MTW145G Limestone Grinding Mill In Sichuan, China Output size:180 mesh2022年5月1日 Coal is the dominant fuel in China to provide primary energy, and 70% of polyvinyl chloride is produced from coalbased CaC 2CaC 2 reacts with water to produce acetylene and calcium carbide slag (CCS) as a solid waste for polyvinyl chloride production Approximate 40 million tons of dry CCS are generated annually in China, among which only a Recycling and utilization of calcium carbide slag ScienceDirect2021年3月9日 Slag vertical mill of the modular design powder company has formed a series of type spectrum, which is divided into 16 types according to the disc diameter, from the minimum disc diameter of 25m to the maximum disc diameter of 65m; according to the number of rollers, it is divided into tworoller mill and threeroller mill, the grinding roller diameter is from 1 400mm Blast Furnace Slag Vertical Mill China Supplier in Zhengzhou, Slag 2 How Vertical Roller Mills Work in Slag Processing Vertical roller mills operate based on the principle of compression and attrition The slag is fed into the mill's grinding chamber, where it is pressed against a rotating disc with grinding rollers The pressure and the abrasive action of the rollers grind the slag into a fine powderThe utilization of vertical roller mills in mineral slag processing

Mechanical, microstructure and reaction process of calcium carbide slag

2022年1月10日 For samples SF0M, the primary activator calcium carbide slag contains calcium hydroxide and calcium oxide Similarly, it has been shown that Ca 2+ produced during CaO bond fracture can react rapidly with Si/Al tetrahedra to form 2022年3月1日 CO 2 mineralization of carbide slag for light calcium carbonates by ammonium chloride circulation route 243 Carbon dioxide sequestration via steelmaking slag carbonation in alkali solutions: Experimental investigation and process evaluation Acta Metall Sin Engl Lett, 31 (7) (2018), pp 771784CO2 mineralization of carbide slag for the production of light calcium The document discusses Gebr Pfeiffer AG's MPS vertical roller mills for grinding slag and their effectiveness It notes that since 1980, an MPS 3750 C mill in Hannover has been producing cement with 4080% slag content Currently an MPS 5600 BC able to produce 120t/h of slag at 5000cm2/g fineness is being installed The MPS series uses a 3roller system and classifier to 2006 Slag Grinding With MPS Vertical Roller Mills PDF MillThis vertical mill machine is applied in electric power, metallurgy, chemical and nonmetallic industries, such as portland cement and blended cements, limestone, slag, manganese, gypsum, coal, barite, calcite etc HLM vertical grinding mill has proven to be a versatile grinding tool that exhibits many advantages over traditional ball milling, it is also faster to install than a traditional Best HLM Vertical Roller Mill Manufacturer and Factory

slag vertical roller mill equipment

SOLUTION; CASES; NEWS; ABOUT US; CONTACT US; WhatsApp +71 Home; Powder equipment, in which slag vertical roller mill is the exclusive equipment to meet the production needs of the industry, Raymond Mill; Vertical Roller Mill; Calcium Carbonate Plant; Limestone Mill; SOLUTIONOur goal is to provide high quality products at competitive prices, and topnotch service to customers around the world We are ISO9001, CE, and GS certified and strictly adhere to their quality specifications for Steel Slag Vertical Roller Mill, Coal Vertical Mill Factory, Clinker Mill, Coal Cinder Grinding Mill,Kaolin Grinding MillChina Steel Slag Vertical Roller Mill Manufacturers and Factory