HOME→The influence of pulverized coal fineness on the kiln The influence of pulverized coal fineness on the kiln The influence of pulverized coal fineness on the kiln

The influence of pulverized coal fineness on the kiln The influence of pulverized coal fineness on the kiln The influence of pulverized coal fineness on the kiln

Modeling of Pulverized Coal Combustion in Cement Rotary Kiln

gassolid flow, heat and mass transfer, and pulverized coal combustion, a set of mathematical models for a fullscale cement rotary kiln were established In terms of commercial CFD code The influence of pulverized coal particle size on combustion and NOx formation of 660MW tangential combustion ultrasupercritical boiler in a power plant was studied by using Numerical simulation study on the influence of pulverized coal 2017年11月15日 A method for choosing the optimum fineness of coal in pulverisedfuel boilers is presented This method is based on economic criteria and takes into account variations of Optimisation of coal fineness in pulverisedfuel boilers2023年9月1日 The load of the mill affects the amount of pulverized coal in the third channel, but also in the other two channels At the same time, increasing the capacity of the mill reduces The Influence of Mill Loading on the Distribution of Pulverized

.jpg)

Online measurement of pulverized coal fineness on a 300 MWe

2021年6月1日 Pulverized coal fineness (PCF) is a key parameter in coalfired power plants, demanding accurate and online monitoring This study presents online measurement of PCF The predicted results indicated that the improved model accounts for the thermal enthalpy of the clinker formation process and can give more insight (such as fluid flow, temperature, etc,) from Modeling of Pulverized Coal Combustion in Cement Rotary Kiln1999年1月1日 A mathematical model is described for the numerical prediction of the distribution of velocity, temperature, species concentration and particle trajectories in an axisymmetric (PDF) Modeling coal combustion in a rotary cement kilnThe experimental results show that under the same conditions such as heatingup rate and reaction environment, the released quantity of volatile matter and DTG peak value increases Experimental Investigation for effects of Pulverizedcoal Fineness

Modeling of Pulverized Coal Combustion in Cement Rotary Kiln

2006年9月6日 The distribution of velocity field, combustion temperature and component concentration field in kiln were analyzed, and the combustion characteristics of pulverized coal 2021年3月4日 Comprehension on the primary fragmentation of coal particles is important in understanding and optimizing practical coal combustion and creating credible combustion Online measurement of pulverized coal fineness on a 300 MWe 2021年3月1日 Pulverized coal fineness (PCF) is a key parameter in coalfired power plants, demanding accurate and online monitoring This study presents online measurement of PCF on a 300 MWe coalfired Online measurement of pulverized coal fineness on a 300 MWe 2021年11月26日 Characteristics of pulverized coals have significant influence on the spontaneous combustion and explosion processes This paper presents an experimental and theoretical framework on physicochemical characteristics of coal and their interrelations from spontaneous combustion and explosion perspectives The chemical properties, morphology, Physicochemical characteristics of pulverized coals and their

(PDF) Numerical simulation study on the influence of pulverized coal

2020年1月1日 The influence of pulverized coal particle size on combustion and NOx formation of 660MW tangential combustion ultrasupercritical boiler in a power plant was studied by using commercial software 2014年4月13日 In this paper, the influence of fineness on the cementitious properties of steel slag and the properties of cement containing steel slag with different finenesses were investigated The results show that increasing the fineness can significantly enhance the early as well as the late cementitious properties of steel slag However, the early hydrations of cement Influence of fineness on the cementitious properties of steel slag2016年6月23日 Our previous research summarized the influence of pulverized coal with different burnoff rates on deposit formation, and expounded the synthetic method for incomplete burnt pulverized coal [34, 35]Combustion Reaction of Pulverized Coal on the Deposit Formation in Kiln ONLINE COAL FLOW MEASURING AND BALANCING (CONTROL) AND ONLINE COAL FINENESS MEASURING SYSTEM FOR COMBUSTION OPTIMISATION IN A THERMAL BOILER Suresh G Chandwani1, Dr Francesco Turoni2, Reinhardt Kock2, Dr Michael Haug2, Dr Michael Schreiber2 1NSGuzder Company Pty Ltd, Neville House, Currimbhoy Road, CPRI Online Coal Flow Balancing and Fineness Adjustment

.jpg)

Online measurement of pulverized coal fineness on a 300

2021年6月1日 Pulverized coal fineness (PCF) is a key parameter in coalfired power plants, demanding accurate and online monitoring This study presents online measurement of PCF on a 300 MWe coalfired power plant with pulsed digital inline holography (DIH) A prototypal instrumentation system, comprised of sampling, measurement, collection, and output, is 2007年3月15日 Download Citation Influence of the micropulverized coal char fineness on NO reduction by reburning The experiment of the micronized coal char reducing NO was done in entrained flow reactor Influence of the micropulverized coal char fineness on2009年11月10日 Request PDF Morphological Characterization of Superfine Pulverized Coal Particles 1 Fractal Characteristics and Economic Fineness Superfine pulverized coal combustion is a new pulverized Morphological Characterization of Superfine Pulverized Coal 2017年8月1日 Particle size distribution (PSD) of coal powder, socalled pulverized coal fineness (PCF) [2], is a crucial parameter in coalfired power plants, with a significant effect on combustion efficiency Optimisation of coal fineness in pulverisedfuel boilers

Numerical simulation investigations into the influence of the

2020年3月6日 Numerical simulations were conducted to study the effects of the pulverizedcoal bias distribution in the primary air on the coal combustion and NOx generation characteristics of a 600MW downfired boiler with multipleinjection and multiplestaging combustion technology The total pulverizedcoal in the primary air was kept constant, and the ratio of the pulverizedcoal 2017年10月2日 Two different fineness of pulverized burnt clay waste classified as coarse and fine portion were obtained by sieving the original pulverized burnt clay waste portion through sieve sizes No 100 (PDF) Effect of Pulverized Burnt Clay Waste Fineness and 2018年5月20日 Three calcined coalseries kaolin (CCK) samples, with same chemical and mineral composition but different fineness (Blaine specific surface of 760, 1369 and 1856 m²/kg), were used as pozzolan in Influence of calcined coalseries kaolin fineness on properties of 2011年5月1日 Request PDF Influence of pulverized coal properties on heat release region in turbulent jet pulverized coal flames The effects of pulverized coal properties, volatile matter, particle size and Influence of pulverized coal properties on heat release region in

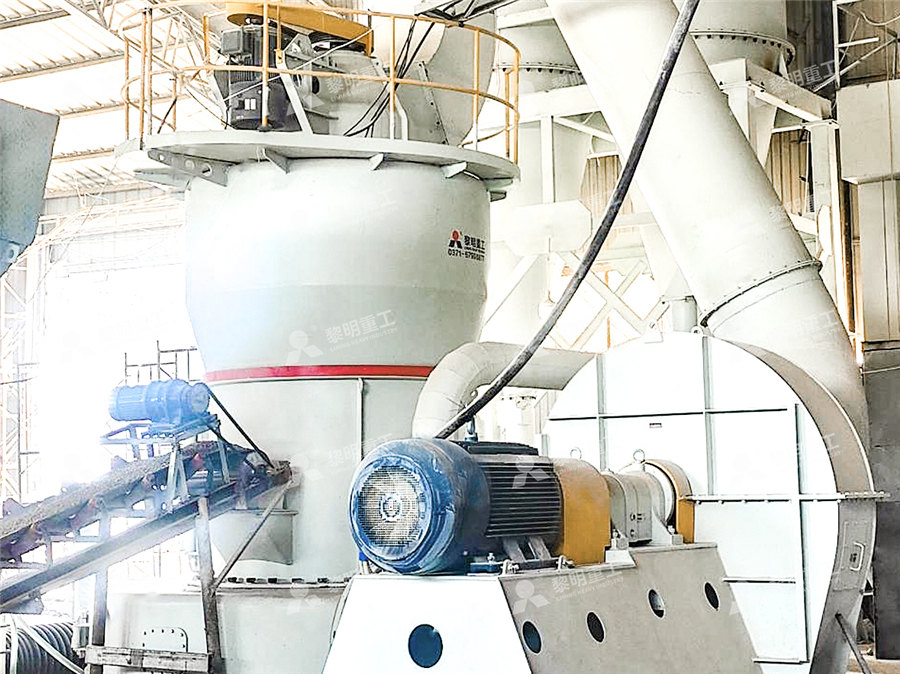

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)53.jpg)

Modeling of Pulverized Coal Combustion in Cement Rotary Kiln

In this paper, based on analysis of the chemical and physical processes of clinker formation, a heat flux function was introduced to take account of the thermal effect of clinker formation Combining the models of gas−solid flow, heat and mass transfer, and pulverized coal combustion, a set of mathematical models for a fullscale cement rotary kiln were established In terms of 2007年9月1日 For pulverized coal with particle size below 63 mm, the PM formed during combustion showed a bimodal size distribution, including a fine mode at about 05 mm resulting from fragmentation and [Coal fineness effect on primary particulate matter features during 2018年5月20日 Coalseries kaolin, a byproduct in the coal mining and dressing procedure with large reserves (about 38 billion tons in China), is rich in chemical constituents of SiO 2 and Al 2 O 3 and hence can be used as pozzolan into cement mortar and concrete after calcination [1] The partial replacement of calcined coalseries kaolin (CCK) into mortar and concrete will slowly Influence of calcined coalseries kaolin fineness on properties 2023年1月13日 Exemplary results of the analysis of the concentration of particles (with a diameter of 50 micrometers) in a dust duct and also their velocities that were assumed in the calculations(PDF) Pulverized CoalFired Boilers: Future Directions of Scientific

NOx Emission of Fine and Superfine Pulverized Coal

2010年11月12日 Final results indicate that the economic fineness of Shenhua pulverized coal particles based on E2 is about 1894, while that of Neimenggu pulverized coal particles is about 36132021年8月18日 Medium oxygenenriched blast furnaces that utilize reducing gas injections are a feasible new ironmaking process that can significantly reduce the coke ratio and carbon dioxide emissions To better inject the reducing gas into the blast furnace, two injection methods were designed in this study, and the effects of the reducing gas on the combustion of pulverized Influence of Reducing Gas Injection Methods on Pulverized Coal 2018年9月1日 The influence of pulverized coal irregularity on acoustic attenuation is investigated, the relationship among the ultrasonic attenuation, the volume fraction and size of pulverized coal is Inline measurement of pulverized coal concentration and size in Various characterization methods are used to investigate the physical and chemical properties of steel plant flying dust and waste oil sludge, and the combustion characteristics of the mixtures with pulverized coal are studied via thermogravimetric analysis; the catalytic combustion mechanism is also explored The results show that two types of metallurgical byproducts with Combustion Characteristics of Coal for Pulverized Coal

Influence of unburned pulverized coal on the viscosity of blast

2022年6月26日 In order to explore the influence of unburned pulverized coal in ironmaking on the viscosity of blast furnace slag, the impact of temperature, volume fraction of solid particles and the rotating 2013年12月1日 This approach cannot change economic fineness of pulverized coal based on the proportion of blending coal timely and accurately, resulting in increasing carbon content of flyash and reduced A New Method for Determining Pulverized Coal Economic Fineness2020年12月1日 characteristics, the fineness of the pulverized coal and slag catching rate, and explores the influence of these four factors on slag blocking of the combustor 3T est Data and AnalysisStudy on the Law of the Influence on Slag Blocking in 2022年1月3日 Request PDF Influence of Injecting Reducing Gas Through Novel Tuyeres on the Combustion of Pulverized Coal in a 40% Oxygen Blast Furnace A medium oxygenenriched blast furnace with injected Influence of Injecting Reducing Gas Through Novel Tuyeres on

Combustion Reaction of Pulverized Coal on the Deposit

The serious deposits on the refractory bricks are found in the grate kiln in iron ore pellet plants, which significantly influence the pellet production The effect of the combustion reaction of pulverized coal on the deposit formation in kiln during iron ore pellet production was investigated in this work Hematite iron ore was used as raw material to be pelletized, and the pulverized 2018年5月20日 DOI: 101016/JCONBUILDMAT201803117 Corpus ID: ; Influence of calcined coalseries kaolin fineness on properties of cement paste and mortar @article{Liu2018InfluenceOC, title={Influence of calcined coalseries kaolin fineness on properties of cement paste and mortar}, author={Yuanyuan Liu and Shaomin Lei and Min Lin and Zhang Influence of calcined coalseries kaolin fineness on properties of 2023年1月1日 In order to explore the influence of unburned pulverized coal in ironmaking on the viscosity of blast furnace slag, the impact of temperature, volume fraction of solid particles and the rotating speed on the viscosity of CaO–MgO–Al 2 O 3 –SiO 2 heterogeneous slag were studied by experiment The calculation model of relative viscosity of heterogeneous slag containing Influence of unburned pulverized coal on the viscosity of blast 2017年9月6日 In order to study the influence of the swirling jet of the gasification agent on coal gasification performance, the gasification process of Ningdong pulverized coal inside a GSP gasifier (2000 t/d Influence of the Swirling Jet on Pulverized Coal Gasification

.jpg)

Pulverised Coal Combustion an overview ScienceDirect Topics

161 Pulverized coal combustion In pulverized coal combustion (PCC), dust burners are used to feed coal into the combustion chamber, where flame core zones of the combustion chamber having a temperature range between 1450°C and 1600°C are present To attain the required efficiency, pulverized coal is given a swirling motion around the flame 2019年12月9日 It may also be used to confirm the influence of coal fineness on combustion performance a The store will not work correctly when cookies are disabled All All Meetings Standard Test Method for Sampling and Fineness Test of Pulverized Coal D019719 ASTMD019719 Standard Test Method for Sampling and Fineness Test of Pulverized CoalCai JieJin and Ma XiaoQian, “Optimization of Pulverized Coal Fineness on Coalfired Power Unit, ” boiler technology, Vol 37, No 5, pp 39–43, 2006 Google Scholar Jiang XiuMin, “Physical properties of micropulverized coal and their influences on combustion characteristics, ” Journal of Fuel Chemistry and Technology, Vol 28, No 2, pp 170–173, 2000Experimental Investigation for effects of Pulverizedcoal Fineness 2019年3月1日 The European cement standard (EN 1971, 2012) defines the requirements of supplementary cementitious materials (SCMs therein) which are the main constituents other than clinker to produce 27 common Portland cements in EuropeThe SCMs are classified according to type and composition A few of them, such as natural pozzolana (P) and limestone (L or LL), Influence of fineness of raw clay and calcination temperature on

.jpg)

The Influence of Coal Water Slurry Particle Size on the Erosion of

2022年8月9日 The liquid phase in coal slurry is mainly water, the density is 998 kg/m 3, and the viscosity is 0 Pa s; the density of the coal slurry mixed solution is 1220 kg/m 3, and the viscosity is 00012 Pa s; the density of pulverized coal particles is 1728 kg/m 3, the particle size distribution is between 005 and 2 mm, the particle size is set to be 005 mm, 01 mm, 035 2023年3月1日 Numerical Investigation of the Influence of Furnace Wall Temperature on Pulverized Coal Combustion and NO x Emissions in a Supercritical CO 2 Boiler(PDF) Numerical Investigation of the Influence of Furnace Wall 2017年11月15日 By the term “quality of pulverized coal” is understood its fineness (cumulative percentage retained R 009 and R 020) in conjunction with its homogeneity described by the uniformity (polydispersity) number nThe majority of hard coals combusted in the Polish power sector are bituminous coals of high volatile matter content in dry ash free state (V daf)Optimisation of coal fineness in pulverisedfuel boilers2010年12月16日 The effects of the fineness and shape of fly ash on the porosity and air permeability of cement pastes were investigated Pulverized coal combustion (PCC) fly ash and fluidized bed coal combustion (FBC) fly ash classified into three different finenesses were used River sand with particle size distribution similar to that of fly ash was also used for comparison Influence of fly ash fineness and shape on the porosity and

VLVRIWKHRQILJXUDWLRQDQG0RWLRQRIRDO

2022年2月17日 The fineness of pulverized coal has significant influence on the combustion pollutant, the image recognition method is directly aimed at the size and shape information of pulverized coal particles, which eliminates the possible errors in the transformation process and makes the measurement results accurately reflect the particle information2018年6月1日 PM 1 is mainly produced by the nucleation of inorganic salt vapor and continuous coagulation among submicrometer nuclei; for PM 110 , the forming process mainly includes the coalescence of Influence of coal cofiring on the particulate matter formation