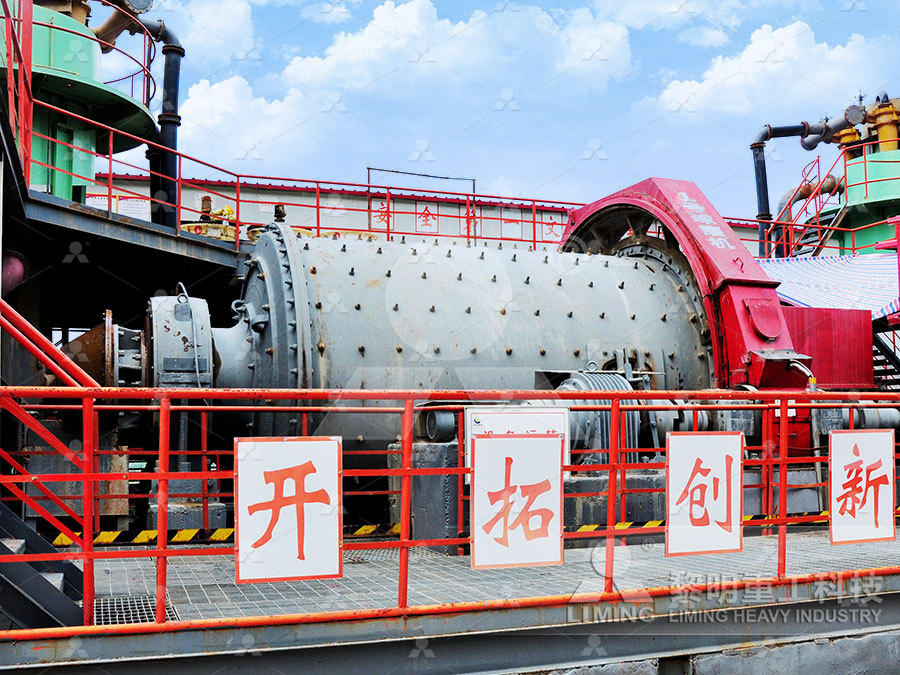

Power plant calcined coke mill model

.jpg)

Modeling and Simulation of Petroleum Coke Calcination in Pot

Measuring the calcined temperature of petroleum Coke is difficult because of the partial sealing property of the pot Usually, the manner of measuring and adjusting gas temperature in flue (layers 3, 5, and 6) is used to indirectly the control calcined temperature of petroleum Coke in a practical production process Thus, 展开Investigated coke produced from feedstock with different compositions the sulphur content, volatile matter, density value and ash content before and after heat treatment to 1100 °C were Mathematical modeling of the rotary coke calcining kilnCalcination is the main technological stage where composition homogeneity and structure peculiarities of a definite coke are formed To meet the technology requirements one should SELECTION OF KEY PARAMETERS FOR GREEN COKE CALCINATION 2001年9月1日 A steadystate onedimensional model that describes petroleum coke calcination in a rotary kiln was presented The model provides a detailed description of the kinetics and Modeling and simulation of petroleum coke calcination in rotary

.jpg)

Systems Design of a Petroleum Coke IGCC Power Plant: Technical

Goal: Evaluate and analyze the environmental impacts of petcoke IGCC power plant Scope: Cradle to Gate (CTG) Functional unit: 1 MWh of electricity Life cycle inventory: Mass Energy 2014年12月20日 Calcined petroleum coke is used for the production of carbon anodes in the HallHéroult aluminum smelting process due to a combination of low impurity levels, ready The History and Future Challenges of Calcined Petroleum Coke As bigger industrial CPC mills produce not more than 30 t/h up to now, the EM17 test mill allows precise predictions with a rather low scaleup factor of usually less than 100 Figure 4 shows, Changing the Fineness of Calcined Petroleum Coke with Ball Race 2010年10月28日 To help improve the energy efficiency of the calcining process, a 3D computational model is developed to gain insight of the thermalflow and combustion behavior Simulation of Combustion and ThermalFlow Inside a Petroleum

Heat Transfer Characteristics of Calcined Petroleum Coke in Waste

Heat Transfer Characteristics of Calcined Petroleum Coke in Waste Heat Recovery Process BinZheng, 1,2 YongqiLiu, 2 LichenZou, 2 andRuiyangLi 1 School of Energy and Power 2024年8月23日 Calcined petroleum coke is a purified form of petroleum coke, obtained through a calcination process that removes volatile components, such as sulfur and residual hydrocarbons, present in raw coke This process is Petroleum Coke: What it is, Function and Industrial Savannah River Mill is ranked #7 out of 13 petroleum coke power plants nationwide in terms of total annual net electricity generation Savannah River Mill is comprised of 4 generators and generated 184 GWh during the 3month period between September 2023 to December 2023Savannah River Mill Petroleum Coke Power Plant in Rincon, GALongyi Calcined Coke Powder Grinding Mill, Models and Parameters: LYHM1560: LYHM1860: LYHM2200: Power( KW) Main Motor: 75: 132 160: 200: Classifying system: Coke Plant New Type Coke Coke Coal Machinery Plastic Coke Coke Making Machine Petroleum Coke Bulkbuy More Less Hot Longyi Calcined Coke Powder Grinding Mill

.jpg)

The layout of the coal mill with a rotary classifier

Vertical Coal Mill (VCM) is equipment for grinding and pulverizing coal into micron size Rotary kilns then use the powders as fuel burners The VCM has a housing section equipped with a lining The group owns and operates a Calcined Petroleum Coke (CPC) Plant that was engineered, 1 X 65 MW WASTE HEAT BASED POWER PLANT; Technology: Conventional steam cycle operating in Rankine cycle consisting of 1 no WHR Boiler of 260 TPH (max) capacity and 1x 65 MW Turbine: Fuel:Calcined Petroleum Coke Atha GroupPetroleum coke ball mill with high efficiency energysaving motor Ball mill for pet coke grinding with good grinding effect is at a discount today Skip to content Home; As a fuel, petroleum coke powder is mostly used as fuel for cement plants, power plant boiler, glass plant, and coal water slurry production linePetroleum Coke Ball MillCALCINED PETROLEUM COKE (CP COKE) (PRODUCTION CAPACITY: 36,000 MT/YEAR) [EIRI/EDPR/4729] JC: 2949INR, 2949US$ Petroleum coke (often abbreviated pet coke or petcoke) is a carbonaceous solid delivered from oil refinery coker units or other cracking processes Coking processes that can be eCalcined Petroleum Coke (CP Coke) (Production Capacity: 36,000

(PDF) REHEATING FURNACES IN THE STEEL INDUSTRY

2020年11月16日 reheating furnaces in the steel industry: determination of the thermal powers in the combustion of coke oven gas, linzdonawitz gas and blast furnace gas November 2020 DOI: 1026678/ABCMENCIT2020 Cokecalcining plants receive green petroleum coke from oil refineries The green coke is blended and fed into rotary kilns operating up to 2800°F under a reducing condition The material exits the rotary kiln as calcined coke with a correct crystalline Coke Calcining Plants HWIPDF On Jan 1, 2014, Aliasghar Rohani and others published Calcinations of Petroleum coke Find, read and cite all the research you need on ResearchGate(PDF) Calcinations of Petroleum coke ResearchGateCALCINED PETROLEUM COKE [CODE NO3440] COKE Coke is a fuel with few impurities and a high carbon content, usually made from coal It is the solid carbonaceous material derived from destructive distillation of lowash, lowsulphur bituminous coal Cokes made from coal are Detailed Project Report on calcined petroleum coke

Petroleum Coke Gasification Based Ammonia Plant

The slurry is bined cycle power plant demonstration project stored in an agitated tank prior to being charged to known as green CASRN 6 Petroleum coke, calcined CASRN 6 The High Production Volume delayed Once the calcined coke is discharged from the kiln, the coke is cooled in a rotary cooler At the feed end of the cooler, water is sprayed on the calcined coke to cool the coke to acceptable temperatures The water is evaporated in the Petroleum Coke Calcining Systems Metso2023年1月29日 There are two main types of petroleum coke: green coke and calcined coke 1 Green Coke Green coke is the raw material used to produce calcined coke It is the solid carbon byproduct of the oil refining process Green coke has a high moisture and volatile matter content 2 Calcined Coke Calcined coke is the product from the “calcining Petroleum Coke Types, Uses and SpecificationsClirik Calcined petroleum coke powder grinding machine and Calcined petroleum coke micro powder grinder mill can grind noninflammable, nonexplosive and brittle materials with Mohs’ hardness under six Such as calcite, chalk, steatite, kaolin, dolomite, kaolin, gypsum, and talc etc, totally more than 100 kinds of materials Product fineness can be controlled between Calcined petroleum coke grinding machine Clirik

.jpg)

Petroleum Coke Grinding Machines

2024年2月27日 Fuelgrade petroleum coke powder is utilized in power plants for steam generation, providing a costeffective and environmentally friendly energy source Aluminum Smelting Calcined petroleum coke powder is essential in the production of carbon anodes for aluminum smelting, ensuring optimal conductivity and efficiency in the electrolytic process2014年1月1日 Calcined coke is the best material for making carbon anodes for smelting of alumina to aluminum Petroleum coke is usually calcined in a gasfired rotary kiln or rotary hearth at high temperatures (PDF) EProduction and Application of Calcined Coke InPower plant size: 550 MWe (Net) Tool: Aspen Plus® v10 •LCA Approach (ISO 14000) Goal: Evaluate and analyze the environmental impacts of petcoke IGCC power plant Scope: Cradle to Gate (CTG) Functional unit: 1 MWh of electricity Life cycle inventory: Mass Energy balance [4], GREET model, US LCISystems Design of a Petroleum Coke IGCC Power Plant: Technical feed the mill power consumption and the maximum mill capacity are is higher This is opposite to horizontal mills, usually called ball mills, which prefer fine feed Therefore, it is in general not good to exchange in plants a horizontal mill against a vertical mill without changing the fineness of the pregrinder 6 OutlookSuperfine Grinding of CPC with Ball Race Mills Challenges and

.jpg)

CB01 Petroleum coke shaft calcining technology final ICSOBA

Keywords: Calcined petroleum coke; shaft calcining technology, rotary kiln technology 1 General While GPC with high Sulphur levels or shot content is mostly used as a fuel for power or cement plants, spongetype GPC with lower Sulphur and acceptable metals content commands a higher price and is mostly calcinedRelated products Modern Era Hot Blast Valve w/mixer $ 550 – $ 18880 Select options This product has multiple variants The options may be chosen on the product page Heavy Electrical Cabinet $ 325 – $ 2200 Select options This SUPERDETAILNG WALTHERS COKE OVENS Steel MillCalcined Petroleum Coke(CPC) is a kind a petrochemical product, whose raw material is green petroleum coke This coke is the product of the coker unit in a crude oil refinery The combination of energy recycling with calcining therefore Calcined Petroleum Coke/CPC Carburizing Machine2004年7月1日 Pet coke can also be used as a green and efficient fuel for combustion and power generation processes by using CaO as a sorbent of CO 2 and SO 2 gases [12,13]In the pet coke calcination process Clean and Efficient Use of Petroleum Coke for Combustion and Power

.jpg)

Development of an Advanced Combined Heat and Power (CHP)

Combined Heat and Power (CHP) System Utilizing OffGas from Coke Calcination Utilization of Process OffGas as a Fuel for Improved Energy Efficiency Introduction Coke calcination is a process that involves the heating of green petroleum coke in order to remove volatile material and purify the coke for further processing Calcined coke is vital 2018年8月28日 Many steel refineries generate significant quantities of coke oven gas (COG), which is in some cases used only to generate low pressure steam and small amounts of electric power In order to improve energy efficiency and reduce net greenhouse gas emissions, a combined cycle power plant (CCPP) where COG is used as fuel is proposed However, Optimization of Coke Oven Gas Desulfurization and Combined Cycle Power CALCINED PETROLEUM COKE (CP COKE) (30 MT/Day )[CODE NO4457] Calcined Petroleum Coke (CPC) is manufactured from Raw Petroleum Coke (RPC) by the process known as high temperature pyrolysis The process is carried out in a rotary or vertical kiln at temperatures exceeding 1300 deg C Calcincalcined petroleum coke (cp coke) (30 mt/day )The document describes the history and process of petroleum coke calcining It details how the industry originated from early refining byproducts and evolved into a global industry The calcining process involves roasting petroleum coke at high temperatures to increase its carbon purity for uses like aluminum smelting anodes The main uses of calcined petroleum coke are discussed Tutorial Petroleum Coke Calcining and

.jpg)

Research and Optimization of Operating Parameters of a Rotor

2024年3月18日 This article explores the impact of operating parameters on the classification efficiency of a rotor classifier Based on the experimental data of calcined petroleum coke classification, a singlefactor experimental analysis is conducted to find the relationship between operating parameters and classification performance The cut size becomes progressively Raw/Green coke as produced Coke calcined at 2375 °F Fixed carbon, wt % 80 − 95 980 − 995 Hydrogen, wt % 30 − 45 01 of fuel for cement kilns and electric power plants • Calcined petcoke (CPC) has the highest carbon purity and is used to manufacture energy, as well as in aluminum, graphite electrode, Petcoke Fact Sheet KCBX ChicagoCalcined Kiln Analysis and Proximate Simulation of HighQuality Coke Products Using Aspen Plus Atika Safitri1*, Ghiyar Ragil Alfath1, Wara Dyah Pita Rengga1, Nugroho Adi Sa songko2, Immanuella Juan Safira1 1 Chemical Engineering Department, Universitas Negeri Semarang, Indonesia 2 Agency for the Assessment and Application of Technology, Indonesia Calcined Kiln Analysis and Proximate Simulation of HighQuality Coke Energy Fuels 2005, 19, 453458 453 Coal Blending with Petroleum Coke in a PulverizedFuel Power Plant Katia S Milenkova, Angeles G Borrego,* Diego Alvarez, and Rosa Menéndez Instituto Nacional del Carbón, CSIC, Apartado Coal Blending with Petroleum Coke in a Pulverized

Metallurgical Coke Price Fob Reference Calcined

Metallurgical Coke Price Fob Reference Calcined Petroleum Coke, It can also be used as fuel, but when doing fuel, it is necessary to use a hierarchical impact mill for ultrafine The coke powder is mainly used as fuel in glass factories 2015年6月1日 Higher grades of calcined coke have nonenergy applications, namely in the production of electrodes, particularly required in the aluminium, steel, and titanium smelting industries (eg, Caruso (PDF) Petroleum Coke in the Urban Environment: A We can modify the project capacity and project cost as per your requirement If you need any customized project report and BANKABLE project reports as per your requirement, Click here to CONTACT US Or Call us at +91, +91, +91 011 , , for quick response All reports are prepared by highly qualified Project Report on CALCINED PETROLEUM COKE Manufacturing CALCINED PETROLEUM COKE (CPC) PRODUCTION RATE – 24,000 TPA[EIRI/EDPR/4742] JC: 2962XLINTRODUCTIONCokeCoke is a fuel with few impurities and high carbon content, usually made from coal It is the solid carbonaceous material derived from destructive distillation of lowash, lowsulphur bituminous coCalcined Petroleum Coke (CPC) Production Rate – 24,000 TPA

Calcined Petroleum Coke Coal Tar Pitch Rain Carbon Inc

Today, Rain Carbon is one of the world’s largest producers of calcined petroleum coke, with seven plants in the United States and India producing a combined 24 million tons per year Contact Ron Garbarino : These heatrecovery projects cogenerate electric power from waste heat recovered in the calcining process2016年1月1日 Simplified calculation model (( 1 ) the internal heat exchange tube, ( 2 ) the calcined petroleum coke, ( 3 ) the 1st external heat exchange tube, ( 4 ) the 2nd external heat exchange tube, and Heat Transfer Characteristics of Calcined Petroleum Coke in 2024年1月14日 Petroleum Coke can be used here in some applications, but others require more processing and are called “Calcined Coke” This process means transferring petroleum coke to a rotary kiln to remove the remaining volatile hydrocarbon residues The calcined petroleum coke can be further processed in an anode baking ovenPetroleum Coke: A Comprehensive Guide to Production, Table 1 Typical sponge coke specifications Item Green coke Calcined coke Table 2 Typical needle coke specifications Item Green coke Calcined coke Volatile Matter Volatile Matter Bulk Density Bulk Density Real Density Real Density Reference no description 101 Kiln feed bin 102 Weigh feeder 103 Feed hood 104 Rotary kiln 105* Tertiary air system 106 Firing hood 107 Coke Calcining Systems Metso Automation DirectIndustry

CALCINED PETROLEUM COKE (CP COKE) 50,000 TONS/ANNUM

CALCINED PETROLEUM COKE (CP COKE) 50,000 TONS/ANNUM Project Report Manufacturing Process Rotary Calcination Technology is being adopted for the Plant as this process shall produce good quality of CPC SUPPLIERS OF BALL MILL EOT CRANE SUPPLIERS OF POWER TRANSFORMER SUPPLIERS OF ELECTRICAL PANEL