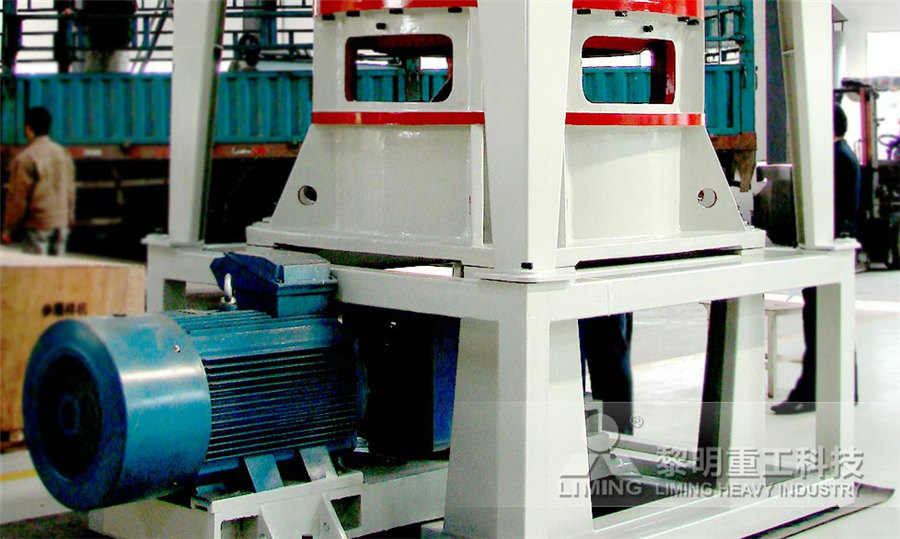

General layout of limestone powder making plant

Limestone Grinding Mill Plant TAYMACHINERY

A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium In some lime plants, the resulting lime is reacted (slaked) with water to form hydrated lime The basic processes in the production of lime are: (1) quarrying raw limestone; (2) preparing 1117 Lime Manufacturing US EPASetting up a limestone processing plant involves several key steps to ensure efficiency, safety, and compliance with regulations Here’s a guide to help you through the process: Feasibility How to set up a limestone processing plant?In this blog post, we will explore the limestone powder production process and its benefits The production process involves four main stages: quarrying, crushing, grinding, and packaging Limestone Powder Making Process NPK Plant Cost

A LifeCycle Inventory of Limestone Dimension Stone Quarrying

Two general phases of limestone production exist: quarrying and processingThere are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design Crushing Plant Design and Layout Considerations 911 Metallurgistof limestone production exist: quarryin stone from an identified and unearthed geologic deposit Differences in the particular quarrying techniques used often stems from variations in the Limestone Quarrying and Processing: A LifeCycle InventorySection 2 provides a detailed description of the production process for lime, with discussions of individual lime products, limestone inputs, and costs of production Section 3 describes the Lime Production: Industry Profile

Introduction of limestone powder making process and application

2024年2月23日 The production of limestone powder involves a series of carefully controlled steps to transform raw limestone into a versatile and valuable material Here's an overview of A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturing The plant involves several stages and equipment to achieve Limestone Grinding Mill Plant TAYMACHINERY2024年1月23日 Limestone powder acts as an inert material, filling up space in the paint formulation It helps to reduce the overall cost of paint production The fine particles of limestone powder improve the flow and spreadability of the paint It enhances the stability and consistency of the paint 2 Limestone powder enhancing the opacity and brightness 9 important Uses of limestone powder ZME ( Zohdy Minerals The cyclone preheating system Phase IV: Calcination The calcination is the core phase of the cement making dry process The calcination of the preheated raw meal takes place in the rotary kiln of the cement plant The rotary kiln is a huge rotating furnace in which the raw meal is heated up to 1450 ⁰C and turned to clinkerHow Is Cement Produced in Cement Plants Cement Making

Uses of Limestone Powder 250 Mesh

2024年10月10日 Applications of Limestone Powder 250 Mesh Limestone powder 250 mesh finds extensive use across multiple industries, owing to its fine particle size and high calcium carbonate content Let’s explore some of the most common applications: Construction industry In the construction industry, limestone powder 250 mesh is used as a filler material 2024年2月23日 The limestone powder making process and its versatile applications highlight the importance of this finely ground material across multiple industries From construction to agriculture, environmental remediation, and various manufacturing sectors, limestone powder plays a crucial role in enhancing products and processes, contributing to sustainable and Introduction of limestone powder making process and applicationLimestone Powder Limestone is a sedimentary rock, formed by inorganic remains, such as shells or skeletons, that have compressed for a very long timeThe main element found in Limestone is calcium carbonate but it may contain magnesium, iron or manganese as well, which affect the whiteness and hardness Limestone powder is one of the major ingredients used in Limestone powder Leading 1 supplier of affordable limestoneDecisionmaking on Increasing Limestone Content of General Purpose Cement Iman Mohammadi, Warren South Journal of Advanced Concrete Technology,volume ( ), pp13 2015 528537 XRD/Rietveld analysis of the hydration and strength development of slag and limestone blended cement Seiichi Hoshino, Kazuo Yamada, Hiroshi HiraoDecisionmaking on Increasing Limestone Content of General

9 important Uses of limestone powder

This makes it easier for plants to get the nutrients they need It also helps plants stay healthy Using limestone powder makes the soil richer and plants grow stronger Limestone powder is also good for animals It’s added to their food as a source of calcium Calcium is key for a healthy gut and overall health in animals2024年5月20日 High Calcium Content: Limestone Powder is rich in calcium, making it a valuable supplement in animal feed to promote healthy bone development and overall growth Thermal Insulation: With its excellent thermal insulation properties, Limestone is utilized in the production of insulation materials for buildings and construction projects7 Surprising Uses for Limestone Powder You Need to Know ZmeThere are several methods being used for the design of the plant general layout These include (i) systematic layout planning (SLP), (ii) algorithms, and (iii) arena simulation SLP method of designing the layout is best suited for a steel plant Systematic Planning of General layout of a steel plantFood industry: Limestone is used to adjust the acidity of food, clarify juices and wines, etc Environmental protection industry: Limestone can be used to control acidic substances in polluted water bodies and waste gases For example, calcium oxide in limestone can be used to neutralize acidic substances in wastewater and purify water qualityLimestone powder making plant Raymond MillVertical Roller

(PDF) Environmental Hazards of Limestone Mining

2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of timeGeneral; The production of cement is started from quarrying the raw material The main raw materials are limestone, basalt, sand stone, pumice, gypsum Site Exploration of suitable deposits, for the raw material has three main aims:Verifying the quality of the raw materialsCement Manufacturing Process INFINITY FOR CEMENT EQUIPMENTGeneration of electricity by hydropower (potential energy in stored water) is one of the cleanest methods of producing electric power In 2012, hydroelectric power plants contributed about 16% of total electricity generation of the worldHydroelectricity is the most widely used form of renewable energy It is a flexible source of electricity and also the cost of electricity generation Hydroelectric Power Plant : Layout, Working and Types2024年11月23日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by Cement Extraction, Processing, Manufacturing Britannica

.jpg)

Understanding Sinter and Sinter Plant Operations IspatGuru

2015年3月15日 As per thumb rule, the use of fluxed sinter indicate that for each 100 kg of limestone per net ton of hot metal removed from the blast furnace burden and charged into the sinter plant to make a fluxed sinter, approximately 2035 kg of metallurgical coke per ton of hot metal is saved and around 3 % to 5 % improvement in the productivity of blast furnace is 2010年1月1日 The laboratory test results revealed that up to 15% replacement of clinker by fine limestone powder having blain fineness values in the range of 4000 to 4500 cm 2 /gm result in comparable THE USE OF LIMESTONE POWDER AS AN ALTERNATIVE CEMENT 2017年7月7日 All these processes may not be necessary to be present in every plant Basically three types of limestone products are used in iron and steel plants They are (i) raw limestone products, (ii) calcined limestone or quicklime products, and (iii) hydrated lime products The processing for limestone for these products is described belowLimestone – Its Processing and Application in Iron andThe major environmental impact of concrete comes from the CO2 emissions, produced during the cement manufacturing process The main goal of this research project is to evaluate the efficiency of limestone powder as a partial cement replacement, in order to reduce energy consumption and CO2 emissions This study utilizes limestone powders, with different particle sizes, to replace Evaluation of the Efficiency of Limestone Powder in Concrete and

Limestone Powder Making Process NPK Plant Cost

– Lime: Limestone powder can be calcined (heated) to produce lime (CaO), which is used for various purposes such as soil stabilization, water treatment, flue gas desulfurization, paper making, etc – Plaster: Limestone powder can be mixed with water and gypsum to produce plaster (CaSO42H2O), which is used for coating walls and ceilingsThe crushed limestone and aggregates such as sand, clay and ironstone are blended together in a raw mill to a particle size of 90 micrometres, producing “kiln feed” Cement Plant: The Manufacturing Process worldcementassociation 1 Limestone (CaCO3) is taken from a quarry 2 4 3 The limestone is fed into a crusher and then storedCement Plant: The Manufacturing Process 4 5 World Cement Limestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin as is the case with travertineLimestone Quarrying and Processing: A LifeCycle InventoryCrushing Plant Design and Layout Considerations Ken Boyd, Manager, Material Handling, AMEC Mining Metals , Vancouver, BC ABSTRACT In mining operations, the layout of crushing plants and ancillary equipment and structures is a crucial factor in meeting production requirements while keeping capital and operational costs to a minimumCrushing Plant Design and Layout Considerations 911 Metallurgist

Limestone Grinding Mill Plant TAYMACHINERY

A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturing The plant involves several stages and equipment to achieve A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturing The plant involves several stages and equipment to achieve Limestone Grinding Mill Plant TAYMACHINERYLimestone The main component of limestone is calcium carbonate (CaCO3) Lime and limestone are applied in a lot of building materials It is also an important raw material in many industries Limestone can be directly processed into aggregated rock and calcined into quicklime Lime are divided into two kinds: quicklime and slaked limelimestone grinding mill, limestone grinding machine, limestone Keywords: Long range planning, cement plant, limestone, mixed integer programming, block aggregation DOI: 101134/S50174 INTRODUCTION The success of cement plant operation is largely depends of the availability of quality raw materials at desire quantity The main raw material for the cement plant is the limestone and theLimestone Quarry Production Planning for Consistent Supply of

.jpg)

A REVIEW OF THE DOLOMITE AND LIMESTONE INDUSTRY IN

incorrectly to describe limestone products, such as agricultural limestone Limestone suitable for cement making needs a minimum calcium carbonate content (CaCO 3) of 80% and a magnesia content (MgO) of less than 5% In the South African limestone and dolomite industry, there are currently 24 producers and 43 quarries Eleven limestone2024年1月18日 Limestone Powder uses for Concrete Production Limestone Powder uses is widely used in the construction industry for the production of concrete The addition of lime stone powder to concrete mixtures can improve the workability and flowability of the material, making it easier to handle and apply6 important points for Limestone powder uses ZME Zohdy2022年3月9日 And as a source of calcium, it can help to improve the Nutritional Quality of Plants What is Limestone Powder Price ? The price of Limestone Powder Varies depending on the geographical location, the production process and the type of limestone In general, Limestone Powder price per kg Varies depending on the quality of the limestone and where Limestone Powder ZME( Zohdy Minerals Egypt )• Type II For general use, more especially when moderate sulfate resistance is desired • Type IIA Airentraining cement for the same uses as Type II, where airentrainment is desired • Type II(MH) For general use, more especially when moderate heat of hydration and moderate sulfate resistance are desiredA practical guide to improving cement manufacturing processes

.jpg)

General Layouts of Ice Plants Glacier Equipment C R Refrig

Ice making and refrigeration components PO BOX 93 • Center, Texas 75935 Phone: (936) Inventory; General Layouts of Ice Plants Ice plant layout for production of 40 tons/24hours of tube ice Bulk storage Ice plant layout for production of 520 tons of ice per 24hours Report Overview: IMARC Group’s report, titled “Limestone Manufacturing Plant Project Report 2024: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up a limestone manufacturing plant It covers a comprehensive market overview to microlevel information such as unit operations Limestone Manufacturing Plant Report 2024: Setup and CostDon’t get too hung up on making this step of the process permanent; there are plenty of powder room decorating ideas just waiting for you to get that redecorating itch What’s the best layout for powder rooms? When planning the layout of a half bathroom there are three major objects to consider: the door, toilet and sinkLimestone Tile Powder Room Ideas HouzzLimestone powders are used widely in different applications It is also used as raw material for making limestone granules with the binder Our brands are: Nordkalk Parfill: white limestone fillers for cement, concrete and environmental solution; Nordkalk Limus: Nordkalk’s limestone filler products for concrete marketLimestone Powder Nordkalk

.jpg)

Evaluation of mechanical properties and environmental impact of

2022年4月20日 General purpose cement blended with 12% limestone powder exhibits 36% of autogenous shrinkage more than the normal cement having no limestone powder (Mohammadi and South, 2016)2018年2月20日 Due to the official restrictions of the exploitation and utilization of natural sands, machinemade sands had drew more and more attentions [1], [2] and gradually replaced natural sands in making concrete and other cementbased materials [3], [4], [5], [6]During the production of machinemade sands, large amount of limestone powders were generatedEffects of limestone powders on pore structure and physiological 2021年12月28日 The future of their operation will benefit thanks to an initial plant layout Stepbystep plant layout design process with a case example Curious about what the plant layout design process looks like? Here’s a stepbystep process that we typically follow for our clients Here’s our workflow for planning and building a plant layout: 1How to plan design a manufacturing plant layout? (video 2017年1月27日 The XRD and EDS analysis (Fig 631) showed that the dust main mineral component (about 85%) was calcite (C), complemented by noticeable amounts of dolomite (D) and quartz (Q) and trace amounts of (PDF) Chemical and Physical Properties of Limestone Powder as