Is calcite ore crushing and processing environmentally friendly

.jpg)

The Processing of Calcium Rich Agricultural and Industrial Waste

2021年5月6日 These calcium based minerals remediate the inorganic and organic pollutants from the environment by the adsorption process The low cost and ecofriendly nature of calcium based minerals reduce the expenditure of the whole adsorption process2024年11月7日 Novel mineral carbonation technologies replicate naturally occurring weathering and hydrothermal processes, and we are researching ways to accelerate these fundamental Calcite: the versatile mineral shaping the future of carbon removal2022年5月31日 This feature, coupled with its suitability for processing low grade ores, significantly lower capital and operating costs, and more environmentalfriendly nature makes Review on metal extraction technologies suitable for critical metal 2020年9月23日 Calcite ores typically contain metal sulphide, silicate, or other calciumcontaining impurity minerals, which can be removed by flotation A tremendous amount of research has been performed on refining the flotation An Overview of Calcite Recovery by Flotation

.jpg)

A rapid and environmentfriendly process for dolomite pellets

2024年1月1日 Herein, we developed a rapid and environmentfriendly strategy for the calcination of dolomite used in subsequent magnesium production through carbothermal Calcite as agrilime: Acidneutralizing qualities of calcite make finely crushed limestone a preferred material for soil treatmentCalcite Mineral Uses and Properties GeologyMicroorganisms are employed to induce the precipitation of calcite, creating a natural cementation process that stabilizes soil structures This innovative approach enhances the stability of Sustainable Mining Technologies – Caliche2009年6月26日 Ore is processed by crushing, treatment by agglomeration, stacking, heap leaching, electrowinning and smelting This chapter identifies the potential environmental impacts of mining andEnvironmental Impact of Mining and Ore Processing

.jpg)

Mineral Planning Factsheet Calcite

Calcite is a common mineral occurring in many mineral veins but was treated as waste in former metal mining operations Only rarely does it occur in sufficient concentrations to be eco Calcite mining and processing involve several steps to transform raw calcite into usable materials Here’s an overview of the typical process: Geologists conduct surveys to locate calcite How calcite is mined and processedCopper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of 9999% pure copper called cathodes, which will ultimately be made into products for everyday useThe Copper Mining and Processing: Processing Copper 2021年4月13日 The construction industry is a major contributor to environmental pollution Cement is a costly material that is one of the largest industrial sources of greenhouse gases As such, there is increased focus on developing Production of Sustainable Concrete by Using

How calcite is mined and processed

Crushing: Once extracted, the raw calcite is transported to a crushing facility The calcite is subjected to primary and secondary crushers to reduce its size to manageable pieces Screening and Washing: The crushed material is screened to separate finer particles from larger ones Washing may be performed to remove impurities and dust from the 2024年3月12日 The equipment can form an independent and complete production system with strong systematicity, from the crushing, conveying, and powdermaking to the collection, storage, and packaging of finished products The grinding machine can process highquality powder with a mesh size of 325 to 3000, widely used in ultrafine crushing processingDolomite Crushing Process And Grinding Equipment2024年10月14日 Remark: For conversion from millimeter to mesh, please refer to mm to mesh Process 3: Calcinating dolomite rock The crushed dolomite is calcined in a rotary kiln, which is used for producing refractory materials, magnesium alloys, cement, etc Dolomite is calcined at 1500°C to obtain magnesiacalcium raw materials, such as dolomite sand, magnesiacalcium How to Process Dolomite Rock and What Is It Used for?2023年10月27日 Step 1: Turn Large stones into small stones Transport the bulk dolomite raw material into the jaw crusher by the vibrating feeder for the coarse crushing process, and then send it to the cone crusher for medium to fine crushing processing until it reaches the feed fineness of the grinding machine (1540mm) before discharge Step 2: Grind small stones into Dolomite Sand Making Plant And Grinding Machine

.jpg)

General Process Introduction Of Barite Beneficiation

2023年9月5日 The general process of barite beneficiation includes crushing, grinding, screening, gravity separation, flotation and dryingAccording to the actual ore type, sometimes washing and magnetic separation processes are also includedJXSC our barite beneficiation process and equipment, impurities can be removed and the purity and density of the mineral can be 2022年8月1日 A systematic review of gold extraction: Fundamentals, advancements, and challenges toward alternative lixiviants(PDF) A systematic review of gold extraction: Fundamentals 2023年10月17日 Factors for choosing a suitable ore powder grinding mill 1 Raw material characteristics: Different raw materials have different hardness, humidity and grinding and crushing properties, and the corresponding ore powder grinding mill needs to be selected to meet the processing requirements 2 Production capacity: Determine the required processing How to choose a suitable ore powder grinding mill?2023年10月16日 Innovative Environmentally Safe Processes for the Extraction of Rare and RareEarth Elements from Complex Ores of Perplexed Material CompositionInnovative Environmentally Safe Processes for the Extraction of

Cement Manufacturing Process and Its Environmental

2023年7月10日 The cement manufacturing process involves the extraction and processing of raw materials, such as limestone, clay, and shale, which are then heated in a kiln at high temperatures to form clinker2024年8月7日 Essential in mineral processing, crushing breaks down large ore blocks into smaller, manageable pieces for further processing Embracing these environmentally friendly technologies not only improves operational Mineral Processing Equipment for Mining Industry2021年7月19日 Mechanochemical synthesis of ecofriendly fertilizer from eggshell (calcite) and KH 2 PO 4 Roger B orges 1 ; Amanda Soares Giroto 1 , Rodrigo Klaic 1,2 , Fernando Wypych 3 , Caue(PDF) Mechanochemical synthesis of ecofriendly fertilizer from 2024年11月21日 Barite ore crushing and washing In the crushing and washing process of barite ore, efficiency is key If the barite ore contains a large amount of mud, the ore washing machine needs to be added Commonly used log washers and spiral sand washers use highpressure water jets to remove the mud and clay attached to the barite ore, making it easier to separate The Four Key Processes For Barite Beneficiation To Elevate Ore

.jpg)

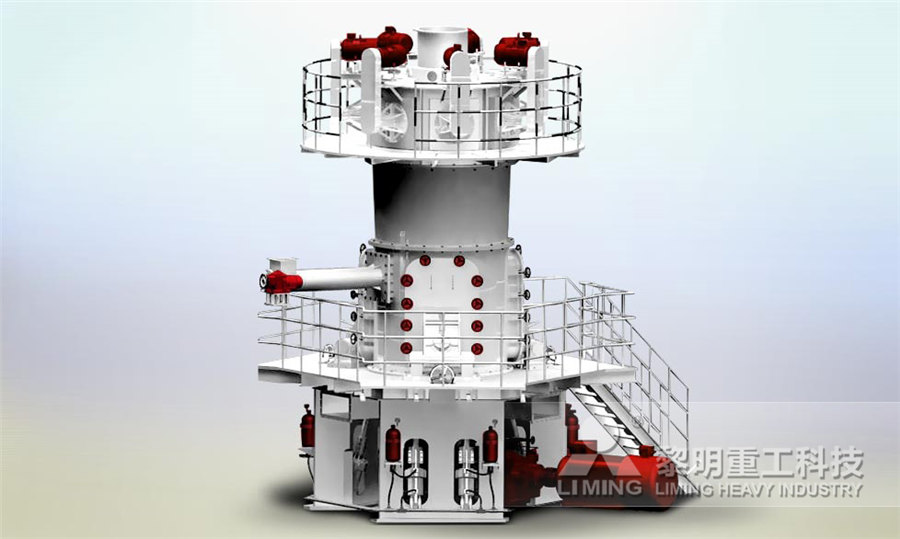

The advantages of ultrafine vertical mill in the processing and

2023年3月21日 Involute type high efficiency crushing chamber High precision spindle Focus on the largescale production of nonmetallic mineral ultrafine powder processing, widely used in calcite, marble, limestone, dolomite, barite, talc, kaolin, dolomite, wollastonite, More environmentally friendly and energysaving2016年1月8日 The first commercial production of phosphate rock began in England in 1847 A wide variety of techniques and equipment is used to mine and process phosphate rocks in order to beneficiate lowgrade ores and remove impurities The eighth chapter of this book deals with mining and beneficiation of phosphate ore The principle and operating conditions of important Mining and Beneficiation of Phosphate Ore IntechOpenCrushing plant for calcite provides smooth processing process and is handled by competent workforce We develop calcite crusher in stationary, portable, mobile series to meet the different calcite crushing demands As calcite (calcspar) occurs in a number of massive forms such as aragonite, marble, limestone, chalk, fibrous etcCalcite Ore Crushing Solutions DSMAC2009年6月26日 Ore is processed by crushing, treatment by agglomeration, stacking, heap leaching, electrowinning and smelting This chapter identifies the potential environmental impacts of mining and ore Environmental Impact of Mining and Ore Processing

.jpg)

Calcite Ultrafine Grinding Machine Opens a New Chapter in the

Calcite Ultrafine Grinding Machine The calcite ultrafine grinding mill is an efficient and environmentally friendly industrial equipment specially used for ultrafine grinding of calcite ore This equipment is not only suitable for calcite , but also for grinding limestone, dolomite, marble and other minerals2024年5月30日 It highlights the limitations of current technologies in processing quartz ore and discusses the advantages of different impurity types under various technological treatments Moreover, it explores the environmental and economic impacts of these highpurity processes, underlining the necessity for more environmentally friendly and costeffective purification Advanced Processing Techniques and Impurity Management for 2020年1月1日 The paper presents the results of research on the use of a pulsed electric discharge in aqueous media for the pretreatment (preliminary crushing and washing) of quartz sand in the glass industryPulsed electric discharge for environmentally friendly cleaning 2024年8月15日 The crushing process of mineral processing plants is usually carried out in the order of primary, secondary, tertiary, Establishing an efficient, costeffective, and environmentally friendly ore processing plant is a complex Mineral Processing Plants: What You Need to Know

(PDF) A Review of Chromite Ore Processing Residue

2014年11月17日 Chromite ore processing residue (COPR) is a waste byproduct of chromate production that contains high levels of hexavalent chromium (Cr[VI]) Although the high temperature chromite process was 2024年3月2日 Uranium, a cornerstone for nuclear energy, facilitates a clean and efficient energy conversion In the era of global clean energy initiatives, uranium resources have emerged as a vital component for achieving sustainability and clean power To fulfill the escalating demand for clean energy, continual advancements in uranium mining technologies are imperativeA Review of In Situ Leaching (ISL) for Uranium Mining MDPI2023年11月30日 Quartz deposits are widely dispersed in nature, but the presence of ore bodies capable of yielding highpurity quartz is exceedingly rare As a result, the effective purification and processing of highpurity quartz from natural siliceous materials has emerged as a prominent area of research within the nonmetallic mineral processing field This article offers an overview of Research Status and Challenges of HighPurity Quartz Processing An environmentally friendly depressant for magnesite and calcite flotation separation: Selective depression and GLDA creates a significant disparity of over 80 % in flotation recovery between magnesite and calcite In artificial mixed ore flotation tests, the GLDA+NaOL system yielded a flotation concentrate with an MgO grade of An environmentally friendly depressant for magnesite and calcite

.jpg)

A Sustainable and Environmentally Friendly Concrete for

2023年10月10日 The purpose of this study is to utilize waste products—precipitated calcium carbonate (PCC) and upcycled recycled concrete aggregate (upcycled RCA or UCA)—in civil works projects To do so, tests must be performed to determine the engineering properties of the materials in which PCC and UCA are sequestered PCC is a fine to coarse grain waste 2023年6月1日 In this study, the structure and properties of environmentally friendly gold lixiviants (thiosulfate, thiourea, thiocyanate, polysulfide, halogens, amino acid, humic acid, etc) are reviewed; Table 1 summarizes the applications of environmentally friendly gold lixiviants Moreover, the gold leaching mechanism of environmentally friendly gold lixiviants is discussedA review of environmentally friendly gold lixiviants: 2015年7月1日 The depletion of ores, a rise in the cost of their extraction, enrichment and processing led in the last 10‒15 years to a sharp rise in prices for tungsten productsProcesses for the recovery of bismuth from ores and concentrates2013年7月3日 Biomineralization and biogenesis of iron ore deposits are illustrated in relation to indigenous microorganisms inhabiting iron ore mines Aerobic and anaerobic microorganisms indigenous to iron oxide mineralization are analyzed Microbiallyinduced flotation and flocculation of iron ore minerals such as hematite, alumina, calcite and quartz are discussed with respect Developments in Biotechnology for Environmentally Benign Iron Ore

Accessing Metals from LowGrade Ores and the

2022年4月20日 Mining has advanced primarily through the use of two strategies: pyrometallurgy and hydrometallurgy Both have been used successfully to extract valuable metals from ore deposits2021年6月29日 Compared with conventional mineral processing methods, bioleaching is lowcost, highly safe, simple to operate, and environmentally friendly Currently, bioleaching is more and more frequently applied to extract, A Review of Tungsten Resources and Potential 2023年10月27日 Advances in comminution, the process of reducing solid material into smaller particles, have been a focal point in the mining and mineral processing industry, with significant developments reflecting both current trends and best practices One prominent trend is the growing emphasis on sustainability Comminution is an energyintensive operation, and there's Trends and Best Practice Mineral ProcessingCalcite is rich in resources globally, and the highquality calcite resources with calcium carbonate content ≥97% are also large Therefore, at present, only performs simple washing and hand selection at the beginning of classification The processing flow for products below 400 mesh is like: raw orecrushinggrindingclassifyingcalcite grinding machine, calcite grinding mill, calcite processing

.jpg)

Calcite : Properties, Formation, Occurrence and Uses Areas

2023年8月25日 Calcite can also be present in ore deposits, especially those related to metallic ores like lead, zinc, and copper Its presence can indicate specific conditions of mineral formation 4 Economic Uses: Calcite has significant economic importance in various industries2022年12月20日 Separation of sphalerite and dolomite using sodium alginate as an environmentally friendly depressant in a carbonate the depress of dolomite is primarily focus on the processing of oxidized ore, such as the flotation of apatite, fluorapatite, magnesite, fluorite, calcite, and bastnaesite (Gence, 2006; Ws et al, 2021) At Separation of sphalerite and dolomite using sodium alginate as an 2023年1月1日 Camphor leaf extract as neoteric and environmentally friendly depressant in flotation between minerals recovery and concentration of CLE Fig 6 Flotation recoveries and grades of WO3 in mixed ore of calcite and 275−284 283 removing silicate from mineral processing wastewater via chemical Camphor leaf extract as neoteric and environmentally friendly 2023年4月26日 There are three main technologies in calcite processing: crushing, sand making, and milling, and crushing is the primary stage Calcite belongs to the type of ore that is easy to grind Calcite grinding powder generally requires the fineness of the finished product to be small 1 Process flow of calcite grinding3 Incredible Flows to Win Calcite Processing (Without Failing)

.jpg)

Enrichment of wollastonite with high calcite content

environmentally friendly way In this study, the ore contains a large amount of calcite and augite, which is an iron bearing mineral that is subjected to magnetic separation, followed by flotation in order to obtain wollastonite and calcite concentrations individually The SiO 2, CaO and Fe 2 O 3 contents in the ore2023年6月28日 Advancements and Environmental Implications in Oil Shale Exploration and Processing June 2023; quartz, kaolinite, montmorillonite, calcite, analcime Environmentally friendly due to the(PDF) Advancements and Environmental Implications in Oil Shale