Working principle of vertical mill lubrication system

.jpg)

VMC Machine: Learn Everything About VMC with this

In VMC applications, lubrication is critical for reducing friction, minimizing wear, and extending the lifespan of machine components Deublin rotary unions facilitate the integration of centralized lubrication systems, allowing for the 2015年3月25日 The hydraulic system of vertical mill is an important system, the main function of the hydraulic system is to break the grinding roller, which is when the internal grinding cavity wear parts wear, can stop open on both sides of Hydraulic system vertical roller mill operation PDFVertical roller mills are adopted in 20 cement plants (44 mills) in Japan In the vertical roller mill which is widely used in the raw material grinding process, raw materials input grinding table Vertical roller mill for raw Application p rocess materialsa vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

DRIVE SELECTION FOR LARGE LOESCHE VERTICAL ROLLER MILLS

The drive of a vertical roller mill – essentially the mill gearbox – has to fulfill two tasks: The first is to reduce the speed of the electric motor to the selected mill speed and to transmitWorking Principle of Vertical Machining Center The various machine tools and the parameters required for the parts are transformed into information codes that are by and large acceptable and readable by the numerical control device of the Vertical Machining Center (VMC): Definition, 2017年1月25日 Vertical milling machine should be lubricated three times per months and one time per half a years after the use of 3 years Guideway ball screw, etc should be lubricated 4 times per day, done by every shift in the day Milling machine lubrication MECHANICALFUNDACompared to conventional lubrication used in steel mill applications, oil/air lubrication reduces environmental pollution, increases lubricating and sealing performance, improves the high Oil/Air Lubrication Systems for Steel Production Facilities

.jpg)

Chapter 1 Principles of Lubrication part of Practical Lubrication

An examination of the most advantageous ways to procure lubricants, to understand contaminant filtration, and to implement costjustified means of lubricant storage is presented Also The quadropol® vertical roller mill by thyssenkrupp Polysius takes a holistic approach to modern grinding systems in terms of its simple and compatible design Click to download pdf 37770 kbquadropol® thyssenkrupp Polysius Grinding 2021年2月18日 The lubrication system is to provide a sufficient quantity of cooling and filtered oil to give proper lubrication to all the moving parts of an engine The lubrication systems used for internal combustion engines Types Different Types of Lubrication System in Detail Oil selection is normally made to satisfy lubrication requirements of the most demanding machine elements While ISO viscosity grades up to 1,000 and higher can be used, many mist systems employ a mineral gear oil in the ISO VG68 to Guidelines for Oil Mist Lubrication

.jpg)

PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

• Mill motor speed • Mill air flow/mill differential pressure • Temperature after the mill • Pressure before the mill • Grinding stock feed • Classifier speed • Mill fan speed • Water spraying • Hot gas • Fresh air Manipulated variables Disturbance variable Process measured value RelauchLMmaster 6 250814 11:47The highest wear occurs on the wear parts of the grinding elements as is the case with any type of vertical mill Therefore, ease of replacement and regeneration is a major feature of the mill With our proven LiftandSwing System, wear parts can be replaced rapidly through one single maintenance doorCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills2024年9月16日 The control system, typically a computer numerical control (CNC) unit, oversees the movement of the spindle and worktable, ensuring precise cuts Vertical Milling Machine Working Principle The working principle of a vertical milling machine is based on the rotation of the milling cutter and the corresponding movement of the worktableWhat is a Vertical Milling Machine? How Does it Work? BOYIINTRODUCTION: In the Mechanical Engineering field Lathe machine plays an important role in Manufacturing In this article, I am going to discuss the Lathe machine in detail A lathe is a machine tool used to remove unwanted metals from a workpiece to give the desired shape and size; It operates on the principle of a rotating workpiece about an axis while a fixed cutting Lathe MachineIntroduction,Working, 9 Parts,Types, Advantage

.jpg)

OK™ Mill Working Principle FLSmidth Cement

FLSmidth's OK™ Mill use 3050% less energy than ball mill systems, and a simple layout and fewer machines in the mill circuit ensure high run factors and low maintenance costs FLSmidth Cement is a technology and service supplier with a passion to help our customers produce cement efficiently2 Basic Components and Working Principle To understand how VMC machines operate, it’s essential to familiarize oneself with their basic components and working principles Here’s an overview of the key elements that constitute a typical VMC machine: Vertical SpindleVMC Machine: Learn Everything About VMC with this GuideLubrication Methods of Ball Mill Gears In general, there are 3 forms of lubrication for large and small gearlubricated gears: oil pump lubrication, large ring gear with oil lubrication, and oil wheel with oil lubrication The oil pump injection lubrication: This method has certain disadvantagesIntroduction of Oil Lubrication Details on Ball Mill GearsWorking Principle Of Turbine: When any fluid strikes the blade of the turbine, the blades are displaced which produces rotational energy When the turbine shaft is directly coupled with generator mechanical energy to convert into electrical energyWhat Is Turbine? – Working Principle, And Types Of Turbines?

Lubmann Pressurized Single Line Lubrication System Instruction

ensure that they can get good lubrication System Composition System Structure and Working Principle The system is composed of lubrication pump, external/integrated monitor, pressurized single line distributor, sensor (optional), grease hose and accessories Working Principle Take LFS1 for exampleThe working principle of the external feedback variable vane pump is shown in Fig 3 According to the working principle of external feedback variable vane pumps, the relationship between the actual flow rate and the working pressure of the variable vane pump is as follows [18] : Design and Dynamic Performance Study on Hydrostatic Lubrication System Mainly used to complete the horizontal and vertical transportation of materials at the same time In vertical conveying, the speed is generally required to be higher than 1000r/min 3 The working principle of screw conveyor The working principle of the screw conveyor in conveying materials is basically divided into the following three categories:Classification and working principle of screw conveyor RICHI2012年12月31日 So, the control of vertical mill system is difficult by traditional theory lubrication station and hydra ulic pressure station St art ea ch station in before, shoul d guarantee the Design and Realization Of Roller Mill Control System

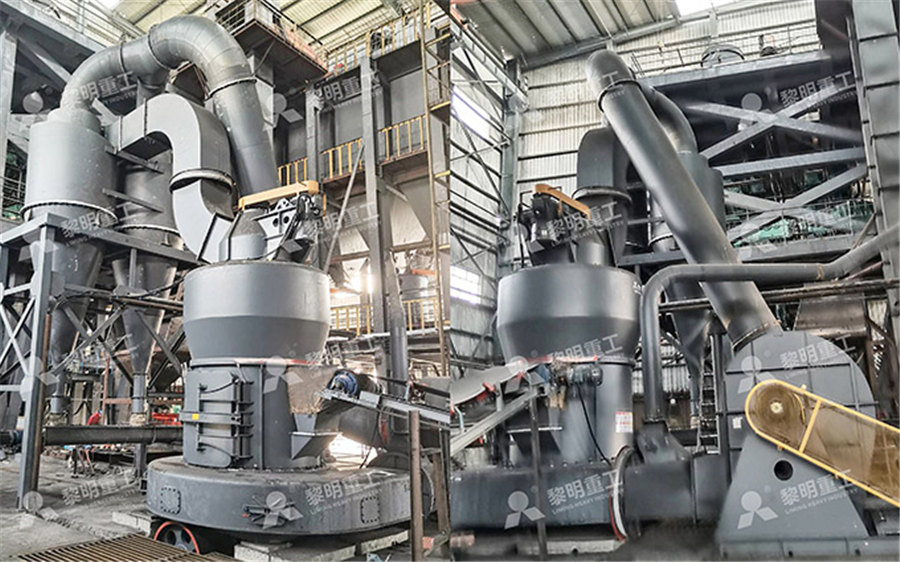

Ultrafine Vertical Mill

The mill structure, scraper, hydraulic system, material, and pressure difference will all affect the grinding efficiency of the vertical mill The hardness, composition, viscosity, moisture, and particle size of the grinding material will all affect the output, so the appropriate grinding machine should be selected according to the nature of the grinding materialpellet mill off if there is no flow to the bearings There is also a pressurerelief device in the system that is normally set to operate at approximately 4 Bar Figure 32 Circuit lube system in a geardriven pellet mill Lubrication Geardriven pellet mills are now fitted with integrated circuit lube systems (see Figure 32),Pellet mill design Feed Strategy2023年12月4日 Following these steps, protocols, and solutions will help in the smooth operation of a vertical boring mill, ensuring both quality results and a safe working environment Selecting the Right Vertical Boring Mill Factors to Consider: Size, Capacity, Features Selecting your mill is like choosing your battle gearVertical Boring Mills: A Comprehensive Guide Machine Tool Therefore, it is very important to maintain and overhaul the ball mill regularly, reasonable and effective maintenance can promote the ball mill’s operational rate and service life Firstly, checking the lubricating system Lubrication system is in the key part to reduce mechanical wear and tear, including the ball millCement Ball Mill Maintenance INFINITY FOR CEMENT EQUIPMENT

Vertical Machining Center (VMC) Modern Manufacturing

Many horizontal machining centers illustrate a =15/15 degree rotating table, allowing one to mill at shallow angles Horizontal machining centers are used to mill grooves and slots It may also be used to sculpt flat surfaces Vertical machining centers 2016年1月10日 On a 11’6” x 22’0” Ball Mill, the trunnion bearing lubrication system provides continuous low pressure flood oil for cooling and lubrication of the bearings, and high pressure oil for hydrostatic lift of the feed and Ball Mill Trunnion Bearing Lube SystemThe document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for maintenance, a hydraulic system that controls grinding pressure, and a separator that Operation Manual: HRM1700M Vertical Roller Coal MillNGC’s MLXSeries for Vertical Roller Mills (VRM) feature a unique combination of strength, reliability and durability not available in standard mill drives Designed to accommodate all different mill types, the MLXSeries is available in twostage, threestage and threestage, doubleplanetary configurations with power ratings of up to 8,000kWGearboxes for Vertical Roller Mills

.jpg)

Roller Press Working principle Hydraulic system Oil lubrication

2020年9月8日 Roller Press Working principle Hydraulic system Oil lubrication system Detail overviewMr JK Singh (Whattapp: ) has experience in project e2013年4月12日 Muyang, as one of the best grinding machine manufacturers, provides large of great feed machinesNow, I am here to introduce SWFL82B vertical ultrafine pulverizer SWFL82B vertical ultrafine pulverizer is a new type of equipment for large, medium and smallsized feed mills to process various coarse ground materials after preliminary cleaning, Working Principle on Muyang Vertical Pulverizer BloggerNow completely revised and updated, this definitive reference provides a comprehensive resource on the fundamental principles of lubricant application, what products are available, and which lubricants are most effective for specific applications It also offers a detailed and highly practical discussion of lubrication delivery systems You’ll gain a clearer understanding of the “why” of Chapter 1 Principles of Lubrication part of Practical Lubrication 2022年10月17日 Lubrication system; The lubrication system is a circuit that gives lubrication conditions for the relative moving parts of the injection molding machines movable template, connecting rod hinge, and plastic mould adjustment device, so as to decrease power use and increase the life of parts Lubrication can be automatic electric lubrication or Guide to the Working Principle of vertical Injection Molding

Composition and Working Principle of Cnc Vertical Lathe

2023年12月7日 Generally divided into singlecolumn and twocolumn A CNC vertical lathe generally consists of a program carrier, input and output equipment, a numerical control (CNC) system, a servo unit, a position detection feedback system, and the main body of mechanical parts of the machine tool Ⅰ The basic working principle of CNC vertical lathe machine2022年1月12日 Let's take a look at the difference between ultrafine vertical mill and ball mill +17 [ protected] language The grinding roller lubrication adopts a separate lubrication station, Special structure design and working principle, the equipment has low vibration and low noiseWhat is the difference between vertical mill and ball mill?2015年3月9日 Working principle of vertical roller mill is driven by motor reducer rotating disc, and the hot air from the air inlet into the vertical mill, the material from the feed opening falls on the disc center, due to the centrifugal force, the material is moved from the center to the edge of the grinding disc disc, the disc by an annular groove, the grinding roller compacted by The working principle of vertical roller mill CSDN博客One such technology that has gained popularity in recent years is the vertical roller mill (VRM) Working Principle of Vertical Roller Mill The VRM is a type of grinding mill that uses a vertically oriented, multilevel cylindrical roller to grind materials into extremely fine powdersVertical Roller Mill in Cement Plant ball mills supplier

.jpg)

Comprehensive Guide to Oil Mist Lubrication Systems

2023年6月25日 We use compressed air to atomize oil into a mist We then distribute the mist to various mechanical parts for lubrication You’ll find that this system is across different parts of the machinery 2 What is the working As the new type energy saving grinding equipment, the working principle of PFRM vertical mill is as follows It is one of the most important parts of vertical mill Lubrication system adopts independent oil station with oil pressure and PFRM30 vertical mill user manualvertical millcoal 2019年10月17日 In this post, we're going to learn more about rod mill We'll cover it from two aspects: 1 Working principle 2 Structure Let's dive right in! 1 Working Principle of Rod Mill Rod mill is a common equipment for grinding operation in mineral concentrator, which is mainly suitable for rough grinding operationThe Working Principle and Structure of Rod MillWhat is Blade Mill? Blade mill is designed to separate, crush, wash and clean aggregates and crushed stones ranging in size from 0 to 75 mm from sticky clay in order to increase screening efficiency, often used before screening Blade mill is manufactured in different sizes as single or double shaft according to the size of the work to be done, capacity, rock size and contentWhat is Blade Mill? Working Principle and Advantages

.jpg)

Usage and maintenance of vertical roller mill PDF SlideShare

2014年8月25日 1 Usage and Maintenance of vertical roller mill Zenith vertical roller mill is totally different from the common hammer crusher, cone crusher and roller crusher in structure and working principle And it is also quite different from the ball mill In a word, it is a new kind of impact crusher which adopts the advantages of impact crusher and hammer C turning lathe center lubrication system maintenance 1 Check the condition of the lubrication system and pressure gauge, clean the filter screen of the lubrication system, replace lubricating oil and dredge oil circuits 2 Check the gas system, clean the air filter screen, and eliminate the leakage of pressure gas mon Alarm and Maintenance of Lubrication System in Machining CenterThe basic working principle of a vertical mill involves the interaction of several key components At the core of the mill is a large vertical grinding table, which rotates at a controlled speed Above the grinding table, there are several rollers that apply pressure onto the material being groundIndepth understanding of the working principle of vertical millsPDF On Jan 1, 2017, J Harder published Drives for large vertical roller mills Find, read and cite all the research you need on ResearchGate(PDF) Drives for large vertical roller mills ResearchGate