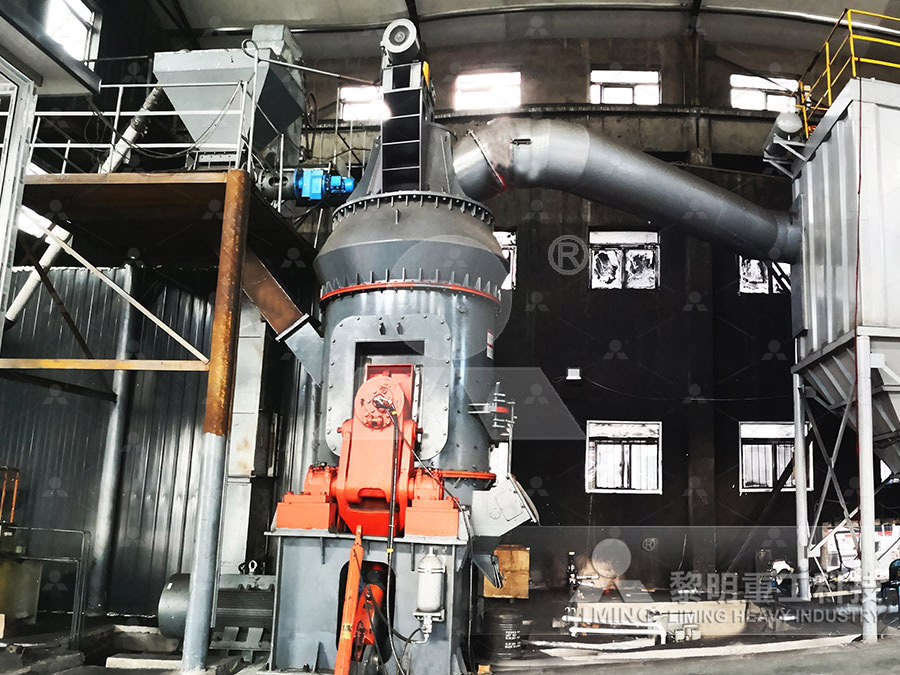

Roller coal mill technical parameters

.jpg)

Technical specifications of vertical roller coal mill

Technical specifications of vertical roller coal mill This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired powerThe document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working Operation Manual: HRM1700M Vertical Roller Coal MillIn this study, pilot scale tests were performed with a mobile verticalrollermill grinding plant to investigate the relationships between operational parameters The identification and (PDF) Operational parameters affecting the vertical roller mill a vertical roller mill (VRM) • Surpasses the classic methods if the controlled process demonstrates significant disturbances • A high degree of attention to the process states is required in order PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

.jpg)

Operational parameters affecting the vertical roller mill

2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants 2020年8月12日 To understand the performance of a vertical roller coal mill, the real operational tests have been performed considering three different coal sources Obtained results indicate thatAn investigation of performance characteristics and The slag removal process can also be carried out during the operation of the coal mill (see Fig 214) 2 Main technical parameters The performance parameters of ZGM medium speed roller mill are shown in table 211,ZGM type Mediumspeed Rolling coal millpower plant 2017年4月1日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of Operational parameters affecting the vertical roller mill

COAL GRINDING IMPS: more than meets the eye Gebr Pfeiffer

Vertical roller mills are not only used for grinding cement raw materials but also find an application in grinding a wide variety of coal types in cement and power plants Gebr Pfeiffer SE (GPSE) 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical An investigation of performance characteristics and energetic thyssenkrupp is one of the few fullrange suppliers for the cement industry – from individual machines, all the way up to complete cement plants, and this since decades The market requirement is easy to define Present kiln lines have quadropol® thyssenkrupp Polysius Grinding The slag removal process can also be carried out during the operation of the coal mill (see Fig 214) 2 Main technical parameters The performance parameters of ZGM medium speed roller mill are shown in table 211,ZGM type Mediumspeed Rolling coal millpower

.jpg)

VERTICAL ROLLER MILLS AMCL

Vertical Roller Mill 1 Rotary Lock 2 Separator 3 Chute 4 Roller 5 Swing Lever 6 Table 7 Gas Inlet Duct 8 Gear Reducer 9 Motor UM Series A B H Five Roller UMseries Coal Mill Models with details of structural dimension, product throughputs and driving power (approx Values) Roller Arrangement A B H Flow Sheet of Coal / PetcokeAdvantage 1 Equipped with a special pulverized coal pulse dust collector, the dust removal effect is as high as 999%, basically realizing dustfree operation in the workshop; 2 The grinding efficiency saves 3050% of the power consumption compared with the ball millVertical Roller MillHongxing MachineryCoal grinding mills LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations Special versions are available with characteristics that meet special safety regulation or output control requirementsCoal Mills for Cement Plants Loesche– Control Parameters for Loesche Vertical Mills Variable clocking • 50 / 100 ms: Signal detection • 1 second – 10 minutes: Signal evaluation • Material grindability • Material temperature • Material moisture • Mixture composition • Composition of raw material • Grinding roller wear • Fineness (Blaine) or residue (VOA)PROCESS OPTIMISATION FOR LOESCHE GRINDING PLANTS

%3C1PGHL[2}HK_]YT.jpg)

Review on vertical roller mill in cement industry its

2021年1月1日 In the study the advantages of vertical roller mill are discussed over ball mills VRM construction, its process and parameters which affects the performance and productivity of vertical roller mill are discussed The wet process requires 028 tons of coal and 110 kWh to produce one ton of cement, Mills Powder Engineering LM Vertical Roller Mill Manufacturer Widely applied to Calcium carbonate, barite, limestone, calcite, illite, gypsum, pyrophyllite, kaolin, bentonite, sepiolite, Technical Parameter for coal Model: Grinding disc diameter (mm) Number of roller (pc) Main power (kw) Product size (μm) Production capacity (t/h) LM08 LM Vertical Roller Mill – Jinghua Powder Engineering1990 Central coal grinding plant (LM 263 D) for gas and steam power station (coal gasification) 1992 Central coal grinding plant (LM 263 D) for the production of lignite (brown) coal dust 2002 Coal grinding plant (LM 232 D) for grinding wood pellets for power stations 2005 First 4roller pressure mill (LM 434 D) becomes availableLOESCHEMILLSOperational parameters affecting the vertical roller mill in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants for coal grinding The mill Eng 73, 109–115 Roy, GR, 2002 Increasing cement grinding capacity with vertical roller mill technology Cement Industry Technical (PDF) Operational parameters affecting the vertical roller mill

.jpg)

Analysis and Optimization of Grinding Performance of

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters For design of experiments (DOE), the response surface method Download scientific diagram The layout of the coal mill with a rotary classifier from publication: An investigation of performance characteristics and energetic efficiency of vertical roller The layout of the coal mill with a rotary classifier【What’s the double roller crusher】 The Doule Roller Crusher, also known as roll crusher, or toothed roll crusher, is suitable for fine crushing medium hardness rock with compressive strength ≤160MPa, such as ore, rock, coke, coal, Double Roller Crusher JXSC MachineTechnical Parameters Vertical Roller Mill Under the background of the current industry, based on the requirement of energy saving and emissions reduction of national policy, vertical grinding machine become the trend of production of grinding, however, restricted by the spiral bevel gear production specifications, in the extended chain and double input methods such as electric Technical Parameters Vertical Roller Mill

Analysis and Optimization of Grinding Performance of Vertical Roller

2022年1月23日 This work concentrates on the energy consumption and grinding energy efficiency of a laboratory vertical roller mill (VRM) under various operating parameters2019年2月21日 The paper analyzes the interrelation of: motion, particle size of ground rice grains, displacement, and grinding in a roller–plate mill The purpose of the study was to analyze and evaluate A study of operating parameters of a roller mill with a new 2009年1月1日 Four grinding circuits are used with different materials: vertical mills (Loesche) for coal and cement feed; vertical roller mills for cement clinkers; and ball mills for cement products Table 2 shows the main technical parameters of the vertical roller mill (CKP) studied in this paperGrinding process within vertical roller mills: experiment and Whether grinding raw coal, clinker, cement and/or slag, we have a VRM solution to suit your grinding needs What’s more, our online condition monitoring services enable you to adopt a proactive maintenance strategy for your OK™ and ATOX® mills that eliminates unexpected downtime and ensures continuous high performanceVertical roller mills FLSmidth Cement

.jpg)

INVESTIGATION OF EFFECT OF OPERATIONAL PARAMETERS ON VERTICAL ROLLER

parameters on vertical roller mill grinding performance In this context, systematic test plans have been generated lots of technical and social features Special thanks go to more than friends, Okay ALTUN, Deniz ALTUN, Wayne PEO, Suphi ÜNAL and Yasin KILLIOĞLUVertical roller mill manufacturers Vertical roller mill or VRM is a largescale grinding equipment designed for pulverizing cement raw meal, cement clinker, slag, coal, fly ash, limestone, and other hard grinding materialIt integrates grinding, drying, separation, and conveying in one machine The equipment is widely used in many industries such as cement, electric power, metallurgy VRM In Cement Plant Maximize Energy Saving CNBMSINOMA2020年4月2日 as mill roller, grin der and mill Coal Parameters Calorific value Steadily increasing environmental requirements and high production costs require compensation of their technical and Analysis of the Coal Milling Operations to the Boiler Download Citation On Oct 14, 2020, Yanping Li and others published A Wear Condition Monitoring Model of Coal Mill Grinding Roller Based on LSTM Find, read and cite all the research you need on A Wear Condition Monitoring Model of Coal Mill Grinding Roller

VERTICAL ROLLER MILL TECHNICAL DETAILS

Download scientific diagram VERTICAL ROLLER MILL TECHNICAL DETAILS from publication: Grinding process optimization — Featuring case studies and operating results of the modular vertical roller ObserverBased and Regression ModelBased Detection of Emerging Faults in Coal Mills Peter Fogh Odgaard, Sten Bay Jørgensen, in Fault Detection, Supervision and Safety of Technical Processes 2006, 2007 2 THE COAL MILL The work presented in this paper, is based on a Babcock MPS 212 coal mill used at Elsam’s Nordjyllandsværktet Unit 3 However, the Coal Mill an overview ScienceDirect Topicsof 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population Raymond Roller Mill are mainly composed of main machine, feeder, classifier, fan, pipeline device, storage hopper, electrical control system, collecting system, etc The main motor of the Raymond Roller Mill is mainly composed of a base, a center shaft frame, a grinding ring, a grinding roller assembly, a center shaft, a blade holder, a blade holder assembly and a coverR Series Raymond Roller Mill Raymond Pulverizer

Modeling and Parameter Identification of Coal Mill

2009年9月20日 A control oriented model was then developed by Fan (1994) and Fan and Rees (1994) In 2009, coal flow and outlet temperature of mill were modelled using mass and heat balance equations for startup 700 Journal of Power Electronics, Vol 9, No 5, September 2009 JPE 954 Modeling and Parameter Identification of Coal Mill HwiBeom Shin *, Xinlan Li , InYoung Jeong **, JongMan Park **, and Soonyoung Lee † †*Department of Electrical Engineering, Gyeongsang National University, Korea ** Korea Western Power Co, Ltd, KoreaModeling and Parameter Identification of Coal MillTechnical Advantages 1 Hydraulic device, overhauling operation is very convenient; 2 Extends the service life of wearresistant materials; 3 Remove difficult boot trouble; 4 Roller limit device, to avoid grinding mill producing severe vibration during work; 5 Due to the hydraulic device and roller limit device, to ensure grinding pressure and stable capacityLM vertical coal mill2017年5月1日 MODULAR VERTICAL ROLLER MILL TECHNICAL process parameters showed a smoothl y running mill as in of cement raw material and coal Since the 1980's this mill type has also been used (PDF) Grinding process optimization — Featuring case studies and

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

Technical data; Throughput rate: up to 110 t/h: Mill drive: up to 2,000 kW: Number of grinding rollers: 3: MPS 200 BK coal mill, Krimzement Bakhchisarayski, Ukraine MPS 180 GC vertical roller mill for the grinding, drying and The vertical roller mill (VRM) is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing processIn recent years, the VRM cement mill has been equipped in more and more cement Vertical Roller Mill Operation in Cement PlantThe quadropol® concept for coal or pet coke grinding, with adapted table speed and high efficiency separator sepol®, ensures a safety mill operation and serves reliable the kiln burning process Mombasa Cement Ltd ordered a QMK² quadropol® Vertical Roller Mill myPolysiusServiceHP coal mill adopts mature roller surfacing technology and large diameter tapered roller For general coal, the design life of grinding roller is more than 12000h, and it can be used repeatedly after wear, so as to reduce the cost Main technical parametersHP Bowl type millspower plant equipment

Copper ore grinding in a mobile vertical roller mill pilot plant

2015年3月10日 Comparison of the vertical roller mill and rodball mill circuit on the gold extraction; C Gerold et al Recent installations and developments of loesche vertical roller mills in the ore industry; M Ito et al Productivity increase of the vertical roller mill for cement grinding; SW Jørgensen2012年11月17日 Coal mill pulverizer in thermal power plants (XRP 883 Bowl mill) Design parameters Mill capacity 4248 T/HR Total moisture10% HGI 50 26 137Logic tree 992% THRU 50 MESH Classifier Loss of Ring or Classifier Exceeding Vane Roller Roller Vane Mill position tension wear wear capacity Coal mill pulverizer in thermal power plants PPT SlideShare2 Xuzhou Longshan Cement Plant 5000t/d production line Φ38×95m coal mill 3 Henan Meng Electric Group Cement Co, LTD 5000t/d production line Φ38×95m wind swept coal mill 4 Riverside Group Co,LTD 3000t/d production line Φ34×6+3m coal mill Technical parameters:(Please refer to attached list)Coal Mill Great Wall2021年1月29日 VRM Production Rate and Specific Power It can be clearly seen in Figure 3 that last 6 months average breakdown frequency Rate was 6016 tripping per month means per day more than 2 trippingIncrease productivity of vertical roller mill using seven QC tools

G[R.jpg)

Modeling and Parameter Identification of Coal Mill ResearchGate

Modeling and Parameter Identification of Coal Mill 701 Fig 1 Sectional view of MBF coal mill It can be seen in the literature that modeling theThe complete system of HCH ultrafine ring roller mill is mainly composed of main engine, feeder, classifier, blower, piping device, storage hopper, electric control system, collection system, etc Process flow of milling system The material is crushed by the jaw crusher into materials smaller than 10mm lifted by the bucket elevator to the storage hopper, and then quantitatively sent to HCH Ultra Fine Ring Roller Mill