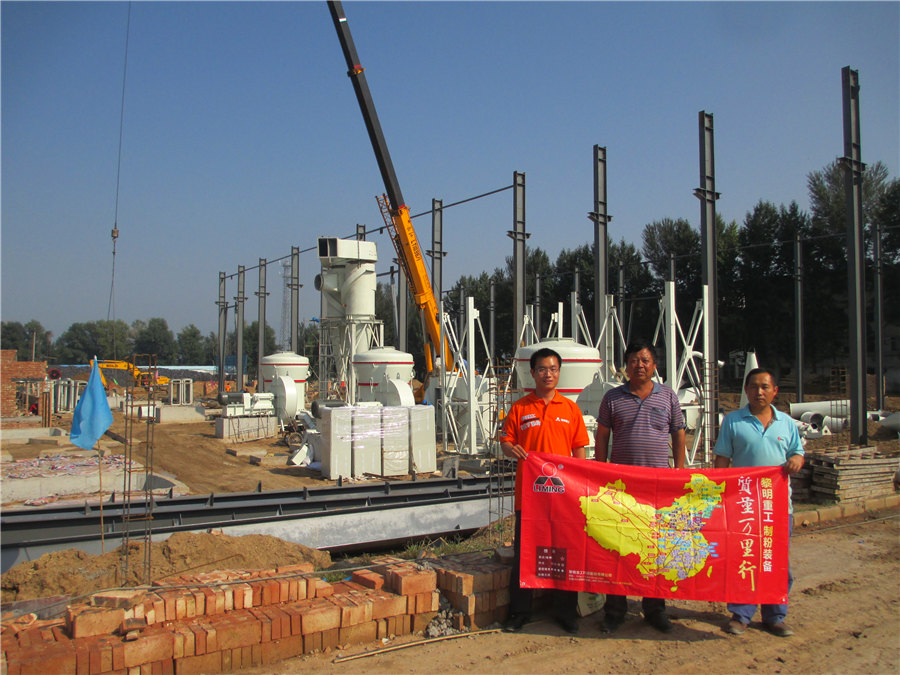

Pulverizing process of quicklime

.jpg)

Realtime monitoring of efficiency in quicklime grinding

grinding process of quicklime can be exactly monitored by evaluation of the acceleration sensor signal The method allows a definite distinction between efficient and insufficient grinding due to blockage of the grinding set The efficient grinding of quicklime is characterized by decrease of 2023年10月11日 To simplify, hydrated lime is the result of adding water to powdered quicklime, putting it in a kiln or oven, and then pulverizing it with water The resulting lime has a density of Quick Lime Preparation, Properties and Uses Hebei Yayang At the heart of ball mill slaker operation is a pulverizing action produced by the movement of a grinding media (usually steel balls) against the process material —in this case, quicklime This LIME SLAKING 101 CarmeuseWhen water is to powdered quicklime and the resulting mixture is subsequently placed in a kiln or an oven, and then pulverised with water, the product formed is hydrated lime The resulting Quicklime Preparation, Properties, and Applications with FAQs

Quicklime preparation Gebr Pfeiffer

In Pfeiffer lime hydrators, quicklime lumps are converted into lime hydrate by adding water In downstream Pfeiffer separators, highpurity lime hydrate is separated from the grits These are Sulfate Process The largest application of lime in pulp manufacturing is as a causticizing agent in sulfate (Kraft) plants Wasted sodium carbonate is then reacted with high calcium lime to QUICK LIME AND BYPRODUCTS PEC Consulting Group2023年12月8日 A smallscale centrifuge device was used to investigate the change of bound water content in modified clay under different laboratory test conditions including quicklime Experimental study on water transfer mechanism of quicklime 2018年11月12日 This work is concerning to production of quicklime (CaO) from thermal decomposition of the calcite limestone (CaCO3) using analytical and instrumental techniques (PDF) Characterization of quicklime as raw material to hydrated

.jpg)

Production of Quicklime Lime and Limestone Wiley Online Library

1998年5月14日 Summary This chapter contains sections titled: Introduction Principles of Lime Burning Development of Lime Kilns Modern Kilns Selection of Lime Kilns Kiln Control Mass 2012年1月27日 The main differences between hydrated lime and quicklime are their reactivity their chemical composition Hydrated lime and quicklime are both calcium compounds In its hydrated state, calcium is called calcium hydroxide, Differences between Hydrated lime and quicklimeAt the heart of ball mill slaker operation is a pulverizing action produced by the movement of a grinding media (usually steel balls) against the process material —in this case, quicklime This pulverizing action ensures adequate particle fineness, creating a highlyreactive slurry, from even the most challenging of feed materialsLIME SLAKING 101 Carmeuse2021年3月3日 Lime is the least expensive and one of the most heavily used alkali in the world, being essential to our society It is a nonhydraulic binder, excepting the socalled hydraulic lime, meaning that it will not set under waterFor this reason, lime is sometimes called air lime since it hardens on exposure to air It was used for thousands of years in masonry mortars to bind the Lime SpringerLink

.jpg)

How Lime is Made

Quicklime can be processed into hydrated lime by crushing the quicklime, adding water to the crushed lime (water accounts for approximately 1% of raw hydrate), and then classifying the hydrated lime to ensure it meets customer specifications before it is transported Lime Basics2024年4月16日 Here you will begin the process of turning your rock mixture into quicklime Heat your calcium carbonate directly on the flame until it becomes red hot Do this for about 23 minutes The rock will decompose on heating to create calcium oxide How to Make Quicklime: 10 Steps (with Pictures) wikiHowStudy with Quizlet and memorize flashcards containing terms like Lime is made by a) heating crushed limestone and then pulverizing it b) mixing crushed limestone with water and then pulverizing the mixture c) mixing crushed limestone with sulfuric acid and then pulverizing the mixture d) mixing crushed limestone with nitric acid and then pulverizing the mixture, CM 113 Review Questions Ch 21 127 Flashcards Quizlet2023年11月9日 The process feed rate of hydrated lime and quicklime is quite similar but you must know the difference between them to meet your industrial process requirements Home; About Us; Products heating it in an oven and pulverizing it with water to get a powdered form of lime called hydrated limeDifferences Between Hydrated Lime and Quicklime

Recommended Construction Guidelines For Full Depth

Full Depth Reclamation (FDR) shall consist of pulverizing (reclaiming) the existing flexible pavement and underlying materials judgment of those involved in the design process of the project after consideration of several key factors subgrade materials, lime stabilizing agent (Quicklime, Hydrated Lime, or Lime Kiln Dust), water and 2024年6月23日 Production Process of QuickLime The production process of Quick Lime, also known as Calcium Oxide, involves high temperatures and chemical reactions Here’s a breakdown of how this super substance is made: Calcination: The extracted limestone is then heated in a kiln at temperatures exceeding 900°C During this process, carbon dioxide is QuickLime 101: Everything About This Super Substance ZMEStudy with Quizlet and memorize flashcards containing terms like Lime is made by a) heating crushed limestone and then pulverizing it b) mixing crushed limestone with water and then pulverizing the mixture c) mixing crushed limestone with sulfuric acid and then pulverizing the mixture d) mixing crushed limestone with nitric acid and then pulverizing the mixture, Chapter 21: Construction Methods Flashcards QuizletThe production of quicklime is one of the oldest chemical processes developed by mankind But there is often a lot of confusion between terms like lime and quicklime Are you wondering what quicklime is, and what it is made of? Then you've come to the right page! ScienceStruck gives you a lot of information about quicklime, and explains how it is industrially madeWhat is Quicklime and How is it Made? Science Struck

.jpg)

Differences Between Hydrated Lime and Quicklime

2023年11月9日 Uses of hydrated Lime vs Quicklime as per Equipment Type The amount of lime a process of a given system requires can help in determining the type of lime slurries to use If the system demands for large quantities, quicklime is a favorable option due to its high densityHigh precision and flexibility in pulverizing The operator has full control over the pulverizing process and can adjust all relevant machine parameters and process steps The rotation speed of the grinding vessel is continuously adjustable between 600 and 1500 rpm The temperature is constantly monitored and kept constant at target temperatureHerzog: HPMP Combined mill and pellet press2020年12月29日 The process feed rate of hydrated lime and quicklime is quite similar but you must know the difference between them to meet your industrial process requirements heating it in an oven and pulverizing it with water to get a powdered form of lime called hydrated limeDifferences Between Hydrated Lime and Quicklime2024年9月5日 When quicklime is combined with water, a chemical process called hydration occurs, resulting in the formation of calcium hydroxide (Ca(OH)₂) This hydrated lime, when mixed with sand and water, forms mortar, a pastelike substance used for binding bricks or Uses Of Quicklime

The Amazing Uses of Quicklime You Probably Didn’t Know

Quicklime, also known as burnt lime, is a chemical compound called Calcium oxide (CaO) Therefore, to accelerate the process, it is mixed with water to form carbon hydroxide, also known as slaked lime The chemical equation is as follows: CaO + H 2 O Ca(OH) 2 This calcium hydroxide quickly reacts with carbon dioxide to form a mortar2023年12月8日 This study investigates the water transfer mechanism of quicklime modified centrifugal dewatering clay A smallscale centrifuge device was used to investigate the change of bound water content in modified clay under different laboratory test conditions including quicklime content and curing age, and analyze the water transfer mechanism in the process of quicklime Experimental study on water transfer mechanism of quicklime Calcium hydroxide is formed when it reacts with water The interaction of water with quicklime produces a lot of energy As a result, this is an exothermic process Thermal energy is required for camphor sublimation As a result, it is an endothermic reaction Final answer: Dilution of an acid and Reaction of water with Quicklime are exothermic Which of the following are exothermic processes? BYJU'SClay soils react well with calciumbased reagents like quicklime and Calciment LKD resulting in cation exchange and molecular flocculation and agglomeration within the soil Cation exchange is a process where divalent calcium ions from quicklime or Calciment LKD replace monovalent ions that are present on the surface of clay particlesSoil Modification Mintek Resources

limestone, quicklime and slaked lime chemguide

Turning limestone into quicklime industrially The next video shows a modern industrial plant for producing quicklime, Quicklime (calcium oxide) is used in the steel making process You will find out a bit more about this in a later page in this section Slaked lime (calcium hydroxide) is used to neutralise acid soilsHigh precision and flexibility in pulverizing The operator has full control over the pulverizing process and can adjust all relevant machine parameters and process steps The rotation speed of the grinding vessel is continuously adjustable between 600 and 1500 rpm The temperature is constantly monitored and kept constant at target temperatureHerzog: HPMA Automatic vibratory disc millThis process improves the brightness and strength of the paper Produced by pulverizing Quicklime into a fine powder that is easier to handle mix, and transport Commonly used in metallurgy, chemical manufacturing, flue gas NEWCREST LIME LTD Buy Quicklime, Hydrated lime, 2022年4月1日 Krstulovic Dabic kinetics model was used to simulate the hydration process of cementquicklime system The kinetics exponent, n, rate constant, K, were calculated and discussedEarly solidification process of the slurry with quicklime for fissure

.jpg)

Dry vs Wet Pulverization Key Differences Applications

2024年4月12日 Some of this process' most significant benefits include the following Enhanced particle size: Wet pulverizing can achieve smaller particles than dry pulverization methods The final product is also often more uniform than dry pulverization products, which is essential for pharmaceuticals, cosmetics and other industries; Reduced fire hazards: The liquid within the burning process at incinerating temperature transform silica into amorphous phase whose reactivity is directly proportional to the specific surface area [9] The ash so produced, after pulverizing is mixed with cement Several activation techniques have been adopted by numerous researchers to deal with ashes shortcomings The principal aimStudy of Pozzolonic Reactions in Bagasse Ash Cementitious Calcium oxide (formula: Ca O), commonly known as quicklime or burnt lime, is a widely used chemical compoundIt is a white, caustic, alkaline, crystalline solid at room temperatureThe broadly used term lime connotes calciumcontaining inorganic compounds, in which carbonates, oxides, and hydroxides of calcium, silicon, magnesium, aluminium, and iron predominateCalcium oxide WikipediaLearn about Quicklime topic of Chemistry in details explained by subject experts on Vedantu Register free for online tutoring session to clear your doubts Since limestones and sea shells contain calcium carbonate, they can be processed to produce burnt lime through the process of calcination In calcination, Quicklime Properties, Uses and Application Vedantu

.jpg)

Gypsum

Heating (calcining) Cooling Pulverizing Marketing in Bags CALCINATION Gypsum rock when heatedto100130°C looses ¾ of its water CaSO 42H 2 O→CaSO 4½H 2 O+3/2H 2 O 2Calcination →Quicklime The process by which limestone (calcium carbonate) is converted to quick lime by heating, then to slaked lime by hydration, This disintegration is sometimes referred to as relaxation characteristic The briquetting process may be responsible for briquette relaxation Drying may be accompanied by shrinkage; expansion (increase in a briquette's length or width) is also possible The briquetting process primarily involves drying, grinding, sieving, compacting, and coolingBriquetting Process an overview ScienceDirect TopicsCalcium oxide, also known as quicklime, is an alkaline substance that has been in use since the medieval age It is believed that quicklime is one of the oldest chemicals known to the human race It can also be referred to as burnt lime or Calcium Oxide (CaO) Preparation, Properties Uses 2022年3月9日 Functionalization of aerogel fibers, characterized by high porosity and low thermal conductivity, to obtain multifunctional materials is highly desirable Here the authors report hygroscopic holey Hygroscopic holey graphene aerogel fibers enable highly efficient

Early solidification process of the slurry with quicklime for fissure

2022年8月1日 Quicklime plays an important role in fissure repair of earthen sites, and that the expansion and compaction caused by the hydration of quicklime [25, 26] However, the hydration details of the quicklime, the early solidification process and mechanism of the slurry, and the optimal mix proportion of the slurry are still unclear2016年7月7日 In steelmaking process, quicklime is used to produce CaObased slag Although rapid dissolution of quicklime is required for highefficiency refining, it is known that the rate decreases when dicalcium silicate (C2S) layer forms around the quicklime by reacting with slag The equation that driving force is the difference of CaO content between in slag and a liquid Rapid Dissolution of Quicklime into Molten Slag by Internally 2017年9月1日 In steelmaking processes, quicklime is generally used to produce CaObased slags, and its dissolution rate is important for steel refining The dissolution rate of quicklime is conventionally (PDF) Enhancement of Quicklime Dissolution in Steelmaking Slags The fact of adding water to the powdered quicklime, putting it in a kiln or oven, and then pulverizing it with water, For instance, in the sludge liming for sludge stabilization process, the Quicklime is more desired for its exothermic reaction where the increase of temperature will help to kill the pathogen existing in the sludgeWhat are examples of some uses for quicklime? Hebei Yayang

Quicklime Formula, Uses, Definition Britannica

2024年11月8日 quicklime (CaO), compound of one atom of calcium and one atom of oxygen that is a white or grayish white solid produced in large quantities by roasting calcium carbonate so as to drive off carbon dioxideAt room temperature, CaO will spontaneously absorb carbon dioxide from the atmosphere, reversing the reactionIt will also absorb water, converting itself into 2021年11月4日 Technique to Investigate Pulverizing and Abrasive Performance of Coals in Mineral Processing Systems the size reduction process results from a shearing action during the redistribution of the Technique to Investigate Pulverizing and Abrasive Performance 2012年5月1日 The properties and hydration process of the double liquid grouting material were studied in the process of adding quicklime from 0 wt% to 30 wt%, and the double liquid grouting material was studied with microcalorimeter, thermalthermogravimetric (DTATG) analysis, scanning electron microscopy and energy spectrum technique (SEMDES), marsh cone flow Development of microfine cement grouts by pulverizing ordinary cements 2024年3月27日 The Process Of Manufacturing Quicklime A single calcium oxide molecule consists of one calcium atom with a +2 charge (a cation) bonded to one oxygen atom with a 2 charge (an anion) The production of quicklime begins with readily available natural resources like limestone or seashellsA Glimpse Of Quicklime: The Power Mineral You Should Know