HOME→SST1200 heavy calcium powder processing equipment SST1200 heavy calcium powder processing equipment SST1200 heavy calcium powder processing equipment

SST1200 heavy calcium powder processing equipment SST1200 heavy calcium powder processing equipment SST1200 heavy calcium powder processing equipment

.jpg)

Heavy calcium + superfine processing equipment ALPA Powder

2021年8月27日 There are many types of heavy calcium grinding and processing equipment They are combined with ultrafine grade machines to form an ultrafine processing system, Ada banyak jenis peralatan penggilingan dan pemrosesan kalsium berat Mereka Indonesia2024年8月23日 Among them, the dry process is generally used to produce heavy calcium carbonate products with d97≥35μm The main crushing equipment includes Raymond mill, impact mill, dry stirred mill, air flow mill, Heavy calcium carbonate dry production process and The heavy calcium powder air classifier production line is a complete set of equipment used to produce heavy calcium powder It consists of a crusher, a feeder, an air classifier, a dust D97: 10μm heavy calcium powder air classifier production line

.jpg)

Calcium Carbonate Powder Processing

At present, calcium carbonate has high application value in papermaking, plastics, rubber, paint, medicine and other industries The high application of heavy calcium powder in the market mainly includes 325 mesh, 400 mesh The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production Calcium Carbonate Grinding Production Line TAYMACHINERY2021年12月20日 Machines Used for Processing Calcium Carbonate Heavy machinery is primarily used during the dry processing phase, when calcium carbonate manufacturing processes focus on reduction through milling, Calcium Carbonate Manufacturing Process and Because different industrial applications have different requirements on the particle size, shape, whiteness and particle size distribution of ground calcium carbonate powder, the processing ALPA Calcium Carbonate powder Processing Technology

Calcium Carbonate Powder Production Line – Powder Equipment

Calcium carbonate powder production line includes several machines such as crushers, dryers, grinding mills, classifiers, coating machines, and packing machines Each stage of the A calcium carbonate production line is vital for making calcium carbonate It’s a widely used industrial mineral This production line typically includes key components They are crushers, Calcium carbonate production line EPIC PowderKason’s powder processing equipment is available in a host of standard and customengineered models that can be designed to meet your specific requirements for sifting, screening, mixing, Powder Processing Equipment Kason CorporationHeavy calcium powder, also known as calcium carbonate, is a commonly used filling material in the industries of plastics, rubber, paper, paint, and pharmaceuticals The particle size of heavy calcium powder directly affects its performance and application fields Ultrafine grinding of heavy calcium powder can effectively improve its activity UltraFine grinding processing method and flow of heavy calcium powder

Powder Processing Equipment Systems Qlar

of the design/build process from the project kickoff all the way to process commissioning From start to finish, our teams are dedicated to meeting your business goals Process Controls Our Process Controls Group has been entrusted to control processes for some of the world’s most recognizable brands We’ve been buildingWith versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate powder of various particle sizes is in great demand around the world As the result, more and more shrewd businessmen want to build or expand their calcium carbonate powder processing plant all over the worldCustomize Suitable Calcium Carbonate Plant DASWELL2023年12月7日 The carbon dioxide reacts with the calcium hydroxide to form calcium carbonate Equipment The equipment used in the manufacturing process for calcium carbonate varies depending on the type of calcium carbonate being produced For natural calcium carbonate, the equipment typically includes crusher, screens, grinder mill, and washersWhat is the steps in the Calcium Carbonate Liming Heavy 2021年9月28日 In terms of cost, calcium carbonate is lower than talcum powder In terms of production process, calcium carbonate is easier to process than talc powder The polypropylene pellets used for strapping should be added with talcum powder and calcium carbonate, the ratio of which is: polypropylene: talcum powder: calcium carbonate = 70:25:5The difference between talcum powder and calcium carbonate

7 types of calcium carbonate commonly used in the paper industry

2023年4月8日 The paper industry is one of the largest markets for calcium carbonate As an important papermaking filler and coating pigment, calcium carbonate is rich in sources and cheap in price; fine particles and high whiteness can significantly improve the opacity of paper; fast ink absorption speed can increase Ink absorption of paper; it can make the paper softer, tighter 2021年9月22日 Light calcium carbonate powder is often added in a relatively large amount, which will help it mix with other components and also help the processing and shaping of plastics The addition of light calcium carbonate, especially after surface treatment of light calcium carbonate, can not only increase the hardness of the product, but also improve the surface Technical indicators of calcium carbonate and its ALPA PowderAt present, HLMX nonmetallic ore ultrafine vertical grinding mill equipment has been widely used in the processing technology of heavy calcium ultrafine powder It not only occupies the main market share in domestic heavy calcium enterprises, but also is exported overseas, and has been recognized by many large and wellknown partnersNews Application of HLMX Ultrafine Vertical Roller Mill for Non Solids and Powder Processing Equipment Categories Balers (141 suppliers) Industrial balers compact material into bales for improved handling, transportation, disposal, storage, or secondary processing Some industrial balers have integrated shearing capabilities (shear Solids and Powder Processing Equipment GlobalSpec

.jpg)

Calcium Carbonate Powder Processing

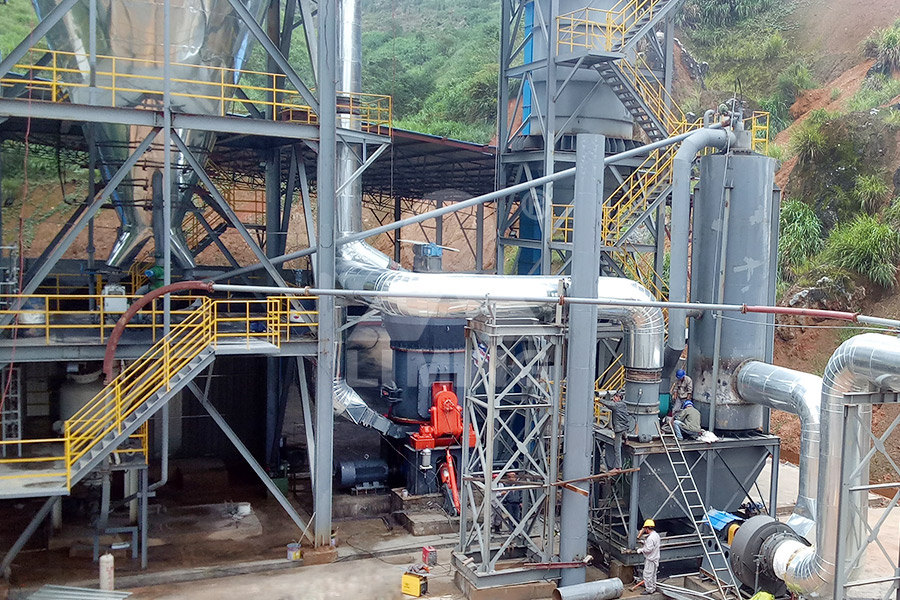

It has the advantages of small floor area, strong completeness, wide use, simple operation, convenient maintenance, stable performance, high cost performance, low investment cost, economic benefits and fast income It is the mainstream equipment for the processing of heavy calcium ultrafine powderIntroduction of calcium powder: Calcium powder is a white powder made by grinding limestone, calcite, marble, etc, commonly known as heavy calcium Due to the different demands on the fineness of heavy calcium powder in all walks of life, the application standards are different, so the processing method and equipment selection of heavy calcium Which equipment is needed for heavy calcium powder processingHeavy calcium powder processed into more than 1000 mesh powder belongs to ultrafine heavy calcium powder, and special ultrafine powder processing equipment needs to be selected In the field of ultrafine powder processing, Zhengzhou SMMVIK Machinery Industry Technology Co, Ltd has developed and launched two types of equipment LUM ultrafine vertical mill and Which equipment is good for processing heavy calcium into powder 2023年3月21日 Comparison of ultrafine heavy calcium processing equipment At present, the nonmetallic ore dry ultrafine grinding process equipment mainly includes Raymond mill, stirring mill, Production project of 6 tons of heavy calcium powder per hour in Myanmar Production fineness: D97 10um (1250 mesh) Yield: 56 tonsThe advantages of ultrafine vertical mill in the processing and

CALCIUM CARBONATE POWDER

um carbonate powder, the processing technology of ground calcium carbonate should also comprehensively consider the process route and equipment selection according to the product positioning Generally speaking, the design of grinding equipment is based on different principles:2022年7月18日 Calcium carbonate is widely used to fill polyvinyl chloride (PVC), polyethylene (PE) and other resins Appropriate addition of calcium carbonate helps to improve the performance and processing performance of PVC products, such as improving the dimensional stability of products and improving product quality Stiffness and hardness, improve the heat Heavy calcium, light calcium, nano calcium, who is the favorite The Global Powder Processing Equipment Market was valued at $45 billion in 2020, and is projected to reach $79 billion by 2032, growing at a CAGR of 51% from 2023 to 2032 Powder processing equipment refers to a range of machinery and systems especially designed for handling and transforming powdered materialPowder Processing Equipment Market Research, 年11月8日 Highend calcium oxide ultrafine powder milling equipmentHGM series 125 model production line, Processing materials: calcium oxide: Finished product particle size: 200600 mesh: China Hubei heavy calcium carbonate HGM100P ultra Highend calcium oxide ultrafine powder making equipment

D97: 10μm heavy calcium powder air classifier production line

The heavy calcium powder air classifier production line is a complete set of equipment used to produce heavy calcium powder It consists of a crusher, a feeder, an air classifier, a dust collector, and other auxiliary equipment This production line is suitable for processing various nonflammable and explosive mineral materials with Mohs hardness below 7 and humidity below 6%This brings a unique competence to all systemcritical parts of a powder processing system, from receiving to conveying, feeding, mixing and size control Automation Gericke’s knowhow in powder processing together with competence in electrical engineering and automation makes us the ideal partner to supply complete turnkey systemsPowder processing solutions Gericke AG2023年10月13日 3 3 IMARC Group’s report titled “Calcium Powder Manufacturing Plant Project Report 2023: Industry Trends, Plant Setup, Machinery, Raw Materials, Investment Opportunities, Cost and Revenue” provides a complete roadmap for setting up an Calcium powder manufacturing plant It covers a comprehensive market overview to microlevel information Calcium Powder Manufacturing Process, Machinery 2020年12月10日 In the past, due to the limitation of crushing equipment, heavy calcium carbonate could not reach this fineness Now, The processing of heavy calcium carbonate is mainly realized by mechanical crushing and Calcium 【Technical analysis】How to choose “industrial

.jpg)

Powder Filling Processing Machines (PLF) FoodTech JBT

Powder Processing, the Simple Way One triedandtrue way to facilitate your production? Use equipment that’s meant for making your specific product Even better – only onboard the most heavyduty, reliable machinery Incorporating the proper, purposebuilt solutions sets you up for a highfunctioning powder processing line2022年5月5日 The YGM Raymond grinding mill can be used to produce calcium carbonate powder between 50500 mesh This equipment is an improvement on the traditional Raymond grinding mill, which is more efficient, more Calcium Carbonate Grinding Mill Powder ModifyManufacturer for set of ultrafine powder equipment +29 Get A Quote Home; About Us; Products Grinding the top ten domestic heavy calcium, large waste recycle of environmental protection helping China's powder processing industry to catch up with the international advanced level and achieving a new highquality and high Powder Equipment Manufacturing Production Lines Longyi2020年4月6日 Powder processing industries exploit the range of behaviors that powders exhibit to deliver an array of valuable products For example, the pharmaceutical industry manufactures formulations that aerosolize, for inhaled drug delivery, or that compact to form oral solid dosage products in the form of granules and tabletsPowder characterization for effective powder processing

.jpg)

Effect of industrialgrade heavy calcium carbonate powder on

2023年5月1日 In order to reduce costs and improve whiteness, industrialgrade heavy calcium carbonate powder (IHCP) is used in white highstrength concrete (WHSC), the influence of IHCP on the workability 2022年9月29日 80425mesh heavy calcium powder grinding mill For processing heavy calcium powder in the range of 80425 mesh fineness, European mills and vertical roller mills can be selected 1 European version grinding mill The European version of the grinding mill system is a closedcircuit system4 Steps To Build A Calcium Carbonate Processing Plant Zenith 2021年9月8日 Nano calcium carbonate is often used in chemical building materials, inks, coatings, sealants, and adhesives About development Gray calcium powder; Gray calcium powder is easy to cause white pollution in the production process, but the green products produced are a contradiction To solve this contradiction, improve equipment, and work hard The relationship between gray calcium powder, light calcium 2021年7月9日 Talc is finally applied in powder form, therefore, fine grinding and ultrafine grinding are one of the necessary processing techniques for talc Talc has a Mohs hardness of 1, which is naturally crushable and has good grindability At present, the processing of ultrafine talc powder mainly adopts a dry processThe processing and application of talc ALPA Powder Equipment

Calcium carbonate manufacturing process

2020年1月7日 It has been mentioned that the grinding equipment for wet grinding of heavy calcium carbonate / heavy calcium powder mainly includes chippers, agitating mills, and sand mills, but no matter which equipment is selected, the purity of the heavy calcium carbonate / heavy calcium powder must be The whiteness and whiteness are not contaminated80425mesh heavy calcium powder grinding mill For processing heavy calcium powder in the range of 80425 mesh fineness, European mills and vertical roller mills can be selected 1 European version grinding mill The European 4 Steps to Build a Calcium Carbonate Processing Plant 2023年9月3日 The postmixed calcium carbonate preparation process is roughly the same as the HCC preparation process, except that the first aggregate is formed only from ground calcium carbonate, and after the ground calcium Four major development trends of calcium carbonate 2024年11月1日 In this study, the ceramic cores were printed with heavy calcium carbonate (HCC, CaMg(CO 3) 2) powder as raw material and Al powder as additive by binder jetting (BJ)The ceramic cores were impregnated with nanoZrO 2 dispersion solution and then sintered at high temperature to prepare the ceramic cores with low sintering shrinkage The effects of Significantly improved sintering shrinkage of heavy calcium

How to Choose a Calcium Carbonate Grinding Mill DASWELL

In terms of production process, calcium carbonate powder is mainly obtained by grinding limestone, marble, dust collectors, classifiers and other equipment The grinding mill is the core of the entire production line is widely used in the fine processing of heavy calcium carbonate, light calcium carbonate, barite, 2023年10月16日 It is usually divided into heavy calcium carbonate and light calcium carbonate according to different processing methods Calcium carbonate, whether it is heavy calcium carbonate or light calcium carbonate, is the most widely used powder filler in plastics, rubber, papermaking and other industries 1 Production methodLearn the 17 differences between light calcium and heavy calcium!Heavy calcium powder processing production process is generally divided into dry and wet production TSP dry production of calcium carbonate can produce 5μm, 10μm and 18μm of GCC products, currently used in the superior performance of the European version of the mill technology professionals to build, can produce more than 80% less than 2μm products, mainly Where to sale Heavy calcium carbonate powder grinder mill processing 2023年12月15日 With the advancement of technology and the improvement of equipment, as well as the growing demand for highend active ultrafine heavy calcium powder in the plastics, rubber and other industries Equipment and solutions for calcium carbonate powder surface

.jpg)

Dry surface modification of heavy calcium carbonate powder

Content from this work may be used under the terms of the CreativeCommonsAttribution 30 licence Any further distribution of this work must maintain attribution to the author(s) and the title of Production equipment and tooling selection Peter Scallan, in Process Planning, 2003 Powder processing The steps involved in powder processing were previously described in Section 4103 and these are powder blending, compacting, sintering and finally secondary processing In terms of equipment, the compacting requires a press that can deliver forces in the region of 10–17 Powder Processing an overview ScienceDirect TopicsCalcium carbonate powder processing equipmentCalcium carbonate powder processing equipment YouTube