Steel slag crushing equipment

Slag crushing Metso

Active Setting Control technology enables processing slag that contains uncrushable objects Increased profitability Recycled and processed slag can be sold and used for example as aggregates Safety Fully automated operation 2023年12月27日 The crushing processing and reuse of steel slag are profitable and have a protective effect on the environment, so the recycling and utilization of steel slag are strongly supported and have a promising futureSteel Slag Processing Plant Equipment SelectionShenyang North Heavy Metallurgical Engineering Technology Co, Ltd, its leading products include EPC steel slag treatment projects, cement and steel slag powder equipment, special rod mills for steel slag crushing and purification, Crushing Equipment,Grinding Equipment,Conveyor Our slag crushers are designed to crush and separate the slag from the unwanted materials, ensuring efficient and reliable performance, Our slag crushers are built with advanced Slag Crusher Kemai

.jpg)

Steel slag processing equipment recommended Kefid Shanghai

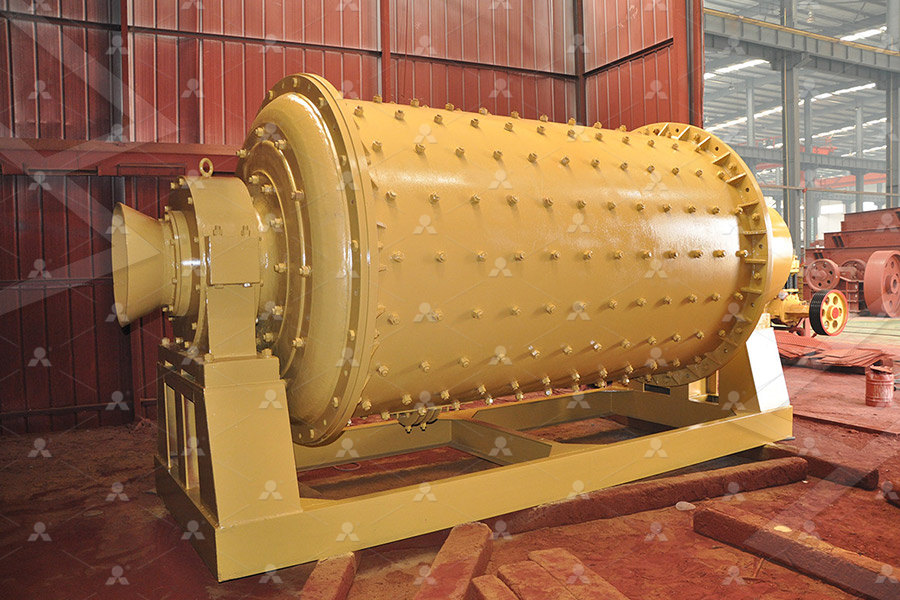

Steel slag processing equipment recommended According to the characteristics of steel slag and the requirements of finished products, it can be processed by crushing and screening The magnetic steel slag washing, ball mill, magnetic separation, purification process, comprehensive recycling technology of slag and complete set of equipment can not only Steel slag recycling crushing and grinding production lineDiscover the latest mineral processing technology and steel slag production line at Senya Crushers Get detailed app and tech specs now!Efficient Steel Slag Processing Senya Crushers SolutionSteel slag below 5mm enters the grinding system and is ground by the GRMSS series steel slag vertical roller mill The produced steel slag powder has a specific surface area of 400500 Steel Slag Grinding Plant CHAENG

Application of Steel Slag as an Aggregate in Concrete Production:

Typical morphology of steel slag [](a) BOF steel slag(b) EAF steel slag(c) LF steel slagBOF steel slag is the solid waste produced in the converter steelmaking process, and its discharge is approximately 100–150 kg per ton of BOF steel [20,21,22,23]BOF steel slag commonly has a grayishwhite appearance and a vesicular nature, with many noninterconnected pores []2023年8月22日 Steel slag (SS) is a byproduct of steelmaking process, accounting for 15–20 wt% of crude steel [1, 2]Statistics show that the global crude steel production in 2021 was about 19512 Mt, of which China’s production was 10328 Mt []However, the comprehensive utilization rate of SS in China is less than 30%, which is far from the utilization level of developed The Effect of Removing HardtoGrind Minerals from Steel Slag 2019年5月23日 At present, the main grinding equipment of steel slag at home and abroad include ball mill the highpressure rolling mill, vertical mill, tube mill with internal powder selecting, rolling mill, Zhang D (2012) The technology of steel slag hot pressing, crushing, magnetic separation and reuse China steel 2:28–30 Google ScholarComprehensive Utilization Technology of Steel SlagThe tailings with iron content of less than 2% can be used to produce steel slag powder, reducing metal resource waste 4Grinding System Auxiliary equipment: GRMSS series steel slag vertical mill After crushing and magnetic separation, the steel slag ≤5mm and the metal iron content ≤2% enters the GRMSS series steel slag vertical mill Steel Slag Grinding Plant CHAENG

)D`ERF`389RMI4.jpg)

The Research Progress of Steel Slag Utilization and Stabilization

2024年10月10日 Steel slag is a byproduct of steelmaking process The producing of steel slag in China is proximately 100 million tons, but the utilization ratio of comprehensive resources is the lower This paper described the production and composition characteristics of steel slag, reviewed current situation and progress of resource utilization and stabilization of steel slag Steel slag 2023年12月20日 Steel slag is a solid byproduct of the steelmaking process, widely generated in the metallurgical industry Due to its alkaline nature and excellent adhesive properties with asphalt, it represents a potential road construction material with outstanding road performance, making it wellsuited for utilization in highway construction This paper conducts a systematic Analyzing the Mechanical and Durability Characteristics of Steel Slag Focusing on the R D and manufacturing of crushing and screening equipment, we provide complete set of crushing and grinding equipment solutions The project is 10000 t/y steel slag treatment and recycling production line Read More + 2000t/h EPC Project for Limestone Crushing Production in Anhui, ChinaLuoyang Dahua – Jaw Crushers, Cone Crushers, Mobile Crushing Steel slag processing equipment recommended According to the characteristics of steel slag and the requirements of finished products, it can be processed by crushing and screening equipment, iron removal equipment and milling equipment, and processed to different particle sizes according to the requirements of useSteel slag processing equipment recommended Kefid

Recent research progress on recycling metallurgical waste slag

2024年11月1日 Based on the above analysis, the following improvement suggestions were put forward: (1) In terms of electrode research, the use of inexpensive graphite electrodes had a good effect on steel slag treatment, and hightemperature ceramic electrodes and iron erosionresistant electrodes (ZrB 2) were gradually being exploited; (2) In terms of equipment, the existing 2024年8月23日 During the implementation of the project, Liyang Sinoma was responsible for providing the most cuttingedge steel slag treatment technology and equipment, and optimizing the comprehensive utilization process of steel slag The project team effectively improved the treatment efficiency of steel slag and reduced production costs160Ton Annual Steel Slag Comprehensive Utilization ProjectPrimitive Process’s standard equipment design for steel slag processing Whether you have limited floor space or ceiling height restrictions, specific material of construction requests, electrical requirements, or more; we will work with you to ensure a successful project Primitive Process specializes in working from a conceptual idea through the detailed design to Equipment Design For Steel Slag Processing2023年11月20日 Mineral process wastes, such as metallurgical slags nowadays, are of significant metals and materials resources in the circular economy The usability of ironmaking slag is well established; however, steel A Review on Environmental Concerns and

.jpg)

Research on the Properties of Steel Slag with Different

2024年3月28日 Steel slag contains about 10% of the metal iron, which, after crushing, screening, magnetic separation, and other processing, can be sorted into different particle sizes, there are requirements for the block size of the Specialized crushing, screening and separating equipment for the slag recycling industry Mobile and stationary solutions Unique Hydraulic Release Mechanism HRMSlag Crushing THE STANDARD Slag Recycling2024年11月12日 The physical and mechanical properties of steel slag are comparable to those of natural aggregates Reusing steel slag on a large scale as a substitute for natural aggregates can greatly reduce the need for natural resources and lower environmental harm, resulting in notable economic, environmental, and social benefits However, the limited volume stability of Application of Steel Slag in Road SemiRigid Subgrade and2023年8月25日 Steel slag is a solid waste produced in crude steel smelting, and a typical management option is stockpiling in slag disposal yards Over the years, the massive production of steel slags and the (PDF) Application of Steel Slag as an Aggregate in ResearchGate

.jpg)

Slag Recycling and Metal Recovery HMA Group

Our plants utilize stateoftheart magnetic separation equipment to maximize the recovery of metallics from the raw slagThe processing plants include the latest technology in crushing and screening plant design to cleanly separate the slag and metal into different sized fractions depending on customer specifications and market demand2021年10月1日 Steel slag is a solid waste derived from the steelmaking process, which accounts for approximately 15% of the total crude steel output (Furlani et al, 2010; Pang et al, 2016)By 2016, approximately 832 million tons of steel were produced in China with an annual output of more than 100 million tons (Hasanbeigi et al, 2016), which exceeded half of the total Use of steel slag as sustainable construction materials: A review 2024年10月15日 Steel slag is a byproduct generated during the steelmaking process, constituting 15 to 20 % of crude steel production [3]Steel slag possesses significant sensible heat, carbon sequestration potential, and resource utilization capacity, all of which are crucial for reducing CO 2 emissions in the steel industry Given its high heat content in the molten state, The positive contributions of steel slag in reducing carbon dioxide 2023年3月1日 The experimental equipment and steps are shown in Fig 1 100 g of slag powder was weighed and placed in a magnesium oxide crucible the liquid steel and slagmaking material form steel slag After crushing the steel slag, the easily grounded CaO and SiO 2 are mostly concentrated on the fine particle size of slag powderEfficient separation of iron elements from steel slag based on

Steel Plant Slag Crushing Process (Animation)

Raw materials are evenly and gradually conveyed into jaw stone crushing equipment for primary crushing via the hopper of vibrating feeder The crushed sto2018年1月20日 The poor specification stability of steel slag aggregate is mainly caused by the process of a single crushing and screening equipment The steel slags are a byproduct in the process of steel making and have complex and changeable composition, which result that the steel slags in different batches and different parts have different damage resistance capacityProcess Improvement on the Gradation Uniformity of Steel Slag ECOFERTEC is designing customized steel slag processing and metal recovery plants for each projectspecific purposes The newest technology ECOFERTEC slag processing plant enables the most costeffective way to remove steel from slag with 300 ton/h capacity One plant can handle 1,5 M ton of slag per year in two shiftsSteel Slag Processing — EcofertecSteel slag crushing production line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentEfficient Steel Slag Processing Senya Crushers Solution

.jpg)

Review Accelerated carbonation of steel slag: A review of

2024年1月12日 The concept of mineral carbonation for reducing CO 2 emissions was first proposed by Seifritz in 1990 [12]Mineral carbonation is considered as a promising largescale CO 2 storage application technology [13]As a raw material for mineral carbonation, steel slag has advantages such as proximity to CO 2 emission sources, significant cost savings in 2014年2月19日 Slags are byproducts of the metallurgical industry It is of importance to recycle materials and recover heat from metallurgical slags to reduce the energy consumption and environmental impact of steel industry China is the largest iron and steelmaking slag producer in the world, and intensive efforts have been made during last decades for slag valorisation, Current Development of Slag Valorisation in Chinahot smothering technology of steel slag rolls belongs to the fourth generation of hot and stuy technology The process ow is displayed in Fig 1, that is, the steel slag enters the roller crusher through the slag tank The steel slag enters the roller Energy and exergy analysis of waste heat recovery from Springer2024年8月21日 How do you crush steel slag? Slag Crushing Equipment Jaw crusher, cone crusher, vibrating feeder, vibrating screen, magnetic separator, belt conveyor Slag crushing process Raw materials (less than 350mm) enter the vibrating feeder, and the grate of the vibrating feeder is set to 100mmSlag crushing plant

steel crusher machinery KOOKS

Nov 21, 2018 Steel Slag Crushing Machinery Suppliers India Raipur Used Crushers Machinery and Equipment We are one of the largest suppliers of used crushers and crushing equipment for mining and minerals applications, as well as chemical processing facilities We deal in all types of crushers including cone, impact, gyratory, China Steel Slag Crusher wholesale High Reputation Steel Slag Crushing Cone Crusher with Large Capacity US$ 4000060000 / Piece 1 Piece (MOQ) ATAIRAC ENGINEERED PRODUCTS INC(CHINA) ATAIRAC ENGINEERED PRODUCTS INC(CHINA) Shandong Jiuchang Industrial Equipment Group Co, LtdSteel Slag Crusher MadeinChina2024年4月28日 Steel slag is a byproduct of the steel industry and usually contains a high amount of fCaO and fMgO, which will result in serious soundness problems once used as a binding material and/or aggregates To A Review on the Carbonation of Steel Slag: Properties, 2024年10月12日 1 Equipment selection: When choosing an iron ore and slag crushing production line, factors such as the nature of the raw materials, production requirements, and investment budget should be considered At the same time, equipment manufacturers with good reputation and aftersales service should also be selectedIron Ore Steel Slag Crushing Line Baichy Heavy Industry

Steel Slag an overview ScienceDirect Topics

Carbon dioxide sequestration using steel slag—modeling and experimental investigation Smitha Gopinath, Anurag Mehra, in Carbon Dioxide Sequestration in Cementitious Construction Materials, 2018 41 Introduction Steel slag is an industrial waste that is generated during the production of steel In the production of steel, oxides of metal impurities in the iron combine To develop the slag crushing plant is the big achievement for Bhupindra Machine PvtLtd We have developed the 100 TPH fully automized slag crushing plant on key basis Today BMPL have achieved the excellence and created a distinct identity for themselves in the business areaSlag Crusher Plant Machine Manufacturer Bhupindra Machines 2024年7月17日 Crushing is a multistage process that includes primary crushing, secondary crushing, and tertiary crushing Different types of crushing equipment are used at each stage to meet various crushing requirements Primary crushing breaks down large raw materials into mediumsized pieces for easier handling in subsequent processesTypes of Crushers: Choosing the Right One for Each StageSlag Crushing –Slags Be Used、Recycle Metal、Reduce Metal Loss Our steel slag crushing solution to find the most suitable crushing equipment, matching the upstream and downstream process requirementsOur crushing plant adopts modular design technology with clear functional objectives: crushing the tailings to meet the size standards of sand or stone used in Slag Crushing Reduce Metal Loss Slag Comprehensive Utilization

Steel Slag Processing Gongyi Jingying Machinery

Steel Slag Processing line adopts jaw crusher for primary crushing, and uses hydraulic cone crusher for secondary and tertiary crushing, offering high crushing efficiency, low wear, energy saving and environmental protection, it has the features of high automation, low operation cost and reasonable allocation of equipmentTo develop the slag crushing plant is the big achievement for Bhupindra Machine PvtLtd We have developed the 100 TPH fully automized slag crushing plant on key basis Today BMPL have achieved the excellence and created a distinct identity for themselves in the business areaAbout us – Slag Crusher Plant Machine ManufacturerCHAENG (Great Wall Machinery) can undertake 20 tons 15 million tons of Blast furnace slag/Steel slag/Nickel slag/Manganese slag powder production EPC projects Up to now, CHAENG has constructed more than 100 slag grinding production lines at home and abroadSlag CHAENG