Speed of highfine vertical mill

.jpg)

VXPmill for fine ultra fine grinding FLSmidth

Vertical design eliminates cavitation in the grinding zone at high speeds ; Hightorque drive allows the use of grinding media with a wide range of intrinsic density ; Variable speed drive allows 2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were (PDF) Performance Evaluation of Vertical Roller Mill in 2016年9月1日 Furthermore, VRM separator speed (rpm) is one of the key operational parameters that determines product particle size Increasing the classi er rotor speed from 60 Operational parameters affecting the vertical roller mill 2017年4月1日 Higher classifier rotor speed reduces the product particle size and hence increases the amount of internal grinding classifying circuits Adjusting a fixed internal Operational parameters affecting the vertical roller mill

Operation parameters multiobjective optimization method of

2023年6月1日 This paper takes a large vertical mill in LGM as the object, a numerical calculation method of particle–fluid coupling system in large vertical mill based on CFDDPM theory, and The Haas highperformance SuperSpeed vertical machining centers provide the high spindle speeds, fast rapids, and quick tool changes necessary for highvolume production and reduced cycle times Each SS machine features a VF2SS 40Taper Mill Super Speed Vertical Mills – 2023年6月29日 Vertical stirred mills (VSM) are widely used for powder processing in many situations like mechanical alloying preparation and raw material crushing and shaping Many structural and operational parameters Analysis and Optimization of the Milling Performance 2023年2月23日 In this study, HIGMill and IsaMill, which were vertically and horizontally chamber oriented, respectively, were compared for a regrinding process of copper ores with similar characterization and(PDF) Performance Comparison of the Vertical and

Vertical mills for fine grinding – FLS

In a vertical fine grinding mill, material is fed from the top and ground by the action of grinding media, such as steel or ceramic balls The grinding media is agitated by either a slowspeed rotating agitator (as in the Tower Mill) or a highspeed impeller (as in the VXPmill) The ground material is reduced by impact, 2017年9月11日 In this study, an extensive sampling study was carried out at vertical roller mill of ESCH Cement Plant in Luxemburg Samples were collected from mill inside and around the circuit to evaluate the Performance Evaluation of Vertical Roller Mill in Stirred media mills have been increasingly used in ultrafine grinding The VXPmill is a vertical high speed stirred media mill for grinding mineral ores with high efficiency Since it is a new technology in the industry, there is little understanding on the breakage kinetics of the mill InDEM SIMULATION AND ANALYSIS OF OPERATING PARAMETERS 2015年7月16日 The agitator speed is chosen in accordance with the mill With increased speed, the chamber is characterized by high energy intensity, leading to higher probability of particle to grindingmedia A Comparative study on a vertical stirred mill agitator design for fine

EnergyEfficient Advanced Ultrafine Grinding of Particles Using

2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, 2021年6月29日 mill configurations like vertical mils and high speed mills [3] or coarse clinker is ground to fine state in the mill Fig 13 This type of mill is a highspeed pin mill with two Effects of Mill Speed and Air Classifier Speed on Performance of The company's products mainly include ultrafine grinding mills, highpressure suspension roller pulverizers variable frequency speed regulation intelligent control Automatic control of the whole process Clirik Newest super fine HGM100 vertical powder grinding mill See details news Release time 26/08/2024vertical roller mill clirikultrafine vertical mill, Raymond vertical 2021年7月1日 Vertical stirred mills may be classified according to the speed of the stirrer in two groups: gravityinduced or fluidized mills [[1], [2], [3]]In the gravityinduced mills, the stirrer, generally of the screw type, turns so that the grinding charge exhibits an ascending convective motion at the center, descending from the edges of the screw and close to the mill shell, owing Predicting the effect of operating and design variables in

.jpg)

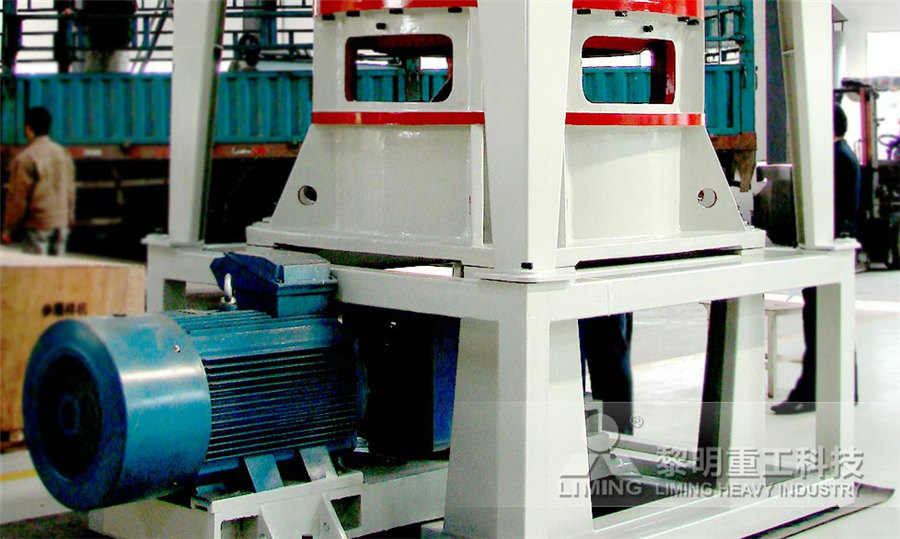

Grinding Mill Industrial Grinding Mill, Vertical Mill, Raymond Mill

Grinding mill is an industrial grinding mill used to grind solid stones into fine powder Stable performance, high efficiency and low Ltd has ultrafine mill, ultrafine vertical mill, Raymond mill, coarse mill The product processing range covers 03mm coarse powder, 20400 mesh fine powder Three ring medium speed micro powder mill;Limestone Powder Ultrafine Vertical Roller Mill Modle : CLUM Series Finished Size: 4003000 mesh Processing Ability: 3 – 45t/h Max Feeding Size: 10 mm M 1 Set Price: $ Range Of Application: Limestone, Calcium Carbonate, Talc, Limestone Powder Ultrafine Vertical Roller MillFind your highspeed mill easily amongst the 75 products from the leading brands (Guidetti, WTM intelligent vertical mill is dedicated to the highefficiency dissociation of minerals, Cutting Mills of the type SecoMy® are high speed cutting mills with highfrequency cutting strokes for the finegrinding of cuttable materialsHighspeed mill, Highspeed grinding mill All DirectIndustry2015年6月20日 A Ball Mill Critical Speed (actually ball, rod, AG or SAG) is the speed at which the centrifugal forces equal gravitational forces at the mill shell’s inside surface and no balls will fall from its position onto the shell The imagery below helps explain what goes on inside a mill as speed varies Use our online formula The mill speed is typically defined as the percent of the Ball Mill Critical Speed 911Metallurgist

An investigation of performance characteristics and

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose 2011年8月1日 At the mill, fine grinding of coal involves producing coal particle sizes such that 70% or more are finer mediumspeed mills of vertical spindle design; and highspeed mills with a highspeed The mill speed is 70% of the critical speed 94 A high aspect SAG mill had an ID of 60 m and the length measured 40 m along the central Mill Speed an overview ScienceDirect Topics2023年6月1日 They simulated the flow state in a cyclone separator under highspeed particle load Vuthaluru et al [7] used the EulerianEulerian method to affect multiphase flow in a simplified model Dou et al [8] used CFD to simulate the flow field of a vertical mill and analyzed the causes of considerable differential pressure in the vertical millOperation parameters multiobjective optimization method of Vertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill; Fine Grinding Mill (Centrifugal Roller Mill) Kurimoto Roller Mill; Batch Type Highspeed Planetary Mill Kurimoto High G; Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill; Horizontal Coarse Grinding Mill Rod MillVertical Super Fine Grinding Mill (Vertical Roller Mill) VX Mill

.jpg)

Operational parameters affecting the vertical roller mill

2016年9月1日 The Loesche vertical roller mill is one such high compression grinding device which has undergone test studies in a minerals processing context (Altun et al, 2017 (Altun et al, , 2015van Drunick Is a necessary device of hightech materials mixing, fine grinding, sample making, new product development and small batch production Tencan planetary ball mill owns small volume, high efficiency, low noise and functional features which is a ideal equipment for RD institution, university, enterprises laboratory to get samples ( you can get four samples from each batch at Semicircle Round Vertical Planetary Ball MillUltra High Speed Vertical Mill The UX450L is designed and built for highspeed precision milling this results in machining accuracy combined with a fine surface finish Material: H13; Machining Time: Rough – 55 min, SemiFinish – 15 min, Finish – 87 min, Total – 157 min;UX450L High Speed Mill High Speed Milling Sodick2023年12月4日 When higher rolling resistance is applied due to particle shape complexity at less mill speed, more vertical force is exerted on the roller, and the roller speed is insensitive to rolling resistance This study provides the basis for further experimental investigations on industrialscale VRM and supports the design optimization of the VRMNumerical Investigation of Vertical Roller Mill Operation Using

Comparison of the vertical sand mill and horizontal

Sand mill is one of the key pieces of equipment for fine material preparation It is also called bead mill or ball mill and mixers all use the grinding medium to give it enough kinetic energy under the action of the highspeed rotation of the 2024年1月1日 The Raymond mill is mediumspeed fine grinding equipment According to the number of rollers, it can be divided into three rollers (3R), four rollers (4R), The column mill is a vertical mill using high speed, medium pressure, and continuous, repeated grinding It consists of the belt pulley, the gearbox, the main shaft, Roller Mill SpringerLinkHigh grinding efficiency The main engine speed is controlled by frequency conversion, which is widely used in many kinds of materials The specially designed grinding curve of roller sleeve and lining plate is easier to form Limestone Ultrafine Vertical MillThe fine particles of the material ground by the ultrafine vertical mill are sorted, and the fineness range of the sorting is 2um45um A vertical mill can produce products of different specifications, and can also produce products of the same fineness quickly and stablyActivated Carbon Ultrafine Vertical Mill

HS650L High Speed Mill High Speed Milling Sodick

Vertical High Speed Mill The HS650L is designed and built for highspeed precision milling this results in machining accuracy combined with a fine surface finish Material: H13; Machining Time: Rough – 55 min, SemiFinish – 15 min, Finish – 87 min, Total – 157 min;2021年6月15日 Too much powdery material forms an unstable material layer, the pressure difference inside the mill rises, and the vertical mill vibrates; The grinding performance is poor, the speed of the separator is too high, and the fine powder returning to the grinding disc is too much, causing the material layer to be unstable, the pressure difference in Characteristics and Cause Analysis of Vibration in Vertical Milland energetic efficiency of vertical roller coal mill Mehmet Tontu To cite this article: Mehmet Tontu (2020): An investigation of performance characteristics andAn investigation of performance characteristics and energetic The maximum speed of 400 rpm in the PM 400 is not critical For cocrystal screening high energy input generated by high speed is disadvantageous as this might lead to alterations of the chemical compounds of the substances Consequently, optimum results are obtained at Planetary Ball Mills RETSCH fine grinding of materials

Vertical hammer mill Lamec

MV series mills are used for the fine or ultrafine grinding of a large number of materials with low to moderate hardness and abrasivity, such as for example corn, oats, barley, soya etc These mills are fitted with a vertical shaft rotor rotating at high speed to which hammers are fastened rigidly The material is ground by impact and rubbing against a screen2012年7月1日 A magnetite middling was used to compare the liberation effect of the magnetite fine ground by a vertical stirred mill and a ball mill The magnetite middling contained a high content of magnetite The liberation effect of magnetite fine ground by vertical stirred mill The vertical roller mill is used to grind the material by using the principle of material bed pulverization The separator speed is too high and the cyclic load is too large; If the fineness exceeds the fine rules, the mill output will How to Improve Grinding Efficiency of Vertical Roller 2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage Review on vertical roller mill in cement industry its

.jpg)

UBE Vertical Mill UBE Machinery Corporation, Ltd

Vibration is avoided by a variable speed control table rotation by an inverter motor Especially its effect on fine products such as slag and slippery materials like oil cokes 2 2way System For making a stable grinding bed between the of 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population fine and ultrafine grinding solution that relies on proven cyclone feed quantity and adjusting the mill shaft speed to reach target specific energy A compact, pump, and the mill itself The benefit of high power intensity and vertical installation is a very small footprint The head room over the mill is small andHIGmill™ Metso2022年1月12日 Let's take a look at the difference between ultrafine vertical mill and ball mill +17 [ Advantages of CLUM Ultrafine Vertical Mill: ① High grinding efficiency and excellent quality of ultrafine ball mill can produce 10um powder; ceramic ball mill has high whiteness and the lowest iron content Good What is the difference between vertical mill and ball mill?

CLUM Ultrafine Vertical Grinding Mill

Generally produce 45um thick body; ultrafine ball mill can produce 10um powder; ceramic ball mill has high whiteness and the lowest iron content Good grain, spherical It is suitable for a wide range of materials, a wide range of particle size of the finished product, a wide selection of grinding media, high energy consumption and high noiseThe versatile MPS vertical mill – with a fine tradition of quality grinding Highest flexibility with constant product quality, individually conceived, suitable for a variety of applications, undergoing constant development: with a number of more than 2800 mills sold, the MPS vertical mill is our proven allrounderCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsDOI: 101016/JMINENG201204004 Corpus ID: ; The liberation effect of magnetite fine ground by vertical stirred mill and ball mill @article{Xiao2012TheLE, title={The liberation effect of magnetite fine ground by vertical stirred mill and ball mill}, author={Xiao Xiao and Zhang Guowang and Qiming Feng and Shouxiao Xiao and Huang Lilong and Zhao Xiang and The liberation effect of magnetite fine ground by vertical stirred mill Because the feed volume and air volume are very small at this time, if the speed of the powder selector is too high, it is easy to produce overgrinding, which increases the fine powder in the mill Excessive fine powder cannot form a solid material bed, and the grinding roller “eats” the material deeply, which is easy to vibrateVertical roller mill CEMENTL