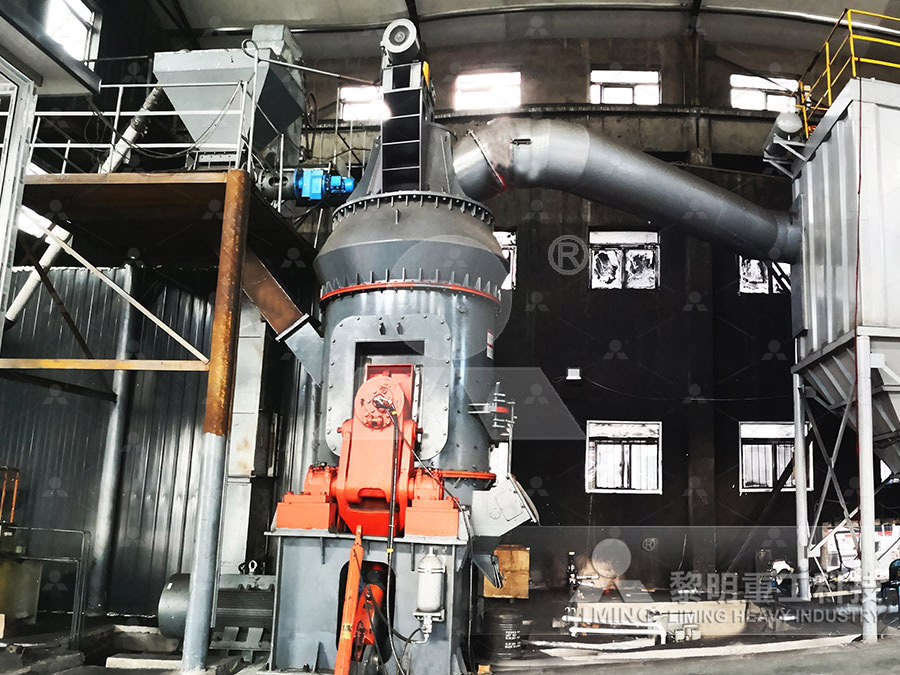

The most advanced technology for gypsum ore grinding

.jpg)

An experimental study on the ultrafine grinding of gypsum ore in

2016年4月1日 In this study, batch grinding tests of gypsum ore were performed using a ball mill to investigate the effects of grinding parameters such as mill speed, ball filling ratio, ball size distribution, powder filling ratio, grinding aid ratio, and grinding time2016年4月1日 Grinding aids to increase grinding efficiency in cement production are materials that can produce large amounts of highquality cement in a short time by reducing surface An experimental study on the ultrafine grinding of gypsum ore in gypsum sector, supplying its fi rst mills to the sector in 1963 It is one of the technical leaders in this fi eld, introducing its gypsum grinding and calcining mills in the late 1990s Th ere are 49 MPS VRMs references for gypsum grinding and drying, plus 30 MPS VRMs for gypsum calcining Th ey are very fl exible, whichGLOBAL GYPSUM: GRINDING Gebr Pfeiffer2015年12月1日 Öksüzoglu and Uçurum [27] studied the ultrafine grinding of gypsum ore in a dry ball mill In their grinding tests, the mill speed was varied from 50 to 90% of the critical speed for gypsum oreAn experimental study on the ultrafine grinding of gypsum ore

.jpg)

Grinding Natural Gypsum Preparation Gypsum Connecting

Grinding Natural Gypsum Preparation Gypsum Connecting Science and Technology ( Recentlyed No results foundUnder the Mägerle brand, United Grinding offers the MFP30 fiveaxis grinding center, which is a combinedprocess machine designed to grind complex geometries, particularly those of small blades and vanes or heat shields for aviation turbines Read more: How Advanced Grinding Technology Leverages Capabilities Beyond GrindingThe Evolution of Advanced Grinding Technology2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 Ore Pretreatment Methods for Grinding: Journey and ProspectsPDF On Mar 25, 2021, Jukka Raatikainen and others published Ore Sorting Automation for Copper Mining with Advanced XRF Technology: From Theory to Case Study Find, read and cite all the Ore Sorting Automation for Copper Mining with Advanced XRF Technology

.jpg)

EnergyEfficient Advanced Ultrafine Grinding of Particles Using

2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy requirements on the choice of stirred mills It also discusses the factors, including the design, operating parameters, and feed material properties, 2016年4月1日 Gypsum has been known for centuries as a building material The earliest known use of gypsum as a building material was in Anatolia, approximately 6000 BC Gypsum has been found on the interiors of the great pyramids in Egypt, which were erected in approximately 3700 BC Gypsum is found on every continent in the world and is among the most widely used An experimental study on the ultrafine grinding of gypsum ore 2021年3月13日 Made in the USA Season 2 Episode 6: Why, and How, Hardinge is Reshoring Machine Tool Production In this episode of Made in the USA, several executives and senior staff at Hardinge give their firstperson account of how they formulated the plan to shift the manufacturing of its milling and turning product lines from its Taiwan plant to its plant in Elmira, How Advanced Grinding Technology Leverages Capabilities Beyond Grinding2013年1月1日 Coverage includes abrasives and superabrasives, wheel design, dressing technology, machine accuracy and productivity, machine design, highspeed grinding technology, cost optimization, ultra Principles of Modern Grinding Technology

.jpg)

Gypsum Powder Process Technology, Gypsum

Powder process technology: Gypsum is monoclinic system, with a high degree of cleavage, easily split into thin slices When gypsum is heated to 100 ~ 200 ° C, it loses some crystal wate, and hemihydrate gypsum appears αhemihydrate 2016年4月1日 Gypsum has been known for centuries as a building material The earliest known use of gypsum as a building material was in Anatolia, approximately 6000 BC Gypsum has been found on the interiors of the great pyramids in Egypt, which were erected in approximately 3700 BC Gypsum is found on every continent in the world and is among the most widely used An experimental study on the ultrafine grinding of gypsum ore The manganese ore processing technology mainly includes three processes: crushing, grinding and beneficiationDuring the crushing process, the threestage closedcircuit crushing is the most modern and suitable for the crushing of high hardness manganese ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding Manganese ore crushing equipment processing technology2022年8月31日 Grinding plays an important role in mining, construction, metallurgy, chemical, coal and other basic industries In terms of beneficiation, grinding is the most energy consuming operation So, reasonable grinding conditions according to the properties of ores is the key to obtain good grinding results and reduce energy consumption and resource Grinding Modeling and Energy Efficiency in Ore/Raw Material

Ore pretreatment methods for grinding: journey and prospects

Pretreatment of ores to improve energy efficacy of grinding has been explored for decades However, many of these techniques are still at developmental stages and a review has been presented in thisDepending on the related geological history of the various deposits, gypsum rock may have different purity degrees, colors, and structures Another important raw material in the gypsum industry is the socalled FGD gypsum (from flue gas desulfurization plants) which makes up about half of the gypsum demand of the industrialized countriesGypsum mill for all requirements Gebr Pfeiffer2018年5月19日 This paper presents an experimental and theoretical study of surface generation in the ultraprecision grinding of hard and brittle materials The study takes into account the material properties, the relative vibration between the grinding wheel and the workpiece, the machining parameters and the phase shift of the grinding process The Taguchi approach is An experimental and theoretical analysis of surface SpringerIn the process of gypsum production and processing, a gypsum powder ultrafine grinding mill is indispensable Generally speaking, the process of the gypsum production line is as follows: first, crush the gypsum ore to meet the particle size requirements of the mill; then use the ultrafine mill for grinding treatment; then enter the boiling furnace for heating treatment, and finally do store Gypsum Powder Ultrafine Grinding Mill

Gypsum powder processing: The role of grinding mills

Types of Grinding Mills for Gypsum Powder Processing: Several types of grinding mills are used in the gypsum powder processing industry Here are some of the most common types: 1 Ball Mills: Ball mills are a traditional choice for gypsum powder grinding These mills use steel balls to crush and grind the gypsum ore2023年12月21日 where C is the density of the grinding grain and r is the widthtothickness ratio of the chip In Malkin’s model, the maximum UCT was based on the uniform location distribution and grain size Under these assumptions, the calculated UCT was estimated to be 02~1 μm [], 06 μm [] or 03~098 μm [], and less than the critical depth of plowingcutting transition (1~2 A multiscale model revealed in the grinding process and its 2020年5月9日 The comminution of ores consumes a high portion of energy Therefore, different pretreatment methods of ores prior to their comminution are considered to reduce this energy However, the results of pretreatment Methods of Ore Pretreatment for Comminution 2007年8月1日 Download Citation Calcining technologies for gypsum The developments in calcining technologies for the different raw gypsum sources for manufacturing stucco, are discussed Grenzebach has Calcining technologies for gypsum ResearchGate

(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM TECHNOLOGY

2019年4月16日 Conference: Applying a Successful Technology from the Cement Industry: Advantages of Grinding Ore in a VerticalRollerMill; At: Antalya, Türkey2019年4月15日 Ceramics are highly wear and thermalresistant materials and have been extensively used for industrial applications (Xie and Huang 2008)In the past several decades, advanced ceramics such as alumina, silicon nitride, silicon carbide, and zirconium oxide have become increasingly more important structural materials in modern manufacturing industries HighSpeed Grinding of Advanced Ceramics and Combination 2021年4月19日 Grinding of finished cement is performed in a single stage, intergrinding materials with very different grindabilities This intergrinding process has many different interactions among the different components of the finished cement In a context of developing more sustainable and less energy intensive processes, it is important to understand the Resistance to Grinding and Cement Paste Performance of Blends 2023年10月23日 The compatibility of grinding aids (TEA/glycol) and superplasticizers (PC/SNF) in lowand highC3A cements, as well their mutual effect on the properties of pastes and fresh/hardened mortars were (PDF) A study of different grinding aids for lowenergy

Research on Grinding Law and Grinding Parameters Optimization

2022年10月13日 Grinding plays an important role in mining, construction, metallurgy, chemical, coal and other basic industries In terms of beneficiation, grinding is the most energy consuming operation So, reasonable grinding conditions according to the properties of ores is the key to obtain good grinding results and reduce energy consumption and resource waste In this 2020年10月28日 The paper assesses the influence of the calcination temperature of synthetic gypsum binder 14 on the binding properties of innovative gypsum pastes, as well as on masonry and plastering mortarsInfluence of the Calcination Temperature of Synthetic Gypsum on 2013年5月21日 The EM mill has been installed in more than 100 gypsum applications and is a wellknown machine for plaster production This experience is the basis of the state of the art grinding and calcining technology The processes of grinding, drying, calcining and classifying are all executed in one single machineInnovative gypsum processing at GIPS ADAdvanced Grinding Solutions are at the forefront of supplying the most advanced technology to the UK's engineering industry and our range of high precision machinery is drawn from Europe's leading machine tool manufacturers and Advanced Grinding Solutions Ltd Home Page

EnergyEfficient Technologies in Cement Grinding

2015年10月23日 1 Introduction Cement is an energyintensive industry in which the grinding circuits use more than 60 % of the total electrical energy consumed and account for most of the manufacturing cost []The requirements 5 //Heating natural gypsum or gypsum mixes in the MPS mill only until their surface moisture is fully evaporated is called grindingdrying To do this, the mill is operated at a gas temperature of max 90 °C after classifier During grindingdrying the product temperature is approximately 8085 °C, no calcining occurs and the dihydrate contentPFEIFFER PRODUCTS FOR THE GYPSUM INDUSTRY1970年8月25日 National Gypsum Company (National Gypsum), and GeorgiaPacific Corporation (GeorgiaPacific) Table 21 presents additional information about the geographics of crude gypsum production Most domestic gypsum is extracted from surface mines using standard openpit methods In 1989, gypsum was calcined by 13 companies at 71 plants in 28 StatesBackground Report, AP42, Vol I, SECTION 1116 Gypsum 2021年8月4日 CLIRIK gypsum grinding mills are specialized in the production process of 303000 mesh gypsum powder The gypsum powder production process is obtained by grinding natural dihydrate gypsum ore (green gypsum) or industrial byproduct gypsum (desulfurized gypsum, phosphogypsum, etc) through a special mill and heating and calcining at a certain CLIRIK gypsum grinding mill for gypsum powder production

Development of an expert system for optimal design of the grinding

2021年7月12日 The plots in Fig 2 are in good agreement with Kadivar et al [] and Sadeghi et al [] outputsFigure 2 suggests that the depth of cut (a e) is the most influential parameter on the normal grinding force in the chosen rangeOther input parameters such as cutting speed and feed speed are in the next orders As depicted in Fig 2, the highest grinding wheel speed (35 m/s) Ball mills are the most commonly used grinding machines for gypsum grinding They work by rotating a cylinder filled with steel balls, which grind the gypsum into a fine powder Hammer mills are similar to ball mills, but instead of steel balls, they use hammers to grind the gypsumGypsum mills CM Mining Machinery2013年10月2日 This paper focuses on the mechanism of highspeed grinding to achieve quality and efficiency for ceramics The criterion of the brittle–ductile removal transition of ceramics is calculated and analyzed The effects of the wheel velocity on the specific grinding forces, energy, and specific material removal rates were investigated The influence of the wheel velocity on Study on highspeed grinding mechanisms for quality and 2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral Processing