High manganese steel wearresistant grinding roller

Preparation and properties of ZTA/alloyed high manganese steel

2024年11月1日 In this paper, a high manganese alloy material with good wear resistance under low stress conditions was prepared by multialloying of 20Mn12C high manganese steel with 2024年7月1日 Among the rockbreaking cutter steels, AISI H13 steel and wearresistant high manganese steel have become the best choices From the characteristics and failure modes Advance on rockbreaking cutter steels: A review of characteristics Grinding rollers produced by SYMMEN METAL Casting have features of high hardness, good anticracking and strong wearresistant capability We promise that, all the grinding rollers shall be NDT inspected on the stress surface Grinding Roller Manufacturer From China Symmen 2024年9月21日 Highmanganese wearresistant steel (HMWS) is the ideal wearresistant material for the machine parts subjected to the force of friction and widely applied in the Elemental segregation, microstructure, and mechanical properties

)D`ERF`389RMI4.jpg)

Development of wearresistant parts from highmanganese

2024年6月17日 These methods are widely used in obtaining highquality steel castings The simplest method of processing steel outside the oven is modification Modified carbon steel is 2021年5月6日 This paper focuses on selected results with respect to the mechanical properties of highmanganese steels, their underlying physical phenomena, and the specific New insights into the properties of highmanganese steelAnhui Yugong Wear Resistant Materials Technology Co, Ltd High manganese steel, low alloy steel, high chromium cast iron, grinding roller, leather lining plate, plate hammer, hammer, High manganese steel, low alloy steel, high chromium cast iron Highenergy density processes John Norrish, in Advanced Welding Processes, 2006 Carbon–manganese ferritic steel The plasma keyhole welding of carbon– manganese steels has recently been evaluated for circumferential root runs in pipes for power generation and offshore applications The use of the process enables thick root sections (6–8 mm) to be welded in a Manganese Steel an overview ScienceDirect Topics

.jpg)

Manganese Wear Castings Manufacturer, Grinding Ring Roller

Zhejiang Shengda Machinery Co, Ltd Think About Wear Think About Shengda As the one of the leading foundry of wear abrasion resistant castings replacement, Zhejiang Shengda Machinery Co, Ltd Takes pride in being an exportoriented foundry who exported over 30000 Mt wear Manganese steel casting and Low Carbon Alloy steel castings to US in the last 10 years for 2023年7月17日 Manganese steel, also known as Hadfield steel or mangalloy, is a highmanganese alloy steel renowned for its exceptional toughness and wear resistance It was invented by Sir Robert Hadfield in 1882 and has since Manganese Steel Composition, Properties, and Uses2024年9月21日 Highmanganese wearresistant steel (HMWS) is the ideal wearresistant material for the machine parts subjected to the force of friction and widely applied in the industries of metallurgy, mining, electricity, and construction []The excellent wear resistance of HMWS can be attributed to its exceptional capacity for workhardening under intense impact energy, Elemental segregation, microstructure, and mechanical properties 2023年3月23日 High Manganese Steel Plates are composed of steel containing 11% to 14% manganese The material’s high wear resistance and toughness make it an ideal choice for various applications in a range of industries Many industries that require wearresistant parts widely use it, including mining, construction, and metallurgy Why Choose High A Comprehensive Guide to High Manganese Steel Plates

Grinding Roller Manufacturer From China Symmen Metal

During grinding roller production, technicians carry out finishing processing with arc air gouging, which can guarantee outlook quality of steel castings Grinding rollers produced by SYMMEN METAL Casting have features of high hardness, good anticracking and strong wearresistant capability We promise that, all the grinding rollers shall be Mn13 is kind of high manganese wear resistant steel material, which is the best choice for resisting high impacts, high pressures among wear resistant steels The features of Mn13 steel plates: 1 The heavier the impacts from outside to the surface of steel plates, the higher performance of abrasive resistance from surface of steel plates will haveMn13 High Manganese Wear Resistant Steel PlatesHSI Impact Crusher parts Common Aliases: Blow bars, HSI Blow Bars, high chrome hammer, high manganese steel hammer Main Material: high manganese steel, high chromium (Cr13, Cr23, Cr26, Cr28 etc) Casting Technology: sand casting, lost foam foundry, vprocess foundry Applicable Materials: coal gangue, river gravel, granite, basalt, iron ore, limestone, quartz, Professional highmanganese steel Blow Bars, highchrome Blow As one of the most professional hot rolled mn13 high manganese hadfield wear resistant steel plate manufacturers and suppliers in China, we're featured by quality products and good service Grinding, especially of primer coated plates, may produce dust with a Hot Rolled Mn13 High Manganese Hadfield Wear Resistant Steel

The wear mechanism of mill beaters for coal grinding madeup from high

2022年12月1日 The test material was plates made of high manganese cast steel that acts as a beater on a MWk 12 (FPM SA Mikołów, Poland) beater mill for coal grinding (Fig 1)The diameter of the beater mill rotor was 2186 mm, 10 beaters were installed2024年11月1日 High manganese steel, as a traditional wearresistant material, is widely used in wearresistant environments such as ore crushing and impact pendulum hammers [9, 10]High manganese steel was first invented by Hadfield, an Englishman, in 1882, and is therefore also known as Hadfield steel [11]The remarkable property of high manganese steel is work Preparation and properties of ZTA/alloyed high manganese steel 2023年12月1日 The wear mechanism of mill beaters for coal grinding madeup from high manganese cast steel Eng Fail Anal , 142 ( 2022 ) , p , 101016/jengfailanal 2022Hardening mechanism of high manganese steel during impact abrasive wear High Quality Mn13 High Manganese WearResistant Steel Plate Sheet, High Quality Coal Mill Grinding Roller Repair Welding Wire US$1,000002,00000 / Ton High Quality Wear Resistant Plate Flux Cored Welding Wire High Quality Mn13 High Manganese WearResistant Steel Plate

Wear Resistance of Austenitic Steel Fe–17Mn–6Si–03C with High

The better wear resistance of the new steel with high silicon and high manganese resulted from the stressinduced Cite this article Haitao Si, Renlong Xiong, Fan Song, Yuhua Wen, Huabei Peng Wear Resistance of Austenitic Steel Fe–17Mn–6Si–03C with High Silicon and High Manganese[J] Acta Metallurgica Sinica (English Letters), 2014 Qiming Casting, a leading manufacturer of high manganese steel and alloy steel casting in China, is dedicated to providing superior quality mill liners for your grinding operations They’re a new type of composite wearresistant grinding roller produced through Maximize Your Mill Lining Performance with Qiming Casting Wear High Manganese Steel Casting WearResistant Liner, Grinding wear parts are subjected to different combinations of impact and abrasion, as they are used in SAG/AG, High Quality Max Diameter 2m Forged Roller Shaft US$1,0000020,00000 / Piece Small Spare Parts High Manganese Steel Casting WearResistant LinerHigh chromium steel casting is the abbreviation of high is a wearresistant material with Chinese characteristics, especially the high silicon to carbon (Si/C) ratio Medium chromium they withstand heavyimpact loadings, such as from impact hammers, roller segments, and ring segments in coal grinding mills, feedend lifter Chromium Steel Casting Wear Parts For Industry Qiming Casting

High Manganese Steel X120mn12 / Hadfield Wear Plate Mn13

High Manganese Steel X120mn12 / Hadfield Wear Plate Mn13, NM series is a highstrength wear resistant steel plate with high hardness High Quality Coal Mill Grinding Roller Repair Welding Wire US$1,000002,00000 / Ton High Quality Wear Supply Condition : As Rolled, Normalized Rolling, Furnace Normalizing, Vacuum Degassing, Simulated PostWeld Heat Treatment or as per customer requirement Thickness : 35mm150mm Item : High Manganese Steel Plates Length : 3000mm18000mm Width : 1000mm4500mm Process of Manufacturing : HotRolled (HR) Impact tested : 52° C View latest price ready High Manganese(Hadfield) 1214 % Wear Resistant Steel PlateCarbide or ceramic particles evenly distributed in the working part have high wear resistance, effectively reduce the wear of the matrix high manganese steel, and increase the service life of vertical grinding rollers, shell for grinding roller, grinding table and other vertical grinding accessories by more than 1 timesHigh Hardness Shell for Grinding Roller for Vertical Mill Spare PartsFactory Direct High Manganese Steel 1810 1515 1510 Grinding Mill Roller Product Name: CONCAVE and MANTLE Applications: Widely used in the mining industry, metallurgical industry, construction industry, road building industry, chemical industry and silicate industry for crushing hard and medium hard ore and rock, such as iron ore, limestone, copper ore, quartz, granite, High Quality High Manganese Steel Mill Liner for Ball Mill

Second phase structure analysis and wear behavior of the ultrahigh

2021年7月1日 The high manganese steel is widely used in wearresisting parts of the cone crusher, such as the grinding mill wall and crushing wall In this work, the microstructure and wear resistance of an 3 The roller crusher has huge advantages over the hammer crusher and impact crusher The average service life of the roller sleeve is more than 2 years 4 Huashengming’s highchromium manganese steel wearresistant material containing rare metal roller skin has applied for a national patentSmooth Roller Crusher huashengmingThe wear spare parts by ceramic insert casting is high wear resistant, the traditional material The technology is suitable for production of Blow bar, Jaw plate, bowl liner, Mantle/Concave, Grinding roller, Liner, Chute liner, Hammer, and etc wear parts MMCMn High Manganese Steel matrix ceramic insert composite castingThe introduction to ceramic inset casting technologyWearresistant steel is widely used in various wear conditions, such as metallurgy, mining, buildings, electric power, railway and military fields, etc [[1], [2], [3]]Currently, wearresistant steel can be roughly divided into low alloy martensite wearresistant steel [4, 5], medium/high manganese austenite wearresistant steel [6, 7], and medium/high carbon bainite wear Sliding wear behaviors of low alloy high strength martensite wear

Hammer Crusher Hammer Heads Crusher Hammers AGICO

We mainly produce wearresistant hammers made of alloyed high manganese steel, which has better wear resistance than that of traditional high manganese steel hammers The head of the hammer has good wear resistance and the handle has good toughness, and it is widely used in large limestone crushers in new dry process cement production linesAntiwear performance of our rubbersteel liner for Ball mill 732 x 12m The company Mill liners for SAG mill in Russia Mar292023 Dia 75X28 Meters SAG Mill, The Mill liners was casted of High Manganese Steel Mn13Cr2 material, Crusher Spare Parts sent Xuzhou HG Wearresistant Material Co,Ltd +86 ; nick@xzhuagang Grinding Media, SAG Mill Liner, White Iron Mill Liner HGMaterial options: Austenitic Manganese Steels, High Chromium White Cast Irons Alloy Steels of various grades The company, covering an area of about 26,680 m², is located at Beidu Aluminum Industrial Park, Gunan street, Qijiang District, Chongqing City, and designed with annual capacity of 15, 000 tonnes at the first stage (Full Capacity up to 30, 000 Tonnes per Year)About the Company Panglei WearResistant Castings Foundry2024年6月17日 Shuxrat Chorshanbiev, Nuriddin Tadjiev, Abdulxamid Erkinjonov; Development of wearresistant parts from highmanganese modified steel 110G13L for oregrinding equipment AIP Conf Proc 17 June 2024; 3152 (1): Development of wearresistant parts from highmanganese modified steel

.jpg)

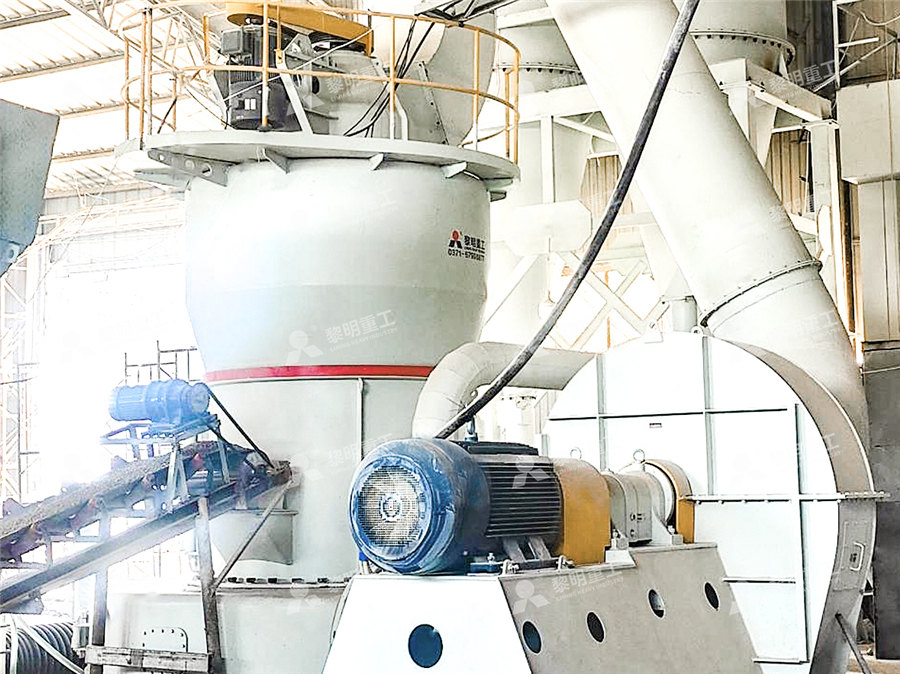

Quick Pick: Compare 4 Top Barite Grinding Mills for Your Needs

2024年4月17日 Typically made of wearresistant materials such as alloy steel, alloy carbon steel, and ZG65Mn manganese alloy steel, with a lifespan ranging from hundreds to thousands of hours Grinding ring: Paired with the grinding roller to form the grinding zoneManganese Steel Manganese steel, or Hadfield steel or mangalloy, is a steel alloy containing 1214% manganese Renowned for its high impact strength and resistance to abrasion in its hardened state, the steel is often described as the Qiming CastingChina’s wearresistant casting 2023年7月28日 High manganese steel typically contains around 11% to 15% manganese, which is significantly higher than traditional steel The high manganese content creates austenitic crystals during solidification, resulting in workhardening ability – a High Manganese Steel Castings A Complete GuideBmw Steels Ltd manufacturer,exporter and supplier of chrome Steel Liners,wear resistant liners,high manganese steel liners in all over India An ISO 90012008 Grinding Media and Liners Grinding Media Balls and Cylpebs; (up to 200°C) applications with wear The High Manganese Steel Liners are hard in nature and resistant to Chrome Steel Liners,Wear Resistant Liners,High Manganese Steel

.jpg)

X120Mn12 High Manganese Wear Resistant Steel Plates

Product name : X120Mn12 High Manganese Wear Resistant Steel Plates Item : X120Mn12 Enlarge Image Back [Next Product] → Details: X120Mn12 is kind of high broken walls, rolling ace tabular wall, roller shell, form relieved teeth, etc Technical Details: 2023年3月1日 High manganese steel has widely been used owing to its good wear resistance High manganese steel with an austenitic phase has first been reported in 1882, and Hadfield filed a patent in 1883 [1,2]The good work hardening characteristics and high wear resistance of high manganese steel made it useful in excavator’s teeth, jaw crusher fork plates, ball mill liners, Effect of Surface Impacting Parameters on Wear Resistance of High 2024年3月1日 The preparation of PRSMCs is extremely complex and difficult, and many factors need to be taken into account The thermophysical properties and interface structure between the reinforcing particles and the matrix play a crucial role in improving the performance of composites [21, 38, 39]Additionally, the size, distribution and content of reinforcing particles in the Recent advances in wearresistant steel matrix composites: A 4 High carbon and high manganese alloy steel balls High carbon and high manganese alloy steel is an alloy added with elements such as chromium and molybdenum, which has the dual advantages of high hardness and good toughness The manufacturing process of Steel grinding balls Casting, forging, and rolling are three methods for the production Ball Mill Balls For Sale WearResistant Grinding Balls Φ20150mm

Defining Manganese Steel: Properties, Uses, and Applications

History of Manganese Steel Sir Robert Hadfield, a British metallurgist, developed what is now known as manganese steel in 1882 Hatfield’s work found that manganese steels obtained high levels of toughness when manganese levels were above 10% and heattreated via quenching Today t his alloy typically contains between 1214% manganese Product name : 13401 High Manganese Wear Resistant Steel Plates Item : 13401 Enlarge Image Back ←[Previous Product] [Next Product] → Details: 13401 is kind of high broken walls, rolling ace tabular wall, roller shell, form relieved teeth, etc Technical Details: 13401 High Manganese Wear Resistant Steel PlatesAustenitic manganese steels have a proven high resistance to abrasive wear including blows and metaltometal wear, even though they have a low initial hardness These steels are supposed to work harden under use and thus give a hard wear resistant surface, but it has been reported that these steels have a good wear resistance in components even without heavy mechanical AUSTENITIC MANGANESE STEEL Dolphin Engineering