How is Kaiyuan micro powder mill

.jpg)

Mikro ACM Air Classifying Mill Brochure HiRespdf

The Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 of 20 microns The Mikro ACM® Air Classifying Mill is available in a range of sizes and can be supplied for HGM series micro powder mill is a processing equipment for fine powder and super fine powder It’s mainly used to grind nonflammable, nonexplosive nonmental materials with medium and Micro Powder MillFrom lab/pilot to production requirements, Hosokawa Micron Powder Systems offers a complete line of size reduction technologies Whether you call it size reduction, micronization, milling, pulverizing, jet milling, air milling, or simply Size Reduction Milling Hosokawa Micron Powder Size reduction is, essentially, the breaking down of materials from a few large particles, usually to a fine powder There are three different kinds of powders that result from a size reduction Basics Size Reduction – Fine Ultrafine Size Reduction

.jpg)

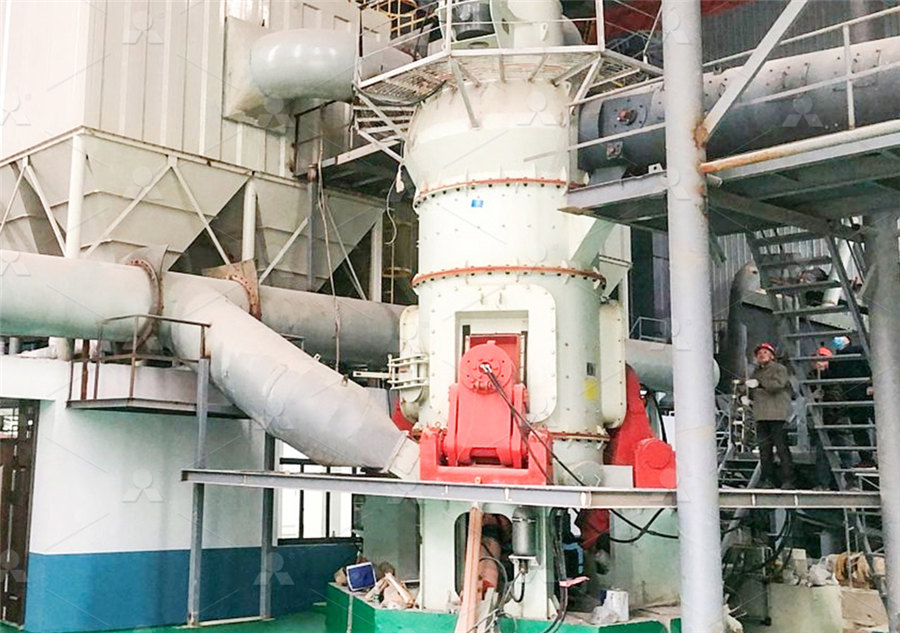

MW Series Micro Powder Mill SMMVIK Machinery

pared with jet mill, mixing grinder and ball mill of same finished product size and motor power, MW MicroPowder Mill has double capacity and saves 30% energy 2The lubricating device is installed outside of the main shaft, so 2017年7月7日 Impact and attrition sizereduction methods include air classifying mills, pin mills, hammer mills and jet mills Shear, impact and compression methods are used in media or ball mills The five types of milling technologies Top 5 productspecific milling technologies used in Micromilling is a precise and flexible technology to manufacture complex 3D geometries in various types of materials (metals and its alloys, polymers, ceramics, graphite, composites etc A review on micromilling: recent advances and future trendsHow does a micro powder roller mill work? After the large size of materials are crushed by the crusher to meet the feeding size of the micro powder grinding machine, they are sent to the storage bin by the elevator Then it passes Micro Powder Roller Mill for Getting Ultrafine Powder

High Performance Low Cost Size Reduction with the

The Mikro Pulverizer® Hammer Screen Mill combines a high speed mechanical impact mill with an outlet screen to control particle size These hammer and screen mills are used in the production environment to provide continuous ZYM Ultrafine Powder Mill Grinding The JOYAL Threering Micro Powder Mill(ultrafine mill) is for superfine grinding materials with hardness less than 6 in Moh’s scale and humidity less than 6 percent such as kaolin, limestone, calcite, marble,talcum, barite, gypsum, dolomite, bentonite mud,mica, pyrophyllite, sepiolite, diatomite, graphite, alunite, fluorite, potassium feldspar JoyalThreering Micro Powder Mill,Threering Micro Powder Mill 2022年3月22日 Micro pulverizer machine manufactured by Mill Powder Technology is made up of three parts: main machine, auxiliary machine and electric control box The micro pulverizer machine has the properties of wind Micro Pulverizer Machine Mill Powder Technology More please visit:breakday/2013en/grinding/hgmmicropowdermillhtml HGM series Threering Mediumspeed micropowder mill is designed basiHGM Micro Powder Grinding Mill YouTube

MW Series Micro Powder Mill SMMVIK Machinery

MW Series Micro Powder Mill is equipment designed for customers who need to make ultrafine powder This machine is equipped with efficient pulse dust collector and muffler, which can reduce dust and noise,The fineness can reach to 0pared with jet mill, It is economiccost, highcapacity, and the spare parts just need to exchange once a year, The bag filter is added 6 POWDER AND PARTICLE PROCESSING SYSTEM CONFIGURATIONS Feeder Product Collector Fan Material Collection Mikro ACM® Air Classifying Mill Controls The Mikro ACM® Air Classifying Mill is designed to produce finer materials with sharper particle size distributions than most other impact milling technologiesAir Classifying Mill2017年7月7日 Pin mill configuration In a pin mill, the particle size is controlled by three parameters: Feed rate, rotor speed and airflow Varying these parameters will have the following effects: Increasing the feed rate will result in a coarser particle size while reducing the feed rate will have the opposite effectTop 5 productspecific milling technologies used in industrial The ACM 1 is one of Hosokawa’s smallest air classifying mills available It was designed to process small batches of research materials down to D 97 = 20 microns This video quickly tours this self contained laboratory milling systemLab Scale Air Classifying Mill Hosokawa Micron Powder Systems

.jpg)

Micro Powder Roller Mill for Getting Ultrafine Powder DASWELL

Micro powder roller mill is also known as ultrafine powder grinding mill It is a new type of powder processing equipment, mainly used for crushing and processing nonmetallic minerals such as calcium carbonate, barite, talc, gypsum, calcite, limestone, calcium oxide, bentonite, dolomite and other nonmetallic minerals with Mohs hardness less than 5 and water content less than 5%2015年9月21日 Flake silver powder with controllable particle size and specific surface area was prepared using planetary ball mill by varying milling parameters including milling time, revolution speed, and the weight ratio of balls to powder (BRP) Asprepared flake silver powder was characterized by laser particle analyzer, scanning electron microscope, Xray diffraction (XRD) Preparation of microsize flake silver powder by planetary ball mill The Ultrafine Grinding Mill, also known as a Micro Powder Grinding Mill or Ultra Fine Powder Grinding Machine, is a highefficiency and lowconsumption grinding mill that is widely used in the powder processing of various materials Bellian Mining Machinery offers a range of Ultrafine Grinding Mills, including the Ultrafine Vertical Mill and Fine Powder Mill Grinder, designed to Ultrafine Grinding Mill, Micro Powder Grinding Mill Bellian 2022年6月25日 The micro powder roller mill is one of the main products of Daswell company It is widely used in many materials grinding especially for calcium carbonate WDaswell DR28 micro powder roller mill YouTube

.jpg)

Micro powdermill PDF Free Download SlideShare

2013年10月30日 5 Working Principle 4 >> EMail:joyal@crusherinc >> Http://joyalcrusher The rotating turbo in the powder Separator makes the coarse materials return to the mill and reground, while the fineness mixes MW Micro Powder Mill (Medium speed microgrinding mill, absorbing advanced Swedish grinding technology, is good at superfine powder processing Chat Online WhatsApp Previous Next Processed Materials: Limestone Barite Calcite Gypsum Applications:MW Micro Powder Mill, micro powder mill, micro powder mill price, micro Micro Powder Mill Micro Powder Grinding Mill is a new type of mill for making super fine powder through more than 20 times of test and improvement The fineness can reach to 0006mm; Micro Powder Mill is mainly used for processing gypsum, calcspar, talc, and other materials used in painting, pigment and cosmetics industryMicro Powder Mill KefidThreering Micro Powder Mill >> EMail:joyal@crusherinc >> Http://joyalcrusher Features 1 Highefficiency and low consumption With the same endproducts fineness and motor power, its output is over 1 time of that of Jet Mill, Mix Mill, and Ball MillMicro Powder Mill Shanghai Joyal Machinery Co, Ltd

Grinding Mills and Their Types – IspatGuru

2015年4月9日 Ball mill is a versatile grinding mill and has a wide range of applications The mill can vary in size from small batch mills up to mills with outputs of hundreds of tons per hour They are the most widely used of all mills Roller mills Roller mills are basically of two distinct typesMikro UMP mills have similar performance to Hosokawa’s Mikro Pulverizer Hammer Screen Mill but with the added value of four rotor options: pin disks, hammer screen, knives and attrition disks Design Options: Designed to mill down to D97 = 35 μm; Available with 1 HP to 40 HP; Models for processing 5 grams/batch and up to 3,000 lbs/hourMikro ® UMP Universal Mill Hosokawa Micron Powder SystemsThe MikroPulverizer ® Hammer Screen Mill is a high speed mechanical impact mill designed for continuous size reduction of a wide range of materials down to D90 = 45 microns This device was originally invented by Hosokawa Micron Powder Systems in 1923 and has evolved into the preeminent industrial mill with thousands of worldwideMikroPulverizer Hammer Mill Hosokawa Micron Powder Systems2021年11月27日 HighPressure Micro Powder Mill Micro Powder Mill is also called a highpressure micro powder mill, which is a highly efficient powder grinding machine manufactured on the basis of a highpressure grinding mill and improving the classification technology of the fineness of the final productsWhat is Powder Grinding Mill? JXSC Machine

Particle Size Reduction Solutions Prater Industries

If your application needs reduction whether it is 6inch to submicron size, choose from Prater’s superior fine grinders, air classifying mills, hammer mills, and lump breakers to meet all of your industrial processing needs We have been 2024年8月29日 Shanghai Clirik Machinery Co, Ltd Is excellent ore mill supplier Our main products include ultrafine powder grinding mill, vertical roller mill, roller grinding mill, stone powder production equipment, Welcome to consultFocus on the field of micro powder grinding equipmentThe micro powder grinding mill is capable of achieving particle sizes as fine as 1 micron or even smaller, making it ideal for applications that require ultrafine powders This mill is a gamechanger for industries that rely on precise particle size control for optimal product performanceThe versatile and efficient micro powder grinding mill2022年3月22日 Micro pulverizer machine manufactured by Mill Powder Technology is made up of three parts: main machine, auxiliary machine and electric control box +86 Solicitar presupuestoMicro Pulverizer Machine Mill Powder Technology Co, Ltd

Three ring medium speed micro powder mill SBM Ultrafine Powder

The three ring medium speed micro powder mill can grind the material to an ultrafine particle size of more than 3000 mesh through fine processing of the material It is a common equipment for processing ultrafine powder in the market +17 [ protected] languageHGM series ultrafine powder mill (threering / fourring mediumspeed micropowder mill) is a highefficiency and lowconsumption ultrafine powder processing equipment that successfully replaces the traditional jet mill and complex process ball mill grinding and powder selection, greatly reducing production costsUltra Fine Powder MillHGM Three Ring micro powder mill (also known as micro powder grinding, micro powder grinding mill or Micro powder machine) is named for its three ring, it is a fine and superfine powder processing equipment, mainly suitable for the super fine powder processing of nonexplosive brittle materials with medium and low hardness, and Mohs hardness below 9 degree, such as HGM Micro Powder MillThe main hallmarks of fine impact mills are that they achieve a small particle size and have a wide range of possible applications The aim here is to ensure costeffective production and offer mills with high throughputs and optimised energy efficiency for a lot of applicationsFine Impact Mills Hosokawa Alpine

.jpg)

Marble Ultrafine Powder Grinding Mill

2021年9月6日 Marble ultrafine powder grinding mill can grind marble into a fine powder(1503000mesh) It can grind totally 100+ kinds of nonmetallic ores +17 [ protected] The HGM micro powder grinding mill is a popular choice for grinding montmorillonite and other minerals due to its high efficiency, Micro Powder Mill is suitable for grinding all kinds of brittle materials with Mohs hardness below 5 It is carried out in a closed system, dust containing gas after dust removal treatment, no pollution, is the ideal equipment for green environmental protectionMicro Powder MillFinal grain size: 1 µm 500 µm Rotational speed: 12,000 rpm 18,000 rpm Output: 5 kg/h The Universal Laboratory Mill (FNG00) is the smallest crushers of the FNG range Manufactured in the mass and built steel stainless 316L Powder mill, Powder grinding mill All industrial Models: HGM80, HGM90, HGM100, HGM100A, HGM125 and HGM1680Power: 1233444 kwFinished size: 325~3000 meshes, 547 micron HGM Micro Powder Grinding Mill is thHGM Micro Powder Grinding MIll,Micro Powder

.jpg)

Planetary Micro Mill PULVERISETTE 7 premium line /

FRITSCH Planetary Ball Mills – highperformance allrounder in routine laboratory work The Planetary Micro Mill PULVERISETTE 7 premium line with 2 grinding stations is designed for a broad range of applications and ideally suited for Micro powder roller mill As the name suggests, the micro powder roller mill mainly crushes the material by rolling and grinding the multilayer ring rollers It is mainly used to produce ultrafine powder of 845μm Our common micro powder roller How to Choose a Calcium Carbonate Grinding Mill DASWELLBrief Introduction HGM Ultra fine grinding mill (also called micro powder mill, superfine powder grinding mill, ultra fine powder grinder) is designed by SBM RD department on the basis of multiple innovations and testing It has been proved by thousands of customers that our ultra fine powder grinder has outstanding features, stable quality, easy operation, and maintenanceUltra Fine Grinding Mill SBM Ultrafine Powder Technology① Integrated design, less comprehensive investment The machine integrates crushing, grinding, powder selection, conveying, and packaging The system is simple, and the layout is compact The floor area is about 50% of the ball mill system, and it can be arranged in the open air, greatly reducing investment costsStone Powder Making Machine

Coating Thickness Conversion Table

The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications networkFebruary 22, 2024 – With the rapid development of the economy, the demand for powder processing in various industries continues to grow As a leading domestic micropowder technology company, SBM is always committed to providing customers with efficient, energysaving and environmentally friendly grinding solutionsSBM micro powder technology leads the market, HGM ultrafine mill In the process of making slag powder from slag, the participation of mill is indispensable In the past, ball mills were widely used in the processing of slag powder SMMVIK Machinery can provide a slag micro vertical mill production line with an annual output of 50000 tonsWhat mill is used for processing slag micro powder? How much 2013年12月2日 Micro Powder Mill Technical Parameters Type Micropowder93 Micropowder86A Micropowder66 ≤25 ≤20 ≤15 01250010 01250010 01250010 221 0512 028 160 160 180 1006 9075 725 300 270 210 160 150 150 Main Motor Y225m830 Y225m822 Y225m815 Fan Motor Y160E222 Y160L415 Y160L411 Analyzer motor Y112m4A3 Yc1204A3 Yc120 Micro powder mill PDF SlideShare