HOME→Chengdu grinding system ore mill Chengdu grinding system ore mill Chengdu grinding system ore mill

Chengdu grinding system ore mill Chengdu grinding system ore mill Chengdu grinding system ore mill

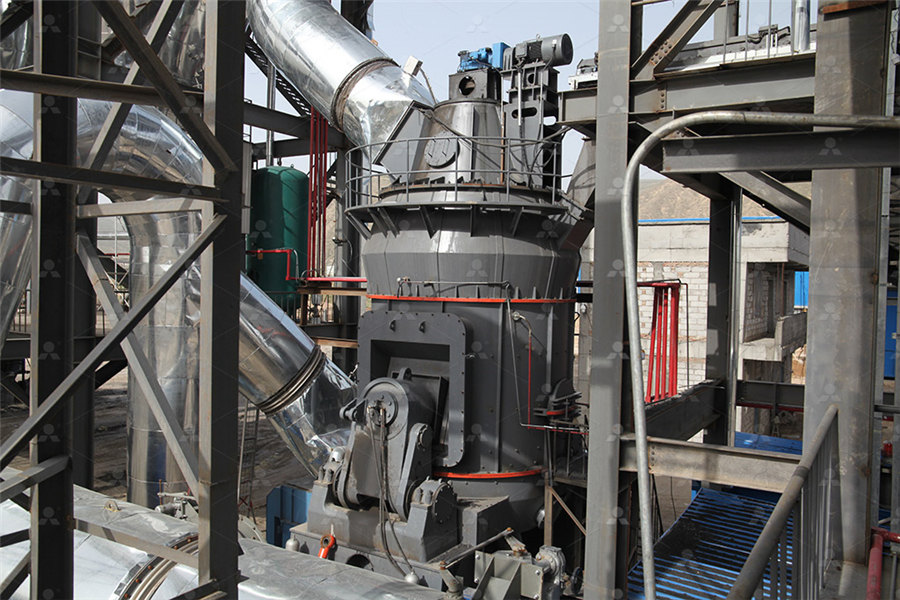

Company ProfileChengdu Leejun Industrial Co, Ltd

The company takes the lead in applying roller press to domestic mine grinding system, and designs different grinding system according to different working conditions and ore categories, We have supplied numberless of wet grinding rod mills for customer in coal chemical industry, to deal with the coal and petroleum coke material and prepare for the coal water slurry making Ore Grinding MillSBM Industrial Technology Group2023年7月20日 Moist grinding, a special grinding method, is used to prepare pellets for smelting According to the grinding medium features, ore grinding is mainly classified into ball grinding Ore Grinding SpringerLink2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral Processing

New Automated System for Optimisation of Ore Grinding Process

1998年9月1日 The brief description of the new method and a sensor for ball mill loading, the microprocessor control module the floating densimeter and the regulable ore and water 2023年6月1日 The main parameters of grinding and classification process include measurement of millfeeding quantity, mill load measurement, measurement of ore slurry density, Online Measurement and Control for Ore Grinding and Classification2023年9月1日 Based on the machine learning method, this study analyzed the full process parameters (ie, ball mill power, fresh ore feed rate, hydrocyclone feed pump power, Analyzing process parameters for industrial grinding circuit based Methods and Process of Ore Grinding According to the material transmission methods, ore grinding is divided into dry grinding, wet grinding, and moist grinding Dry grinding relies on Ore Grinding Methods and Process of Ore Grinding

Intelligent process control system for predicting operating

2024年1月31日 Results demonstrated reduced vibration and energy use versus manual control Validation confirmed improved accuracy in predicting mill responses Significant energy Ball mill is suitable to grind various mineral and other materials, which is widely used in various industries such as benefication, construction materials, chemical industry, etc, it has two ore Ore mill, Ore grinding mill All industrial manufacturers2 Grinding process description The ball mill grinding process is mainly composed of a ball mill, a hydrocyclone cluster, a sump, a slurry pump and an ore bin The schematic diagram of this process is shown in Fig 1 Fig 1 Schematic diagram of ball mill grinding process The variables of this process shown in Fig 1 are explained as follows: WIntelligent optimal control system for ball mill grinding process2017年2月20日 On the other hand, the wear of mill lining and grinding media is lower in dry grinding Thus dry grinding can be less costly A closed circuit dry grinding system is very space consuming because of the classifier, the transport devices, the dedusting filter, etc The feed to a dry grinding system must be dried if the moisture content is highGrinding Mill Design Ball Mill Manufacturer 911Metallurgist

Copper Ore Crushing, Grinding Flotation 911Metallurgist

2017年5月21日 Crushing and Grinding You will note that the Oracle Ridge project has utilized a twostage crushing circuit with a double acting jaw crusher and cone crusher In order to utilize this system, the jaw crusher is oversized to produce all 5 material for the cone mill with a screen in closed circuit2015年4月9日 Grinding Mills and Their Types satyendra; April 9, 2015; 12 Comments ; autogenous grinding, ball mill, grinding mills, hammer mill, rod mill, roller mill, SAG,; Grinding Mills and Their Types In various fields of the process industry, reduction of size of different materials is a basic unit operationGrinding Mills and Their Types – IspatGurudrive system to be overloaded when the mill filled with copper ore is started For this reason, the mill is stopped only in the case of a failure or planned maintenance work The aim is to minimize the potential number of startups, as the mill at a standstill must be later started under full loadEnergy Efficiency Analysis of Copper Ore Ball Mill Drive SystemsChina Grinding Mill System wholesale Select 2024 high quality Grinding Mill System products in best price from certified Chinese Professional System manufacturers, Gold Ore Ball Mill Stone Grinding System US$ 1900020000 / Piece 1 Piece (MOQ) Jiangxi Gandong Mining Equipment Machinery ManufacturerGrinding Mill System MadeinChina

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGate2017年1月17日 Other process activities, such as spraying the ore with water for dust control or the fact that runofmine ore moisture is approximately 2%5% are not generally considered (Bleiwas, 2012a)Breaking down energy consumption in industrial grinding mills2016年2月2日 The grinding circuit operator must ensure that the ball mill runs properly loaded and gives the correct ore grind A major practical indication of mill loading is the sound made by the mill A properly loaded mill will have a deep rhythmic roar, while an under loaded mill will have a metallic rattling type noise and an overloaded mill will be quite silentGrinding Circuit Startup and Shutdown Procedure3 天之前 UTC/GMT +8 ore : Non c’è l’ora legale al momento: Aeroporti Aeroporto IATA ICAO Distanza da Chengdu; Aeroporto di ChengduShuangliu: CTU: ZUUU: 15 km Coordinate geografiche Latitudine: 30 Chengdu, Cina ora esatta, fuso Chengdu, Cina ora esatta, fuso orario, differenza oraria, fusi

L'ora attuale in Chengdu , Cina Timeis

4 天之前 Alba, tramonto, durata del giorno e ora solare per Chengdu Alba: 07:41; Tramonto: 18:04; Durata del giorno: 10h 23m; Mezzogiorno solare: 12:52; L'ora locale in Chengdu Chengdu è 52 minuti avanti rispetto l'ora solare Le 50 più grandi città in CinaOur main products include ultrafine vertical roller mill, ultrafine grinding mill, stone powder production equipment, Welcome to consult +17 [ protected]SBM Ultrafine Powder Technology Industrial We are usually limited by practicality, finances and permitting to a simple crushing and grinding circuit, with a gravity recovery system for the free milling values and valuecontaining sulfides Mt Baker Mining and Metals is focused on providing a costeffective and durable ore processing plant that includes a jaw crusher, hammer mill, size classification equipment, and sluice/shaker tableOre Milling Mt Baker Mining and Metals2016年6月3日 IsaMills, Tower Mill and Verti Mill Ultrafine Grinding in a Tower Mill The Tower Mill is a vertical “stirred” ball/pebble mill recently introduced in the Western Hemisphere This device offers a significant power savings on wet fine grinding applications when compared to conventional tumbling millsTower Mill Operating Work Index 911Metallurgist

.jpg)

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 The choice of grinding mill depends on factors such as the desired product size, capacity requirements, and energy consumption b Autogenous and SemiAutogenous Mills: In some cases, autogenous (AG) and semiautogenous (SAG) mills are used for grinding These mills utilize the ore itself as the grinding media, reducing the need for additional The VKE mill is the most efficient fine grinding mill available Extremely fast and very energy efficient, the VKE mill is very versatile and can be operated either wet or dry The air injection system provided with the dry mills can be used to elutriate the material during the grind to pull sized fines out of the mill and allow the mill to grind only oversize materialMicroGrinding Systems, Inc EnergyEfficient Vibratory Mills2021年1月22日 Grinding operation is used extensively in the industry of beneficiation, metallurgy, chemical engineering, and electric power Assisted by the impact and abrasion between media (steel ball, steel rod, gravel, ceramic ball) and ore, the grinding operation reduces the particle size in the mill [[1], [2], [3]]To produce the qualified size and high liberation of An innovative approach for determining the grinding media system 2020年1月27日 Figure 2: Cascadingimpact action in a SAG mill Rubber and composite mill lining systems In the past, grinding mills were typically lined with cast metal linings of varying steel or iron alloys, and lining system selection was typically driven by level of Key considerations when selecting a mill lining system

.jpg)

Processing of Magnetite Iron Ores–Comparing Grinding Options

2009年1月1日 Also, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of operation (1) Structure parameters of grinding mill, including its specifications, model, aspect ratio, ore discharging method, and liner form (2) Various working parameters of grinding mill, including fraction of critical speed for grinding mill, filling rate for grinding mill, grinding concentration,grindingcycleload,etc(3)AndgrindOre Grinding Methods and Process of Ore Grinding2015年3月15日 The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a hydro pneumatic spring systemBetween the working surfaces of track and rollers, particle bed comminution takes place A dynamic air separator (3) is located above the grinding chamber, Research of iron ore grinding in a verticalrollermill2020年10月18日 An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesThe effects of iron ore concentrate grinding methods (HPGR and

.jpg)

Optimization of stirred mill parameters for fine

2020年7月23日 Optimization of stirred mill parameters for fine grinding of PGE bearing chromite ore, Particulate Science and Technology, DOI: 101080/2020 To link to this article: https://doi 2016年10月12日 by increasing the circulating load round the closed circuit so as to pass the ore more rapidly through the mill, by adopting two and even threestage grinding, each stage having its own system of classifiers, and; by installing intermediate classifiers, where the gain in efficiency is worth more than the extra costClosed Circuit Grinding VS Open Circuit Grinding2016年6月6日 Mill operating conditions including mill speed (for circuits with variablespeed drives), density, and total mill load; The effect of feed hardness is the most significant driver for AG/SAG performance: with variations in ore hardness come variations in circuit throughputSAG Mill Grinding Circuit Design 911MetallurgistOur grinding mill inspection packages can help you save thousands of Euros per day Gear and pinion services A complete range of gear and pinion sets, inspections, design, installation and alignment services to drive your mill’s performance Stirred mill inspectionsGrinding mills for mining and minerals processing Metso

.jpg)

(PDF) Control of ball mill operation depending on ball load and ore

2023年12月12日 Ore can have various properties, such as hardness, density, moisture content, etc, which can affect the ore’s productivity and grinding efficiency Discover the world's research 25+ million members2024年1月1日 Therefore, the rod mill is mostly used for coarse grinding of the previous period of ball mill, or grinding of brittle materials and materials against overcrushing, such as tungsten and tin ore before gravity separation; and (3) autogenous mill – it refers to the materials which themselves are collided and ground mutually to be crushed when the grinding mill rotates, and Ore Grinding SpringerLinkDownload scientific diagram Grinding system consisting of two classifiers and an electromagnetic mill from publication: Assessment of classification with variable air flow for inertial Grinding system consisting of two classifiers and an electromagnetic millHammer Mill Grinding With over 160 years of industry experience and continued cutting edge research and development, Bühler is proud to present the next generation grinding portfolio, with all new and updated equipment to provide the highest performance and value for your businessHorizontal Hammer Mill Grinding System Bühler Group

Ore Pretreatment Methods for Grinding: Journey and Prospects

2018年6月18日 Ore pretreatment methods for grinding: journey and prospects, Mineral Processing and Extractive Metallurgy Review, DOI: 101080/2018 To link to this article: https://doior g/10 You can apply our ball mill in ore beneficiation plant to grind iron ore, copper ore, gold ore, lead ore, zinc ore, kaolin, bentonite, feldspar, silica, etc Grid Type Ball Mill The Grid Type Ball Mill has high discharge speed and high productivity Ball Mill Ball Grinding Mill SKE1 The ball mill can efficiently and finely grind various materials with different hardness and abrasion properties, including metallic ores, nonmetallic ores, cement clinker, etc 2 It has a highly automated control system, including Ball Mill Mining Grinding Mill JXSC MachineryMill Milling is the process of crushing, grinding, and treating of raw material from the mine to extract a saleable product It also involves the processes of hoisting and transporting of broken ore to the mill via trucks or conveyor belts Minetomill integrationMonitoring ore loss and dilution for minetomill integration in

Research of iron ore grinding in a verticalrollermill

2015年3月15日 For the grinding tests, a Loesche mill LM45 (table diameter 045 m) is used (Fig 2a) This pilot scale mill is a special development for ore grinding, which is reflected by several features The mill has four rollers, which are able to stress the particle bed with grinding pressures of up to 5000 kN/m 22023年6月7日 The product from autogenous mill will enter into the ball mill for fine grinding Advantages of wet autogenous mill: its classification system is simpler than that of dry autogenous mill, and the ore with high content of slime can be processed by wet autogenous mill without the need for washingAutogenous Mill SpringerLink2013年4月1日 However, a lot of academic applications have been developed using Matlab/Simulink R le Roux et al (2013) proposed and validated a novel and simple nonlinear model, Sbárbaro (2010), Liu and Analysis and validation of a runofmine ore grinding mill circuit 1 Population balance model approach to ball mill optimization in iron ore grinding Patricia M C Faria1,2, Luís Marcelo Tavares2 and Raj K Rajamani3 1 Vale SA, Brazil 2 Department of Population balance model approach to ball mill optimization in iron ore

Company ProfileChengdu Leejun Industrial Co, Ltd

Grinding system overall solution provider to create value for customers Chengdu Leejun Industrial Co, the company's research and development of "roller mill grinding system" was listed by the National Development and Reform Commission as "the first batch of national key energysaving technology promotion project"2019年4月16日 The paper demonstrates why the Loesche VerticalRollerMill (VRM) is a serious alternative to conventional grinding technologies and where the limitations of the system are(PDF) LEARNING FROM OTHER INDUSTRIES; WHY THE VRM