Safety knowledge of ore mill for powder processing

.jpg)

Safety during handling of metal powders in the course of additive

hazardous substances released from the process zone can be expected during powder filling, workpiece removal and system cleaning When filling the system with microscale metal powder, however, there has been no interaction with the laser radiation Accordingly, no nanoparticles When grinding sponge iron in mills it is necessary to provide access for air, depending on the oxidation conditions, so that the active surface that is forming is sufficiently oxidized The LABOR PROTECTION AND SAFETY ENGINEERING IN POWDER Proper operation and safety precautions are vital when working with ball mills By following the recommended procedures and safety guidelines, operators can ensure safe and efficient Ball mill operation procedures and safety precautionsThe Kek Universal Mill is designed for highperformance fine grinding, versatility and safety Available with various interchangeable grinding media, this mill offers unsurpassed high Powder Processing Equipment Systems Qlar

Safety in Handling of Metal Powders ASM Digital Library

This article is a detailed account of the types of safety hazards that can exist and the issues that occur during metal powder handling, as well as recommendations and strategies that can be Health and safety are critically important issues, and there are numerous aspects of the production and use of metal powders that may entail exposure to hazardous conditions This Safety and Environmental Aspects Powder MetallurgyOur Safety Services include the necessary training, consulting and testing on all aspects of powder handling and processing operationsPowder Handling and Processing Operations Intertek2001年6月20日 Commencing with an overview of developments in the health and safety aspects of handling powders, the book then goes on to look at the new technologies being applied to Powders and Solids: Development in Handling and Processing

Hazard Identification, Risk Assessment, and Control Measures as

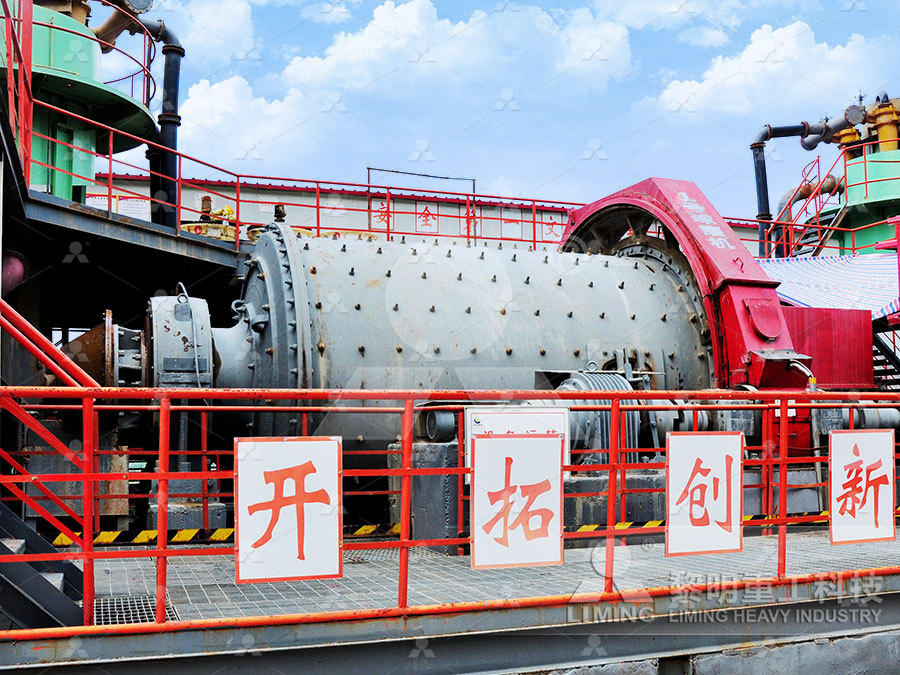

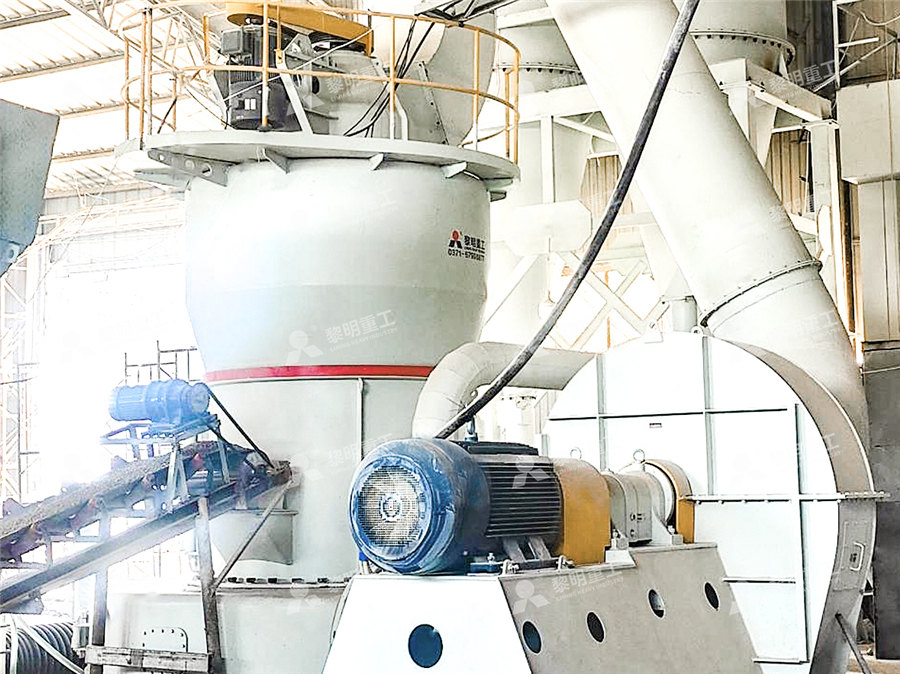

2017年5月1日 The bentonite is stored and ground in a Vertical mill by dry grinding process to desired fineness (−200 mesh, 80%) The powdered bentonite is stored for further mixing 2021年9月5日 This study aimed to model bauxite grinding and assess the optimum material filling volume in a laboratory ball mill in order to improve mill and overall process efficiency Modeling of Bauxite Ore Wet Milling for the Improvement of 2016年2月2日 However, powder processing is widely recognized as being challenging, with unit operations often exhibiting lower reliability and greater variability than those only involving liquids and gases Different grades of Efficient powder handling critical for success ofBall mill in the Philippines Ball mill is the most widely used grinding machine It is widely used in the mine ore mining and processing, cement plant and nonmetal powder manufacturing plant According to the working principle , ball mill is divided into wet and dry ball mill Wet ball millBall mill used for copper ore processing in the Philippines

82: Mining and Ore Processing Geosciences LibreTexts

Media Attributions; Metal deposits are mined in a variety of different ways depending on their depth, shape, size and grade Relatively large deposits that are quite close to surface and somewhat regular in shape are mined using a process called mechanical alloying, a postprocessing technique that allows production of homogeneous alloy from blended elemental or prealloyed powders This technique realizes the processing of powder particles in highenergy mills Different types of highenergy milling equipment are used to produce mechanically alloyed powdersDevelopment of a HighEnergy Mill for Powder Metallurgy2021年3月23日 Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational massesEnergy Efficiency Analysis of Copper Ore Ball Mill Drive Systemsoperational safety DENTAL COMPOUNDS Contaminationfree processes for immaculate ceramic inlays of premium supplier of powder processing equipment WE CULTIVATE LONGTERM CUSTOMER RELATIONS Quality is also the result of consistency, 2 Zirkoplex classifier mill 315 ZPS POWDER WITH A SYSTEM Our lines and systems process all powderTHE PURSUIT OF PERFECTION IN POWDER PROCESSING

.jpg)

Understanding the SAG Mill in Copper Ore Mining Process

Understanding how SAG mills work in copper ore mining requires knowledge about both technical processes as well as practical considerations such as maintenance schedules and safety protocols Only by mastering these elements can mining companies achieve optimal performance from their milling operations while ensuring worker safety is always paramountIn minerals processing, unit operations must prepare and classify ores before separating the valuable materials These processes form valuable minerals Necessary unit operations include: Comminution / Size Reduction To achieve the goal of recovering valuable materials, the raw ore must be reduced to a reasonable size before separationMineral processing news and technology BulkInside2023年10月16日 He has over 18 years of experience in sales and business development for the food processing industry His knowledge covers ergonomics and operator safety, product quality and safety, protection against the risk of explosion, and reduction of downtime of the lines In his role, he helps automate customers’ powder handling processesTurning powder handling challenges into solutions Processing 2022年10月4日 A notable fact is that the energy efficiency of conventional milling is only about 1%, as mentioned in Sect 1 An earlier experimental study indicated that about 80–90% of the energy input of a ball mill was used in heating the material (Schellinger 1951, 1952), and a recent study showed that over 75% of the electrical energy was used to heat the slurry (Bouchard et Reduction of Fragment Size from Mining to Mineral Processing: A

Assessment of Occupational Health Hazard and the Use of Safety

To assess the use of safety measures among rice mill worker in Ebonyi State, Nigeria Significance of Study: This study attempted to create awareness of the occupational health hazards prevalent among rice mill workers and improve the occupational health and safety management system of the Organization Occupational safety and health is good for2015年8月3日 This study investigates the potential application of microwave imaging (MWI) in ore sorting systems for mineral processing Modern sensorbased ore sorting employs various sensing methods, such as (PDF) Overview of Mineral Processing MethodsThe use of a SmartTag™ system allows development of relationships between ore characteristics (available in the mine block models) and operating parameters in the mine and processing plant (such as ore dilution, fragmentation, Physical Processing: Innovations in Mineral Processingbauxite ores is froth flotation (direct or reverse) using various reagents [12–14], while magnetic/gravimetric separation, reductive roasting, or selective grinding followed by magnetic separation has also been used over the years [ 10, 15–17] Prior to any ore processing, comminution is a nece ssary operation attracting particular attentionModeling of Bauxite Ore Wet Milling for the Improvement of

Particle Size Reduction Milling Equipment

Conical milling equipment has become one of the most common methods used for powder processing in the pharmaceutical, chemical, and food industries A conical mill is often used for size reduction, deagglomeration and delumping, but which machine is best for your application? Read our blog to learn more about Quadro's Conical Milling equipment1 Principles of milling bulk solids Milling is the action of reducing the size of particles thanks to a mechanical action The mechanical action is submitting the particles to a stress, under the stress, some cracks will appear and subsequently the particle will be broken in different partsSolids and powder milling Size reductionoperational safety dental coMpounds Contaminationfree processes for immaculate ceramic inlays of premium quality Metal powders and alloys Processing of rare earth elements, eg for the production of heavyduty magnets for the IT industry pe wax Optimum processing of ultrafine PE wax at ambient temperatures sterilized powder Systems for aseptic,The pursuiT of perfecTion in powder processing HosokawaThe present study investigates the propensity of predicting ore grindability characteristics and varying pulp densities through acoustic measurements on the Magotteaux ball millA typical flowsheet for processing refractory gold ore (Sulphidic

.jpg)

Simulating the Impact of Ore Competence Variability on Process

2019年9月24日 The Extended Drop Weight Test (ExDWT) improves understanding concerning sources of variation in ore competence through the value chain This technique measures and describes the variability in ore 2022年7月30日 In order to study in depth the differences in basic characteristics between iron ore fines commonly used by a steel company, and guide the sintering performance plant to choose the best ore allocation method, experimental studies on the basic characteristics of seven iron ore powders of three sizes were carried out using microsintering equipment, mainly Study on the Basic Characteristics of Iron Ore Powder with MDPI2024年11月21日 The advantage of the grid type ball mill is that the ore discharge speed is fast, it can reduce the overcrushing of ore, and at the same time it can increase the output per unit volume 1 Large row of ore mouth Ball Mill Is Indispensable For Lithium Ore ProcessingIndustry Knowledge We have many decades of experience processing a wide variety of difficulttohandle hazardous powders Our equipment is particularly wellknown for being able to successfully process battery powders, sodium nitrate, Teflon, and HerbicidesSize Reduction Milling Equipment for Chemical and Hazardous

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Crushing is the initial stage in the iron ore processing journey, where large chunks of ore are broken down into smaller fragments The primary objective of crushing is to reduce the ore size for subsequent processing and Powder Bulk Processing Five essentials for optimizing hammermill operations a number of “hammers” are mounted to a shaft that rotates at high speed within a chamber to “mill” bulk solid material to a desired particle Follow 5 steps to ensure food packaging safety 10 factors to consider for successful bulk material system Five essentials for optimizing hammermill operations Processing The process plant consists of a 26 ft 65 MW SAGBall mill circuit feeding a conventional carbon in leach (CIL) circuit Three ore types have been defined at Ban Houayxai based on the weathering profile—oxide, transitional and primary Average throughputs were assigned to these ore types, based on test work within the feasibility study and Predicting Mill Ore Feed Variability Using Integrated Geotechnical 2021年2月26日 Milling is among the most energyconsuming technological stages of copper ore processing It is performed in mills, which are machines of high rotational masses The start of a mill filled to capacity requires appropriate solutions that mitigate the overloading One method for increasing the energy efficiency of ball mills is to optimize their drive systems This article Energy Efficiency Analysis of Copper Ore Ball Mill Drive

.jpg)

Gold Fields South Deep Gold Mine How we process

From the time that the ore hoisted from underground and enters the processing plant, it takes up to five days before the process of smelting into gold bars can commence South Deep’s gold plant has the capacity to process around 330,000 tonnes of ore per month and the capability to treat more underground ore than most other plants in the Far West Rand Region of South Africa2016年3月21日 Pulp Densities Pulp densities indicate by means of a tabulation the percentages of solids (or liquidtosolid ratio) in a sample of pulp This figure is valuable in two ways—directly, because for each unit process and operation in milling the optimum pulp density must be established and maintained, and indirectly, because certain important tonnage calculations are Common Basic Formulas for Mineral Processing Calculations2013年4月1日 A simple and novel nonlinear model of a runofmine ore grinding mill circuit, developed for process control and estimation purposes, is validatedAnalysis and validation of a runofmine ore grinding mill circuit 2021年5月26日 We are delighted to supply our pharma milling and powder processing equipment to some of the biggest names in the pharmaceutical sector One of the leading companies in the production of potent prescription medication for North American patients looked to Quadro to help them improve their manufacturing capabilities and improve safetyIncreasing Efficiency in Pharmaceutical Milling and Powder Processing

A Review of the Grinding Media in Ball Mills for Mineral Processing

2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the mass loss, as 2024年6月17日 The Importance of Hammer Mill Safety Milling machine safety is essential for the following reasons: Protect personnel: Hammer mills contain powerful moving parts that can lead to accidents Implementing safety Ensure Workplace Safety: Hammer Mill Operation391 Chronic Exposure Scenarios during Processing and Material Handling 138 139 393 Fire and Explosion Exposure Scenarios 142 934 Incident Cleanup Exposure Scenarios 144 References 144 392 Acute Exposure Accident Scenarios 4 Assessing Particulate Hazards 41 Preliminary Assessments via Material Safety Data Sheets,GUIDELINES FOR Safe Handling of Powders and Bulk Solids2024年8月7日 Mineral processing involves key stages to extract valuable minerals from ores, including crushing to reduce ore size for further processing, grinding to further refine particle size and liberate minerals, classification to separate particles by size and density, and separation to isolate valuable minerals from waste materialsMineral Processing Equipment for Mining Industry

Frequent Asked Questions about Powder Milling and Sizing Equipment

Founded in 1976, Quadro has earned the respect and trust of customers worldwide via our commitment to improve the performance of powder processing and milling operations We are recognized as manufacturers of specialized process equipment, with over 40,000 machines installed globally as well as decades of experience with problemsolving and product innovation2023年10月27日 The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral A Review of the Grinding Media in Ball Mills for Mineral ProcessingRolling mills play a crucial role in the steel industry, enabling the shaping and processing of metal materials As businesses consider investing in rolling mill machinery or upgrading their existing infrastructure, it is imperative to prioritize the safety of employees and create a secure working environment This article presents comprehensive and practical general safety norms for rolling Rolling Mill Safety: Essential Guidelines for a Secure Workplace2023年12月3日 For some historical context, when Powder Bulk Solids published its first issue in 1983, Ronald Reagan was completing his first term as US president, and the global economy was starting to emerge from the stagflation of the 1970s The global population was approximately 47 billion 1 (half of what it is today), and Space Shuttle missions were starting to take The Future of Dry Processing and Bulk Solids Handling

.jpg)

What are the safe operating procedures for Raymond mills?

Raymond mill is a common nonmetallic ore grinding equipment, There is actually a lot of knowledge about the safety operating procedures of Raymond mill, Powder Paint Grinding Mill From China Supplier, Ultra Fine Grinding Mill, Ultra Fine Mill, Phone Tel 86 E Powder processing often involves bulk powders, additives, or ingredients being milled for particle size reduction A mill or grinder uses a mechanical action to break the material and reduce it to the required size This may encompass a whole range of requirements from deagglomeration and coarse grinding through to fine grinding and classifyingGrinding Milling Powder ProcessSolutions